Leaderboard

Popular Content

Showing content with the highest reputation on 07/02/18 in Posts

-

Yup. I mask the worktop with pvc ( insulation ) tape, silicone, wipe with baby wipes, and then de-mask. Once the mask is removed one more wipe up so the silicone is not visible any more.1 point

-

Lol, I have a central vac - another unused relic here! I was thinking I would be able to buy a couple of new filters and rotate them if I ever get near enough to the bloody thing to remove them!1 point

-

After 9 years, I hope you have an industrial vacuum cleaner! Ours can be vacuumed, and we got about 18 months of out the filters (vacuuming every 3 months or so) before they started going fluffy and didn't seem to clean up that well. I bought a couple of replacements and will buy some filter media to cut and attach to the original frame when I remove the old filter media. I now have three pairs, so each time I can put in a new/reconditioned one, and still have a spare to tide me over until a recondition the one I've just taken out.1 point

-

Keep fighting away, it stressful but might get results. Maybe even consider dropping your MSP an email and then cc them into the next complaint.1 point

-

How come grants are available only if you live north of Dunblane? And good on you for pushing the connection issue, especially if they have a pole on your land that you can't use!1 point

-

It’s a flat topped attic truss really but you could struggle to find someone who can manufacture them in one piece with the ability to support the flat roof structure. I would go steel portal frame and cut roof and work from that.1 point

-

https://www.diy.com/departments/universal-square-glazed-metal-silver-effect-plant-pot-h-410mm-l-370mm/1283515_BQ.prd What goes in it is up to you.1 point

-

1 point

-

1 point

-

1 point

-

and an extract from another paper which talks about insects on imported timber:1 point

-

Hi, I sure you understand that being an employee of Sunamp I have to keep on the right side of the BH Police. I do try to have a look in here from time to time but it's by no means every day @Nickfromwales has my contact details if you need me. Kind regards to all. AndyT.1 point

-

1 point

-

We have rodding points at the ends of the runs so we can get all the way under the house from one side all the way down to the manhole.1 point

-

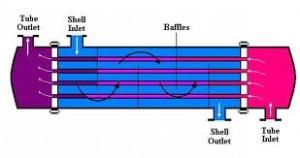

To a point, but longer also means more resistance. It'll work either way around - look at the arrows in this diagram - one end of the tube is stale air in and fresh air out (interior) and the other is stale air out and fresh air in (exterior). You do need to arrange things so that it's easy to guide any condensate to a drain. If tube inlet and outlet are as you say, then the shell inlet is fresh air from outside, and the shell outlet is fresh air to the inside of the house. One possible approach (not to any sort of scale): Orange is air from inside the house being extracted, blue is fresh air from outside. The other coloured blocks are fans. There's no reason why you couldn't have the branches both facing down - I just did it this way because I copied the layout of the unit above. If you tilt the right hand side down, condensation naturally flows out without the need for a separate condensate drain, although of course you'd need to figure out how to direct it somewhere if you don't want it just dripping on the ground. You'd also need to think about insect screens. The main thing that gives me pause about this whole project is how you're going to access the heat exchanger to clean it. I think this is an important consideration.1 point

-

Clear CT1 to bed it in for fixing purposes, and wipe back with the baby wipes. Have a look at the casting and see if the shadow gap isn't excessive, if it is then wipe a bit deeper and leave to dry. Then finish with a bead of ( cosmetic ) white silicone which can be refreshed when necessary.1 point

-

I discussed this problem with our BCO who helped out by saying that once you get above.the highest water+ flow point the stack can stop running straight and go where you like as after that point it is only gas venting. He did not exactly say but I think he hinted at the idea of reducing the diameter provided there were Air Admittance Valves (AAV) in the system as well. So my plan is to take the stack up in the internal walls and bring it out in a Cowell on the roof. Why can't you go direct into the 110mm pipe -what does the gully trap add if you have water traps under each sink and for things like disk washers?1 point

-

Yes you can run overground and I would as it’s a simple job of moving the pipe into a trench and sticking a pair of connectors in. Using lead - even temporarily - is just not something to contemplate. Trace it and rip it up and weigh it in - it will pay for the extra connectors ...!1 point

-

We considered wall hung, but honestly I could not see the benefit of the huge extra cost just for not having the pan touch the floor. I absolutely "get" back to wall pans, but just don't "get" wall hung. I guess it is a personal choice.1 point

-

1 point

-

We have slated and rendered the house and garage 90% of electrical is done Three bathrooms are fully tiled I’ve started fitting the bathrooms out but still have baths and taps to buy All plastering is done All sash widows are in and external doors Still half the bifolds to pay for UFH is in downstairs 150 mtrs of ditra is paid for and awaiting the arrival of a 150 mtrs of floor tiles from Italy Spend so far is 135000 and change £21000 of that is laboure mainly on brickwork and some ground works Most other works done ourselfs Exspect to spend another 650001 point

-

I reckon that the real half way point is when you think that the build is around 90% complete: http://www.mayfly.eu/2014/04/part-twenty-eight-90-finished-so-only-around-90-left-to-do/1 point

-

I had a similar experience with sunamp, many phone calls and promises of to phone back when somebody was available and nothing (over a few weeks). I did contact AndyT direct who made time (on his own time) to explain a few things, ultimately the system didn't fit what we needed but high possibility we will be using a unit on build 2.1 point

-

I know I've missed the discount (work and family commitments) but in case a good deal comes up again I have a question. We currently have a vented system with a relatively small hot water tank. Water is heated by a condensing boiler and there is an immersion heating element which we use regularly as washing long hair (not mine -:-)) takes a lot of time. The boiler short cycles quite often while heating water. We have hard water with no softener. As it a is not clear when we're going to get PP and following that builders to actually do anything I want to know whether it could be possible and feasible at all to buy a 12Kw Sunamp and hopefully directly replace the existing tank. Again, the idea is at some point it would be moved and the system would change quite a lot. Hopefully, the connections can be redone. Thanks in advance for any suggestions.1 point

-

Screwfix seem to be giving out footballs with every order, including my £7 one. Fill yer boots. They are not pumped up however. Who will be first to test a compressor in the shop ? To be fair, I’d let the World Cup go to hell in a handcart oif we hadn’t been so comprehensively embarrassed by Scotland at cricket last week.1 point

-

Timber frame structure was started last week and the ground floor erected 180 degrees round the wrong way. This was corrected within a day (small house) and the build went on. Now one of the Glulams has turned up about 400mm too short. They intend to replace the beam with 3x9x2 planks bolted together and supply calcs to show this is an adequate replacement. The exterior weather proof membrane has been holed and torn in several places. The interior airtight panels have been damaged and some of the external boarding as also been damaged. The supplier/erector claims the membrane can be patched and this is quite common with this type of build and will make no difference. They have offered to repair sections of the external and internal board. We have asked them to replace any damaged boards rather than not repair, to recover complete sections of the weather proofing membrane rather than patch it. The suppliers seem to think this is unreasonable. It's taken over two years to get to this stage and I'm seriously pissed off.0 points

-

So this is driving me crazy, can’t even look forward to the arrival of the kit next week, so yesterday I sent an email to sp energy telling them this letter forms a complaint. I had spoken to a chap up the road who lives near their transformer and he told me there had been a plan to increase capacity and in fact ducting had been put in but then the plan was shelved. I had also looked at the boasts on there website about keeping their infrastructure in good shape to accommodate future calls for more power bla blah blah . In the letter I told them I felt they had looked for the easiest solution for them with total disregard to the cost for me , I quoted some of their boasts then I finished off by saying as for the pole in my garden I have no agreement with you to accommodate this pole therefore since it is of no good to me perhaps I should make an application to have it removed. 9 o clock this morning they phoned me giving me a reference number and telling me I would be contacted by a design manager in due course, this being stage 1 in the procedure. Sure enough 10 minutes later I get another call and this time it’s from the original person I dealt with. He starts off saying he doesn’t understand what I’m not happy about—Really! 25k and he doesn’t understand? He thinks he’s going to browbeat me until I say just a minute here’s my husband, so hubby tells him in no uncertain terms why we’re not happy, asks for an overhead line- oh we don’t do that now, no of course you don’t you want to update your infrastructure at my expense,he then says well if we can’t get an affordable supply I want the pole removed, do you know what he said? Then you’d be cutting off your supply!!what supply?! It ends with my hubby asking for the complaint to be escalated to stage 2 , by this time he’s stuttering and stammering, turns out he’s not even a manager just a team leader! However it has been escalated and we await the next stage, annoyingly if we lived north of dunblane we’d be able to apply for a grant for the connection, I’ve got my fighting hat on now-bring it on!0 points

-

0 points

This leaderboard is set to London/GMT+01:00

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.84720b9262bdfdd639b2257471fce9e7.jpg)