Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/25 in all areas

-

What’s the problem with increased energy use if it is renewable powered? Sunny day in summer is when we seem to have an oversupply of energy as everyone’s PV is generating flat out. Might even solve a problem.3 points

-

Many thanks! That just goes to show how easy it is to be mislead by stuff on the internet! I suppose the reason people are promoting these things so heavily is because they are quick and easy to use, then, so they save a lot of time on a job. That figures, but it is depressing, all the same. I'd like to think that people who promote stuff like this are honest, but I guess honesty is just another commodity to be bought and sold. . .2 points

-

2 points

-

This approach of releasing immature products to the market and allowing the early adopters to test them is now the norm with some cars, too, it seems. I made the massive mistake of buying a new Tesla Model 3 in 2019, when it was first available here. That car had so many manufacturing defects, mostly down to process control (or the absence of) and poor software that clearly hadn't been fully tested, that it had to get taken back to the nearest Tesla service centre 6 times during my first few months of ownership. Given that this was a ~150 mile round trip each time I ended up sick and tired of the thing, so sold it after 14 months (and I'd never buy another one). Its replacement was a car that had been in production for three years, and it showed. Zero defects or issues in three years of ownership. The moral of this story is to never, ever, buy a brand new product. It's not a new thing, either. There's an old saying in aviation "Never fly the Mk 1 of anything". It does seem that technology companies, in particular, are far too willing to inconvenience early adopters, though.2 points

-

Yes that's about it. Except all the loops from one mainfold will run at the same temperature. You adjust the heat output to ballance it by adjusting the flow rate to each loop. Most manifolds have flow meters that allow you to adjust and measure the flow rate to each loop. Whether you have a temperature blending valve on each manifold to set the temperature, or rely on the ASHP doing that is a matter for debate, and whether you have separate zones or run the whole house at the same temperature is another debate.2 points

-

Been reading up on UFH system. Do I have the below right? > Loop: This is a section of the UFH pipe that the water flows through. > Zone: This is an area of the house 'sectioned' from other areas of the house (e.g. ground floor as zone #1, first floor as zone #2). > Loops & Zones: More than one loop may be needed to cover the floor area in one zone (e.g. ground floor of 100m2 may need two loops). > Micro Zone: This is a specific area of the house selected to have a different heating level than another specific area of the house (e.g. bathroom vs sitting room). > Manifold: The heated water comes to the manifold from the A2W HP. Each loop comes off the manifold and goes into whichever zone of the house it was placed. > Zoning, Looping, Microzoning: If you have placed separate loops into each individual room in the house (living #1, bathroom #2, dining room #3 etc.) but run all of these microzones at one temperature, then you're still technically running a broader 'zone'.1 point

-

My go-to ASHP guys used these (2 different companies / installers) and on both jobs there has not been a 100% success rate, but to be fair this can be said of any soldered joint or compression joint; the big difference is when the bastard requires a huge effort and chopping out of a lot of the local pipe etc to change it which winds me up. Even a failed soldered joint can be successfully re-sweated in situ in most instances, and compressions can be removed, olive changed, sorted fast and that happens without touching anything more than a spanner. Not an issue for me as the companies both returned swiftly and made good where it was critical to do so, at their cost, but if it is a compression joint then it just needs a pinch up. Press-fit is used everywhere these days, because of its speed of installation and its relative simplicity, but nothings going to be documented here that is 100% guaranteed leak / bomb-proof as mostly it's either a manufacture defect or installer error that produces a failed joint, and that's never going away regardless of the system or product types; just called "life". The reason I stick to compression / brass / copper in all plant installations is that it has never really let me down, but I am very attentive in my workmanship (for good reason) as I would have to travel a considerable distance to facilitate a service call for such a failure which would sap a lot of the profit made from the job.....hence I try and fill & test when I am at the hotel and make sure I am back again the next day doing X/Y/Z meaning I am able to observe the plumbing to check for leaks before packing up and heading home. It doesn't always work, such is life, so one weeping fitting is not the end of the world in actuality, and you could have called the chaps back on warranty to do the repair for free? Was probably your nature to take the path of simplicity and speed, eg do the bloody thing yourself as it's quicker and easier, and you have the skills.1 point

-

Thanks for allowing me to join the group. I am a home owner, and I am looking for inspiration that may help me in my future home renovations, and potentially a garden workshop build. Looking forward to chatting to you all. Henry.1 point

-

I’ve had one weep like that too. Same rate. I have a few of these crimped elbows but fortunately all in accessible and visible places.1 point

-

Not recently, no. My one experience, with a commercially-available system (can't remember what it was called) was 24-25 years ago and only served to convince me what a good idea rainwater harvesting was! The system (£1000 - £2000 from memory, excluding installation costs) consisted of a rainwater butt sunk in the back yard. Grey water ran to that 'sump', where it was kept from 'fermenting' by 'treatment' - a basket full of chlorine bleach blocks!! . If the contents of the sump did not get used ion 24hrs it got pumped out to the main drain. From this experience I took the view that grey water goes furry, and rainwater doesn't. Simplistic, I know... Low-tech use, perhaps dilute, in garden watering, Grey OK. For storage, maybe not... OTOH over-complicated rainwater harvesting systems can be a right pain!1 point

-

1 point

-

Principal way was to design the loops to match heat loss and target temperature. Balance to get the temperature correct. But if you are building well insulated do you even need heating in bedrooms? Many on here such as @ProDave live in the Highlands of Scotland and get well below -10, without issue. Plus don't underestimate how long a floor and house retains heat. The thicker the screed the longer the heat is retained. My grand plan was heating all room differently, lots of zones etc. But the first quarter gas bill killed that - it was over double the expected, mostly due to short cycling, due to small zone being open. I now heat for a few hours and house stays stable the rest of the day. Did try setbacks, but gave up when the timing became 12 hours displaced.1 point

-

Just got back to Penzance for a coffee and then a kebab. Was good to see you. Going to send you a PM in a sec as there was something totally unrelated I meant to ask you.1 point

-

1 point

-

A breach is a breach But it hardly seems fair We lost patience and requested the planning officer be replaced As she had passed a build near by without any requests We cited inconsistencies Her boss requested 48 to make a decision Then passed it a couple of hours later I would say they don’t want the attention Everybody has someone above them1 point

-

Ask for her to be replaced We did and it was passed the following day1 point

-

Good question. On a flat rate tariff, the ideal is run weather compensation, no need for thermostat. On a time of use tariff, you may what to trigger heating events. I use a thermostat as a conditional timer, to make use of E7 tariff at night. Generally the rest of the time the heat pump is off. But for me (thick screed) I use a 0.1 Deg hysterisis thermostat to stop under and over swings in house temperature.1 point

-

The wiring centre I bought https://www.ebay.co.uk/itm/315153782771?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=KzwJTGtMQAi&sssrc=4429486&ssuid=8KgwDlAbTJS&var=&widget_ver=artemis&media=EMAIL Same seller has the remote screen listed also. Sensors https://www.ebay.co.uk/itm/267046429821?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=grAjxs1RQGq&sssrc=4429486&ssuid=8KgwDl Other units similar but different based on the same package Roth https://www.roth-uk.com/products/control-systems/roth-touchliner-sl-wireless-system Other seller, think it's the maker but not sure1 point

-

It was a December 2020 Jaguar I-Pace HSE. Far from being an efficient EV, but reasonable performance from 400hp and AWD, if not quite up there with the Model 3 LR AWD. Very comfortable and extremely reliable, as well as seeming to be completely free from software bugs (something of a rarity in modern cars!). I replaced the I-Pace in June last year with a Mercedes EQA Premium +. Smaller than the I-Pace and better suited to the roads around here, and a lot lower performance. It is pretty efficient though, massively more so than the I-Pace. My only minor gripe is that the software isn't as intuitive as it could be, although it announced it was updating just as I got home last night, so I've not yet had time to experience whatever may have been changed.1 point

-

...quite possibly for less than £1000, OP, if you can send pictures, as previously requested, of the nature and extent of the damage, and words confirming how and when you feel the damage first manifested itself.1 point

-

Let them get built in. If they even notice and complain, apply retrospectively, and if refused fit some ON roof ones over the top to demonstrate what nonsense it is. During my planning, I only realised at the last minute that I needed PP for the ASHP so quickly added that at the last minute. All these sort of green updates should not be needing PP imho.1 point

-

So based on a topic by @Beelbeebub I have been playing with my system and in the most part trying to get a system not connected in any part to the internet. This is now in place. No internet connectivity to anything that controls, but do some internet monitoring. Have used a wiring centre, with lots of good features. It has a wireless outdoor sensor, can do Opentherm WC for boiler control, also has volt free NO and NC contacts, maybe able to use these to allow heat pump to run or stop it running - needs some thought. You can set an outside temperature threshold for the boiler to come on, so if average temp above X degs boiler is not started. It has wired/wireless room sensors (not thermostats), the wiring centre can then be set with schedules and individual room hysterisis and target temperature. It can do cooling control based on humidity thresholds etc. The controller I purchased is branded Polypipe, but also marketed by several others including Roth, but think made by Tech Controllers. The one I am using is being sold on eBay and was never formally released on sale. Bit to complex for the UK market, I suspect. I have no actuators in the system, so it's all a single zone. Each room will have a sensor, but only two will be utilised for boiler control kone in hall and other in kitchen). So either can call for heat, both off to stop heat. Running WC mode via Opentherm, and have an outside temperature threshold for the boiler to heating based on 5 degs averaged over 24 hours (this setting will need fine tuning). Heat pump settings or controls are not changed. Have found the heat pump runs only as needed. Room sensors were £11, plus a Roth sensor with humidity £49 Wiring centre £149 Purchased a remote display/controller also (not needed) £49 Wireless outside sensor (no holes in the walls) £29. Room sensor Remote monitor - only two room connected at the moment.1 point

-

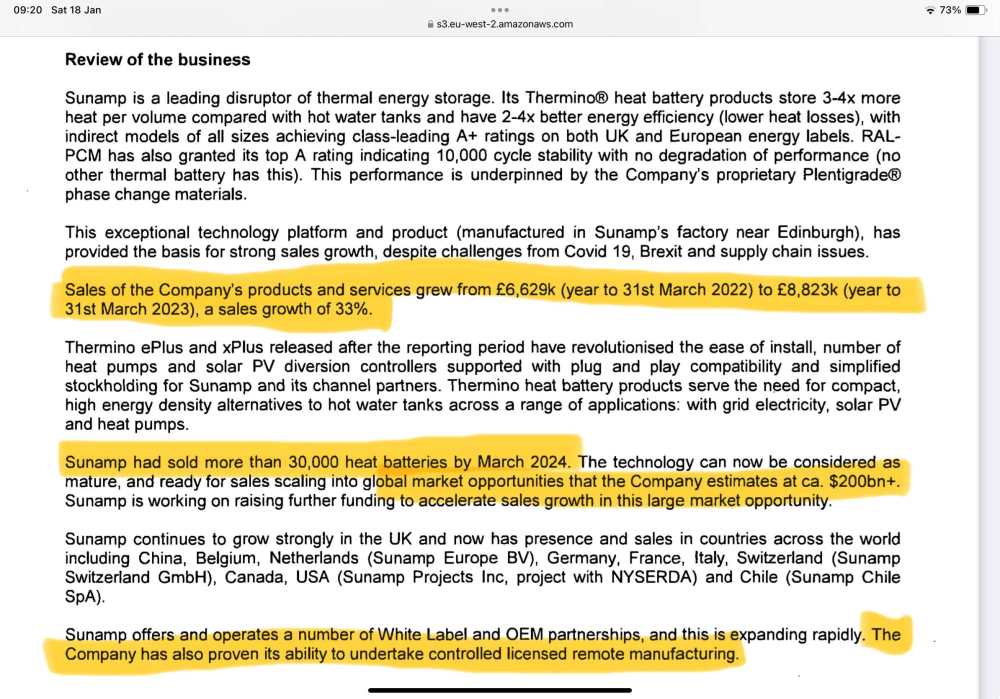

Here’s an extract from their accounts. Some impressive numbers which perhaps underlines that self build won’t even be registering in their core marketing plans. However, if the failure rate of units on this forum is representative of all sales then they have an eye watering legacy cost. I suspect they will be doing everything they can to reduce those costs (I.e. not paying!) thus I think @Jeremy Harris has had a great result. I read a book last week (which I’d highly recommend) called “Supremacy: AI, ChatGPT and the Race That Will Change the World”. I seem to remember it mentioned that using general release of products early and let let Jo public be the testers was now a completely acceptable risk. Anyway making a profit is so last year 😀, it’s all about the exit.1 point

-

Depending what you need the warranty for All make it very difficult to claim Architects cert are not accepted by many lenders So worth considering if you need to sell on at some stage We used Protec on our previous Nearly 3k Three visits lasting less than ten minutes His completion visit took even less time This time we went with a professional certificate While we have no intention of selling No one knows what’s around the corner Over 400m2 meters two floors £1500 CMLC1 point

-

Not read all the posts but was thinking about the salt leak when plumbing in my dog shower yesterday. Shouldn’t the unit sit in some sort of containment tray in case it does leak. Chemical storage tanks often have bunds built around them for example.1 point

-

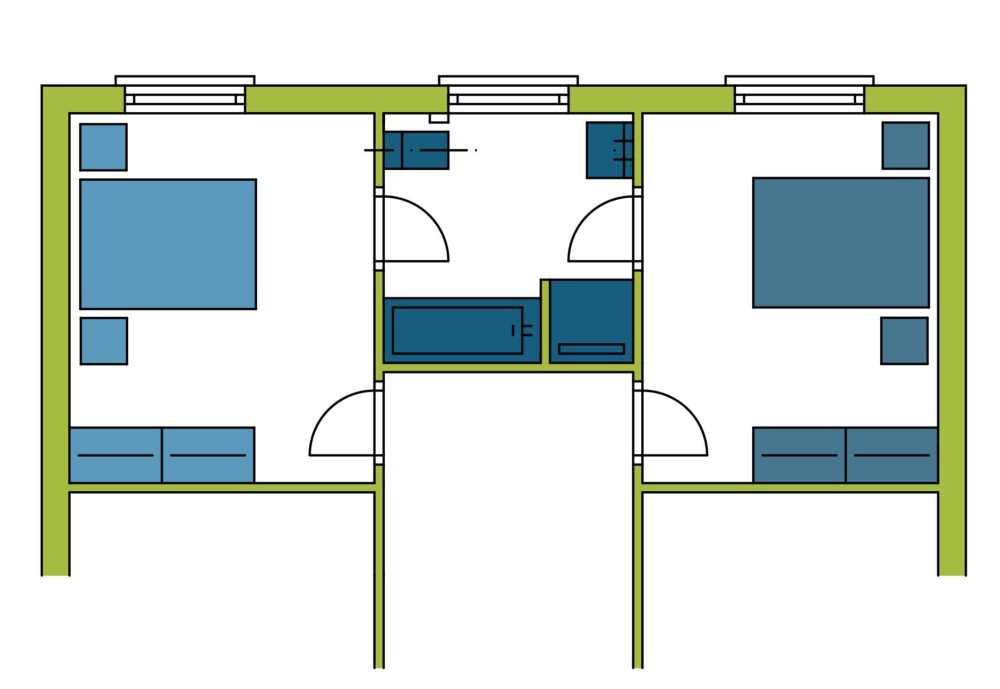

Hi all 👋🏼, I wanted to introduce myself and our project as I anticipate I'll be in hot pursuit of the forums thoughts, opinions and experiences in the forthcoming months. We purchased a 3-bedroom 1970's bungalow in August 2022 but had some planing complications due to a parish council policy that attempted to dictate that "a bungalow must stay a bungalow". 15 months later our planning application was finally granted, albeit with some compromises. Here's a few points on what we're attempting... Replace existing roof (& ceilings) entirely, building up the walls ~80cm, adding a new roof with 1.2m increased ridge height and steeper pitch Upstairs will accomodate two bedrooms, bathroom and "breakout area" overlooking hallway void Large single-storey flat roof side and back extension out to locate 65sqm kitchen/diner Complete re-configuration of downstairs layout Complete replacement of heating system (gas will be cut off entirely) New ASHP (current thinking Valliant Arotherm Plus, one-zone, no buffer) UFH all-round on ground floor (retrofit lo-profile UFH on top of the existing slab (Wunda?), insulated/screeded in new extension). Possibly fan convectors in bed-rooms upstairs Complete rewire I would assume MVHR (current thinking is a radial system installed through new posi-joists, manufacturer TBH but will get BCF to design) New solar panels, and battery (current thinking GivEnergy to unlock Octopus Intelligent Flux) New double-glazing all round (Residence R7 probably) also 2.7m high, ~8m wide sliding doors at rear (either Corteso Cor-vision or Minima) The biggest grey-area for us at the moment is how much to focus on/invest in improving the insulation and air-tightness of the existing exterior walls. I'll raise a separate thread for this in due course. Fortunately we were able to leverage a second mortgage and keep our existing home so we don't intend to live in the place whilst the majority of the work is taking place. The properties are only 0.5 mile apart so I am hoping I'll be able to keep a close eye on the build whilst I work from home. We are also intending to do a little of the work our-selves as possible (i.e. fitting MVHR, UFH, painting & decorating, airtightness membrane?, etc). Thanks for having me and in advance for any advice, Ollie Fleet, Hampshire Plans 24 OD - Amendments Combined.pdf Concept Images Existing Images1 point

-

A lintel would't be too hard to set in surely, its not structural after all...1 point

-

This whole Sunamp failure seems a case of someone with a clever, clearly workable PCM formula not appreciating or understanding real world materials behaviour in the case (pun intended) of the containment. The hand stirring it is probably the bean counters. If I recall correctly the product was at one point value engineered for the mass market. I've been fixing, modifying and providing feedback on bespoke kit for a living for nearly 30 years. Designed by chartered & software engineers in a warm office who didn't realise "it" would (or more often wouldn't) behave like that in the real world. I know plenty of God like TIG welders who make swirl pots and custom fuel tanks in their sleep / for fun. I personally would construct an outer and inner stainless shell. After fabrication the space between the two would be filled with "expanding foam". That would require careful welding of braces to limit unsightly swelling. It could be done. Heating elements, pressure relief valves & thermistor stacks could be replaced from outside the shell. As aforementioned the PCM could be filled via a screw cap perhaps even with a low point drain to assist replace replacement. Totally doable imo. It's only time, money, knowledge & ability stopping me...mainly just the last 4!1 point

-

ChatGPT suggests SAT will have a minimal effect on stainless steel, particularly 316L )in part due to the absence of chlorides as Jeremy mentioned). So it's salt Jim but not as we know it! https://chatgpt.com/share/678b5bfc-67dc-8006-abdf-68dedb82e4181 point

-

Does that breach any regs I wonder and if you are having a big party would it not make sense to have a second one accessible without going through a bedroom, perhaps look at a Jack and Jill arrangement. I am also with @JohnMo in respect of sorting it now and then leaving well alone for the build.1 point

-

Just to avoid thread drift, if we want to discuss failed government projects, perhaps someone could start a separate thread for that.1 point

-

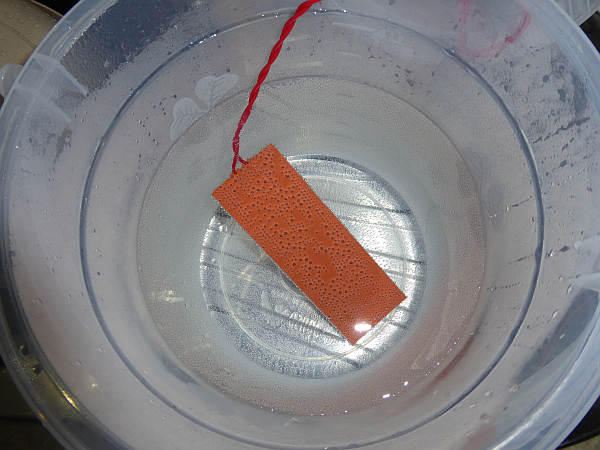

Funnily enough I ordered one of those USB rechargeable camping showers 2 days ago! To get warm water for a shower I put together a Heath Robinson arrangement using stuff I had around, two spare 20W, 12V silicone rubber heating mats (I had to buy four when I only needed one for a bag warmer), a 6A, 12V power supply and a couple of 5 litre lidded buckets. This worked very well, the heaters were plonked into each bucket and left on all night. By the morning we had two buckets of water at around 38°C, which was fine for a sort of cup-over-head type shower. we could have filled them from the boiling water tap, as the boiler for that holds 20 litres, but that would have meant carrying the buckets upstairs, which seemed like too much effort first thing in the morning! The bucket warming experiment, before I set them up properly upstairs:1 point

-

Mesh directly over the timber then render if sand and vent Breathable renders Cement board fibre mesh and base coat1 point

-

Do the ones I was subjected to during the week count? 🙂, and thanks for your kind offer to be on the end of a phone. My electrician did this via a switch, so the installer was able to commission today. Over the weekend or early next week I'll swap that out for a thermostat. They've set all the actuators to manual (open) on the one manifold we have loops connected to, and we've deactivated the hot water and its setup to gradually changing the flow temperature over the next week. All the loops are embedded in the foundation slab (250mm) which sits on top of Jackon Atlas insulation (300mm if I recall correctly) which has been in for 4+ years so should already be fairly dry. Next week I'll be getting a temporary kitchen and bathroom setup for when we camp out there in February (long story) so both the heating and the hot water are going to be tested. Pics next week if I remember.1 point

-

Natural insulations will always cost more in the UK as it is such a small market and buyers have to absorb the increased costs of production, shipping and Brexit red tape. Unlike many countries in the EU, there are no local political forces to drive wider adoption. In most of Europe, there is price parity due to the scale of sales; in France and Italy for instance it is very hard to specify unnatural insulations due to building regulations. In the UK, the best we can say is that prices are on par with mineral wools and have better availability - rockwool costs a bomb to manufacture as it requires huge amounts of heat, and recently it needs to be ordered weeks in advance to ensure supply. There are many advantages to natural breathable insulations, especially for internal insulation. Regarding the OP's specific question, Steico should be cut roughly 5-10mm oversize between the battens. I wouldn't compress the surface more than 3-5mm behind plasterboard - any more than this and you will get bowing. 400 centres on your battens should work well, but I'd add 10mm strips to the face as you suggest. Installation info can be found here: STEICOflex_handling_instructions_en.pdf It is important to note that STEICO does not generally recommend achieving high U-values with IWI due to the condensation risk to the structure. There is, generally, a sweet spot between 40-100mm of woodfibre that balances the energy savings, cost, and condensation risk. If it’s of interest, their Technical Director took part in a webinar that covers some of these points: Rethinking IWI with Natural Fibre Insulation Useful advice can also be found in the following links: Insulation and retrofit - Finding the sweet spot - The Alliance for Sustainable Building Products (asbp.org.uk) The-use-of-natural-insulation-materials-in-retrofit.pdf (stbauk.org) If used behind plasterboard, you will need a moisture vapour variable membrane, (e.g. STEICOmulti renova or SIGA Majrex® or PRO CLIMA intello plus). These ‘smart’ membranes will limit the amount of water vapour entering the fabric but still allow the wall to ‘breathe’ during warmer periods. Correct installation of the membrane, and sealing connections to all surrounding elements is the critical factor with this approach. The best advice is to have the external walls assessed via hygrothermal software - such as WUFI - which will take all of the site variables into account. Internal wall insulation is more complicated than external due to the way it moves the dew point within the construction. In addition, standard U-value calculations will not correctly account for the sorption properties of wood fibres nor their ability to pass on liquid water through capillary action. WUFI purely considers moisture issues and how the various elements of the building fabric will deal with the volumes based on site-specific conditions. STEICO doesn't offer this additional calculation service on a site-by-site basis, but one of their distribution partners, Back to Earth, does. Chris is a great font of knowledge regarding renovation and upgrading of older properties and is a good first point of contact when specifying IWI. Siga & Pro climba with also provide free WUFI assessments if their V-VCL membranes are specified and used in a batten and board approach.1 point

-

Or, more discretely as it's not your problem, just inform the neighbour and allow him to take it up with the BCO. I'm not saying it's good, but I've seen far worse from 'brick technicians' laying overhand. An old-fashioned time-served craftsman 'brickie' would find this unacceptable, but there can't be more than a handful of breeding pairs left in the country... probably extinct by the end of this year!1 point

-

After what seems like an age (but is not compared to others on here) we have at last are formal planning approval! We had quite journey, some of which is detailed here. We were told by our planning consultant just before Christmas that it would be approved by the 10th but of course until it actually states "Application Approved" on the portal then of course nothing is guaranteed. We were on site today cutting the overgrown boundary to the rear when I got the call to say that it had been approved. So, just a bit to do over the next year or so! Onwards and Upwards.1 point

-

I rent out an old stone cottage. The previous occupant always complained it was cold and damp and cost a fortune to heat. The new tenants say it is surprisingly warm and dry. Now. I did do some upgrades but the biggest thing is how they hear the place. Old tenant was out a lot so would turn the heating off, then come home at 7, turn it on for a few hours so it would run flat out and warm up a degree or two becaue of the massive walls. It would thnr go off overnight and repeat in the morning. It occilated between 12 and 15C and so was humid as well. New tenants work from home alot so leave the heating at 20. Turns off overnight where it drops to 18C then climbs again in the morning. They pay a little bit more as the losses are more but they ah e a warm dry house.1 point

This leaderboard is set to London/GMT+01:00