Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/24 in all areas

-

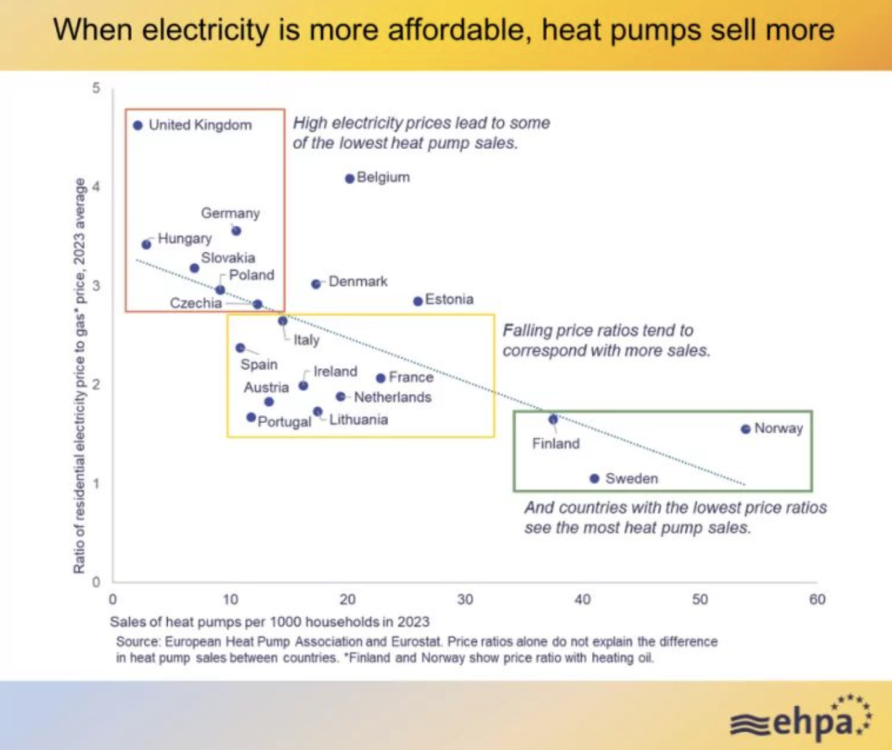

It's been said on here before, but this graph from the European Heat Pump Association shows clearly the relationship. A higher ratio of electricity price to gas price ("spark gap") correlates with fewer heat pump installs. The UK has the highest spark gap amongst the countries included in the analysis. No surprise then that people in the UK are not choosing to install heat pumps so much as other countries .... when there is a choice. Btw, it's helpful that the UK are included in this analysis.3 points

-

One advantage of being in one’s seventh decade is that ‘forever’ is a different time span compared to when we first built with us both in our 20’s. 😉2 points

-

Tend to agree, although, it rings a bit hollow having spent yesterday at a graduation ceremony for 600 Engineering and Science students all of whom got a certificate telling other people what the students and the staff already know so sometimes it is for other peoples consumption and holding it has a personal value. I also happen to think that the Passive House standard is now getting better understood and much more widely talked about so we may well be heading the way of more acceptability of the certificates value among buyers.2 points

-

Not at all, achieving the standard is not particularly difficult for the self-builder. Probably because the standard is very well considered, setting achievable targets for justified reasons that deliver a return. Certification is a personal choice. It does cost extra, but doesn't tell you anything about your home that you don't already know. Living in a PH house has given me more significant reasons as to "why", than I had when I chose to build one. I initially wanted reduced bills, I was building a long-term family home. Since the targets are significantly higher than Building Regs at the time, especially for a conversion, I did wonder if they'd be achievable and wasn't too concerned if I didn't quite get there. I also knew that I wanted more glazing than a PH house should really have. Through the Design phase the PHPP software really informed my decisions, and demonstrated where budget was best spent to achieve the overall building performance. The PH targets became my targets, as the PHPP software showed what changes were needed and didn't leave me guessing whether or not I had too much roof light area or not enough insulation. Had I just been building "better than regs", there are loads of minor changes I wouldn't have made, because I wouldn't have been using the tools that showed me exactly how the building would perform without those changes. While PH does deliver the low bills that I was after, the greater impact is comfort. I believe it's the lack of temperature gradients across rooms, with no perceivable convection currents, stable internal temps across the day, no perceivable air infiltration, the quietness of 3G glazing and while not specifically PH, the solidity of blown cellulose insulation gives rise to a comfort level I've not felt in any other building.2 points

-

A couple of weekends ago, my wife and I spent some time at the MBC factory and got to ask some questions of the team there. There were quite a few different people there; sales, design, windows, even Kevin Blair, son of the founder Joe Blair, who took us on part of the factory tour. We were there for over 2 hours, including a 1-1 session where I covered any outstanding questions I still had. It was an informative day and great to see how they've developed and expanded. Seems they just keep buying more and more space whenever any adjacent units become available! Great session and I took a lot of photos. A couple are attached but the remainder can all be found at https://www.dropbox.com/scl/fo/11i21jn1n6ko1uclcbrm7/AMtb-Jt48ljlTc0lPfiQeKk?rlkey=f08zqofj4l1qllgrxphtnawtc&st=uxhdqk71&dl=0 They seem quite busy and are seeing an increase in demand from people building lots of houses, especially in the social sector where they explained it is easier for a company to secure any additional funding required for Passivhaus standards as they can offset it against potential future requirements to help with heating costs etc. From a pure materials perspective, they acknowledged the challenges of Brexit, COVID-19, etc. and how that initially affected costs and quotes quite significantly but things are a little more settled now and as they expand, they're able to secure pricing for longer periods as they're able to commit to larger orders. They're also sourcing from multiple suppliers and multiple regions as costs and availability flex due to growing seasons etc. Process Pre-start meeting - they discuss design guidelines and decisions with you and get your architectural drawings if available. MBC redo the designs in their software, including the 3D roof design. This takes about 4 days and they can then be provided back to your architect (if applicable) to update anything that did not translate from your original vision into an engineering specification. General arrangement - that design is then turned into the build instructions for the factory. The full structural engineering package is provided by Adept who MBC have been working with for over 22 years. They have 20+ engineers. Once erected - cut all your holes for service penetrations etc. and then MBC will come back to tape etc. and provide their full airtight package. These teams are all employed by MBC so are well versed in airtight requirements. PHPP - standard MBC timber-frame features are available for PHPP modelling, but they don't do any modelling themselves; you'll need someone to do that. Building Regulations - MBC don't do building regulations drawings/documentation so your architect or an architectural designer would need to do those. File ownership - MBC don't provide you with the source files from their various software packages but will do exports in various formats for you. General MBC Passive Foundation - they don't subcontract this (technically) as they own the company that does it. This is the same for the timber-frame insulation - they own that company too. You excavate the ground to (mostly) a 100kn bearing capacity and backfill with MOT Type 3. MBC then come along and puts in MOT Type 1, sand blinding, EPS etc. If you're putting UFH in the slab, you need to do this, MBC doesn't. Then comes the concrete. Site access issues - they can work around most issues. They've not been able to find some way to make it work. They send someone to the site to investigate constraints and then plan accordingly. What things influence higher cost - big open spaces, the weight of things (like green roofs) and features that require hidden fixings or complicated connection details. They have not seen any issues with mortgage companies or warranties concerning their timber-frame installations. Materials and Sources They source their materials from different places depending on the market and where things are growing. All timber is FSC sustainably harvested with documentation. They secure pricing with suppliers based on estimated cubed usage, and swallow any pricing fluctuations once a price for your timber-frame has been agreed. External walls and floors are treated. Some locations require additional treatments for things like longhorn beetles. Windows They supply and install Rationel and Velfac windows. Solarlux (generally aluminium) as a gap filler when there are requirements that can't be met by Rationel or Velfac. The Rationel windows are primarily timber/ali-clad with a larger profile, whereas the Velfac are composite, aluminium/timber and have thinner profiles. MBC are of course happy for you to choose windows from someone else so long as you use an installer that is manufacturer-approved and that they are installed to MBC airtightness specifications which they will provide. Choosing MBC to design and build the timber-frame and to install the windows can save some time in some situations; MBC will happily place the order for the windows based on their design drawings. Some window companies will want a structure to measure against unless you are willing to take the risk of measurements being incorrect. Furthermore, there is no possibility of the timber-frame supplier and the window supplier blaming each other for any issues if MBC does both! Installation of windows is by NKG as sole installers. They are very experienced with housing and deliver consistently good quality installs. Their window systems manager, Jason, was at Rationel for 15 years, was an installer himself for 3.5 years, and before that was a carpenter. How can you save money with windows? Bifolds are more expensive than sliders. The taller and wider the glass, the more expensive it gets, large spans especially. Openers are more expensive, but only marginally so in the grand scheme of things.1 point

-

That’s really good info, well done. Our Jeremy Harris used MBC and he really sang their praises when they did his build.1 point

-

They were around in the late 90s or early 2000s. Mostly in thin film amorphous. If you want them still sold slightly different spec.1 point

-

They’ll look the same as they do now, but be a couple of % more efficient!1 point

-

Well this is entirely our original design but adapted for the DW system so they can do it (if you alter any of their standard designs by say moving a window it becomes "bespoke"). We omitted additional cladding due to cost and didn't do the glazed gable and fancy aluminium glazing as their system couldn't handle it. The interior is however exactly as we wanted. Sure there were compromises to make but we should be in, carpets laid and sitting on the sofa watching TV within 12 months of clearing the site and bringing on the static. We are both in our later 60's so didn't want a prolonged build on site, been there, done that. Garden to sort but can enjoy a warm modern house this winter after the last couple of renovations of old, cold "characterful" houses.1 point

-

I've eventually got around to typing up my notes and putting the photos somewhere accessible. See the new post below...1 point

-

Nothing new here, it was predicted two decades ago. The rain, down here, I am used to, could do with a few more hot days. https://www.bbc.co.uk/news/articles/c147v82gxp2o UK getting more hot and more wet days – Met Office IMAGE SOURCE,EPA Justin Rowlatt BBC climate editor @BBCJustinR Published 5 hours ago Climate change is dramatically increasing the frequency of extreme high temperatures in the UK, new Met Office analysis has confirmed. Its annual State of the Climate report says data from 2023 shows the country is experiencing significantly more really hot days. Its observations suggest there has been an increase in the number of really wet days too, such as the prolonged and heavy rain Storm Babet brought to wide areas of the country in October last year. The report finds the UK is also seeing a 40% increase in the number of what the Met Office describes as “pleasant” days - those with temperatures of 20C or more – and has become 9% sunnier over the last few decades. Those changes may sound positive, but the UK’s shifting climate represents a dangerous upheaval for our ecosystems as well as our infrastructure. For example, between 1961 and 1990 only London and Hampshire recorded six or more days a year with temperatures over 28C – which the Met Office defines as “hot days”. By the latest decade (2014-2023) virtually everywhere in England and Wales was seeing this many hot days, while the South East now gets over 12 in a year. The increase in the number of “very hot days” of 30C or more has been even more dramatic, trebling over the last few decades. Rainfall patterns vary much more than temperature, but the Met Office says it is still possible to identify an increase in the frequency of the wettest days. It looked at the top 5% of wettest days in the period 1961 to 1990 and found extremely wet days like these were occurring 20% more frequently in the most recent decade. "Some of the statistics in this report really do speak for themselves," said lead author and Met Office climate scientist, Mike Kendon. "The climate is not just going to change in the future, it is already changing." The new report confirms 2023 was the second warmest year on record for the UK, had the hottest June ever recorded and the joint warmest September. Separate studies by Met Office scientists found all these events were made much more likely to happen because of human-induced climate change. February, May, June and September 2023 were all ranked in the top-ten warmest on record in the UK for the same months in a series dating back 140 years. The Met Office says there has been a rapid increase in the frequency of record-breaking warm temperatures in recent years, while there have been virtually no new records for cool weather. For the UK overall the warmest months on record have been May 2024, June 2023, December 2015 and April 2011. The last record cold month was December 2010. IMAGE SOURCE,AFP Image caption, People play football on dry grass pitches at Hackney Marshes, in northeast London, during a late summer heatwave in September 2023 April The State of the Climate report finds 2023 was the seventh wettest year on records going back to 1836. March, July, October and December were all amongst the top-ten wettest for the same month in the series. It is these weather extremes - of heat or rainfall - that have the biggest impact on people, says Prof Liz Bentley, the Chief Executive of the Royal Meteorology Society. “These changes are leading to more heatwaves and flooding, which profoundly impact communities by straining healthcare systems, damaging infrastructure, and disrupting daily life”, says Prof Bentley. Other significant weather events include seven consecutive days with temperatures above 30C in September – a UK first. Unusually the hottest day of the year was also recorded in September (33.5C on 10 September). Scotland had its wettest two days on record on 6 and 7 October in a daily series dating back to 1891, with 6.5cm of rain – almost 40% of the average you would expect for October. IMAGE SOURCE,GETTY IMAGES Image caption, A car near Dundee was left stranded on a collapsed bridge following torrential rain and heavy flooding from Storm Babet in October 2023 Storm Babet was the single weather event with the most impact during the year. It hit the country between 16 and 21 October, bringing widespread prolonged and heavy rainfall. And the country had a very dramatic near miss too. Storm Ciaran had the potential to be as severe as the “Great Storm” of 16 October 1987, says the Met Office. Winds of up to 100 mph (160 km/h) killed 21 people across Europe when it struck in early November 2023, but the UK was lucky, the strongest winds bypassed the country to the south. The report came as the record for the world's hottest day tumbled twice in one week, according to the European climate change service. On Monday the global average surface air temperature reached 17.15C, breaking the record of 17.09C set on Sunday. It beats the record set in July 2023, and it could break again. Climate change has already made extreme weather events, such as heatwaves, heavy rainfall, storms and droughts, more frequent and stronger in many parts of the world. Scientists say they these events will become more intense and happen more often unless the world can make dramatic reductions in greenhouse gas emissions. IMAGE SOURCE,GETTY IMAGES Image caption, Storm Ciaran swept across the southwest and south of England in November 20231 point

-

You need a gauge or tester. Will be looking for that next. Quick look looks like about £30.1 point

-

If you are not doing DHW then maybe not an issue. But the heat geek text says " salt based softened water. The different makeup of the water can mean the self-alkalization process settles above 10 which is not healthy for aluminium systems and can affect the warranty of boilers that have heat exchangers made of it." May be worth getting some litmus paper and testing where you are. Industry has a big issue with most grades of stainless steel in saline environments when the temperature hits 60 degs and get what is called pitty corrosion. Basically for pin holes in the metal. Most likely the ASHP heat exchanger will be stainless.1 point

-

Yes it is not rocket science. At the moment, at best, a well installed heat pump working well will just about match the running cost of a gas boiler. That is not much of a selling point is it? Most of us on here do it for other reasons, mine being no mains gas here, and I did not want an oil tank.1 point

-

IMO this would “wash” the lower side of the 110 pipe (and give you more room to have a slope to your shower tray).1 point

-

and there is the problem you can recycle nearly everything -but as long as its cheaper not to -then it won,t happen lithium batteries are the latest instance we dig more raw lithium ,rather than recyling ,cos it is cheaper same goes for grp turbine blades -the cost to grind them down to recyle them into usable grp again is too expensive - so they go to landfill you need a government to insist on this ,but it will never happen due to vested interests we should be promoting hydro and tidal power ,but the return takes too long for the money men ,so we end up with wind trubines with a fixed life span and a waste problem look at any hydro scheme and the life span --most are still going nearly 100 years from when they were built we got 3 on the river dee here in s/w scotland -uses the same water 3 times --and now that is the way to do it built in1936 and still going we are forecast to have a warmer wetter climate and the tides come in and out twice a day --every day and the beauty of hydro is you decide when you want the power -- the dam is the biggest battery ever most rivers could accomadate some sot of hydro scheme- or arcemedes screw if smaller river with decent flow but not great height drop and it would also help eleviate the flooding problems ,by smoothing water flow If they think that beavers are the solution to flash flooding in a lot of places ,then why not a proper dam and generate electric at same time I know a few farmers that would love to harness the water on thier farms ,but the rate they get for the electric + the planning problems + grid pproblems means it does not happen the money men rule every goverment there has or ever will be no one takes a long enough view on these things -1 point

-

Just in case anyone looks at this in the future - I did find out! Just press the menu button BY ITSELF for about 3 seconds - this loads the service menu. The manual is wrong!1 point

-

Sorry I perhaps was not clear. The reason we will have an ASHP is more nuanced than the AECB approach (was a member for about 5 years but have let that lapse.) On our original plan, 2018, we had a gas boiler - no problem getting PH requirements. We decided we didn't want gas for all the reasons we now understand so well. As I was quite taken with the work @TerryE had done with the Willis heaters that was, until late last year, our plan. However, when you go direct electric heating everything else needs tightening up to meet the energy limitations for the house which we did but now as we are further into the build the room for maneuver is limited. Then we noticed that the EPC system trips in and you cannot get a good EPC, see discussion elsewhere on this forum, with direct electric heating! So although we could get PH certification, just, the EPC would have been rubbish and as we feel the need for both we will adopt an ASHP to make it all hang together again - PH certification possible and a, hopefully, better that 100 EPC. For us the spin off will be very low heating bills and a warm airtight home that matches our personal 'machine for living in' requirments - certificate or no certificate. So no different to anybody else really. SO I will now jump down from the head of this pin. Is that the annual cost?1 point

-

We built the most inefficient home possible, by the nature of a large bungalow in the shape of an 'H' effectively, with a lot of glazing, very high ceilings everywhere and simply put an extra £6500 ish into upgrading insulation everywhere we could and 'try for good airtightness (2.7)..... Then hoped for the best! (incl MVHR, ASHP, UFH, PV) End result is bills of somewhere between £150 and £175 for our electricity for a warm house. There is a pragmatic middle ground in everything, but don't compromise on a home design for the sack of savings £50 a month on bills....1 point

-

Like Joe90 we built to passive ideals but did not agree with certain aspects of the standard. In particular the need for and ASHP. The whole point of passive is a focus on energy reduction. A house built to them frequently doesn't consume enough energy to make and ASHP install sensible, the alternative of a low cost A2A makes more sense. Understanding the basics of passive build is fundamental to reducing inputs, certification isn't. I can't overstate the benefits of living in a house built on the passive principles, it's an incredibly comfortable living environment.1 point

-

We did set out to build a certified Passive House (PH) and we are very close now to doing it although we may not certify as we now have other priorities. For us the lower impact on the planet, in the long term, was/is the key driver. I do tend to agree with: while I think any impact is worth while and we will use a lot less of the local generation than many in our all electric house. Can't see how it could be done any other way really. The costs are higher and the challenge more technical, my life partner - wife says she might have thought twice had she known just how technical is has become, because you are working with a bigger number of constraints which often result in difficult compromises. For instance - we, our situation, cannot now get PH certification without an ASHP in the mix - so we will fit one. As a self builder, who did not employ a PH professional at the design stage or an experienced PH Architect there were additional challenges. Instead I did a course on PH and the PH Planning Package (PHPP), read loads, worked with our architect and structural engineer to take their outline designs through the PHPP and make sure it would pass and once the design was finalised we have stuck to keeping the PHPP model up to date and building as close to as designed as we could. I feel that the Cold bridging element is the toughest aspect because the PH certified standard needs evidence of any cold bridges being worked through which we did twice because we changed the windows system during the build. (Went from Rationel to Norrsken) So things have changed a little. We also dropped the gas boiler idea early and changed the insulation from frametherm to blown cellulose which made the overall balance go a little awry, the insulation's U value goes from .35 - .38, but we brought it back by adjustments elsewhere. This, incremental change approach, is quite hard once the house is under way hence the ASHP became a requirement to get us down into the energy demand zone.1 point

-

1 point

-

Too long, didn't read or similar. (Wants the precis because people don't like lots of words.) No inhibitor in my system so you could call it VDI 2035 if you wanted to be pretentious. I've long been sceptical of the value of chemical additions to a properly sealed system.1 point

-

He is travelling to me in Ennis, so I assume so.1 point

-

You don't hear about them much these days, but back in the 80s there was an uptick in community self-build schemes (also known as self-build co-operatives and various other names). They do still happen, and if you can find others interested, you could potentially set one up. It's the sort of things that councils once supported / help organise. Normally they employed a pro site manager and had a mix of people - some with building trades knowledge, others none. The idea was often to build everyone a house of similar size, so typically each contributed the same number of hours and those without skills learnt as they went. Though there are other models. More reading at https://mycommunity.org.uk/what-is-a-community-self-build-housing-project1 point

-

Wandering slightly off subject....I really dislike how developers name their estates after what they have destroyed. The Orchard etc.1 point

-

Thanks for the reply Eric. My builder has said he doesn't see the need for a service void and he will just chase the electrics out of the PIR. Any downsides to that? I guess it makes any future changes more difficult (although after this build I am hoping not to make any changes for at least 20 years).0 points