Leaderboard

Popular Content

Showing content with the highest reputation on 08/27/17 in all areas

-

It'll only teach the money makers how to better distance themselves from blame. Nowt else.2 points

-

If the whole top of the container is shot, then you could just take the easy way out; wire brush the worst of the rust off and give the whole top of the container a layer of fibreglass. Pretty quick to do, will last a long time and will be waterproof. Probably a lot quicker than faffing about trying to patch up lots of holes.2 points

-

In this entry I'm going to discuss in more detail how I came to choose our heating and hot water system, and how it has performed to date. As other forum members have found, deciding which fuel source and type of technology to use in a low energy house, is a challenge given the different requirements each of us has. We had three stipulations – low running costs, hot water available on tap 24/7 and maintenance of the whole house at an even and constant temperature 24/7. Having calculated our heating demand, taking the impact of solar gain, incidental household gain, human occupancy and wind speed into account, I was confident that I had a good indication of the amount of heating I would need. I was also confident, based on historical use, of the amount of hot water we as a family use. Living in an area without mains gas, my options were somewhat limited to using either oil or electricity as my fuel source. LPG was initially considered but discounted due to the lack of availability in my location. As part of the decision making process, I spent a fair amount of time carrying out a cost comparison of both oil and electricity based heating and hot water systems, using 500kWh increments from 2500kWh to 5000kWh. I considered direct electric of various type, oil and air source heat pumps, both air to water and air to air. Solar PV was also considered and costed in terms of each method of heat and hot water delivery. In line with previous cost comparisons that I had carried out, I found direct electric to be the most cost effective in terms of capital outlay and running costs when both heating and hot water demand were less than 2500 kilowatt hours each year. As heating requirement and hot water requirement increases so the balance began to tip in favour of other technologies. Oil was quickly dropped from the list as it became apparent that any rise in fuel prices over then then low point, would significantly increase running costs. Having conducted significant investigation in respect of the viability of Sunamp units, although attractive in many ways, I found that the capital outlay and running cost was simply too high to be able to justify, given that the main benefit (low heat losses) were not as critical for me as they have been for others. Part of that decision was also driven by the cost of fitting Solar PV, which in our remote location was extortionate. I looked into a non MCS DIY install, but couldn’t make the figures stack up, the break-even point being around 17 years. Much as I wanted to install PV, it didn't make any sense financially. In time, I hope to revisit PV, if and when battery storage reduces the break-even point to a more realistic timescale. A wind turbine, given our location and the virtually constant presence of wind, would have been an ideal energy source and paired with Sunamp technology, probably unbeatable. The proximity of nearby houses ruled out that option in terms of planning permission. Air to Air heat pumps were ruled out based on my own experience of them and a road test at a friends house. Neither myself or my good lady found them particularly pleasant as a heat source. Having gone through the list of options, an air to water air source heat pump, paired with a large UVC and UFH for the distribution of heat, represented the best balance in terms of capital outlay, running costs and crucially, comfort and convenience. We opted for a package from Mitsubishi Ecodan, an 8.5kW heat pump and 300 litre pre-plumbed cylinder fitted with the Mitsubishi FTC5 control panel. Given our location, we opted for the coastal model, which is treated with acrylic resin for enhanced corrosion resistance. Whilst a pre-plumbed cylinder is more expensive than a bare cylinder and associated parts, after taking labour (plumber and electrician) into account, I found there was very little difference in cost. I sourced the package from a trade supplier, Secon Solar. I found their price list while searching online and having phoned the company, and perhaps fortuitously speaking to the managing director of the firm, found they were quite happy to sell me package at trade / installer price, the bonus being that delivery to my location was free. The package is configured for the UK market, the only difference to the system as sold in the rest of Europe (AFAIK) being that the cooling function of the heat pump is disabled so that the product complies with MCS approval for claiming RHI. It is however a simple task to activate the cooling function, by flipping a dip switch in the control module on the cylinder. Cooling can then be controlled from the master controller. As stated in an earlier blog entry, the heat pump and cylinder were fitted very quickly with simple connections on the plumbing side – flow and return from the ASHP, cold water, hot water and flow and return to the underfloor heating manifold. Electrical connections consisted of power to the ASHP, a cable from the ASHP to the control module and a plug-in controller. I had initially planned to have the cylinder in the utility room close to the ASHP Monobloc, but changed the location to a service cupboard in the middle of the house, to reduce internal DHW pipe runs. This does mean a 15 metre pipe run for flow and return to the ASHP, but as virtually all is within the insulated envelope, it doesn’t represent much of an issue, and does not appear to be having an adverse effect on performance. The ASHP Monobloc itself is located beside our back door, open to the elements. It seems happy enough where it is, despite the wind that traverses the space between house and garage walls. Locating the ASHP within the garage itself was an option but one I decided against simply on the grounds that I didn’t want to give up floor space within the garage. A timber housing for the ASHP is something we may look at in the future. We opted to fit individual room thermostats to all 3 bedrooms, to give us the option of being able to reduce the bedroom temperatures if we so wished. We have not used these and keep the whole house at one temperature 24/7, treating the underfloor heating as a single zone. At present I only have limited data as to how the heat pump has performed since moving in. On board energy metering (energy consumed and energy produced) shows the CoP for heating has ranged between 3.5 and 4. DHW is maintained at 47C-50C in the cylinder, boosted every fortnight to 60 degrees by the immersion on an anti-legionella cycle. To date the CoP for DHW is 2.4 As members know, heat pumps are best suited to the production of low temperature heat as opposed to the higher temperatures required for domestic hot water. Whilst the CoP for DHW is lower than that for heating, the cost per kWh of our DHW, based on a CoP of 2.4, is 5p, which is significantly better than an E7 electricity tariff. We may be taking a hit on efficiency, but in reality all of the other options would have cost us more. The 300 litre capacity of the cylinder means that we have plenty of hot water on tap and can comfortably run a full bath and still have sufficient left over for another person to shower. The ASHP is currently operating on a 24/7 basis, providing heat input to the UFH and topping off the DHW as and when it determines it needs to, at whatever flow temperature it determines. Whilst that does sound like a recipe for high bills and high flow temperatures, in practice, the heat pump delivers the lowest flow temp it can get away with to maintain our set temperature. If I so choose, the controller lets me set various parameters such as heating curves or set flow temperatures, or indeed a timed schedule for heating and DHW. However,as the system is operating efficiently on its auto setting, and providing the level of comfort we want, I see very little reason to mess around and create my own settings. If say electricity tariffs were to change from a single tariff to a dynamic tariff, then I would have the option of timing the heat pump operation to coincide with lower rate tariffs. After much thought, and indeed discussion on this forum, I opted for an 8.5 kWh ASHP over a 5 kWh ASHP, as I felt happier running a larger unit more gently than pushing a smaller capacity unit harder. A 5 kWh unit would probably have sufficed, and in time, may be what the current unit is replaced with when it reaches the end of its life. We haven’t yet had to activate the cooling function as any overheating (defined as internal temperatures over 23C) caused by solar gain, can, as modeled, be managed by natural cross ventilation. Neither have we found it necessary to constantly circulate the UFH to even out the house temperature / redistribute solar gain from one part of the house to the other. In the heating season, we found that there was sufficient circulation of the UFH during the heating cycle to maintain the house at an even temperature. Outwith the heating season, when solar gain is at its peak, the house zones itself, the bedroom section remaining slightly cooler than the public areas, very useful on a warm summers day. Overall I’m very happy and impressed with our system. It has, so far, delivered everything we have asked of it in terms of comfort and convenience, and the running costs are low. I have the capability to cool the house (via slab cooling) if I so wish, and the option to bolt on a second zone pack onto the pre-plumb cylinder if I ever found it necessary to install a second heating / cooling function – i.e. fan coil or duct heater / cooler. The one criticism that I have is about the controller thermostat function and its hysteresis - 1C increments only. A finer degree of control would have been preferable. Our installation was recently inspected by an MCS accreditor (our plumber is going through the accreditation process). In due course that will give us the option to apply for RHI, although that will be very much dependant on whether the figures stack up.1 point

-

1 point

-

Iain, I am a convert to believing in gut instinct . So sorry you have had all this grief but I firmly believe there are good eggs out there, my builder proves that.1 point

-

Sadly, Ian, I do not think your experience of indifferent workers and poor standards is unique to South Lancashire, or even that uncommon. Quality has been slipping in the UK building industry for years. Every weekday I drive past an old farm, with brick built barns and outbuildings. At a guess it's late Victorian, with outstanding workmanship; beautiful corbelled supports for the eaves, very elegant and tidy brick arched lintels and it just illustrates that the craftsmen that built it took a real pride in their work, even if it was "just a barn". The pressure to cut costs by the big players in the construction industry, the removal of proper training and apprenticeship schemes, and the general ethos that all that matters is getting paid, has made finding good people very challenging. I have a theory about one reason that MBC are generally well regarded. It's to do with what happened in Ireland during the boom. Lots of really crap houses were put up, some so bad that they had to be demolished. Even now Ireland is littered with "ghost developments" that will most probably never be lived in. That changed when the crash came, and all the cowboys went out of business. It was compounded when the Irish government introduced strict new building regulations and inspections. Only those companies who were determined to do a good job survived, and MBC was one of them. They came over here, and their work ethic stands out when compared to the majority of UK companies, as most here who have used them will confirm. What we need is a similar way to enforce building standards, and to make sure that people have the skills needed. That means government intervention, as happened in Ireland, I'm sure. I doubt that our construction industry is suddenly going to transform itself unless it is forced to.1 point

-

Very loyal of you Jack, but what really happened was..... We went on a days training course, architect, the boss and me, and weighed the job up. We decided on paying day rate because it felt more fair, but that we would review that decision weekly. Which for a time we did. Durisol came out and did a days training on site with the whole team. In the trainer's view some of the lads 'had it', others didn't. So far so normal. Add into the mix a boss who, at key points decides to go away on his own - for hours and sometimes days at a time and you have a staff who are getting 'restive' . He was incommunicado. Then twice in quick succession the whole team went away for a fortnight; and on one of those trips the wind blew. (the wall down: the sole cause of the wall falling down was in my view, the exceptionally turbulent easterly.) On their return, they all got a huge evidence-based bollocking from me about standards. That set teeth on edge. Because (as @SteamyTea hinted) they didn't want to live with their mistakes. I pointed out that I expected mistakes, and that's why they were being paid day rate. The boss promptly left the site; the lads were seething I think. To hear 'We don't do Durisol' as a response was a tipping point. It was three issues occurring simultaneously; the boss leaving , his '' unreachableness" the unfamiliarity of the material, and generally poor personal standards of workmanship that all worked together to get them sacked. They'd also left a job in Cornwall the night before and had got here at 0300. So, no sleep either. South Lancashire does what it does, without much thought for change. Certainly no appetite for change and novelty. It's too comfortable. Not on my cash. That rather large invoice can remain on the table, unpaid until I can be, on the basis of evidence, convinced otherwise.1 point

-

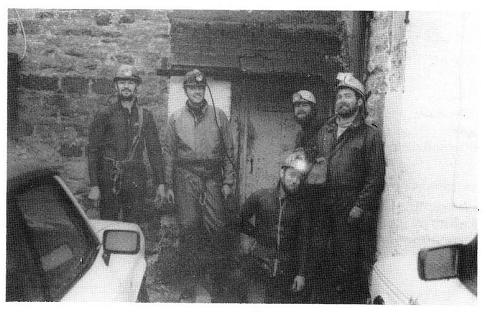

With reference to this anecdote: http://forum.buildhub.org.uk/ipb/topic/3478-electric-towel-rail-above-end-of-bath/?do=findComment&comment=54532 I've just found a copy of an archived SWCC Newsletter from 1986 referring to this trip up North: http://www.swcc.org.uk/aboutswcc/newslett/archive/Newsletter_101_1986.pdf There's even a photo of a very much younger me, and a very brief report of our trip down Lancaster Pot, that I've just snipped out: That's me standing right at the back in the doorway to the club house, with John Lister (who was to be my best man a while later) kneeling down in the front. All the others are also visiting SWCC members who went on that trip through Ease Gill, although I can't recall all of the names.1 point

-

1 point

-

Avoid having an internal DHW cylinder inside the property because you don't want a inside heat source in the heat. Use solar PV; surprisingly little in Spain. Solar thermal tanks are very common. Bear in mind electricity is very much more expensive than in the UK. Mains gas is rare, LPG is common but mainly for cooking. Have an external hot water tank on the roof to supply DHW. In-line hot water heaters and electric showers are normal in hot climates. Use external shutters for solar shading. Don't forget a pool and the best ways for maintaining water quality and minimizing maintenance and running costs. For 4 months in the winter it will be too cold unless you plan in heating at the design stage. You will need both a English speaking solicitor and accountant in Spain. Tiled flooring throughout is normal. Bear in mind the colour of the tiles you use; particularly if it is subject to solar gain. Tiles are cheap. Most properties have out of necessity, wrought iron security protection on all external doors and windows; burglary is far worse in Spain. You need as much cross ventilation as possible and A/C in main rooms and bedrooms for cooling and heating in winter, Plumbing is diabolical in some places, make sure you have non-return valves on your sewage outlets. Flooding is common in winter, hence why that have so many dry river beds. ensure you make provision to protect your property, We were in a national flood disaster zone last year, it was a very sad site. In winter there are cold spells when you need solar gain and a source of heat, do not under estimate this requirement it is very important; we spend two winter months every year in Spain. Use a decent internet supply and use this for TV, you will need a special TV box, dare I say with KODI, and perhaps a large satellite dish. I doubt you need a Telephone landline now that roaming charges have been cancelled in the EU, we use WIFI and messenger/whatsapp for calls, we use video calling all the time when calling UK and it is all free, except normal internet charges. Consider using passive cooling by having a large vent in the top part of your roof , insect mesh and then a top hat above vent. Have insect mesh on windows and consider inward opening windows; mosquitoes are a real problem in some areas. In Florida they have a insect mesh around the whole of the pool and Lanai because the insect problem is so great. Suggest you join "expats in Spain" website - ask your questions there and for getting tradesmen. That will lead you onto other forums more specific to the areas you are considering. Consider using "DOYOUSPAIN.com" for car hire, very cheap in Winter , £5 per day inclusive, just booked it Good luck.1 point

-

1 point

-

With all this talk of cylinders, I thought this piece of research would interest some of you. The research project’s aim was to provide a definitive answer to how effective a copper coil type heat exchanger was, in comparison to that of a stainless steel coil. The results of the report found that using a copper hot water cylinder on an exact like for like specification reduced the heat up time of the water by 28.8% over stainless steel. https://www.mcdonald-engineers.com/sites/mcdonald/files/copper_v_stainless_research_report_-_small.pdf1 point

-

Nope. As a business initiative I bought them all and destroyed them.1 point

-

1 point

-

Surely if you discharge into it, then it'll be flowing year round...1 point

-

1 point

-

Our ASHP instructions said that fitting of a bypass valve was compulsory.1 point

-

I've got the Wilo pump - pure preference being those are now plastic casings and the noise is lower.1 point

-

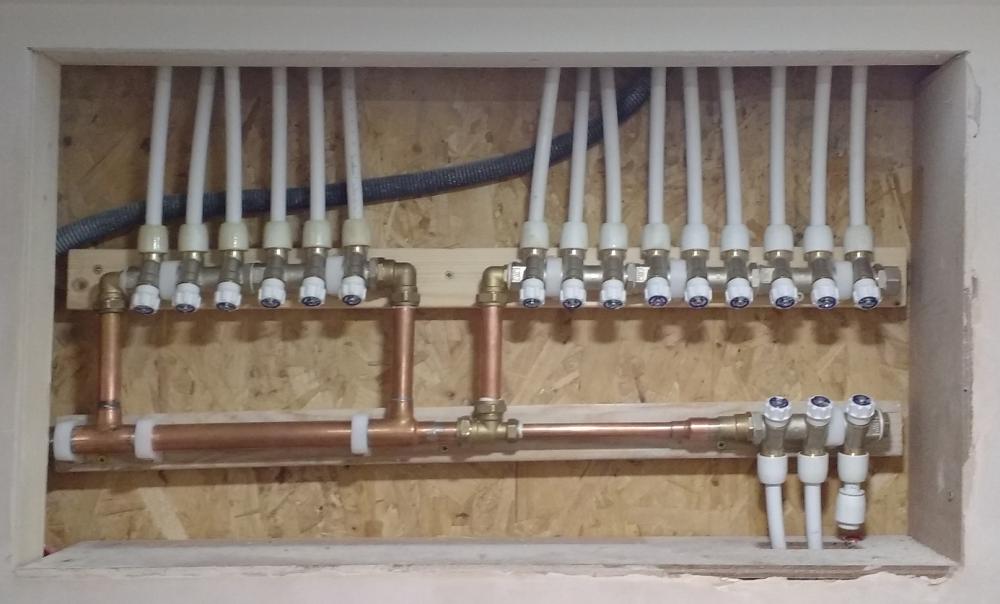

Potable water all plumbed up (apart from one pipe section which has been cut to length and fitted but not as yet soldered up). Time for a glass of wine intervened. To give you a sense of the size of the water services area, the two SunAmps on the left are hard against the LH wall and the Harvey water softener on the right hard against the right one. You will see from the picture below that I've still got to add the loop between the manifolds, Willis Heater and PHE, plus the expansion vessel / fill system for the UFH, but that's tomorrow's job. I've designed the connections to the SunAmps so the two SunAmp units can be isolated, disconnected and removed or swapped, so I can always take one out for maintenance. @Alphonsox, also note the two flow meters on the feeds into the SunaAmps. This flow and the temperature rise will together tell me how much (and when) I am using DHW. I've also gone to great lengths to minimise or remove any unnecessary bends on the main water paths. The manifolds on the left pic are the DHW so I will be boxing these in.1 point

-

In that case, I'd be happy with no PRedV, but I'd fit a 5 or 6 bar cold mains prv as a failsafe if it were me. That's a good recourse-mitigation measure against manufacture based warranties being refused .1 point

-

Also note my mounting the manifold on a mounting board. I did this partly because there's only OSB behind this, but if also proved very useful for another reason. MBC use PexAlPex UFH pipe which is a lot more rigid then the stuff Wunda supply and the tails only came up 60cm or so our of the floor. It would have been really fiddly trying to manoeuvring them into position with the manifold fixer, so I put the board in place, measured and marked the correct tail lengths, then took the board away again. I then cuts the tails to length, chamfered and fitted the insert fittings, before lowering the board into place and over the tails. I then screwed up the tails, and finally screwed the board back to the partition wall. This worked well and was painless.1 point

-

@Barney12, yes on both accounts. Have a look at the Wunda videos on YouTube. The only difference is that I didn't buy the Wunda pressure test kit, because I already had my home brew one.1 point

-

Only advice to add to this phase is to add one or two automatic air vents ( bottle vents ) instead of the manual ones. Will make commissioning a much easier job . These will screw straight into the empty holes ?1 point

-

1 point

-

Yup, the Wundatrade people have a series of excellent YouTube videos which explain how to intall their UFH manifolds and I only picked up about this by watching them.1 point

-

I'm a little more 'rough and ready' . I use my Bahco Spanner with the jaws wide apart, and push one jaw into the open end of the pipe. A quick 1/2 turn left, and another to the right, and it gives a perfect chamfer to the internal bore so, as Jeremy rightly says, it doesn't damage the seals on the fittings or inserts. A bit of silicone lube is advised, and can make this a bit less precarious a job for the uninitiated .1 point

-

We do have a few hidden joins -- some of the runs travel vertically down the walls but need to come out at 90° to the wall (e.g. for the shower fittings) so these have elbows just behind the plasterboard. Other than that, none. If there is a leak at one of these, then at least it's just a matter of cutting a hole in the board fixing and repairing. But you want to buy a load of Hep2O end-stops, and then you can at least pressure test before boarding out -- if you don't want to take the risk.1 point

-

Pretty much what I have. There are two tundishes draining into 1 1/2" waste pipes that then drops vertically down to the ground floor and across to the foul drain, via a U bend trap fitted at the ground floor level. The condensate drain from the MVHR and the 10mm waste pipe from the water softener also connect to this, so the trap is always kept full of water, negating the need for the HepVO. You can't get a high temperature discharge from this system, anyway, so it's fine to run it into a big enough waste pipe, unlike something like a UVC with an immersion or solid fuel appliance, where you could have very hot water discharging.1 point

-

Back to the flow regulation issue, I've been checking our taps and they all use a standard diameter aerator / flow limiter and increased flow restriction versions are cheaply available, so for any that fail the flow tests, I can swap them out for the test. They all seem to have a preferred 1-5 bar rating and our 3 bar pressure is bang in the middle of this, so the whole "need to do flow restriction" is pretty much a non-issue if done at the appliance end. Phew. Another panic over. However, with all of these restrictors around the place, having a decent clean filtered water seems a really good idea, so I want to find a decent limescale inhibitor and a filter that I can clean without having to do any major disassembly. However, having looked into this there are no WRAS approved chemical filters for potable water, since these work by swapping out the calcium and magnesium ions in the water for sodium ions, and this effects both the taste and wholesomeness of the water. The magnetic descalers seem to be based purely on pseudo-science and there is no real evidence that they do anything at all. As to filters, the magic search term to use is strainer (thanks Jeremy) which yielded the business on the JTM site: Brass Strainer 22 mm. Another step forward. Where is your Welshman when you need him!1 point

-

We had to fit (and test) flow limiters on all outlets. I just fitted flow rate limiting washers, cheap, easy to fit (and remove after inspection................) and do the job over a wide pressure range. For a shower you can just replace the existing washer in the fitting with a flow limiting one, for a bit of pipe you need to fit the flow limiting washer in an adapter. You can pay through the nose for adapters with ball valves on, but if you hunt around there are cheaper straight ones available. The washers I used are like these, colour coded for flow rate in litres/min, over their working pressure range: These work by the elastomer bit in the middle deflecting under changes in water pressure to open or close the peripheral water flow space, hence regulating the flow rate more or less independent of pressure.1 point

-

A quick update. I've added a wet 0-6 bar gauge to my home-brew pressure test setup and connected up my DCW manifold and cranked it up to 7 bar. One advantage of breaking your system down into separate subsystems if that you can assemble each on the bench and test properly before installing in place. To be honest I had a 28mm dry joint so its lucky that we did this. The problem was that the end of the 28 pipe had a shallow ding in it that I hadn't noticed -- goodness knows why -- but the result was that the end feed solder had a dry bridge, and this caused a joint failure that I needed to redo before the 7 bar test worked. The main fill will be where the 28mm endstop is to the left and the 15mm below will ultimately have a draincock on it, but it is currently a pressure test point. And this is the manifold in position. Not quite as neat as Nick, but it will do Compare this to the photos on the original post. I blame Jan for it being slightly crooked.1 point

-

@TerryE Cold Supply MDPE 25mm/22mm Stopcock 22mm tee to draincock 22mm PRV with strainer 22mm full bore lever valve (FBLV) (Tee into 15mm feeding toilets - temporary until rainwater installed) At UVC 22mm FBLV Y Strainer 22mm Control Set 22mm PRV - feed to balanced cold on all taps w 22mm FBLV down to 22/15 for all feeds UVC 22mm / 15mm tee (multiples) feeds to taps (isolated) 22mm to ensuite 3 way mixer 22mm to bathroom 3 way mixer Think that's it - for various reasons the rainwater system isn't going in until it's all signed off (Anglian Water being one reason ..) so it looks like we have an unbalanced tee however if it stays long term it will get a 1 bar PRV, otherwise it's on a pump and filter set up.1 point

-

Probably as good a place as any to impress upon folk the need to strip and clean these filters / strainers directly after commissioning, and again after about a month or two of normal service ( use ). Any crap in the incoming supply (new MDPE etc.), or solder, flux, PTFE tape and jointing compounds can get to / and sit on the valve seat and cause it to malfunction. The effect of that failure is for mains pressure to get past the non-sealed seat and damage upstream equipment.1 point

-

1 point

-

A simple Y strainer should do the job OK, I can't see a need for anything more expensive/complex, and it's all that our ASHP manufacturer asked for. I used one of these: https://www.bes.co.uk/plumbing-supplies/brassware/strainers1 point

-

I bought a Wiltec stainless brazed PHE, from Germany, the 20 plate, 44kW version, here: http://shop.wiltec.info/index.php/language/EN/cat/c511_Heat-Exchanger.html The reason for getting a 44kW, even thoguh at most it's delivering only a few kW, was to allow for the difference between the higher temperature difference used testing. I wanted as low a temperature difference as possible, and as the 44kW one was only around £50 inc postage, it made sense to go for that one rather than the one half the size.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)