Search the Community

Showing results for tags 'manifold'.

-

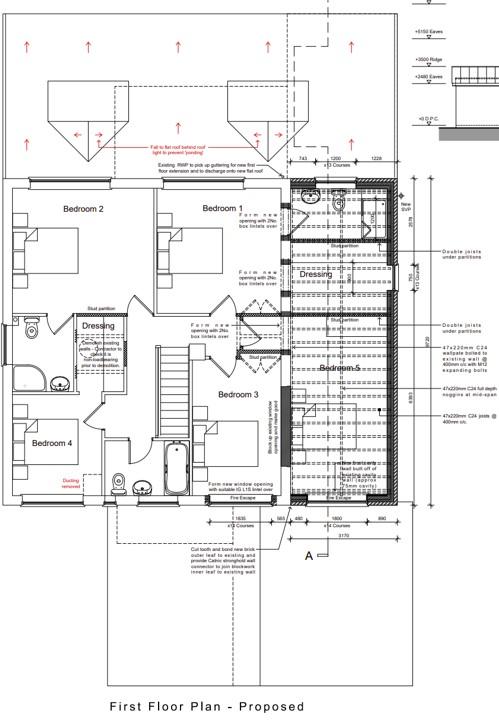

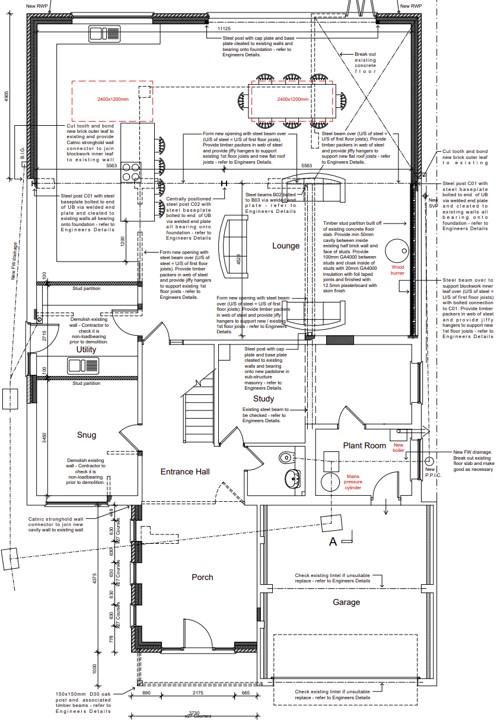

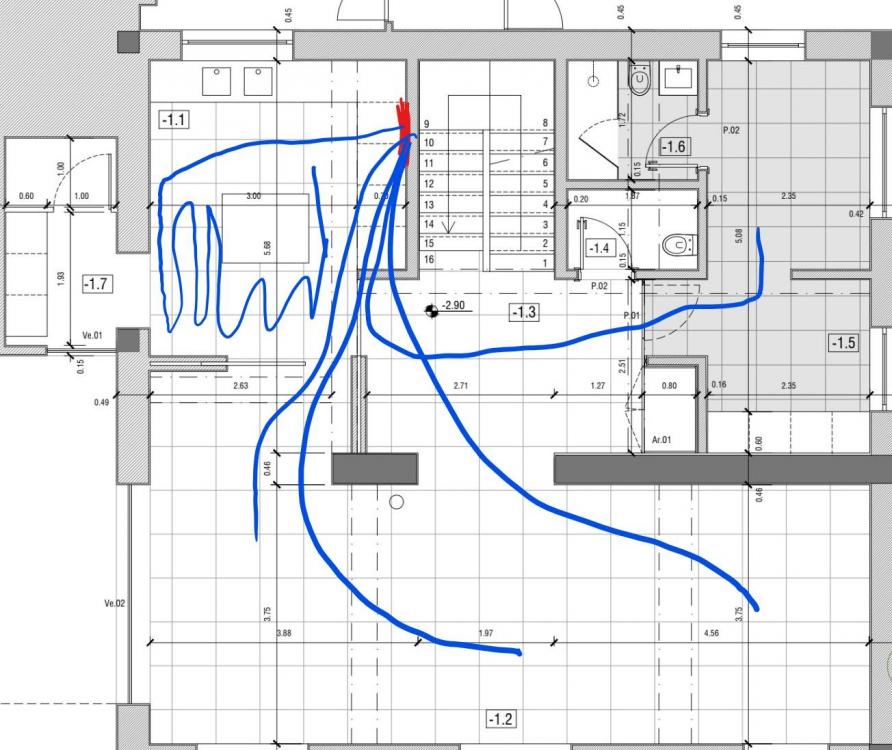

Afternoon all, I've been browsing the forums for a while, messaged a few users direct but as we are fast approaching water tight I'm after a steer from the group on all things plumbing...... Attached are a couple of pictures of what will be the finished ground and first floor plans. The existing house is/was heated using a warm air boiler (located in what will become a snug) ducting through floor to ground floor rooms and into the loft and into 1st floor via ceilings. hot water was previously provided by an electric hot water cylinder (i know $$$) located on the first floor. (Cold Water tank in the loft) Mains gas and water come into the house in the snug (it used to be the kitchen). The intention is to re-route the mains water/gas to a plant room accessed off the garage which will house new System Boiler Unvented Cylinder Water Softener Heating will be provided by radiators in bedrooms, snug, study (8 Rads) towel radiators in bathrooms/ensuite (4 Rads) underfloor heating in open plan kitchen/living room and porch This will be a completely new plumbing system with all existing plumbing decommissioned as the job goes on as we are still living in the house as while work progresses. The first floor joists run side to side (across the front) of the house, except the rear extension which runs front to back. Up until last week I was intent on using a branch/tee plumbing system for the hot water and central heating (because that's what I was familiar with) but I then realised how much more common the manifold systems have become. I've plumbed in plastic before when renovating our last house and I like the idea of using a manifold system because it gives a continuous run of pipe to the appliance/rad (reducing scope for leaky fittings at junctions/turns etc) but I also note the issues with having to empty fairly long sections of pipe before it receives hot water, to give an idea of scale the house is about 12m wide 14m deep. In terms of design my questions to you lovely people would be, should I Use one manifold in the plant room to serve CH pipe runs to all rads and towel rails and secondary manifolds serving the UFH? In respect of DHW and CW run a feed to each bathroom and install a manifold in each bathroom (therefore a using a shower means a significantly shorter length of pipe needs to be vacated for the sink hot tap)? Is running a manifold off another manifold a no, no in terms of maintaining consistent water pressure etc? In terms of manifolds etc, I'm familiar with 15mm, 22mm etc. but I'm seeing reference to 10mm, 16mm across some brands. Is there a preferred brand of pipe, manifold etc. you would recommend? I'll probably have more questions as we go on but I am actively scouting threads looking for answers etc. so thank you in advance for all the contributions

-

- renovation

- manifolds

- (and 10 more)

-

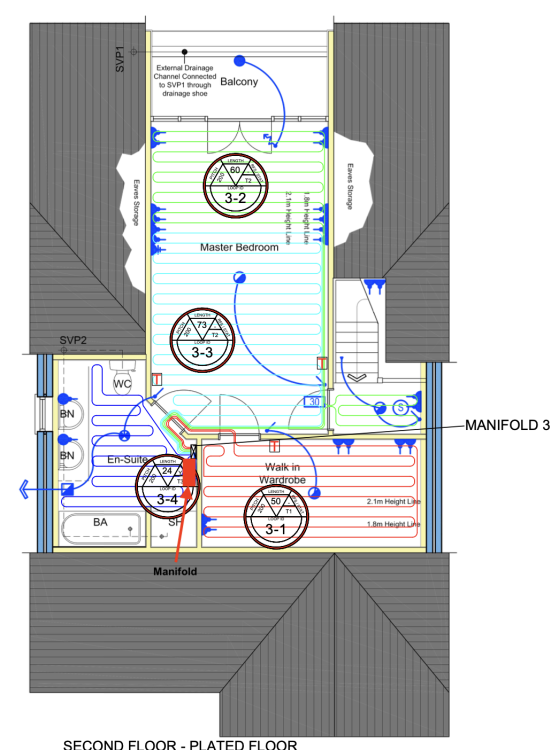

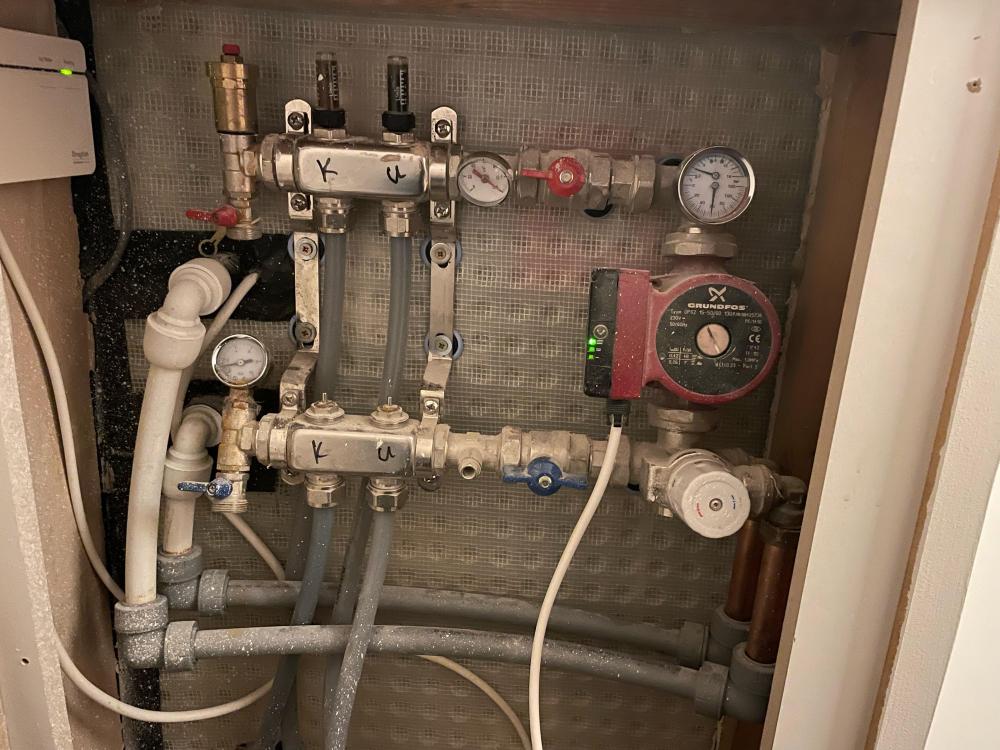

Hello everyone, I wasn't sure whether to post this in the UFH sub forum or here, so feel free to move this if you see fit. I currently have UFH installed through the house, on 3 floors. Ground floor (screed), first and second floors using aluminium spreader plates. The house was renovated 2018. The ground floor works pretty well and I don't really have an issue with the UFH per se, the system itself works as intended (especially after Nick on here fitted a buffer tank a while back). The upstairs floors however are a different matter - the spreader plates are fitted on joists, on top is 22mm wyrock, 2mm underlay and then 14mm engineered wood flooring. Beneath the spreader plates is rock wool. As you can imagine this doesn't it an ideal way to dissipate heat quickly into the rooms, whoever thought encasing the pipes in wood would ever work well (that would be my builder with me giving the gormless nod lol). It just doesn't let enough heat out to warm the bedrooms. I've nursed it through 3 winters and I think I now need to get this sorted one way or another. Here's the attic floor: Each room has its own thermostat and the attic floor being a new addition is pretty well insulated with 200mm celotex in the rafters. The idea I had in mind is to first work on the attic floor, which is devoid of furniture at the moment. I was thinking lift up the wood floor, then the 22mm deck. Remove the pipes and spreader plates. Then run pipes (barrier?) to connect radiators to the 4 port manifold: Before I waste anyone's time - Is this feasible? In an ideal world I'd like to have the radiators connected point to point rather than on a ring - I'm not fussed either way but I would like to retain the ability to heat the floor as one zone independently with it's own thermostat from the rest of the house. I'd also like to connect 5 small/medium size radiators (1 bathroom, 1 wardrobe, 2 bedroom, 1 landing). Having done the heat calcs using an online calculator this looks acceptable to provide enough heat in the winter. First issue I can see is that the manifold mixer valve only goes up to approx 65C - and I can't really oversize the radiators as I don't have that much wall space to hang the radiators on. I may need to replace the manifold with something else? Am I on a hiding to nothing (!) Penny for your collective thoughts, and thanks for your insight valmiki

-

So I had some Underfloor heating (re)installed in my kitchen/diner. With the thermostat set to 19C, the floor in the kitchen gets up to about 33C (measured with a gun) while the larger living area rarely gets to about 24C. This isn't too comfortable underfoot and I'd rather the kitchen wan't being heated so much, food etc. The whole area is one zone from the manifold. The water temperature at the manifold is set to minimum (35C) but the manifold temperature gauge says 50-55C when the system is running. the engineer that installed it said to try turning the zone's flow rate down, which seemed to make it worse. I tried turning it up but there is still a big difference between these areas. Is there anything else I can try? 55C seems a bit hot from what I've read, but I don't know how to turn the temperature down any more.

- 4 replies

-

- underfloor heating

- temperature

-

(and 1 more)

Tagged with:

-

Hello guys, I have searched google but I could not find an answer in my attempts to find out why the red cap flow meters of UFH systems are always fixed on top of the manifold, and the actuators are placed below. Could anyone explain, is there a specific reason why is it so? Is it allowed to fix them contrary, and would that have any negative consequence?? Thank you for your answers.

-

Hi just trying to decide if I should use 10mm Hep20 or 15mm Hep20 pipe to feed three radiators and four towel rails via a manifold. 10mm is much easier to run and turn etc. but when you look at the inside dia. compared to the 15mm especially with the insert in, the difference looks huge. Will it create too much resistance or be prone to noise and clogging. The runs will be circa 5-8 metres between manifold and rads. Would it be possible to mix the pipe dia on the same manifold. Have used 10mm pipe to the basins and 15mm to the kitchen sink on the potable runs. Finding the plumbing a little more confusing than anticipated!

-

So I have stripped out all the existing pipework, back to the incoming main, on my major renovation extension. I have an overall concept of what I am trying to do gleaned from reading this forum, but have many questions! Trying to make sure I am on the right track before buying all the kit. I have three bedrooms all with ensuite WC, basin and shower, one has a bath. Heating is UFH on ground and lower ground floor, radiator in each bedroom, and towel rail/radiator in each ensuite/bathroom. Downstairs also has a bathroom with shower, WC, basin. I have mains gas. so the concept is to have a new gas system boiler, an unvented cylinder and run UFH, heating and hot water, all from the tank. Is this how it works? The tank I am looking at is from AVChttps://www.acv.com/gb/professional/new_product/06627401-465/smart-e-plus-240#tabspace=unit&tabid=diagrams, and is a tank in tank system, so using the primary heating water as a buffer for the UFH and radiators. Using Hep20 from a manifold for hot and cold water, and run the upstairs radiators from another manifold upstairs. I know I need a double check valve and stop cock on the incoming main, and a PRV before the tank, the tank comes with a mixer valve. After that I am not sure what I need I have seen some on here use one large, valved, brass Hep20 manifold say in the utility room next to the boiler and tank, to feed everything, others have used sub manifolds for each room, using the much cheaper, plastic, non valved Hep20 manifolds. Is this purely to save money, I like the idea of being able to turn off individual consumers from the manifold, but unsure in real life how often this could happen, cost difference is considerable, but then it is a one off cost. Control wise I am planning on using Heatmiser Neo thermostats on each zone, and a Neohub and their wiring centre for the UFH and also for the radiator manifold circuits. Boiler was looking at Veissman Vitodan 200 series but unsure on sizing, these are available with weather compensation, but will this work with Heatmiser, how do they talk to each other? Was trying to find modulating thermostats but Heatmiser don't offer them. Also unsure on UVC sizing, as it appears I could run a smaller tank, 210 litres, if I have a large enough output boiler to reheat it fast enough, or is it better to have a larger tank, 300 litres and a smaller boiler, also have a solar array of 3.7KW so was hoping to use a diverter to an immersion in the tank for all excess solar. I apologise for so many questions, but feeling a bit overwhelmed by everything.

-

Hi All; We need to insulate the timber joist floor rooms which have curved bay window radiators as part of renovation. While looking for insulation boards, I came across these between joist UFH solutions: https://www.theunderfloorheatingsto...eating-for-between-joists-or-suspended-floors I would like to get your advice and opinions on: - the "spreader plate" and "foil board" solutions seems easier to install but I wonder how efficient they are as there is no "thermal storage" screed. - around 50% of the bedroom floor area is covered with king size bed and furniture so the open floor area is limited. Is this enough for the UFH efficiency? - shall I keep the bay window radiator as a back up on a separate zone? - I was told there are manifolds for central heating with radiator systems as well which makes zone control quite easy and efficient. Is it worth to change pipe works of the other rooms' radiators as well with centralised manifolds? Thanks for your helps

-

Hello, maybe some of the educated people on here are able to shed some light onto this purchase. As the Foundation is progressing, I needed a manifold for the UFH system. To have that in place before the screed goes down. So i looked on ebay , and found that loads are coming from Germany . Thought I skip the importers and just order directly. Had a quick look on German Gumtree as well and found a cheap offer for a Manifold including a LAING FP5000 Heat exchange pump(At least thats what it translates as), pickup only but next to mums town, so she quickly done me that favour. Looks like this: The Label says: TYPE: FP5000 Serial No.: 110110 primary: boiler circle max pressure: 10 bar max. Temp : 110deg secondary : heating circuit max pressure : 6 bar max. Temp : 110deg Laing was bought by Xylem and so the Laing pumps are not produced anymore My technical knowledge in regards to heating system is fairly limited and I am struggling even more with translating between German/English terminology. There is only a German manual (http://www.bosy-online.de/Systemtrennung/Laing_Systemanbindung.pdf ). I can read it , but it s telling me nothing tbh. The tricky bit is that I am fluent in German, but never worked anything to do with construction or anything technical at all over there. Now I do, but all i learned in the years between is the English terminology. Maybe someone is able to tell me what kind of pump this is. Because it says it is a heat exchange pump with it s own separate 6kw heater , which I didnt come across yet (again, what do i know) I mainly bought the item for the manifold . The rest really was just a bonus. The seller bought it around 18years ago and never installed it (rich farmer) and now just wanted to tidy his garages . Said he paid 1000£ for it , so it might be worth installing the pump as well. Any opinions on it?

-

My distribution box for the MVHR ( sometimes called spigot box or manifold) will sit beneath a flat roof , but above a ceiling. The roof build up from top down is; Alvitra Avalon over 270mm of insulation on some super expensive vapour stuff - forgotten the name - the price was so traumatic 22mm OSB3 POSIs above the ceiling build up which is Vapour control layer 25mm insulation 12 mm plasterboard 2mm plaster skim. There's enough space for spigot boxes to sit comfortably under the POSIs. That means they are outside the heated envelope. (just) The supplier says not to worry : but they would wouldn't they? Everyone has that problem, said the rep, What do you think?

-

Hi all, I am just completing a conversion but hired professionals for UFL. What I find strange is that the manifold (RED) is in the kitchen, and all sections (4 excluding kitchen) go through the kitchen floor and not through the staircase (behind the kitchen) and therefore leaving the potential to overheat the kitchen, when all areas are on and kitchen is already at temperature. Should't they have taken into consideration that the kitchen is potentially the warmest place in the house and it will become a potential sauna? Also the Manifold is right behind the oven and stove. Can I should I insulate the pipes from the screed? Will lay down normal sand+cement screed... Any pointers really appreciated. Thanks

-

Just deciding on some aspects of my plumbing and will be using the manifold for my H&C system. Question I have is why have people chosen the manifold with isolation valves over the non isolation valve ones which are quite a bit cheaper? Is it just to be able to isolate individual pipes or is there something more to it? If I chose the non valve ones I could still put one isolation valve at the inlet which I know would isolate the entire manifold but that in itself would not be a problem. TIA

- 10 replies

-

Hi, I will email the heating engineer in the morning, but if anyone knows a simple fix I can try it today. We have 4 UFH manifolds, all has been fine until Friday. The kitchen seemed cold. I thought the thermostat maybe wasn't calling for heat correctly and checked that out. It still seemed to be slow warming up, so I went to the manifold and turned the flow up slightly. What seems to be happening is that if you turn the flow up past a certain point the water stops flowing. Basically any higher than 2 on the mixer which is 22-23C and the flow stops. Even then I had to jack the pump up to maximum to get much flow. The other manifolds are set between 36 and 42 and running as expected. Probably wasn't an issue until the temperature dropped below zero. Any thought?

-

I've just laid out my underfloor heating pipes prior to pouring the concrete in my insulated raft foundation slab. Ideally, I'd like to pressurise the pipes before the concrete is poured, so that any damage/leaks would be apparent. I thought easy! Just buy a manifold online, job done! Wrong! There are so many options and the more I think about it the more confused I get. I'm building a well-insulated house which faces South, so My thoughts were that I'd fit UFH into the ground floor slab to allow heating of the living space. The bedrooms would be unheated as they are on the upper floors and hopefully should be cooler. I've not even started to think about the design of DHW and heating system! I'm after a Six zone manifold, but depending on my final heating/cooling system design I might want to expend it to eight zones. I want to do both heating and cooling, Do I need a special manifold? Do I want thermostatically controlled mixing or a simple manual mixing.valve? Pumped or not? Thoughts?

-

Hi All, More questions I'm afraid. I'm going down the route of a manifold water distribution system. I'm using the 16mm PERT-a_Pert pipe as I'm running the pipe in the concrete passive slab and it will withstand a bit more abuse when going in. Also it was recommended by the supplier as being better. I'm presuming that I will need to use a 16->15mm reducer every where I connect on to bathroom fittings etc. as almost all fittings I'm looking at buying have 15mm connectors. Thoughts appreciated. Feel free to question my sanity as I'm doing it quite a bit myself these days anyway Thanks, Ed

-

I am sorting out the 30yr old central heating and would like some help deciding on the two options It is a 3 storey Victorian house with 4 bedroom and 2 bath Option 1 Keep all radiators upstairs and link them to a single programmable thermostat with TRVs UFH downstairs and a single radiator, all running off an Emmeti manifold which allows control of the radiator and UFH separately Option 2 Keep all radiators upstairs but each room on a separate loop controlled via its own thermostat running off a manifold (Same as option 1)UFH downstairs and a single radiator, all running off an Emmeti manifold which allows control of the radiator and UFH separately The second option is more expensive as it requires new plumbing so each room are on a separate loop, thermostats, manifold costs etc. however, this option allows me to add a wet UFH to each of the bathrooms with some degree of control Is option 2 an overkill?

-

Hi I was just wondering is there a benfit to getting the premium pump set as opposed to the standard? Diff of about £30-40 thanks ed

-

Excerpt from a previous thread. A member asked..... Hi, I'm currently in progress with gutting, extending and refitting my 50's semi including all plumbing, electrics etc. Stud partition walls have been ripped out, upstairs floors are (almost) up, ceilings down, downstairs ceilings coming down and concrete ground floor being dug up.. I pretty much have a blank canvas on which to work having moved out a few weeks ago. The idea is to have full UFH downstairs and radiators upstairs, with ideally an unvented cylinder to supply hot water to a bathroom and ensuite. The boiler and unvented cyclinder are to go in the loft. Due to the completely different location of the new boiler, and relocated mains water feed, all downstairs plumbing is to be re-done and the only worthwhile plumbing that could remain is the loop that feeds three radiators on the first floor. I have a couple of questions - Would it be best to re-do all plumbing for heating and dhw / cold water in plastic pipe or to reinstate in copper? What are the relative merits of doing either? It would be nice to have the visible pipework for the rads in copper and I'm guessing that with plastic I'd save quite a bit of time and cost not requiring earthing of all pipework. The other question is around the spec of a boiler. If I wish to have UFH and rad circuits along with an unvented cycinder (the latter is not critical but I think would be better due to wanting a power shower and such like) what kind of spec boiler am I going to be requiring? Any pointers on this lot would be very much appreciated.