valmiki

Members-

Posts

16 -

Joined

-

Last visited

Personal Information

-

Location

Swansea

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

valmiki's Achievements

Member (3/5)

0

Reputation

-

Connecting radiators to UFH Manifold?

valmiki replied to valmiki's topic in Central Heating (Radiators)

Hi, I haven't been able to carry out the work yet, and now it's summer so it's on the back burner (!) radiator bleeds probably best in your case -

Connecting radiators to UFH Manifold?

valmiki replied to valmiki's topic in Central Heating (Radiators)

Thanks Nick and everyone for your replies, much appreciated. I've got something to go on for now. -

Connecting radiators to UFH Manifold?

valmiki replied to valmiki's topic in Central Heating (Radiators)

👍 Did you mean remove the mixer valve rather than the pump? -

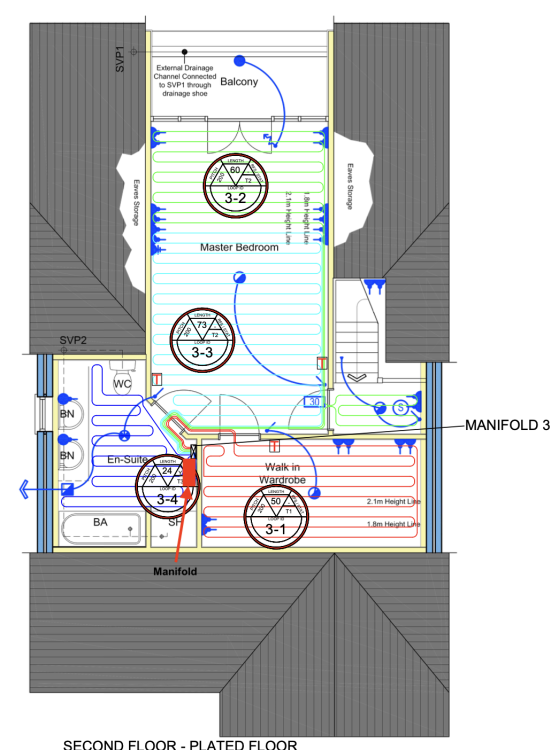

Hello everyone, I wasn't sure whether to post this in the UFH sub forum or here, so feel free to move this if you see fit. I currently have UFH installed through the house, on 3 floors. Ground floor (screed), first and second floors using aluminium spreader plates. The house was renovated 2018. The ground floor works pretty well and I don't really have an issue with the UFH per se, the system itself works as intended (especially after Nick on here fitted a buffer tank a while back). The upstairs floors however are a different matter - the spreader plates are fitted on joists, on top is 22mm wyrock, 2mm underlay and then 14mm engineered wood flooring. Beneath the spreader plates is rock wool. As you can imagine this doesn't it an ideal way to dissipate heat quickly into the rooms, whoever thought encasing the pipes in wood would ever work well (that would be my builder with me giving the gormless nod lol). It just doesn't let enough heat out to warm the bedrooms. I've nursed it through 3 winters and I think I now need to get this sorted one way or another. Here's the attic floor: Each room has its own thermostat and the attic floor being a new addition is pretty well insulated with 200mm celotex in the rafters. The idea I had in mind is to first work on the attic floor, which is devoid of furniture at the moment. I was thinking lift up the wood floor, then the 22mm deck. Remove the pipes and spreader plates. Then run pipes (barrier?) to connect radiators to the 4 port manifold: Before I waste anyone's time - Is this feasible? In an ideal world I'd like to have the radiators connected point to point rather than on a ring - I'm not fussed either way but I would like to retain the ability to heat the floor as one zone independently with it's own thermostat from the rest of the house. I'd also like to connect 5 small/medium size radiators (1 bathroom, 1 wardrobe, 2 bedroom, 1 landing). Having done the heat calcs using an online calculator this looks acceptable to provide enough heat in the winter. First issue I can see is that the manifold mixer valve only goes up to approx 65C - and I can't really oversize the radiators as I don't have that much wall space to hang the radiators on. I may need to replace the manifold with something else? Am I on a hiding to nothing (!) Penny for your collective thoughts, and thanks for your insight valmiki

-

Salus Auto Balancing Actuators - Problems!.

valmiki replied to Miller3857's topic in Underfloor Heating

Hello mate, sorry I never went any further with this - I read about everyone having problems setting up the Salus actuators and thought why do I need another headache 😆 However, that link you posted - and I took a look at the related products below the P19 nut lead me to this: https://static.giacomini.com/giacomini.com/catalog/technical_documentation/K275.pdf Looks new? [edit] No, I don't think that temperature controlled actuator works the same as the Salus ones -

Salus Auto Balancing Actuators - Problems!.

valmiki replied to Miller3857's topic in Underfloor Heating

Hi, I don't believe the Salus actuators fit on Giacomini manifolds. Giacomini use M28 thread and Salus use M30. I asked Giacomini about a year ago and they said no. If you find an adapter that works let me know! -

Boiler frequent cycling with underfloor heating - Common problem??

valmiki replied to Pipes's topic in Underfloor Heating

Hello mate, there’s no way round it I’m going to need a buffer tank, and I’m glad to say I’ve got a local wizard on the case ? -

Boiler frequent cycling with underfloor heating - Common problem??

valmiki replied to Pipes's topic in Underfloor Heating

@Temp Wondering how you resolved your issues in the end as I’m for facing them too (albeit with just ufh, no radiators and a slightly larger boiler with higher min output) Thanks -

Thank you Nick, I appreciate the help ? Do you need any other information?

-

The pipework goes up for the manifolds on the upper floors. The ground floor manifold is installed on the wall opposite (in the utility). I can't be 100% but I think it does come down from above. The cabinet on the left contains the manifold. .

-

Managed to get the cat off the boiler, so here's the space above it (it's quite high ceiling), and I've taken one of the downstairs manifold. I've been looking into Salus self-balancing actuators , as Giacomini use their own thread sizes they won't fit straight on. I did hear that you can use adapters, but not heard anything more. I'll just have to wait for now. I'm not a fan of the mixer valve that's being used, the scale on it is 1-8, ranging from 30-60c but even on 5 as shown above the flow temp is still quite high. Not sure why that is. The boiler is set to flow at 65c.

-

Thanks Nick, I can see from other threads it's not one size fits all. Do you know anyone that can advise me and fit one? Thanks again

-

Thanks guys. The refurb stripped back the house to the walls and added everything back in, plus added a new extension and raised the height (new roof) to add an attic floor. The screed had 120mm celotex below, new extension was timber frame (140mm celotex) and what was left had 50mm celotex + 12.5 plasterboard lining the inside of the outer walls. These numbers I've just pulled quickly from the BoQ so don't quote me but the house does feel warm enough. The upper floors have 14mm engineered wood + 2mm ufh-compatible underlay, on a deck of 22mm weyroc screwed on top of aluminium spreader plates across joists, earthwool loft roll 44 in-between the floors. The ground floor front of the house has the same wood flooring, the rear is open plan which has 10mm porcelain tiles which works really well but that's to be expected. Nick, I did find an installer setting (in the service booklet) to dial down the heating output of the boiler, but I don't think it will take it below the min rated output which is approx. 10kw, if you can find out anything else I'd appreciate it. Because the house is relatively well-insulated after a while it's just the odd zones that come on and off, in these instances the temp at the manifold never seems to get hot enough and (I'm no heating engineer) it looks like the boiler is short-cycling constantly. With hindsight I would have a smaller, wall-hung boiler and a tank rather than the 550cdi beast but I didn't have much of a say at the time, and now that the house is plastered and painted the thought of fitting a tank in somewhere...! I'm stuck with it for a few years now until it's time to fit a new one, but I think I have room for a buffer tank.

-

Hello everyone, I have a Giacomini ufh system installed in my home (happy to post some pics if anyone’s interested). No radiators at all, ground floor is screed, first and second floors aluminium spreader plates. Each floor has its own manifold. The kit was installed about 18 months ago by the builder whilst refurbishing the entire house (1930s detached). We only moved in the end of last year. Now that I’m finding my feet, I feel the need to get it working at its best. The builder fitted the biggest boiler that he could find - a WB Highflow 550cdi. A huge beast, that took up the space I needed for a dryer (but that’s a different story). Great for DHW flow, but not so great on the ufh side of things. I’m finding that on occasions when just one or two zones are calling for heat, they never seem to get to the required temp. Wait - what’s that, short-cycling? I think I desperately need a buffer tank! I also feel that the whole system overall could also do with a knowledgeable pair of eyes to give it a once over, and the odd tweak here and there. So, what I’m really asking for is help to find someone trustworthy that could do the two things above. My regular gas man knows next to nothing about ufh and won’t touch it, and I don’t know anyone else who has it installed! If you know anybody in the Swansea area please let me know (NickfromWales?), I live in Ynystawe. Thanks in advance valmiki

-

Boiler frequent cycling with underfloor heating - Common problem??

valmiki replied to Pipes's topic in Underfloor Heating

I have a Worcester Bosch Highflow 550cdi. You can reduce the heating output I, have a look at the following engineers guide (it covers highflow boilers but I can't find a newer one anywhere): https://www.heatingsparesltd.com/download/boiler_manuals/Worcester/Greenstar_CDI_Service_Booklet_For_Engineers.pdf page 23, installer setting 1.A is "Max Output (Heating)" and the descriptor says "min adjustable output - 100%" nb. this is different to setting 2.b which is Max. Flow Temperature. On my model the value can be changed between a minimum of 36 and a max of 76. I've reduced mine to 60 - I'm using with UFH throughout the house (no radiators on all 3 floors). This setting only affects CH, not DHW (for which max is always available). I can't find the modulation ratio for this boiler, but I'm hoping the above will make the system marginally more efficient than it is. This is reflected in my gas usage has gone down but it's hard to know for sure when the weather temps change every day. Hope this helps valmiki Swansea