Leaderboard

Popular Content

Showing content with the highest reputation on 10/06/19 in all areas

-

Made a start on the other pillar: Used mortar gun: All pointed and cleaned off now. Dead handy to be able to shift the gate way over to the right with the extension rail. Cheap Chinese laser used to make sure its level with the other side.2 points

-

That sounds like the valve might have a limited range. Eg it can't mix 100% flow and 0% return but limits at say 90% flow and 10% return?2 points

-

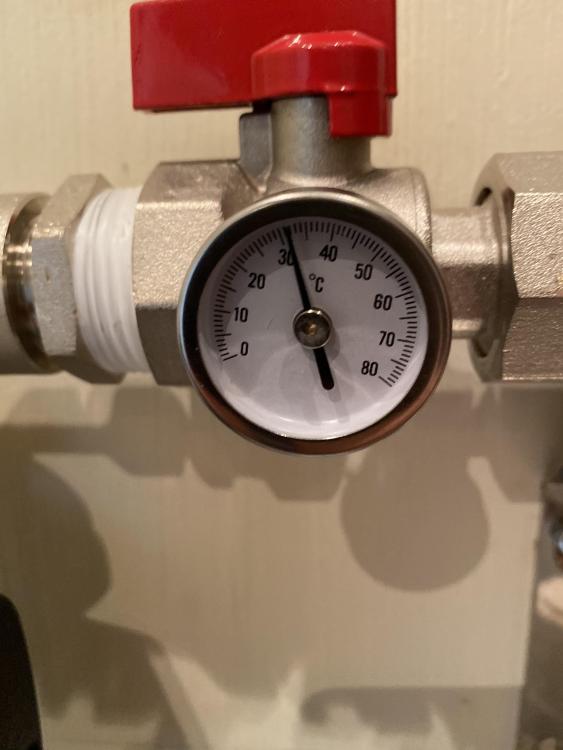

I have an ASHP which runs UFH and rads the flow temp from the heat pump is usually 38-45c Wr can run the UFH at a lower temp than this. However, the valve seems a bit... shit. if I set to 35c I only get flow temp of 25. If I set to 45, it gets to about 30-35. However that 10c difference changes depending upon the heat pump flow temp. The instructions for the valve state that for it to work correctly the incoming hot flow needs to be approx 15c higher than the desired temp. is that normal? Or have a just got a cheap mixing valve? ideally I’d like the UFH to stay at about 35 as it’s only really the rads that need a higher temp when it’s cold.1 point

-

The body of the unit will get warm to the touch by comparison after first running stone cold water through it. Just being able to feel the bits you have exposed should suffice. One will stay chilly the other won’t.1 point

-

Water vapour, rather than steam. One reason for using mercury in a barometer is that it has a very low vapour pressure.1 point

-

Let's put a stop to that then, say what you really think.1 point

-

Yup. Put some pipe jointing compound on every face that meets another. Don't leave any excess inside the bore. Don't over-tighten, same force as the standard compression stuff.1 point

-

Good point. That's what I did before to diagnose a duff NRV in a shower after we fitted a new combi and the customer was trying to blame us. That was the first time I came across this problem. A bugger to find on your own doing process of elimination ( cutting ad capping all over the place !!! ). Every day is a school day.1 point

-

1 point

-

I expect you have already tried this or can't but... I would turn on the cold supply and run cold out of the shower, tap and to the WC to get the pipes cold. Then turn off the cold supply and run the kitchen taps. Then feel the temperature of the cold pipes at the shower and the bathroom tap. If one of those is now warm the problem will be with that device.1 point

-

Sorry, I can't bring myself to write what is actually on my mind - it's a family forum after all ?? Brightened up a dull Sunday afternoon for me anyway.1 point

-

-Use compression fittings -No. Chop the MB out and try the bathrooms first. -If it all goes wrong, we never spoke OK.1 point

-

1 point

-

Good fun to do as an experiment if you have a vacuum pump and chamber. I have one (an old fridge compressor) that I use for degassing resin mixes, with a glass bell jar so I can see what's going on inside. Put a glass of water in there and take the pressure down and it doesn't take long before the water just boils off. It doesn't need to be that high a vacuum, either. At room temperature water will boil when the pressure drops to about 23mbara1 point

-

There are variants of that scheme with two units which synchronize: one pushes while the other pulls then v-v. Not sure how the communicate, whether you need extra wires or not.1 point

-

1 point

-

One way of estimating whether a borehole might be feasible would be to take a look at BGS borehole records (select the borehole scans option and zoom in to see any boreholes nearby): http://mapapps.bgs.ac.uk/geologyofbritain/home.html Typical price for a water borehole down here is around £100 to £120 per metre, including all rig costs, liner, grouting, well chamber etc, but excluding the pump, controls, pipe work, pressure vessel etc. Costs would probably be higher for hard rock drilling, due to the increased time taken. At a guess, drilling a ~140m borehole is likely to cost around £15k or so, plus maybe another £2k to £3k for the pump, controls, pipework etc. The chances are that the level of any aquifer will be just above the level of any spring fed ponds forming in quarries etc nearby. A borehole pump that's able to push a head of over 140m is no problem, the small SQ range from Grundfos includes models with a working head of up to about 230m.1 point

-

1 point

-

1 point

-

1 point

-

An UFH manifold controller / wiring centre usually takes a number of thermostat inputs. When one (or more) thermostats opens, it turns on the manifold pump, opens the actuators for that zone, and calls for heat from the heating system. You can buy expensive ones that may have a few extra unique features, or you can but them as cheap as chips from ebay (they are the ones I have) I have my house zoned into 3 zones but as others have pointed out, you won't get much temperature difference between them. Perhaps the best reason for having zones might be if one room gets a lot of sun and another room faces north and never gets any sun, then on a bright winter day the sunny room may overheat, which would be less likely to happen if it's UFH was off.1 point

-

It almost sounds as if cold is mixing with the hot, going the wrong way around the system. Years ago I had this happen with a faulty shower mixer, inside the thing the hot and cold feeds managed to get connected together when a seal failed. This did pretty much what you're describing, as when a hot tap was opened, cold water would flow backwards from the shower mixer.1 point

-

If you have mains water at sea level, then it will have enough pressure to get part way up the hill. You would need to measure the pressure to see how far. This is sounding like a house I worked on years ago in Glen Urquahart. The mains water went as far as it could up the hill and emptied into an underground break tank. From there it was pumped up with a borehole pump up to the house. You can't suck from the water main so it has to go via a break tank. You just need to see first if the mains pressure will get it high enough to do the second lift in one go with one pump.1 point