Leaderboard

Popular Content

Showing content with the highest reputation on 08/03/16 in all areas

-

M = multifoil, unless you are a Freemat or MatLab programmer, that makes me sweat more than a hot chilli.2 points

-

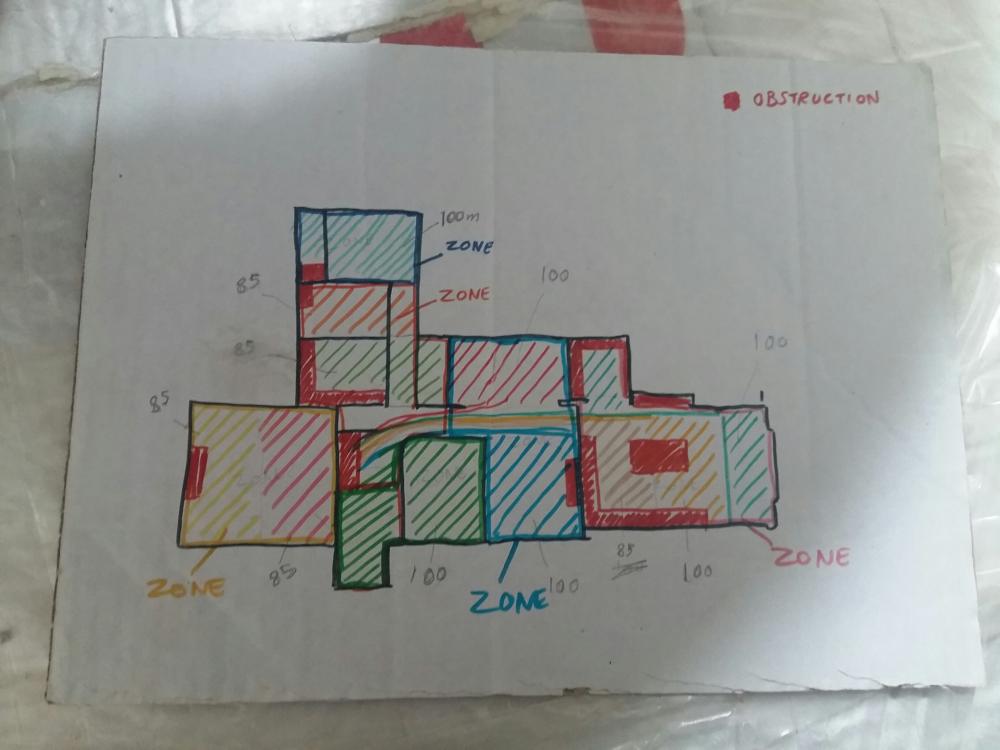

Half the battle is now done as the install was completed today and successfully tested to 6 bar, which just leaves the matter of some sort of recompense to hopefully be worked out with the supplier. I roughly worked out the layout in terms of zones (as defined by the room stats), areas covered by a length of pipe and estimated length of pipe required for each loop (either 85 or 100m based on the goods we received). Here is the "plan" I created: The plumber was then responsible for how he laid the pipes on the floor and not only managed to create a layout that places each flow and return adjacent to each other, but did so without one solitary pipe being crossed by another. We also kept all loops under 100m, therefore avoiding the need for any joints, have the correct pipe density in the hallways and included the pantry within one of the loops to the kitchen. I think our achievements make a total farce of the design I paid for and everything that was said in its defence by the supplier. Under stair manifolds in the hallway Two pipes detour out of the hallway before the pinch point at the far end In the Living Room and Formal Dining Area we managed to avoid the need for any pipes to cross The Kitchen is served by three circuits One of which also serves the Pantry at increased centres2 points

-

i have read with interest all of the thoughts on fire in buildings, with or without MVHR and how people seem to want to overcome this issue. Basically I can assure you that all you need to worry about is early detection and getting out of the building. People have mentioned using fire blankets and extinguishers as a means to preventing the fire getting worse and giving more time to evacuate. All I can say is that unless you have been trained to use either the blanket or extinguisher you are not only putting yourself at risk but can create a rescue situation when there would not have been one if you had just left the building. I am a retired Firefighter and if I had a penny for the amount of people who assured me they could use a fire blanket and when I asked them to show me they would have ended up in hospital with severe burns to their hands, Same goes for using an extinguisher, even with the best will in the world you can turn a small fire that could be contained by just shutting the door if you can safely and getting out of the building or seriously spreading the fire by mis direction/application of the extinguisher. The UK Fire service now use a portable fan to fight fires in buildings but the precautions they have to undertake to ensure that the fire is not spread around the building is quite an an art form. Basically they seal the doorway with a large fan placed externally and wait until a team of firefighters go inside to ascertain the room that contains the fire, close all doorways to other rooms, open the door to the room with the fire and create an opening usually by breaking a window in that room They must ensure they have a jet on the exterior of the building to stop fire spread up the outside of the building and then once all that is done they turn the fan on which dramatically reduces the heat in the building and pushes all the hot gases and smoke out of the window. The reason they do this is to make their working environment easier and aid any trapped people who might still be inside the building. As far as I can see what would be beneficial is for some sort of damper/ shutter that closed in the ceiling/wall vents so in the event of fire the MVHR trunking does not allow smoke/fire to travel to other rooms/floors and turn the MVHR off as you would not believe how fast a fire can travel if the only source of oxygen is coming from the MVHR unit, especially in a Passive house. I still think early detection is what you need to ensure to enable you to get out and always have a plan as to what you are going to do as a family in case of fire in the house.It is imperative that if you have young children then you understand who is getting the children from their bedroom (fires predominantly at night), who is calling the fire service and if you cannot get out what room you need to go to to enable you to maybe escape out of the window or make it easier for the fire service to rescue you. .2 points

-

Our neighbours talk of them in hushed tones. Our friends look puzzled, and then after a few moments get that thousand yard stare. It’s easy to bore people when you mention the humble newt. But people on buildhub.org.uk searching for what to do about them in planning terms won’t be bored. So here is a summary of our experience in the hope that I can save you some time, money and worry. Quick Read: The great crested newt (GCN) is a protected species. It is unlawful to handle them (unless you are qualified) and illegal to -knowingly- injure or kill them. If you live near (250m) a pond, an initial survey must be done to see if they are present (as well as other species). If that initial survey finds evidence of them, a full survey must be done. That survey forms the basis of an application for a license to exclude GCNs from the construction area. The exclusion exercise must be properly run, and can take up to 80 days, during which time no other building work can be done inside the site boundaries. Imagine the rictus grin on our faces when we realised the consequences of our dear dear children’s favourite summer holiday pastime. Fetching buckets full of GCNs from the surrounding ponds and pools and putting them in ‘our’ ponds. We are, even as we speak, trying to reclaim the pocket money we gave them. Ah, such innocent times they were when it ‘were-all-green-fieulds-rouwnd-heer’ earlier last century. GCNs add at least a year to any building project; one bit of building-lore that we were told that seems to be proving to be true. We started planning our Outline Planning Permission application in January last year. GCNs are active when the outside air temperature is (roughly) +7C. And go to bed when it’s less than 7. So that makes their active time from about late April to early October. Right now (January) they are tucked up in bed in a foundation block near you, snoring gently. They are nocturnal beasts: so they are sneaky little things: you might spend all your life never knowing that a GCN is rat-like, never more that 10 meters from where you are. I overstate a little – mostly it matters not a tinkers cuss. But when you want to build, there’s no avoiding the issue. The full pre-planning application survey which must be done by qualified ecologists is, in essence, an educated guess at the population size. That survey (which will focus on other species too) forms the core of the application toNatural England (link last checked January 2015). I thought the survey we paid for was a definitive document. It isn’t. It’s an educated guess. The confidence levels in predicting population size on the basis of the ecologists’ survey is close to zero. Mustn’t grumble eh? We were given full planning permission to build in October 2015 and we've only just been give the EPS Licence (May 2016). A work schedule was agreed in October 2015, but not followed. I have expressed my disappointment in the appropriate places. There's a lesson then. Project management is important - the devil is in the detail. Costs? I’ll do a separate article about that. About £1500 spent getting us this far, and a guess of another £1500 at least for the next phase.1 point

-

Here it is: as accurate as I can get it. No pretense of getting it done cheaper than anyone else. Just the raw numbers and a few words to explain context if necessary (why did I buy a chain-hoist for example). Yes, you'll probably get it cheaper. That's excellent. The point is openness and telling it like it is. March 2014 Home Building and Renovation Show NEC: £100, including fuel and tickets Phone calls about £15:00 extra, and about £70:00 fuel. July 2014 Land: already owned Planner: £1050, plus £70 initial consultation fee, (in cash). LPA Outline Planning Application fee £770 Phone calls: about £15:00 extra, and about £50:00 fuel. August 2014 Ecologist: £1390.15 (works out at about £1 per Great Crested Newt – a further £2000 budgeted for. But see below June 2016) November 2014 Topographical Survey: £540 January 2015 Trips to Timber frame companies and various local suppliers : £50 fuel Subscriptions to various magazines: £70(ish) February 2015 Architect: £4000 (design plus all other matters up to and including submission for Full PP application) QS: £630 – feasibility study Legal: £360; altering title LPA fees: £385 Structural Engineer: £1782; foundations calculations Land registry Fee: £40 Contamination Desk Study and Geophysics : £1260 (plus possible indeterminate decontamination costs) Phone calls: about £20:00 extra, and very little fuel. March 2015 Discharge of Conditions Fee £97.00 Health and Safety Services are being handled for free by a colleague: I’m coding his website in exchange. Notice: no site insurance yet……. :huh: I’m just too mean. Projected cost £568.65 (May 2015) August 2015 Architects fees £2000; from award of Outline PP to Full PP (6th of August) and £40 for bottle of champagne to thank our him: his judgement in relation to what would pass was exactly right. Read paragraph 9 of the Delegated Report (here) Trip to Swindon to visit the NSBRC Fuel £36, overnight stay £85 Strimmer: Polycut head, and set of knives for strimmer £46.60. (No lawn for Salamander Cottage: at last, no mowing…… bliss) September 2015 Legal Fees; alteration to title status £232 October Purchase a four wheel trailer (new) £2500 Purchase a Mutts Nuts (Nick’s term, not mine) Bosch Laser Level £250 First Aid Course (ref. H+S policy) £80 Chainsaw Course £130 December Off mains drainage legal agreement Legal fees and £1000 for access to the land to discharge to stream (wayleave?): £1862 (£300 over budget) Cladding Preparation for processing the wood; Serious Stihl saw (660) and ancillary equipment £2000 (resale value £1000) Trips to open passivhauses £50 + Off – road parking (ground matz) £2800 (resale value £2500) January 2016 SPONS Architects and Builders’ Price Guide 2016. Can’t do without it. And there’s an App that goes with it. £150 Small shipping container (for tools) £300 (resale value £400) Base for container: 4 tons of 20 mm to dust from my mate: £35, yep £35 New wheelbarrow £97 (French made Hammerlin: two flat tyres (in 2 weeks) and a stupidly forward C of G so the damn thing tips forward ON ITS OWN... sodding thing) Local Oak trees (for the shakes and cladding) £1200 (1 square meter of oak shakes retails for £100!) T.K Knipe Allithwaite. £100s of pounds worth of free advice. 1 Sweet Chestnut tree (high tannin content) £140 5 local oak trees £100 (they were going to be cut up for fire wood - I kid you not) Another container (you can't have too many): £1000 (resale value £1000) February 2016 Small hand tools and boys toys £1500 May 2016 2.5 tonne Mini Digger = £14,000 (PV Dobsons, Levens) EPS Licence £1200 (I still haven't paid the bill - because of some really unprofessional behaviour.) Red Diesel £15 120 meters of Temporary Amphibian Fencing (TAF), 80 stakes (37 by 37 by 700) £267.37 Lifting gear: a 2 tonne chain block and tackle 2 shackles, and two beam clamps £181.03 (to run on the RSJs below) 2 RSJs, (6 meters long to span between the two containers) £230 +VAT Filing frame to assist sharpening my chainsaw chains £97 Site signage (ebay) £10 for several (more needed) Plastic Barrier Fencing Safety Mesh Fence Netting Net With Metal Pins £50.95 (for the edge of the car park and pedestrian walkway) Three stillage cages to store material on the site (one cage fitted inside the container) £50 Another two stillage cages today. £25 And £80 worth of 2 inch wire mesh so I can weld it to the stillage cages: slows light fingers down Two (full-on-big-boys) deck brooms £24 A grease gun for my digger and two cartridges of grease £22 Another High Security Digital padlock and hardened, sheathed, hardened chain to secure the buckets (that aren't hooked up) for my digger £55 A 2 Tonne x 1.5 meter Leverhoist £79.95 2 off 2 tonne Beam Clamps £25.98 4 off 2 Ton Alloy Bow Shackles, with Safety Pins £11.96 The above is initially for lifting trees and heavy objects safely off the trailer (on my own) Later the hoist and clamps will do the same job, but in a small purpose-built workshop. 100 meters of 16 amp electricity cable. £71.89 Building Control Fees £600 Red Diesel £18.21 June 2016 Two more stillage cages £25 A Douglas Fir tree and a Larch tree. £40 (Fir tree £10) Will produce stock worth about double that (conservative estimate) 20 8" coach screws £4. 4 sheets of reinforcing mesh £20 (16 by 8 foot for welding to the stillage cages to slow down thieves ) Structural Engineer £1774. And worth every penny (so far) First Aid Kit (10 person HSE Approved) £7.57 (tried getting one locally, couldn't get one for love nor money) Security marker pens £1.99 (a requirement of the Site Insurance: all scaffolding poles must be security marked - not the digger or the saws!) "Curiouser and curiouser" Wood for lining my container £81 HERAS panels, feet, clips, struts, pins for the struts £200 Some steel stock to practise welding £12 (making a small tool table for my SuperJaws clamp: cost on the open market £30) Four Point Lifting Chains ('shorten-able') £139. Fed up of worrying about the webbing strops - they are quite worn already Site H+S sign. £24 ( and I begrudge every penny: it's expensive wallpaper... why do I say that - read on - last but one point) 2 tins of Hammerite for the rust spots on the container. £28 The ecologist had the good grace to halve his bill given the less than prompt approach to fulfilling his contract. £900 July Builder's Merchant bill: £704 - bits and bobs, sand 25mm water pipe and stuff like that August Builder's Merchant bill: < £100 all sorts of tiny things September Builder's Merchants bill £1379.24, Ply wood for the stillage and to make some internal storage in the container, a DeWalt nailer (luxury beyond compare) It starts to get serious now........... Piling will be about £6000, Groundwork price yet to come in, site clearance - I've hired a lumberjack who's coming from Canada - muscles coming out of his ears - off mains drainage and site drainage.... Off to Harrogate next week. (4th of November)1 point

-

Visited a site being built by Sips of Clays today, who are our choice of supplier. Had called Clays to ask a question about lead times (it's around 12 weeks) following a query from one of the builders I've asked to quote for the outer walls, roof etc. and discovered by chance that they are erecting a SIPs build about 15 miles from me -now that's not something that happens often in Northumberland so it was great to have the opportunity to go and see the work in action, and their client kindly agreed I could. Really helpful staff gave me lots to think about and some ideas already that will save cash - like far cheaper to add extra Kingspan internally than go for thicker SIPs panels and actually a better result as you get a better thermal break at window reveals for example that way too. Very impressed by how keen and helpful the two guys from Clays working on the site were. Below is what we intend to build. We have full PP so I am just now awaiting responses from several builders I sourced via the check trade type organisations and asked to quote. Some I spoke to were at a bit of a loss when I mentioned SIPs, (but really, it's simply timber frame from their build point of view of course), but it does suggest they might not "get" my requirement for strict attention to thermal bridging etc. so I haven't asked those ones to quote. That still leaves us with 6 who have shown a serious interest, and just today learned of one who has built at least 3 previous houses from Clays Sips.....1 point

-

The BRegs, and specifically B3 Section 2 Internal Fire Spread (Linings) B3 Section 3 Internal Fire Spread (Structure) B3 Section 5 Compartmentalisation B3 Section 6 Cavities B3 Section 7 Protection of openings and fire-stopping have an impact on the construction detailing within the house. As a self-builder my aims are twofold: (i) to keep my Building Inspector on my side and happy to sign off our build as complying; (ii) to do the right thing in sensibly protecting the house occupants in the case of a fire and to avoid losing the entire house in the case of a fire. I mentioned on a previous post that one of the fun things that I did whilst I was an army officer in my 20s, was to run a fire station for a couple of months during the fireman's strike in 1977/78, and so I had first-hand experience a quite a few house fires and their aftermath, and which I can still vividly remember. Now all of these were in Brick / block fabric houses and a couple of garages, but in general my personal view is that you can broadly divide fires into two categories: localised and non-localised. A localised fire is just that: it has a defined seat such as a piece of electrical equipment or a pan on the cooker. A non-localised fire is one that spreads from the room containing the fire into the fabric of the building. Whatever the type of the fire, the primary goal is to protect life and to minimise any health impacts on the occupants and neighbours. This being done, the next goal should be to minimise the consequential damage to the property. In the case of a localised fire, if this is dealt with quickly and correctly then the fire can be stopped, and the major damage localised to the room containing the fire. Though of course there are still issues of wider smoke damage, risk to occupants, post-fire assessment and remediation, etc.. In the case of of a non-localised fire in a timber framed house, I would suspect that the consequences would almost certain lead to the destruction or condemning of the structure. So IMO, it makes a lot of sense to incorporate into your design and build sensible measures to help keep fires localised. In general I take the BRegs to be a sensible codification of a set of measures to achieve these goals. A lot of this is guidance rather than mandatory requirements (in this discussion, I am assuming a detached single dwelling, as there are extra mandatory requirements in the case of attached multiple dwellings) and so is really up a negotiation between you and your Inspector, though I could imagine that I might well decided to do in excess of what my inspector wants at a minimum. So what should I do to keep the Inspector "off my back" and to do what is sensible for my own benefit? My first question is what readable guidance is out there? Can anyone recommend any good references or Internet downloadable materials? What are the particular risks in a Timber-framed or Passive House? To be honest, I have for more open questions than answers, one issues such as: Flammable gas containment. Even something like a pan fire can produce a lot of hot gases that are past the ignition temperature for some plastics and exposed wood. In a room with plastered walls you might still have a few minutes to kill the fire whilst the plastered fabric contains the combustible gases. But not if there are gas conduits above the fire. MVHR for example. So in another post there was a discussion about the wisdom of how the MVHR should be programmed to respond to a fire. My view is that it should be powered down as this has the best chance of keeping the fire local to one room. We have 3 boxed-in ducting cavities carrying a total of 8 MVHR pipes from the ground floor vents to the manifold on the second floor. What is the best way to implement containment here? Compartment closure. Thanks to our Gerberit loos and hidden plumbing we have boxing in panels to hide all of this. This should be closed from a fire perspective and not open to floor voids. Ceiling and floor breeches for services such as potable water, waste and MVHR. How best to seal these and where to we do implement some level of self sealing? Drywall spaces. In general we are using acoustic insulation in ceilings and stud walls, and this has secondary advantages for fire suppression. But we also have a thin (33mm) service cavity on the external walls which we currently plan to leave hollow. If this best filled out? So many Qs and not enough answers. So I would really value your discussion and input to help inform our decisions and dialogue with our BInsp.1 point

-

1 point

-

it does seem that way. we all make mistakes, its how you deal with them that makes the difference1 point

-

1 point

-

That's me snookered then. Take me now lord.1 point

-

I just checked out the website and can't believe who is selling it! Promise I had no idea prior to posting this topic!1 point

-

Don't worry, screeders are booked and coming on Friday Fast dry screed should be well enough on in 3 weeks to let the painter in all being well.1 point

-

Clearly, the celebration here is that you found a good plumber. Im lost for words as to how this has been responded to, and can only hope that Byron will come back to me after his holiday and offer some resolve. I will most definitely be providing closure from this matter, through accounts of my own exchanges, by means of posting here accordingly with the outcome. Ill hold off recommending a screed company1 point

-

Well done. The price you paid should have gotten you a highly competent piece of design work (the cost was more than a full day's work for most trades, even in the south east). Stick to your guns and let us know how you get on.1 point

-

1 point

-

1 point

-

Mine has just been fitted in a block and beam floor all went through doorways apart from 2 rooms which have been acsessed by drilling through the dolly block, our manifold is sited in utility room although boiler will be outside, what reasons for not being in utility im intrigued?1 point

-

Hi all one idea is to ask the local fire safety officer at the fire station. They will normally come and advise you of what is needed in event of a fire. As we let out the last cottage we built we have annual fire inspections and they are happy to give advise. about all aspects. I know from working in a building with massive smoke extract fans they can only be switched on by the fire service once the fire was out to clear the smoke. Ask them what they would like as they will be the ones coming to help.1 point

-

Yep thats pretty much what I plan although the hole will be lined with plastic first - more so if I need to get the damn things out then I'm not breaking up concrete ! They are surprisingly robust even when empty - point loads are the problem and hence why its going below a patio1 point

-

Found this thread on the GBF - to quote...'i buried an ibc for my collection tank . I dug the hole slightly larger than the ibc poured concrete into the base and dropped the ibc with its cage in. then filled it up with water and filled hole with concrete'1 point

-

So here we are, owning a bit of field in a National Park. The plan is to build a house for less than it would cost to buy one and of course to a much higher standard, particularly where insulation is concerned. We can build in the national park because I grew up in the village (local occupancy clause on all new builds) Now in this rural area, that is do-able as market forces mean retirees and people on city wages have driven the prices up well beyond what anyone on a rural wage can afford, in fact the only people from my generation who have been able to stay in the village have inherited houses or rent. So it's definitely cheaper to build than to buy. Being in the national park the house has to fit in with existing properties very much more than in a LA planning controlled area, but that's fine with us as a Grand Designs type thing really would not go. So using the National Parks design guide, you basically are looking at building a traditional stone house on the outside. Since we're a stones throw from an ancient fortified border peel tower and a Norman Motte & Bailey and Saxon (in parts) church, anything else really would look out of place to be fair. After going to the Homebuilding & Renovating shows for a couple of years, reading all the magazines and haunting eBuild and the Green building forum, we settled on SIPs for our structure and recycled natural stone and slate for the outside. We wanted the stone to be ready weathered to fit in, but it also has the happy quality of being a lot cheaper too!1 point

-

I'm going for a buried IBC or three to provide storage under the patio, and either a submersible pump or a jet pump to provide a rainwater based supply. Not as easy as a water butt, however at about the same price for 3 times the storage it seems a no brainer,1 point

-

I find this table to be useful sometimes. http://www.hendersons.co.uk/pipework2/page2.html1 point

-

@Nickfromwales the whole issue of fire barriers and BReg compliance is a subject in its own right and merits is own topic. I'll do a little background research and start one1 point

-

Easy Barney, easy there lad! It's before 9:00 pm.1 point

-

1 point

-

Cheers for the thought, but just another thing to charge, have a lead for etc, when I already own a phone . Saw one on the bay for around £60, and another seller selling the same thing for £120. Gave up at that point and I'll just keep my eyes and ears open until a cheap 'I' flavoured one pops up until then I'll use my current inspection device.1 point

-

There are several threads here discussing buying from elsewhere in Europe, because you get better value, and, in some cases, a greater choice or better quality products. I've just been looking at the price for a part for our MVHR, a "Sommerbox" that is a 5 minute slot-in replacement for the heat exchanger to gain better cooling in the summer. I got hold of the part number from Genvex (who are always very helpful, BTW) but Genvex don't sell direct so I asked two of their suppliers for prices. Here are the prices for comparison: UK supplier - unit price £174.00 inc VAT for the part, plus £30.00 inc VAT for delivery, giving a total of £204.00 inc VAT Danish supplier - unit price £128.82 inc, VAT for the part plus £62.48 inc VAT for delivery, giving a total of £191.40 inc VAT Now this was a VAT reclaimable item (I think), so the ex VAT prices including delivery would be: UK supplier - total price = £170.00 Danish supplier - total price = £153.12 Looking at just the unit price, ex-VAT, as the Danish supplier has to charge more for delivery to the UK, whereas the UK supplier presumably gets better rates for bulk shipment, then the prices are: UK supplier - part only price, ex-VAT = £145.00 Danish supplier - part only price, ex-VAT = £103.06 Given that both the UK and the Danish supplier are authorised Genvex dealers, and so are almost certainly getting the same sort of price from Genvex, what's the justification for the UK unit price being 40% higher than the Danish supplier price? My understanding is that the cost of living, doing business etc in Denmark is similar to the UK, may even be a bit higher, as their VAT rate is 25%, rather than our 20%. The only conclusion I can reach is that the UK supplier is upping the price because they can, which is most probably because people aren't shopping around to get a better price.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)