-

Posts

398 -

Joined

-

Last visited

-

Days Won

4

Everything posted by Benpointer

-

Week 34 - Kitchen, doors, and more...

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Thanks Mike! The plan for hob extraction is to rely on the MVHR. In our last house we also had a recirculating cooker hob... but never bothered to switch it on as the MVHR dealt with smells and damp quickly enough.- 4 comments

-

- 1

-

-

Week 34 - Kitchen, doors, and more...

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Haha, absolutely Pete!- 4 comments

-

Week 34 - Kitchen, doors, and more...

Benpointer posted a blog entry in Contemporary build in north Dorset

Hi everyone. It’s been four weeks since the last blog instalment and despite the Christmas and New Year break, quite a lot has happened. Apologies for a somewhat scattergun approach but I wanted to try to cover all the progress. Kitchen units and appliances Last time, just before Christmas, carpenter Chris was halfway through fitting our kitchen units. That work was completed during the first week of January in readiness for… Kitchen worktops Martin from Langford Stone came out to template the kitchen/pantry/utility units for our worktops. While he was at it, we also asked him to template for several granite surfaces for our master ensuite. A week later Langford’s team of four fitters arrived with some very large slabs of granite, which they duly fitted without issue and to a high standard. We’re very pleased with the results: Internal doors Chris and Alan fitted the four pocket doors to the sliding gear installed back in September, before plastering. They then fitted the oak door linings for the 8 conventional doors and hung those doors. The door linings required some thinking about because we originally opted for rebated linings but these have had to be reinforced with ply backing to give enough meat to confidently screw in hinges that can take the weight of the (44 kg!) doors. We hope still to get the rebated look by fixing full width door jams, which we’ve now ordered. The doors themselves are 33” Avon Oak fire doors from Todd doors. We opted to buy them unfinished because the factory finish doors felt a bit ‘plasticky’. Mrs P. has done a brilliant job with sealing them with Osmo Door oil and we are very pleased with the results - they have a lovely look and feel to them . The doors supplied were really good quality - no need for further sanding before oiling and no complaints from the carpenters (except about the weight!) Troy Pointer supervising operations: 2nd fix electrics After a pause at the beginning of January, Darren is now back with us and making good progress on the second fix electric. Skirtings Steve, our tiler came in to fix the porcelain skirting tiles and was able to make a start, but the rethink needed for the door linings meant we are not ready to fix all the architraves just yet. So he has promised to come in on a future Saturday to finish those off. The skirting tiles themselves are 900 mm long and have more of a bow in than we were expecting (well I was expecting them to be flat to be honest!). Steve was worried that they would not look great but in reality unless you look along the line of the wall you can’t really notice the bowing and we are happy to live with it (especially since we can’t think of any sensible alternative at this stage). Once grouted or caulked to the same colour as the walls we don’t think it will be an issue. Ensuite boxing-in I’ve been whiling away the odd hour here and there preparing the ensuite for final fix by my brother next week. There’s quite a lot of pipework which needs to be hidden - given the way the house design squeezes three bathrooms into a small space, the stud walls are just not wide enough to take it all. So my idea was to create some boxing-in using spare 4x2s to hide the pipes, provide some built-in cupboard space, and form a framework for timber cladding on the lower walls. Sure, I could have asked the chippies to do this and they’d have done a great job in no time... but where’s the fun in that? For the timber cladding itself we’re going be using some of the left over Brimstone heat treated ash we have used to clad the outside of the house. This time of course we'll seal it with Osmo oil. The quality of that Brimstone Ash is too good to waste solely on the outside. You will hopefully be able to see from future blogs whether this bathroom design idea has been successful or not but for now here's some 'boxing-in'. Moving in next month! I mentioned in the previous blog that we had brought forward our target moving in date to the end of February. We now have a removal date booked of 23rd February. - so only five weeks away! We should be fine, we could probably move in and camp now if needed. The main things we really need sorting are a fully working bathroom, electrics, and ideally smooth and solid access to the front of the property. Hopefully we can get all that done in the next five weeks. Council tax Mrs P. and I were wondering about bin collection and also how soon the council would want to start charging council tax, when lo and behold the man from the council turned up. He explained the process, gave us a form, and told us we could request bins (for which we have to pay a £81 one off charge - of course we do). Since we will be ceasing the council tax liability on our rented house, we are happy to start paying council tax on the new house. The council man said it could take three or four months to get a council tax valuation but they will backdate the charge to our move in date. Address After seven months(!) Royal Mail have finally got round to adding our address to their postcode checker database. They say on their website that they will only add it when you move in but as anyone who has self-built will know it’s really very difficult to arrange deliveries, service installs, etc. if your postcode is not on that Royal Mail database. My advice for anybody starting a self-build is get that address registered as early as possible. Fibre Another service that’s taken seven months from request to delivery is our full fibre to the house. Many of you will know this is a new build building control requirement for England, so we requested (and paid for it) back in June. It finally arrived last week. Unfortunately we didn’t get added to the Openreach fibre database straight away so no service providers could offer us a fibre service until that was resolved earlier this week. We’re hoping to get the broadband service up and running next week. Focus for the next two weeks: Electrics, still lots to do. We’re hoping to have two sparkies in for most of next week so they should make a lot of headway. Plumbing. My brother Chris is back for 4 days next week and will focus on getting our master ensuite up and running, the kitchen & utility sinks fully plumbed in, and then if there’s time progress on the family bathroom and guest ensuite. Landscaping. Ashley, our garden landscaper is making a start on the front landscaping from Monday. We’re really looking forward to seeing the crushed aggregate disappear under something more wheelchair-friendly. Dashboard: Contractor days on site this past four weeks: 47 Contractor days on site since build start: 495 Budget: No change - over budget but within contingency. Plan: Moving in booked for 23rd February. Issues and worries closed this fortnight: N/A Current top issues and worries: None.- 4 comments

-

- 8

-

-

Week 15 - UFH, screed, and render base coat

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Firstly, yes we cut out the sole plates in all the doorways. Regarding the windows, I have trawled through our photos here's the best I can do. First, Norrsken supplied and fitted the windows and they wrapped the breather membrane round into the reveals then filled fully the gap with sealant. Here's a picture from the inside before they applied the sealant. You can see the sealant here (from the outside). I think this sealant is the key. Ventilated cavity on the outside, sills clipped in: Cement board: Beading Render + another bead of silicone -

Week 15 - UFH, screed, and render base coat

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

The blue foam surround is perimeter expansion strip. The screed layers insist on it. I assume the screed slab expands a bit when the UFH is on and this foam allows some 'give'. https://www.theunderfloorheatingstore.com/products/prowarm-premium-8mm-underfloor-heating-edge-insulation-50m Our UFH pipes are buried in the screed - in as much as the screed was poured over the pipes. If you are having someone lay the UFH pipes and the screed, I expect they will fit the perimeter expansion foam but you might want to double-check. -

Triple glazed Vs double glazed patio doors

Benpointer replied to flanagaj's topic in Doors & Door Frames

Glass U-value = 0.53 W/m²K for the Norrsken 3g Lift and Slide doors. Whole window U-value = 0.87 W/m²K, which does indicate the importance of the frames in the overall calculation. For comparison, Norrsken's similar 2g doors are 1.1 W/m²K (pane) and 1.4 W/m²K (whole door). https://www.norrsken.co.uk/products/lift-slide-alu-clad-door-s315a -

Triple glazed Vs double glazed patio doors

Benpointer replied to flanagaj's topic in Doors & Door Frames

We had 3g windows throughout our last house except for the patio doors which were 2g slide and folders. They were definitely cold. This time we have gone for 3g throughout (from Norrsken) including some 4m lift and sliders. Too soon to say how they feel because we aren't in yet but early indications are good - running the house at just 18deg for the 2nd fix trades it feels amazingly comfortable and those sliders are not giving any impression of feeling cold. I'd go for it if you can. -

Great blog and good progress - well done! Interesting that the DPM and underfloor insulation took you much longer than you expected - that was the task which most severely stress us out and also took longer and cost a lot more than I estimated. If I were doing another build, I'd seriously consider poured floor insulation.

-

Bath fillers - Mira, or Aqualisa

Benpointer replied to crispy_wafer's topic in Bathrooms, Ensuites & Wetrooms

That Kohler filler is listed as £825. £825! for a 0.95" chrome orifice ?! WTAF? How about this for £27? Projects just 22mm from the bath wall. https://www.bathroomrepublic.co.uk/bath-filler-sprung-waste-overflow-and-easy-clean-1.html -

Week 30 - Cladding, kitchen, electrics

Benpointer posted a blog entry in Contemporary build in north Dorset

We are now in that phase where we can see the finish line not far away but, bizarrely, the closer we get the more there seems to be to do. The list the jobs that yet need to be done is a bit depressing; reflecting on all we have achieved so far is much more uplifting. We are certainly in a significantly better position as we approach the end of the year than we expected to be when we started the project. Work has continued in the run up to Christmas and several trades have asked if they can work some days during the holiday period (er… yes please!). We have sadly suffered a family bereavement this week which has naturally led to reduced focus on the house, so apologies if this week’s blog is a bit rambling. We do find creating the blog helpful and therapeutic, so we’re inflicting it on you regardless! Cladding Alan and Chris have now completed the ash cladding at the front of the house and the scaffold is down - yay! The cladding looks quite dark at the moment but it should fade to silver over the next year where exposed to daylight. It will be interesting to see how the silvering graduates under the soffits which will presumably remain darker for many years. Kitchen Our carpenter Chris has started to install the kitchen, utility and pantry units. In the past we’ve installed kitchens ourselves but various circumstances have meant we’ve not been in a position to do this and Chris is undoubtedly doing a better job than we could do. The main kitchen is bespoke from Husk Kitchens in Bristol and uses ply drawer fronts faced with Fenix. Mrs P. is, as you would expect, Artistic Director and I defer to her on all colour choices (or else we would probably end up with beige/grey everywhere). We both really like the effect now that we see the kitchen beginning to take shape. Of course Mrs P. does have extraordinary good taste - she chose me after all! Our signature 'Wall of Ovens': Here's the utility room. Mrs P. may have allowed me free rein with the colours on this one - I know my place 😉 Electric second fix Darren has been progressing fixing of sockets switches and lights. First lights fitted! Our batteries and inverters have finally arrived and been connected, so the solar panels we had fitted in July(!) are now actually generating for us. Annoyingly, OpenReach still haven’t installed the fibre, so we can’t monitor our generation in real-time just yet - the geek in me will have to wait a bit longer for that. For those interested, we have 14.88kW of solar panels and 27.12 kWh batteries. Focus for the next two weeks: Obviously a quieter period than usual but we expect there will still be progress in a number of areas: Floor tiling - Steve should be back over the holiday period to fix the porcelain skirting tiles. Second fix electrics - More progress expected on lights and switches. That depressing list of things to do: Kitchen worktops Porcelain skirtings Finish bathrooms (x3) 2nd fix Commission STP Electric 2nd fix including lights, switches, heating wiring centre, CCTV, PIRs… Install fibre to house Internal door linings, architraves Internal doors Hatches to loft storage areas (x3) Fitted wardrobes Rear timber cladding Cladding front and rear canopy soffits Front landscaping, including level access, highway apron, parking and turning Rear landscaping, including level access and garden lighting Final airtightness test ‘As built’ SAP report Building Control sign-off VAT reclaim! + probably others we haven’t thought of. Dashboard: Contractor days on site this fortnight: 16.5 Contractor days on site since build start: 458 Budget: No change - over budget but within contingency. Plan: Breaking news! We are now aiming to move in at the end of February. So, a month earlier than previously planned. Issues and worries closed this fortnight: Kitchen units are substantially in so will be ready for worktop templating. Current top issues and worries: None. -

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

It's impossible to cover every decision and get them all right. 'Mistakes, we've made a few, but then again... '- 25 comments

-

- 1

-

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

Further update from Octopus: "I’m sorry to hear that Royal Mail is taking some time to update their address database. Unfortunately, if we put through the request and the address is not updated with Royal Mail, it will be rejected on their end." Which begs a couple of questions: 1. Why do Octopus need Royal Mail's approval? 2. How did the current fictitious address come to be assigned to the meter? This is becoming Kafka-esque.

-

Indeed, and it's the sort of thing that can hold up a future house sale as the solicitors see a way to charge the buyer more money 'investigate further'.

-

Thanks for that info and link, very useful. I am currently trying to get Octopus to change the 'address' of our supply meter from a completely fictitious address made up be the plot vendor, to our actual 'approved by the council' address... I email the request as per the instructions on the Octopus website. They email back and asked for evidence that the council had approved the address, so I sent that. Then they came back and asked for a photo of the meter. Ok, I took one and sent it to them. Then they said: "I can process the address change for you, but first, please update your address with Royal Mail. Once you've done that, could you please send me a screenshot showing the updated address on the Royal Mail website?" Which of course RM have failed to do despite a request via their online form in June and two chasers since. So I have now sent Octopus a link to http://www.findmyaddress.co.uk in the hope they will pull their finger out and sort this. Octopus not covering themselves in glory here.

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Interesting idea but I can imagine Mrs. P's reaction when I tell her I've opened a Velux for her to climb through. I suspect she'd tell me where to go ('go and get a hammer').- 25 comments

-

- 1

-

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

I have been messaging @craig about this and he has suggested possibly replacing the current striker latch for a day latch on at least one door. It doesn't look that straightforward but may be doable.- 25 comments

-

- 2

-

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

I've now found Dorset Council's policy, I assume other council will have their own similar policies. https://www.dorsetcouncil.gov.uk/w/new-build-properties In summary, once first fix is complete they can issue a Completion Notice allowing up to 3 months for 2nd fix. We are through first fix on our build but haven't had a completion notice yet so I am hoping that: a) their usual tardiness/backlog is delaying this, and b) they can't back date a completion notice.

-

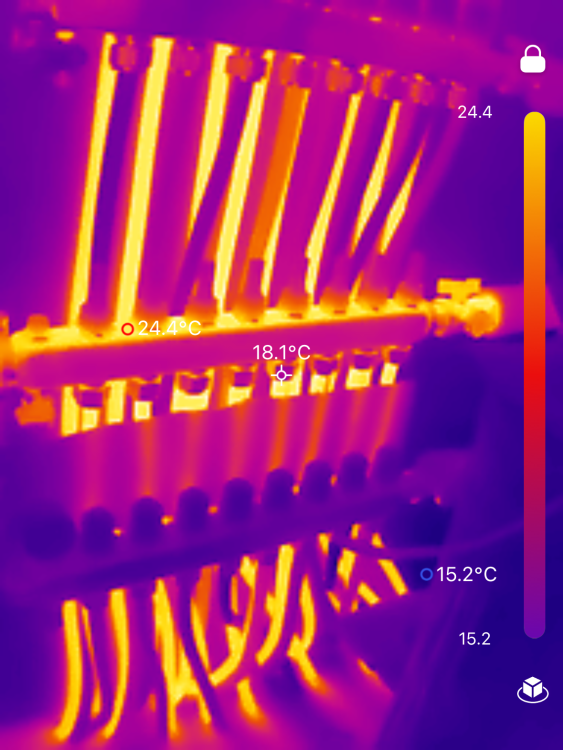

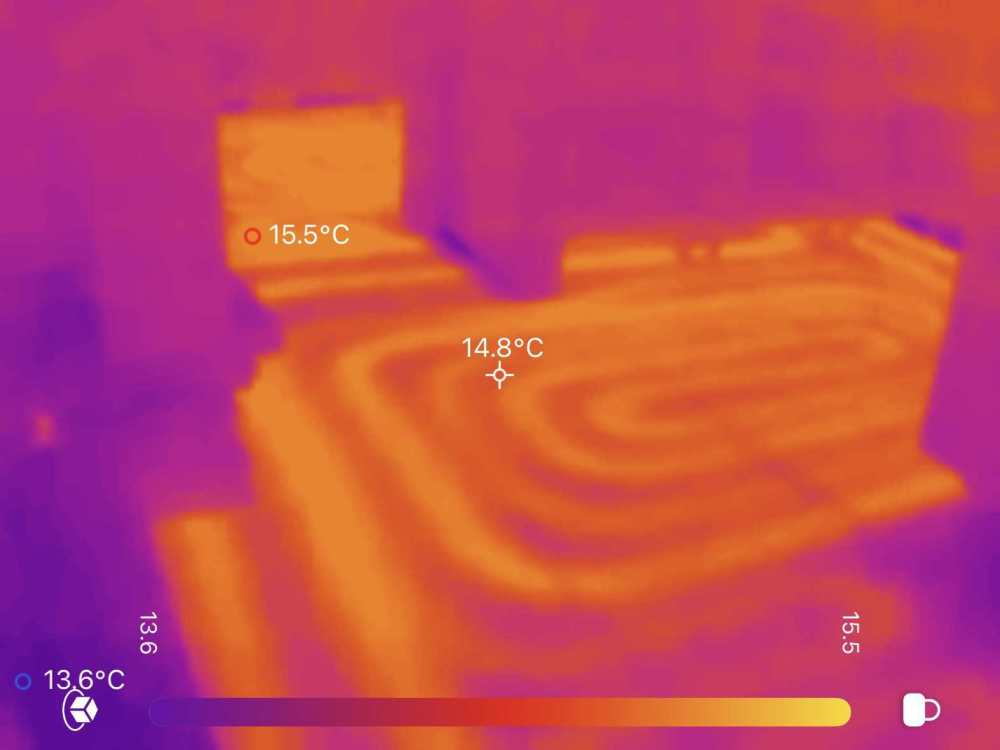

Get one of these: https://www.amazon.co.uk/TOPDON-TC001-Plus-Resolution-Maintenance/dp/B0D46K5CMK/?th=1 Worth the investment imo. Pics from our UFH on very low during the build.

-

What insurance needed to move in before completion?

Benpointer replied to YorkieSelfBuild's topic in Self Build Insurance

Just to confirm, Protek say we are covered to live in the house until our Building Completion Certificate is issued, at which point our self-build insurance ceases and we need standard buildings insurance. -

What insurance needed to move in before completion?

Benpointer replied to YorkieSelfBuild's topic in Self Build Insurance

Just to add that I have checked our Protek site/build insurance and it doesn't really mention whether the cover persists if we occupy the house but there is an exclusion as follows: The Insurer shall not be liable under this Sub-section in respect of: 4 Occupation of the works Loss or Damage due to the use or occupancy other than as dwellings of any portion of the Contract Works by any owner, tenant or occupier other than as herein provided. But since we would be occupying as a dwelling, my reading is that we would continue to be covered (no contents cover though). I am going to give Protek a call and double-check. -

What insurance needed to move in before completion?

Benpointer replied to YorkieSelfBuild's topic in Self Build Insurance

Hi Hannah, We're in the same boat - also timber frame, timber cladding and zinc roof, aiming to move in in the spring, probably before a completion certificate is issued. We currently have build insurance that runs until November 2026 but I suspect it won't cover us if we're actually living at the site (need to check). A month or so ago I did a search on a comparison site (Money Supermarket I think) as if the house was occupied, and it came back with a couple of options in the £400 p.a. range, which didn't seem too awful and eased our insurance concerns but I haven't yet put anything in place. Good luck - do please let us know where you get to with this. -

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Left hand diagram looks very similar to our wall build-up. Right hand side: we haven't used an angled timber head drip but we don't have very much clad wall above the window, as single storey but I can't see any reason why your design won't work fine. IANAE though.- 25 comments

-

- 1

-

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Benpointer commented on Benpointer's blog entry in Contemporary build in north Dorset

Checked - it's as I thought, they are going to fix a strip of the ash to the cross batten, they have already done this on the tall window (photo looks a bit odd due to it being an angled reveal + the camera perspective). We are not going to worry about weep holes because: ventilated cavity, small gaps between the half lap boards, and its a relatively sheltered east facing wall. The window itself is set back from the cladding and very well sealed.- 25 comments

-

- 2

-

-

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with: