Leaderboard

Popular Content

Showing content with the highest reputation on 01/26/17 in all areas

-

Not really when you have things like pressure reducing valves or thermostatic mixer valves down stream, as the last thing you want is a spec of scale or stuff jamming them up. The same goes for an ASHP or plate heat exchanger, it's good practice, and in some cases essential (as it's in the manufacturers installation instructions) that some form of screen or filter be installed to keep stuff out of the narrow passageways in the heat exchangers in these devices. Our ASHP instructions were clear that a Y strainer was the bare minimum on the return to the ASHP, just to stop anything getting back into it's heat exchanger. Congrats on becoming an aged Grandparent, BTW................................2 points

-

Evening squire As you've got 2x 15mm outlets on the SPV's which are combined to give flow from both units simultaneously ( in parallel ) then there is merit to go to the 28mm TMV for reduced flow restriction and increased litres per min at the set temp. The questions are :- Do you ever see that many hot water outlets being used simultaneously to warrant such a decision? Will the incoming cold mains be man enough to allow this max velocity to be a realistic consideration? The flow through a 22mm TMV is really quite high tbh, and to give one example I previously fitted a 450ltr TS for a customer which had 22mm TMV set to 51oC. I ran both the showers simultaneously and the kitchen sink and they all ran more than adequately. There was a 300ltr cold mains accumulator to reinforce the cold main so it could maintain these rates, but the hot side certainly didn't seem to struggle at all. It may have if a bath was in the picture but running the bath whilst 2 showers are being drawn is a bit extreme. Anyhoo, a fortune? Check this TMV out. And, drum roll please........... Wales delivers once again2 points

-

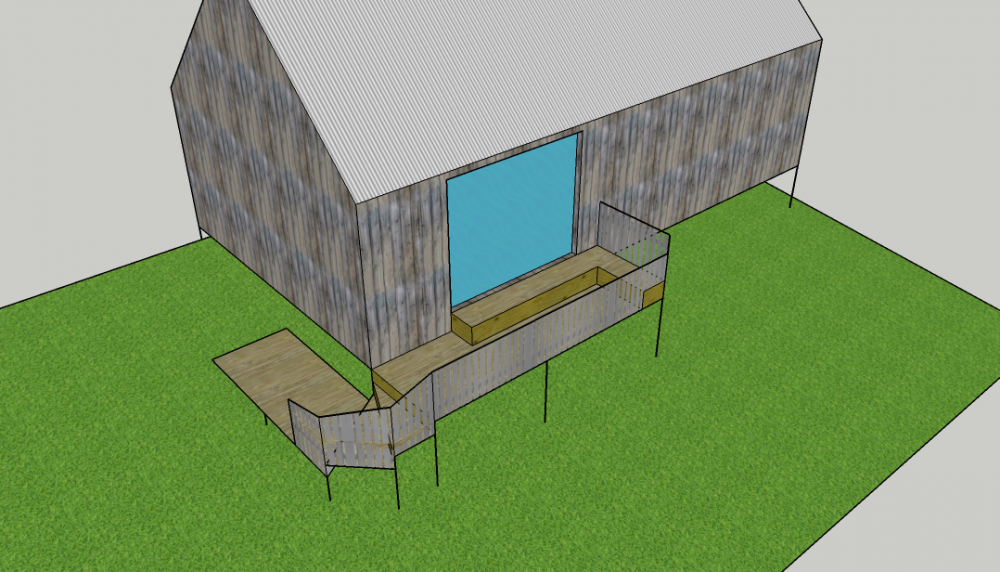

I've got an 8ft wide tilt/slide door on the front of the house, which currently opens a metre above the ground- obviously not ideal! This is due to the house sitting on piers above a sloping site. The plan is to have some sort of decking out here, where you can enjoy the view over the loch. I'd like it to lead around the side as well so that I can put a bench for people to sit with some shelter from the wind. I've searched Google images for decking ideas but most decking projects are far bigger than I had in mind, and would look pretty silly next to such a small house. A really big deck would also dominate the view out of the window. And with the sloping site, the further the deck extends from the front of the house, the taller the legs supporting it will have to be. I've thrown together a crude sketch of one possible design. The decking is 300mm lower than the floor of the house, so the step at the door is actually where you sit. This helps keep the pier height to 1072mm and also makes it easier to drop down meet the garden at the side of the house. Have given no thought yet to how I actually put it together... the winder stairs at the corner are easy in Sketchup but I suspect a little tricky in the real world Is it too small? Is the integrated seating a daft idea? What would *you* do??1 point

-

Agreed. Anorher way to cheat around a cheaper unit is to fit an aftermarket TMV on the outlet to cap the max temp .1 point

-

youre not going to be putting one of those in your house , well, I'd hope not anyway, no, I was just referring to the instantaneous hidden dual outlet types, as I said, it really depends on how much you want to use it, and just how high spec you wanted, I was only pointing out that self regulating temp and flow controlled units can be had fairly cheaply, not as all singing or precise as a modulating unit, but quite effective for a lot of people, I suppose its like a Quooker, some people see them as overkill, others wouldnt be without one, personally, I love them, but only at the right price, and as my BiL sells high end kitchens to trade,,,,,,,1 point

-

Probably as good a place as any to impress upon folk the need to strip and clean these filters / strainers directly after commissioning, and again after about a month or two of normal service ( use ). Any crap in the incoming supply (new MDPE etc.), or solder, flux, PTFE tape and jointing compounds can get to / and sit on the valve seat and cause it to malfunction. The effect of that failure is for mains pressure to get past the non-sealed seat and damage upstream equipment.1 point

-

You made a mortar capping rather than a concrete one. I would go with what @Triassic said - thin coat of coloured mortar preferably made with waterproofing agent in it and then a strong concrete mix with some ballast in it too.1 point

-

A simple Y strainer should do the job OK, I can't see a need for anything more expensive/complex, and it's all that our ASHP manufacturer asked for. I used one of these: https://www.bes.co.uk/plumbing-supplies/brassware/strainers1 point

-

1 point

-

Diaphragm, filter, spring and adjustment screw for the pressure setting.1 point

-

The electronic heat control models,like the Stiebel Eltron DHC-E, will only use as much electricity as needed to deliver the set temperature, so if you turn the flow down on, say, a washbasin tap, then it will turn the power down in order to stop the water getting too hot. The fixed power models will deliver a water temperature that depends on flow rate, so close the tap a bit and the water gets hotter, open the tap and it gets cooler. Both will be similar when first turned on, in terms of heat-up performance. The difference is really like that between a thermostatic mixer shower, where the mixer tries to maintain a fixed shower temperature, no matter what happens to the supply water pressure or temperature, and an electric shower, where you have to vary the water flow rate in order to get the temperature you want, and may need to do that whenever anything affects the flow rate, like another tap being turned on, dropping the local pipe pressure slightly and reducing the flow at the electric shower, so increasing it's temperature, or the opposite when the pressure suddenly increases and the flow rate increases, making the electric shower run cooler. edited to add: I've just read that back and it doesn't seem that clear! If you think of a standard instant water heater as being like an ordinary electric shower (they are near-identical internally) and the electronic control instant water heater as being like a thermostatic mixer shower, that's what I was trying to compare above. Also, if you have vulnerable people around then the electronic ones can be a help, as they can be set to never exceed a maximum temperature, to avoid scalding.1 point

-

My place couldn't be less insulated, it's dire. Part of me has put it off as I want to change the roof to gable ends. That being said I can't see the point of heating areas where you don't want it. My feeling is you want the "heat" in that pipe to get to its final destination without leeching heat en route.1 point

-

Sometimes the opposite. If pouring a glass of water do you want the water warm? That's why it's good to insulate the mains water in a well insulated house so you can get nice cool water at the sink without having to let it run.1 point

-

As above, but there are broadly three groups of these things. Some have a small reservoir of hot water, in an insulated tank, and are intended for use with wash basins, for hand washing. They aren't true "instantaneous" water heaters, they are really just a miniature UVC with an electric heating element and a pressure release valve to deal with expansion. The second type are the ones like an electric shower, with a fixed, or hand switchable, heating element, that delivers a fixed amount of power to heat the water. Vary the flow and the temperature varies, so the temperature control on these is by varying the flow - if you want hotter water, cut the flow rate, if you want cooler water, increase the flow rate. The third type is like the Stiebel Eltron DHC-E that we have. It measures the flow temperature and adjusts the power to the element to maintain the set temperature, if it can. This means that it will, generally, have two advantages. The first is that, as long as the flow rate doesn't exceed the maximum, it will deliver water at a constant temperature, as set on the front panel, irrespective of water flow rate. If the flow rate drops, the heater drops the power to the heating element, electronically, to keep the temperature the same. The second advantage is that it will only use as much electricity as needed, so can be a fair bit more economical. In our case, it's a backup in case our thermal batteries in the Sunamp PV don't get enough charge. The water will still be pre-heated to around 30 to 35 deg C by the ASHP and plate heat exchanger, and all the Stiebel Eltron has to do is lift that up to 42 deg C, it's set temperature, that is the bare minimum we think is acceptable for hot water (it will just run a comfortable shower OK). At 35 deg C input temperature, the Stiebel Eltron only needs just over half the available heating power, at 10 litres/minute flow rate. If the preheat temperature drops to 29 deg C, then the Stiebel Eltron would be running at full power to maintain 42 deg C at 10 litres per minute. Hope this helps explain the differences.1 point

-

Shoes lined up in the morning, shirts all pressed to perfection, tooth brush colour-coded, neatly spaced ties in the tie rack, bread well-polished? I admire you both.1 point

-

Ours is a lot more modest, with just two, four way manifolds, a H+C to each bathroom take up two outlets, H+C to the kitchen another two, and as the utility room is adjacent to the downstairs WC, they share the last H+C outlets. If you have the manifolds in an easy to access location (ours are mid way up the wall in the services room) then you have the big advantage of being able to turn a whole room off from an easy to get at place if there's a problem. This saves crawling around trying to get at ballofix valves that are tucked neatly away out of sight, in our case almost always inside fitted furniture. We also had the unusual problem of not having drinkable water on site to test the plumbing after first fix, because of our borehole problems. I didn't want to test it with water that may have been contaminated, so took the view that a leak in a length of pipe with no joins in it was a very rare possibility, and didn't test until second fix. Like others, I had no leaks anywhere from any of the plastic stuff, the only leak I had in the whole house was a poorly sealed 1" brass iron thread fitting into a filter. There is one slight issue with plastic, and that is that it's very hard to get it to look neat when it's surface mounted and visible. For this reason, I switched to short length of copper wherever a pipe could be seen, like in the cupboard under the sink, or the cupboards under the wash basins. It may be just a personal thing, but opening a cupboard door and seeing a less than perfectly straight bit of plastic pipe offends my eye. This is the cupboard under our kitchen sink, that shows where I switched to short lengths of copper:1 point

-

It's one I did 1st bank cold 2nd bank hot @ 51oC 3rd bank hot @ 46oC ( basins) 4th 2-port out of view was 2 x hard water. One to kitchen sink & O/S tap ( back to back ) and the other to utility cold and boiler fill loop ( back to back ). 2 x TMV's for each temp zone Black thing is a 2 Ltr hot water expansion vessel. Blue cylinder is a 500 Ltr Telford TS with a 46kw 28mm DHW heat exchanger ( coil ). ?1 point

-

With no dependants / infirm in the house there really wouldn't be any need for the second drop down, other than for comfort / convenience. I prefer the latter, so I have one in my house. The joy of just flicking the tap on at the full hot position and having comfortably hot ( user definable of course as TMV's are fully adjustable with a simple turn of an Allen-key ) is what I like. No flicking the tap between hot and cold to get the right temp, then the pipe work temp stabilises and you have to readjust it, then someone flushes a loo elsewhere and you have to adjust it again........why do this to yourself for change of £40? @TerryE, your old farmhouse would have had a large bore ( 22mm or bigger ) DHW pipe work setup with full bore taps and no restrictive valves such as a TMV. The flow rate therefore would have been good or very good. When you introduce 15mm pipe work though a PHE, then take it through a TMV, you have to start adding the various resistances together and summise from there. As that TMV is 1" body by default, then I'd use a piece of 28mm pipe coming out, going into a 22x22x28mm compression tee, ( Demountable for servicing ). Then 22mm to each manifold.1 point

-

1 point

-

Nick swears by HEP2O. As to the layout, the basic rule if you use a manifold system is no buried joins if at all possible, and one (H +) C to one appliance. Our exceptions to this rule are: We have some elbows in the studding where the pipe is coming down the wall and needs to do a sharp 90° (e.g. the shower tails) We have the cold feed dishwasher T'ed off the kitchen sink cold. We have the cold feed washing machine T'ed off the utlity sink cold. IMO, laying out the pipe approaches to the manifolds is a bit like laying out a circuit board: it can get busy and messy and you need to avoid getting pipework in knots. Do your foulwater first because those are fat and difficult to route. Then the plumbing, then the electrics. I reserved the roof space in the GFL toilet adjacent to my manifolds for my "Clapham Junction" and actually did a full routing diagram for this before I laid a single pipe, and I had to go through three design iterations to get everything in the right order. Jan though I was being totally anal and going overboard -- until we started pulling the pipes and then she did a volte-face and agreed that it was a bloody good idea. Remember to space out the hot and cold manifolds to give yourself routing room. I am using 2×SunAmp instead of a TS or UVC. They immediately below the hot manifold so my hot copper runs total about 2m of pipework. That's it. Read through the various worked descriptions on the forum.1 point

-

1 point

-

It's a doddle. Ref the long pipe runs: From my (traditional) cylinder to the bath is about 20m (is that a long run?) 12m in 22mm (2m up from the cylinder in the loft, 8m across the top of the dormer then 2m down). All the 22mm is copper with old style, grey Hep2O fittings. From there it goes to 15mm to the bath - all new that I've just done. Last joint before the taps is new style Hep2O. Cold from the 25gal CWS tank follows pretty much the same route/ configuration save that tank is on top of the dormer. I was worried about the 15mm but @Nickfromwales said it'd be OK.....and it is! Excellent flow to the bath. The ONLY Hep2O fitting I ever had leak was when I removed and refitted one side of an old, grey 22mm straight coupler. Tbh I might have got the internals mixed up with a newer style grey fitting so probably operator error!1 point

-

@jamiehamy, Have a look at the thread I've got running at the moment. We are doing ours in HEP2O using a manifold system as well. Deciding the runs and placing the manifolds is the bit that needs careful planning. We did all of ours in 15mm because our layout means that nearly all of the runs to the manifold were pretty short so standardising on one bore simplified it all. Though I admit using up a coil of 10mm for the low flow toilets and hand basins is something that we could have considered. I would question the need to use 22mm to the bath in a pressurised system. Unless you've a got ridiculously long run then 15mm will be fine, and avoid needing to use buried bends or joints.1 point

-

I've done two complete houses with HEP2O and its really very straightforward as others have said above. Get yourself a nice sharp plastic pipe cutter and your up and going! In the house before last I employed a plumber to do the first fix and I was so horrified by the care free way she (yes female plumber) was hacking the pipe cuts and chucking pipe through voids etc I sacked her and did it myself. One thing you really do need though; "an extra pair of hands" when dealing with coiled pipe, its a right PITA and is soooo much easier if there is two of you. Especially if your routing through posi-joists which have webs like razor blades (well certainly the last ones I used did!).1 point

-

The window cleaner. Meths'll get it sorted. As some may know I spent 7 years cleaning windows to keep the wolf from the door while studying. Customers regularly asked me to do little 'extras'. Don't ask.1 point

-

You move into a house that is maybe 90% of what you have always wanted a house to be to work for you and how you live. Or you buy a standard builders house and spend the next 20 years rearranging it to get to maybe 60% of what you want and then realise it just doesn't work so have to move again. That's why we self build.1 point

-

I had an issue with a tree. But I anticipated this before planning (no protection order). Next day tree had vanished! Neighbours complain (of course) and draw a picture of my plot and highlight 'non existent tree' - surely a contradiction in terms ! lol1 point