Nestor

Members-

Posts

752 -

Joined

-

Last visited

-

Days Won

6

Everything posted by Nestor

-

Why did you choose an air source heat pump?

Nestor replied to SimonD's topic in Air Source Heat Pumps (ASHP)

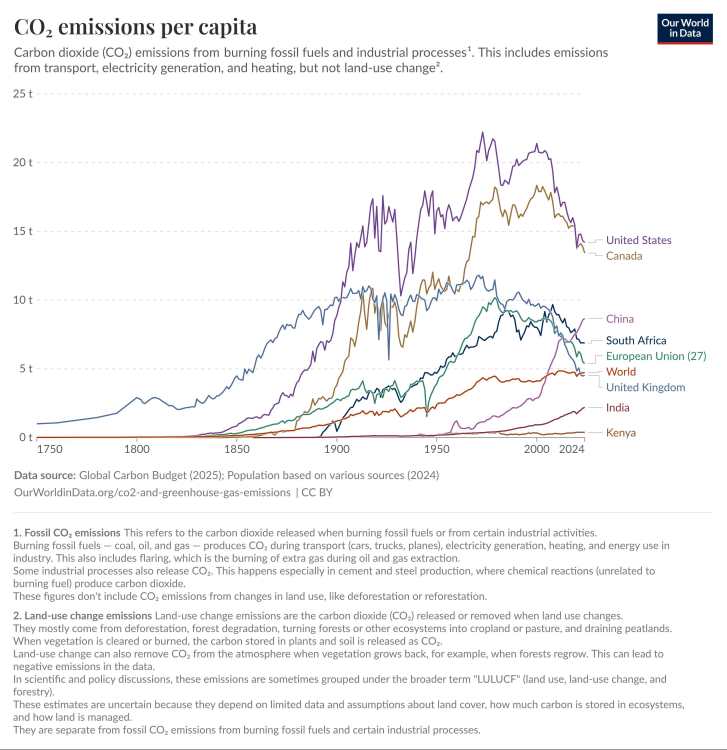

No mains gas and used oil in the past. New self build, air tight, MVHR, 3G etc. 275sqm. RHI was available so paid for kit and install. Our personal use for 2025 was 2700kWh for hot water and heating. However, I would not recommend ASHP in average insulated home with mains gas available if cost is a major factor. -

Yeeessss we bloody done it.

Nestor replied to Russell griffiths's topic in General Self Build & DIY Discussion

Congratulations Russell, looks amazing and do post a few more photos when ready. Similar here, started in 2017 and moved in after 3 years. 6 years later some minor tasks to complete.... -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

I have both the Makita and Milwaukee 18V oil driven impact drivers, the Makita is twice the price though quieter. 12V is probably enough for most tasks. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

I had the MAKITA DTS141ZJ, silly money but was a pleasure to use whilst building a house, very quiet. It did develop a fault after 6 years heavy use. Now using a Milwaukee M18 FQID, more torque, cheaper but not as quiet as the Makita. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

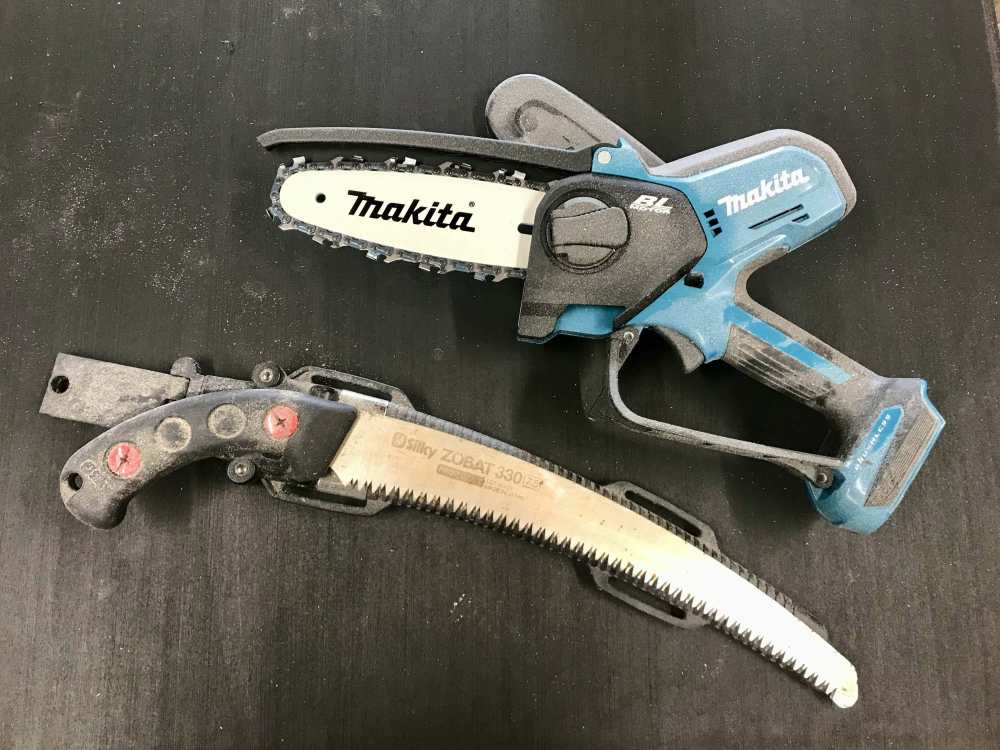

About to give this ago, DUC150Z for 50 metres of Devon bank medium hedge pruning / cutting back. Will let you know my thoughts in a few days Silky saw, no batteries required. -

What is this made of? Ceiling wood fibre board type stuff

Nestor replied to paro's topic in Building Materials

Looks like hardboard due to the staining but It could be a type of Sundeala board, wood fibre pin board originally. Is it slightly soft if you apply a little pressure to it from inside the loft? Very impressed with your clear up, proper job. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

The Makita kit has been great. Just bought some 6.0Ah batteries from Toolden, always worth a search around for best prices. FFX now ITS https://www.lawson-his.co.uk https://its.co.uk https://www.powertoolworld.co.uk https://www.worldofpower.co.uk https://www.toolden.co.uk/tool-brands/makita/?utm_source=Klaviyo&utm_medium=flow&utm_campaign=Makita Cross Sell&utm_id=VXmYPi&_kx=iewy0UUI_HNqAKAOi3JbrAcYoka6HO07az6VLHTOI0U.WVZJJz -

This.

-

Retrofit timber frame in stone building

Nestor replied to RoIrl's topic in New House & Self Build Design

@Hastings Great work, love the pulley approach. My parents ,now late octogenarians converted dilapidated flint stone barn late 90's. Tons of work. Only now, due to feeling the cold decided to insulate the walls with Pavatherm and lime plaster. Huge difference in comfort and minimal space lost. They also converted another shed using the approach above, internal timber frame, Pavatherm and lime. Keeps them busy! -

War. It's a cult. Let's get back to weather compensation.

-

Low points: and how to get out of them

Nestor replied to ToughButterCup's topic in General Self Build & DIY Discussion

We hear you Ian, I now try to focus on one task only and do not deviate. (Not easy) January has been to complete the bat roost. Baffles, partitions, F1 bitumen felt, crawl access etc. It will be done. Not been on holiday since 2017 when the build started, though have crossed the Taymar bridge a few times! February's plan is hopefully outside dealing with hedges, fences. A good clear up and sort out, dip in the river or sea helps me. -

Morning @Duncan62 Were you expecting the self levelling concrete to be your final flooring or adding another layer? I sense that a concrete surface was / is your desired outcome. If you have the time and energy I would recommend you do a test with a grinder. The grinding discs or pads are the costly part. I made some concrete worktops with fibres, lots of wet grinding and very pleased with the outcome.

-

I used to regularly clean with a diamond pad and recoat with water proofer but not for 5 years now. I does take on more of a mottled surface visually overtime so not everyones taste. But it works here, a slight relief as most other materials in the build are very uniform, floors, doors, cills, etc. The concrete samples I received were so perfect they could have been moulded plastic. I do like a challenge and did test first.

-

Up for an adventure? Homemade worktops, utility, kitchen and island. Biggest issues were moving from garage to kitchen. More compliments from visitors about the worktops than the rest of the house. Cost was 10% (excluding my time) of the quotes received. It was an enjoyable part of the build.

-

-

-

We have a single pendants above the island and dining table, 4 floor lamps and 2 wall Anglepoise. Bit of chaos but it works for us. 3000K seems just right. Fitted with a Philips 14W 2700/2500/2200K which works off the wall switch. Can you find a LED with adjustable temperatures? Brightness is also a consideration. As @Mike consistency throughout the room if possible.

-

I don't have green fingers, what to do?

Nestor replied to Post and beam's topic in Landscaping, Decking & Patios

Sounds great. If the ride on is more of a finishing mower it might struggle until most of the field is under control unless it is a brush cutter / flail, you will know if it starts shredding belts. Areas for wild flowers ideally need to be power harrowed (you could try a rotovator) before seeding with Yellow rattle (helps reduce the perennial grasses) and other wild flower seeds. What to do with the meadow grass needs to be considered, ours is cut and bailed late summer, once the seed heads have flowered, cut and leave on the ground for a few days during a dry, warm period and then remove all the cut material. I have used a scythe. Continually dig out, remove the roots, cut back the unwanted shrubs, some even spot spray as well. It is a bit of a task, takes a few years to establish but very rewarding. -

I don't have green fingers, what to do?

Nestor replied to Post and beam's topic in Landscaping, Decking & Patios

We can but dream, had a Husaberg 600 which I used at Lydden and Brands for supermoto days out. Had to call out the AA outside the gates at Brands to take me home as big end gone!! -

I don't have green fingers, what to do?

Nestor replied to Post and beam's topic in Landscaping, Decking & Patios