TerryE

Members-

Posts

3633 -

Joined

-

Last visited

-

Days Won

22

TerryE last won the day on May 25

TerryE had the most liked content!

Personal Information

-

Location

Northamptonshire, UK

Recent Profile Visitors

17177 profile views

TerryE's Achievements

Advanced Member (5/5)

1.2k

Reputation

-

I have just been searching the forum for posts on oil-filled rads, because my "big old clunky" has finally given up the ghost after 20 years, and TBH the most informative posts are my own. 🤣 I've been through a number of supplier sites and Amazon and the postings continue to be misleading quoting the electrical heating element power rather than the actual typical thermal output. I note that the CPC technical datasheets on the site that @ProDave linked to do quote an actual thermal power O/P so 👍 for CPC. I also note that many now include some form of embedded micro control with timer and remote options. I want a dumb heater where I can (statically) switch select the heater power that I want, and then control the timing and actual energy use through a Tasmota smartplug and my HA system. CPC lists some nice simple models. Simple is good as far as I am concerned.

-

If the ext walls, floor, roof do genuinely have a U-value of 0.1 then that is pretty much an order of magnitude better then interior wall so treating floors as a single zone and ignoring interior walls is a good simplification. Don't forget airtightness and go for 0.5 ACH + MVHR. so no weep vents. I circulate my UFH loops for 15 min every 3 hours so I can use the manifold return temp to take the average slab temp and this also spreads any solar gain across the whole slab.

-

We've lived in a 3 storey new build with a comparable spec for 7 years now. Our ACH is around 0.5. We have an MBC WarmSlab that's 100 mm reinforced concrete on ring-beams encased in (mostly) 300 mm structural EPS and UFH embedded in the concrete raft, so ground floor only. The UFH is run as a single zone and heated by a single 3kW inline resistive heater. We keep the whole ground floor 24 × 7 within a ~ 1°C tramline of 22½°C, the 1st floor is typical 1-2°C cooler in peak midwinder, though I do use an 1kW oil-filled rad (controlled by my CH system) on the 1st floor for the peak midwinter period. My son's bedsit in the warm loft is mostly heated by his Games PC and huge TV screens. 🤣 The house was built as ASHP ready, but we put the inline heater as a stopgap until we had confirmed the heating characteristics and loses of the house. However in practice, the heating costs are relatively small, and we have never made a payback case to install, maintain and depreciate an ASHP. We have never missed upper floor CH. I also use the Green Octopus Agile Tariff so my CH system schedules the CH and HW on-times to buy and use the cheapest half-hourly price slots. I am not necessarily suggesting you do the same, but what I am saying is that for this class of house running the whole GFL as a single zone is entirely workable, and we use less than 30 kWh heat daily even in cold Dec-Feb, so a ~ 5kW ASHP should be fine for this class of house. With a ~ 10m³ slab acting as a thermal store, it is even questionable whether you need a separate buffer tank for the UFH. I suspect that most ASHP installers have no idea how to design and right-size an ASHP for a (near) passive-class house.

-

IMO, if you have a reasonably low energy build with UFH then you need to think very carefully about the pros and cons of multiple zones, upper floor heating, etc.. There's a lot to be said for KISS (Keep It Simple Stupid) IMO, as this saves in installation costs, complexity and through life maintenance. E.g. upper floor heating is a PITA. You can run UFH at ~30°C so you can run your ASHP at a low temp and have a significant boost in CoP in doing so. Low temp rads take up lots of wall space and are expensive to install. We have no heating on our 1st and 2nd floors, but use a cheap oil-fill electric rad for a few hours on cheap rate electricity during the really cold months just to top-up upstairs.

-

@JohnBishop, you need to be careful switching 240 VAC stuff especially at high current draw especially if you don't have a grasp of current Building and IEEE regs. If you do this without Certified Electrician sign-off and have a fire then you could find that your insurance company rejects the claim. This is my set up. The CU to right was installed by my sparky. I added the left-hand extension myself because he couldn't find the time when I needed it installed, but I did this in a way that he'd be happy to sign off. He's comfortable with the 24VDC / 240VAC spilt as there isn't really a safety issue with the 24VDC side. Node-RED is a Javascript based environment that is well suited to IoT control and comes as a Home Assistant add-on as well as being able to run standalone. There are lots of YouTube videos on this.

-

This depends on what you are controlling and what inputs it needs. You can't make a general choice, as it depends on context. A lot of this was discussed in my topic with this post summarising my final setup and we are pretty happy with it. In short I have a bunch of contractors in a CU extension next to the main Consumer Unit and these switch power to the HW immersion, slab heater and pump. These are in turn driven with 24 VDC control signals by an off-the-shelf ESP32 relay board running Tasmota. The Tasmota firmware is switched by my NodeRED app. I do have a lot of Zigbee sensors but I prefer to use TCP layered stacks such as Tasmota for any switched devices relating to Central and HW Heating.

-

UVC Retrofit: Tundish D2 Discharge Pipe in a Passive House

TerryE replied to TerryE's topic in Boilers & Hot Water Tanks

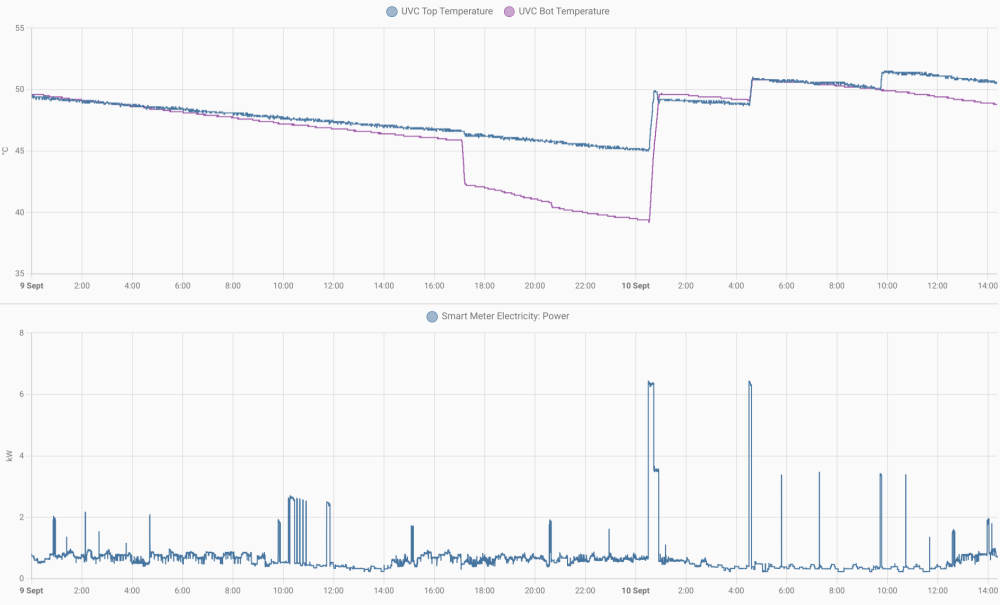

@WisteriaMews, sorry I am in Greece ATM, and so not checking the forum daily. The OSO UVC has an double skin: inner steel pressure vessel and our plastic or powder coated aluminium with vacuum panel insulation between. The two immersions are installed in small access panels with the wiring terminals, thermostatic switches etc. There is an internal duct channel for the 3kW flex cabling running from the bottom to up the two access panels. I used a couple of waterproof ds18b20 digital thermostats to measure temperatures. Look them up on eBay etc. The "waterproof" bit isn't important, but they are encapsulated in a ~8mm dia aluminum can that can be thermal-taped directly to the steel cylinder with a bit of foil+mineral wool insulation on top; you can get a get a range of lead lengths but 1½ or 2m is enough to take it down to the bottom channel of the cylinder, and thin enough to be run alongside the flex in the internal cabling duct. These thermometers are wired into a small IoT board, a Wemos D1 Mini which in a small ABS box about 25×40×50mm IIRC and powered using a USB lead; This ESP8266-based module uses ESPhome firmware to talk back to my home automation system over local Wifi. I use the Node-RED javascript code to track temperatures, do the heating calcs, and send the MQTT commands to power on and off the power to the two immersions. Here is a screen grab from my Home Automation system for the last 24 hours. You can see that my son had a bath or long shower at 5PM, and it scheduled top up at 00:30, 04:30 and 09:30 to bring the UNC to target 50°C because of the cheap spply pricing in those slots. (The price actually went negative in two of these slots so I actually got paid to heat the water.) The ~ 4°C cooling / day is the parasitic heat loss from the UVC which is very small compared to conventional cylinders or thermal stores. -

UVC Retrofit: Tundish D2 Discharge Pipe in a Passive House

TerryE replied to TerryE's topic in Boilers & Hot Water Tanks

@ProDave, in a nutshell, our decision to replace the SunAmps was because of the poor reliability of their engineering implementation: the circuit boards broke basic layout design guidelines, e.g. lack of 240V isolation and inadequate track sizing for 3kW power routing, so they had an MTBF of maybe 2 years; all of the pump and control plumbing was hidden inside a pretty steel case, which looks sexy but makes maintenance and repair a total dog. Yes, the concept of a PCM thermal store for DHW has great potential, but not this model and company. @Duncan62, Jan is our procurement specialist; she found a supplier online, which had the model we wanted in stock and could deliver it in a week. Seek and ye shall find. @WisteriaMews, We have an electric-only passive-class house. All of our white goods use timer-controllable cold-fill in-device heated water, so our HW use is pretty low: primarily showers for three adults and occasional shared baths for the 2 OAPs (mostly in the winter). Our OSO model is double immersion heated only, which makes sense for our use. I need to do I full blog post on this, but my CH control system uses 4×Finder contactors driving the 2 OSO UVC Immersions, my UFH pump and a 3kW heater that heats the UFH. I use Home Assistant to do the user interface and graphics for my Home Automation, but in terms of CH and HW control I have a custom NodeRED application (about 900 lines of Javascript that I wrote) to control a 4-relay Tasmota module via MQTT, and this in turn outputs 24V control signals to drive the contactors. I buy my electricity using an Octopus Agile Tariff. This has an API which published its day-ahead half-hourly prices at around 5PM starting midnight C.E.T. In essence, at 11PM each night, this app schedules the daily CH and HW heating for the next 24 hrs to use the cheapest half-hour slots. In terms of HW and heating the OSO, I have installed top and bottom digital thermometers to monitor the tank temp. The app uses these 2 tank temps to estimate the total kWh needed to bring the tank up to 50°C and it uses the day-ahead prices to schedules the cheapest time slots to heat the tank. (If the top temp falls below a preset, it also stuffs in a ½hr top-up regardless of price, but this happens so rarely that this isn't a significant cost premium for always having HW.) The OSO has a parasitic loss of just over 1 kWh / day, plus replenishing used water, which varies but is typically equates to another 2-3 kWh at most except during the winter bath season. The kWh price for this last couple of weeks has been negative on 4 days , small pence on another 4 and only peaking at 14½p on the stiller overcast days, so the cost of of our water use runs at under 50p / day on average. We tend to have our big bath days when Octopus will pay us to do this or it only costs pence. I've been coding for over 50 years so the Javascript bit is easy for me, but I understand that those who aren't so IT literate will have a lot fewer options. I believe the like of Octopus and OVO are exploring some Smart Control options, but these aren't yet prime time. -

I call our build passive-class or low energy rather than passiveHaus complaint. For me, IanR hit the spot with his above comment. BTW, we use resistive heating only, and on current Octopus Agile tariff pricing our monthly energy bill varies from about £75 or so in the warm season to maybe £200 for the coldest months. It's hard to put a precise value for the bill as we take all of the price variation risk on the Agile tariff. However, looking at the potential monthly savings in going from a CoP of 1 to an ASHP-based 4, say, for the heating element of these costs; These savings are significantly less than amortised cost for the installation, maintenance and depreciation costs of adding an ASHP, so unless something changes radically in our case we won't be installing an ASHP.

-

Cornish Cottage Renovation and Extension

TerryE replied to Aggierockdoc's topic in Introduce Yourself

I am 182 cm tall, and a couple of our internal doors were about 181 !! I'd just duck slightly automatically, but about twice a year (especially is some spoke to me from behind) I'd forget and clip my bonce. Ouch. 🤣 -

Cornish Cottage Renovation and Extension

TerryE replied to Aggierockdoc's topic in Introduce Yourself

In our previous ~2-300 year old Cotswold stone farmhouse we put it a silicon DPC back in the mid 80s and completely repointed over the next 10-20 years the infill showly turned from damp loam to bone dry dust and grain husk. The effective U-value slowly improved down to around 1½ W/m2K. The main problem was that the house leaked air terribly and the floor slab was uninsulated. Our current house has a U-value for exterior walls, roof, floor in the range 0.12-0.15 W/m2K and an an ACH of around 0.4, plus MVHR. Just no comparison in terms of winter comfort. When the kids were young, they ran around naked in doors in the winter but then again gas was dirt cheap in the 90s so the boiler was going flat out when we were in the house. -

Cornish Cottage Renovation and Extension

TerryE replied to Aggierockdoc's topic in Introduce Yourself

Actually the code and graph were mine; the context was a passive house twinwall (high insulation with decent thermal capacity) with an outer stone skin. This is a world away from the thermal characteristics of you stone cottage (which is of similar construction to my previous house). The U-values you get from a solid stone wall are terrible as stone is an awful insulator compared to a passive profile (the U-values are typically 10-20× greater). Yes there is little temperature variation inside as the walls are just always cold in the winter. You can really only mitigate this by adding something like an inner aerogel backed plasterboard liner to the exterior walls. As heat just wicks away through every external surface, you just need to input a lot of heat to get a comfortable room temperature. -

That being said, I believe most ASHPs can be programmed to have a few time slots each day when the ASHP outputs at the higher temperature setting and a Y-plan valve switches between the UCV and the manifold loop, so the CoP is 4, say, when doing the heating, but 2½ say when heating the water. This assumes of course that you using that you are using low temp rads or UFH. But this all adds complexity. @JohnMo or @ProDave will tell us if I am talking rubbish. 🙂

-

The LCoE for new solar and wind is about £30 / MWh, that's 3× less. The revenue starts to come into on about a year after the mean investment point, that 10-15× less. It is just really hard to make new nuclear numbers economically competitive, even SMR technology. We can get up to ~90% renewable with investment in grid-scale battery and maybe pumped hydro, whilst running our existing gas peaker stock until EoL. By then other options will be available.