Alexx

Members-

Posts

47 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Alexx's Achievements

Member (3/5)

2

Reputation

-

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

ah, yep that would be impossible for me to track without microinverters or optimisers indeed. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

all victron documentation strongly discourage using optimisers as they would conflict with the MPPT own way of dealing with the panels. Also panels have 3 diodes from what I can see. As soon I have some data from the system I'll put my findings to confirm how this works in practice. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

from my understanding that can happen, but the likelihood is much smaller than an inverter or microinverter failing. multiplying the single inverter by 20 times will definitely increase the chances of getting a bad microinverter for sure, that is just statistic, If that is 0.01% rate, now you multiply that by 20, then now you start having 0.2% failure rate. I understand micro inverters have their place, like multiple different orientations, and if you have an AC coupled battery, besides that I struggle to see the benefits. In my case I ended up going all the way with additional MPPTs on the Victron system. I'm even considering in the near future making a solar fence, so I can just buy another £150 to £300 MPPT depending on the size and put several panels on it. That is the modularity I was after, but I'm definitely having to pay a fair bit more money for the privilege -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

definitely not, if a micro inverter goes bad, I need scaffolding and a lot of hassle to replace it. if my inverter fails, I can just replace it without having to touch the roof. To my point of view it makes no sense to touch micro inverters, they offer no benefit over a regular inverter. I would need AC coupled batteries to start with which is a completely no go for me. DC couple batteries like Gobel, Seplo, Fogstar and others are many times cheaper. Your point about multiple orientations would be the only benefit if I could not replicate the same with another system. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Do you have a link/URL for that by any chance? I'm not sure if I'm checking the correct document. Thanks! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

ow, I missed that bit, thanks for pointing out! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I just realised I have another problem now. My energy meter was between the old inverter and my consumer unit, that was a system with no batteries. New inverter is in a garage about 20m away from the house on a sub consumer unit. My generation will only be realised when the house uses it, not when it is actually generated because I will store on the batteries a good portion of it, which will be accounted as generation once the house demands it or I export. This would not allow me to have a night tariff to charge my batteries as the FIT is only valid for energy generated from solar PV. I was thinking maybe I get a bi directional meter to subtract what I import overnight from what I export during other hours, but it seems I cannot do that due to FIT requiring all generation to come from solar (even if stored on batteries) as long it does not come from the grid. Not sure what to do -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

-

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

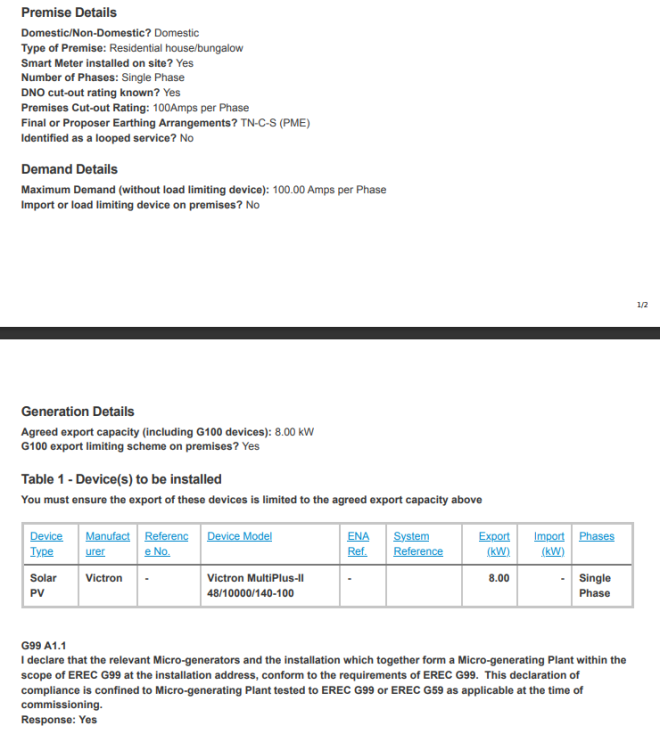

Great news, I've just got approval today from DNO and we have the 8kw approved. We used the document I mentioned earlier. Yay! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I moved into a house that had already a solar PV system in place, but it was old, not performing well, at best it generated 500w of the 2000. I didn't install or touched it, as soon I moved in I started converting the loft so the whole roof went, and with it all the existing solar PV array. Great to know, so the system will pay itself back much quicker this way. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

You may be right; I'm still gathering fragments of information and putting it all together so don't take what I'm saying as fact. I'll report back here once I make further progress. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Ah, so I could only export the excess as SEG then, not regular export like with Octopus? I'm trying to clarify with British Gas, they dodge questions all the time, I had to give them screen shots of Ofgem documentation for them to accept what they were meant to accept without questioning. Once I get this sorted, I'll move the FIT to another provider in hope I get better service. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I have FIT from an existing installation for 2kw that was completely replaced with the Victron kit and panels. They will pay me 25% of my 8kw production, last time I had payment it was like 70p per kwh so that will definitely help with the pay back. I'm still trying to understand if I can get paid for generation and still export at 15p as well. I'm not 100% sure if I can mix and match. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Inverter can be G100 compliant, here is a document from Victron about it. I have installed pretty much everything already. DNO has been notified, they just keep dragging their feet. victron-g100-declaration-multi .pdf -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

It is expensive, it is complex, I'm looking to make the most of a once in a lifetime kind of investment. To make better return on the investment, I can lower the payback time considerably by selling excess. I'm aware I'm well beyond the scope of a normal system install, I have "over engineered" things before and with time the pay back was worth it in one way or another. I ended up finding an MCS installer that is flexible enough to install things in the way I want so we will be fully compliant. Kit is nearly all installed already, regardless what the DNO approves I will either self consume/store or limit the export rate. yes I do have a smart meter, but I'm not sure which tariff I will use yet. I may end up using the flat 15p export and cheap overnight tariff. I'm also making progress with FIT that will pay probably 25% of my 8kw generation as well.