Search the Community

Showing results for tags 'timber'.

-

I am embarking on a kitchen/diner and repair project on my home that will require the installation of new/replacement windows and a bi-fold or French door. My property is a grade two listed building so my planning/listed building consent is conditional. The conditions are that I use wood for the construction of windows and doors and that they are painted white. They will have to have Georgian glazing bars and these will have to pass through the window so no stuck-on bars will be permitted. Each pain will have to be an individual unit such as the Wescountry Heritage range http://www.westcountryglass.co.uk/westcountry-heritage My application can be seen at https://planning.eastdevon.gov.uk/online-applications/simpleSearchResults.do?action=firstPage I am contacting joiners at present and have had a number of different suggestions as to the type of timber to be used. The suggestions include: Accoya Douglas Fir European Oak Utile Idigbo Baltic Pine/Scandinavian Redwood I have contacted the Wood Window Alliance http://www.woodwindowalliance.com/, which is already providing me with some good information. I would be grateful for any views on the suitability of timbers in my list or alternative suggestions. Also any links to useful sources of information or forums would help. Many thanks in anticipation!

-

Hello, I have a number of wooden items running from side to side in my loft. However, I am unsure if this diagonal beam in the picture attached is doing anything? For context, my very old loft satellite was affixed to it. Now, one side is in the brickwork attached to my neighbours wall and the other side connects to the eaves of my roof. My question is, can I remove it? What function does it serve? And what about the other wooden pieces in the background, can they be removed? I understand there probably is some level of function. But, the main annoyance is the diaognal beam that is floating mid air across the loft. It has some wobble to it when you lean on it, so it doesn't feel that sturdy. any advice is highly appreciated!

- 20 replies

-

- loft

- timber beam

-

(and 2 more)

Tagged with:

-

Hi I am installing an electrical roller garage door. The guide rails will be installed on the inside of the garage so they won't be visible. My issue is that both side of the opening are not Plumb or level. One side you place the guide rail to the bottom brick and it runs out by arround 20mm And the other side is the same but runs out at the bottom I am not sure what would be the best way to attach the rails so they are plum as its quite a big run out. Was thinking of placing a piece of wood the hole height and packing out allowing the rail to be attached to a plumb service Attached some photos Thanks

-

I am in the process of final bits of design on my self build garden office. However I have hit a conundrum and can’t seem to find any advice online as to how many concrete blocks plinths I need for my foundations. The building is to be made from timber as you will see below. How many concrete block plinths to support the base? and how far should each be spaced from each other? My building is: 4211mm x 3188mm These are the two options I was playing with. One with more blocks is what I had before watching a few videos and the one on the right is what I'm now thinking... if it'll hold up! It's just for an office / play room so doesn't need to house extremely heavy equipment. Any advice is greatly appreciated!!

- 15 replies

-

- foundation

- foundations

-

(and 2 more)

Tagged with:

-

Hi All I'm looking for advice on what type of timber to use deep treads on a steel and timber stair case. I'm looking at using a local fabricator to do the staircase stringers and balustrade with myself making the treads. The stair case will be a bit industrial and i don't mind if the treads are a little rustic. I want the threads to be solid wood, 88mm deep, 250 wide by 900. so what type of wood for this? and who could supply at this size. I look forward to hearing your suggestions Thanks

-

Hi everyone I'm stuck with my construction method and insulation... Please can you help me with the pros and cons? I'm getting a lot of mixed reports from the things I'm reading and the people I'm speaking to! Background: I have just bought a 1950s house in Hertfordshire, cavity wall construction, completely uninsulated. It's in pretty good condition structurally, but hasn't been touched since it was built. Project: I will be completely renovating and modernising the property, taking it back to brick, moving a lot of internal walls, new plumbing, wiring, windows, doors, floors, ceilings, etc. Oh, and getting rid of the asbestos! I will also be adding a 4x10m double storey extension on the back. The back of the house is South-facing. Externally, I want to finish the house in a combination of brick slips and render. (I don't like the colour of the current brick that is used). I will also be retiling the roof, and adding a couple of gables over the rear extension. I want to take a fabric first approach to the build to make it as energy efficient as possible (within reason and budget constraints). I am not trying to take it to PassiveHaus or EnerPHTT standards at all, but I would like to try and achieve the best I can afford to do that makes sense and isn't over engineering it at large costs for the sake of small incremental gains. I also really want to install MVHR. Where I'm at: My plans are still awaiting approval, but I want to crack on with structural calcs and BC drawings. However, unless I tell them otherwise, the extension will be specified to built in cavity wall construction, and the specifications & details will just be to satisfy normal building regs. My thoughts were that I would full fill the existing cavities in the existing house, then wrap the whole house in EWI. Insulation material for both the cavity fill and EWI is TBC. Questions: What should I build the rear extension in, and how should I insulate? Brick & Block with cavity? I assume this would be easier to tie in with the original house, as it is the same construction method as the original, and would be easier to find tradesman for this as it is the most common. If I do this, I assume I would then continue the same full-fill of the cavity and EWI as per what I plan on the original house? Single Block with EWI? Given that I want to use EWI on the existing house, perhaps it doens't make sense to build the extension in cavity brick and block, and instead I could use a single blockwork and continue the EWI on that? A different monolithic single block construction method? E.g. the JUWO evolved SmartWall? (https://evolvedsupplies.co.uk/juwo-evolved-smartwall). The sales materials sound convincing (obviously!) as it seems it would be cheaper and quicker to build the brick and block, provides a slimmer finished wall, has better thermal properties and means I wouldn't need to use EWI on the extension as well. But don't know if that is just all hot air (pardon the pun) and also don't know if that might give me an issue in the future with lenders and insurers? Timber Frame? I've been told that this could be cheaper and quicker to build, and could be more thermally efficient? But it could be difficult to tie in, and I'm unclear if just insulating the frame is enough or if you would also wrap EWI over the outer leaf before finishing with the brick slips and render? I'm also getting confused re thermal mass, and whether it is good or not to have!! My original thinking was that a solid wall from e.g. bricks, blocks, concrete, etc has a great thermal mass and therefore will store the heat generated inside and outside and release it slowly during the day, keeping it warm in winter and cool in summer, and creating a cosier environment etc. i.e. construction using materials with a higher thermal mass is a good thing. However, when researching timber frame construction, I'm reading that their lower thermal mass is a good thing, and is more likely to create a better living environment than with a solid-wall construction method! Argh!! Regarding insulation, I'm also getting mixed reports re products, so any advice there is appreciated! Looking forward to hearing your views! Thanks in advance

- 25 replies

-

- timber

- renovation

-

(and 3 more)

Tagged with:

-

I have 20mm polystyrene sheet to insulate the interior of the roof (the polystyrene is appropriate to this use, relevant BS EN standards - the 'outbuilding' is my new posh shed not a dwelling of any kind ? The roof (sloping not flat) is constructed of 20mm OSB on wood joists (photo) and covered with heavy duty bituminous felt externally. I'm thinking of applying the polystyrene direct to the underside of the OSB using a spray adhesive. Is it ok to do this?...Im wondering if there could be any issues with the OSB being 'sealed' both sides? Thanks Andy https://photos.app.goo.gl/hR3GJWvXyNuwqsVJ6

- 2 replies

-

- insulation

- osb

-

(and 3 more)

Tagged with:

-

Hi all, I'm about to embark on a timber garage build (3m x 5.5m) on a concrete base that has just been laid on our drive, which is 3.2m x 5.7m. The concrete base isn't perfect (long story on this one but there is some pooling of water on one side of it when it rains) and so I've been told to lay a layer of engineering bricks and a DPC on top and then build the garage on top of this. I'm a complete newbie and was hoping for some advice on this. What type of brick? is this a DIY job or do I get a brickie in? Any more tips to stop moisture reaching the bearers of the garage? Any advice or tips would be really appreciated!

-

I'm starting off this topic as it has been mentioned on this forum various time :Combined material orders. I have organsied something similar for roofing materials and since have become engaged with the roofing company as well as some door/ window manufacturer, but would not want to start being a distributor for every single item I am planning to order. I just very often get quite good offers for whole truckloads of timber or tiles and just can't make use of it as I am missing the storage. Maybe some members on here are interested in saving substantial % of their orders by ordering material early and storing it (for others) and therefore combining purchase power. I am aware of the logistics problems that arise with it as well of the warranty and payment issues. It s not for the savety/security driven builders but more for the risk-takers on here. This is not me offering to organise all of this neither saying that I got the best connections/offers but I think that a lot of members on here stumbled (by accident or not) across a great offer(e.g. Half a container of tiles, Oak flooring by the truckload or anything remotely similar) that was just too much to take by themselves. I do also think that one-off or fire sales are not suitable as you would need to react and buy quickly, making it difficult to coordinate with potential other interested parties. It could be organised via some shared platform like Airtable. Depending on amount of interest I might just start a Buildhub Airtable, but mainly want to see what opinions are like and have others input or initiative.

-

Hi all, Hope you having a good Crimbo ...so far! I have started thinking about my fence ....I am clearing the site and will be getting a mini-digger in just to smooth it about and also dig the soakaway and other BIG holes! But now all the trees are bare it is really exposed to the road and the wife has asked me how much it will cost to do ...I am dreading all those bloody holes ...but there you go . currently it is a mixture of council Post and rail ...along road side about 200 foot of it ....which i wont be moving just erecting within it. The remainder of the side is mostly facing my inlaws and the back of the neighbours gardens and is composed of mainly rotting waney lap panels and in some cases ...no fence at all , i have had to chicken wire it to keep the dog in So the plan is to erect a closeboard fence on post and rail to match the 30 foot that was erected by a neighbour 2 years ago and is good looking and solid I have only ever done Concrete and Panel ...so I am hoping I got my calcs right...its about 350 foot all around excluding gate and good bit and i was told Post and rail is normally 10 foot spans ..So i come up with (the attached) To match the good fence there it needs to be 7 foot ..SO I have allowed for this...Down here I have noticed Southerners refer to "gravel boards" While us up north call them "base panels" ...I am sure they are the same I plan top treat the 2 foot of the post in he ground with roofing bitumen to over ground level and also drive several 6" nail into it before concrete (I used to see my old dad do this ...and his fences seemed to stand forever ...so I will copy it!) Wherever i look to buy the wood seems to suggest the following 1. Feather boards (shaped like a wedge) .....but the good ones in place are 10x1 cm planks (lapping 1cm) ...so should i not copy them ? 2. Also the rails I am quoted seem to be cut diagonally ..I have never seen this ...I would normally "presume" they were 4x2 ..stronger? 3. Some timber place told me I would need to put a rebated capping along the top ...presumable to help water drip off ...the current solid fence doesn't have this...its more money again ....but is it worth it ? Any advice of clarification from anyone that knows better is appreciated

- 15 replies

-

- fence

- post and rail

-

(and 2 more)

Tagged with:

-

Reading through all the guff about timber - my God there's loads about it - I am still not sure what the difference is between treated and untreated timber. Is it possible to ' ... treat ... ' timber yourself?

-

We have full planning permissions to demolish a stone built cottage and rebuild it with block and render. In addition we will extend, at the same time. Both the cottage and the extension will be a timber kit. The extension will give an addition 100% floor space to the property, and it will be clad in Siberian larch timber. We are currently trying to mortgage through Buildstore. They are quite adamant that any mortgage we take will require the extension to have a block work skin. Is this correct? Has anyone else come up against this? Is there a way round it?

-

The main bit of our house is just under 11m long and therefore the purlins (200x100mm green oak) aren't going to be single lengths as 11m+ oak isn't easy to come by. So given I'll be using a couple of lengths where should I scarf them together? Close to one of the four trusses? In the middle?

-

Hi All Can anyone recommend a floor levelling screed that is suitable for a 22mm caberdeck chipboard floor. Its going to need to go from 20mm to 0mm. The floor is capable of taking a 50mm screed so no issues with structural integrity but I'm concerned about flexibility. The eventual floor finish is still in debate but most likely engineered oak but possibly carpet if someone gets her way. TA!

-

Hi, I need to pick a material to clad the underside of a balcony and porch roof. Would there be a problem using composite wood cladding boards or deck boards. Some cladding says it was not made to be fitted horizontally. The boards seem to come as hollow or solid, although solid might be stronger for decking, I would think lighter hollow boards would be better fitted to the underside of a roof. I have been looking at WPC, Hyperion and Duraclad among others. In general these items seem to come in at around £45+ a square metre, has anyone seen cheaper prices? I want something that looks like wood but doesn't require maintenance. In my current house the wood under the porch has shrunk and requires painting every few years despite not actually being directly exposed to the weather, although I suspect this is due to the fact that the builder used softwood painted white. Thanks

-

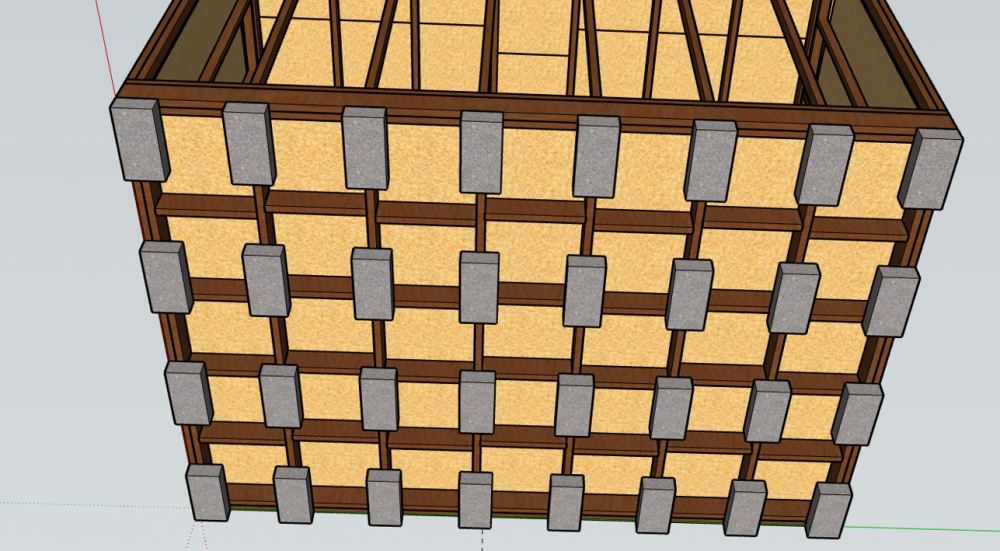

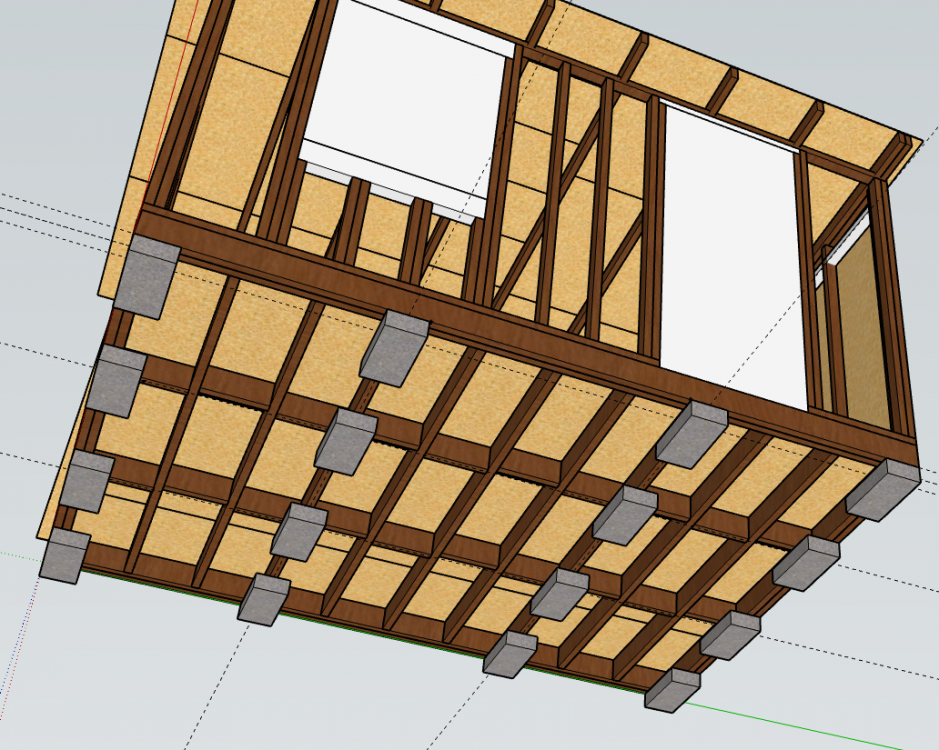

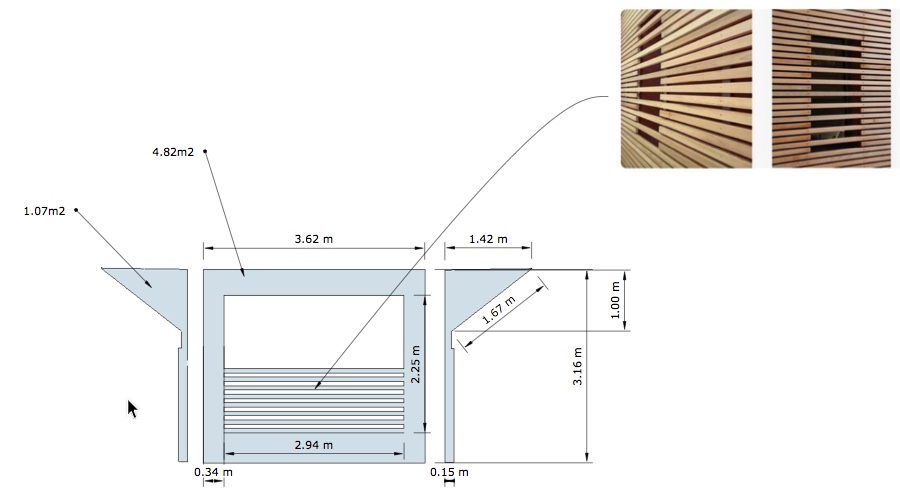

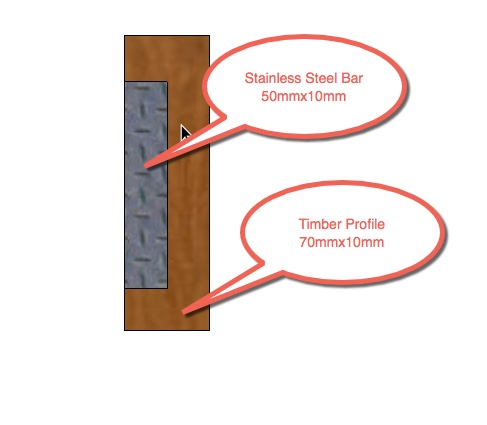

Warning: Long post. Questions at the end OK, so I know we've got some really clever technical people in this parish so I've got a nice little technical question for you. I have a feeling that allot of people are just going to say "use a structural engineer" but I like to understand things first as my experience is their insurance policies LOVE them to massively over-engineer. Here goes: Our front dormer has a Juliet balcony. My planning conditions state it must be timber and the idea is it will match the brise soleil slats. So I've been thinking that what I would really like to do is integrate the Juliet balcony into the cladding. Its taking from this sort of idea: However, for reasons I'm not going to bore you with I've only got aprox 40mm of depth from the face of the window and the face of the cladding. Here's the actual dims of my dormer: Now I've been doing some research and balconies need to meet a couple of point load requirements (as well as the height and gap elements of Part K of the building regs). As I understand it they are thus: Rigid and strong, be able to resist and not bend, buckle or break under pressure. Durable and suitable to the area they are to be applied to. Two British standards apply; BS6180:2011 "Barriers in and about buildings - Code of practice" which relates to the code of practice for balustrades in buildings and BS6399-1:1996 "Loadings for buildings - Part1: Code of practice for dead and imposed loads" which specifies the information on loadings. For domestic dwellings this translates to: Handrails: For external balconies 0.74 kN/m. This can be compared to having one averagely weighing person 75kg applying the full force of their body on every metre of the balcony. Infill Panels/Rails: 0.5kN/m. Now what I'd like to do is use the same cladding profile (20mm thick by 70mm) to create my infill panels. The handrail can be machined to sit on top using the same timber so that shouldn't be too much of an issue. Because of the way the doors open I cant easily have a centre rail so the span is going to be 2.94m. I could though devise a way to attach a bar to the bottom of the dormer which would rise up the centre. So, I was thinking that the solution would be to create a steel support behind the cladding. I can get the pieces of cladding that will make up the rails machined to accept this steel support. This is rough sketch of what I mean: So now two my two questions: 1) Is this idea crazy? 2) Where/how can I calculate the point load strength of any bar design like the above? Thanks for making it to the end!

-

I've been researching cladding options and I quite like the idea of splayed cladding detailing. I.e. All the companies that supply it mention that you need "weather protection" due to the open nature of the boards (which is pretty obvious). But, nowhere can I find what the recommended means of weather protection is? It would be going onto a timber frame. Is the answer as simple as; batten, fully weatherproof board, batten, splayed timber? In other words you clad it twice!