Search the Community

Showing results for tags 'stairs'.

-

I'm building a 2 storey house. The following applies - one entire side of stairs is a solid wall - the first downstairs step is a quarter landing, because stairs immediately turns right - a handrail runs up from first step to top step without breaks My question, please. Can I start my spindles from step 3 (ie no spindles on quarter landing or the first step)?

- 3 replies

-

- stairs

- regulation

-

(and 1 more)

Tagged with:

-

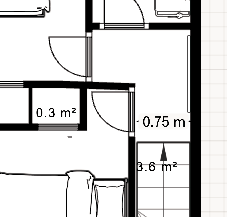

Hello, Does anyone know if you can have a door (that swings into the room) at the top of a set of stairs without the 400mm? I've attached a drawing Thanks

-

Hi All I'm looking for advice on what type of timber to use deep treads on a steel and timber stair case. I'm looking at using a local fabricator to do the staircase stringers and balustrade with myself making the treads. The stair case will be a bit industrial and i don't mind if the treads are a little rustic. I want the threads to be solid wood, 88mm deep, 250 wide by 900. so what type of wood for this? and who could supply at this size. I look forward to hearing your suggestions Thanks

-

Our stairs is nothing fancy, a standard Stairbox product with oak treads and handrail (which I would prefer to leave unpainted) and softwood risers and balustrade (to be soon painted white). Can't decide on the treatment for the oak treads - they clearly need some sort of varnish (or oil?..) to be dirt-resistant but keep the natural wood look. Got 3x samples of some hardwax oil (??) from Stairbox, can't tell the difference between the samples we painted. Not sure it's the right product. Never before had any experience with natural wood treatment, so am at a loss. Help, please...

-

I have an issue with my stairs that I would like to try and solve. It looks as though an extension has been added to my 19th Century Welsh Terraced Cottage. At some point the loft of the extension has been converted into a bedroom. The issue I have is that the doorway to the bedroom is off the main stairs. When you enter or leave the room there is a big drop onto the stairs, which is dodgy at times, especially when you’re tired or in the middle of the night. I have attached some pictures of the stairs from the bottom then the doorway onto the stairs. Any ideas would be helpful. Many thanks

- 9 replies

-

- stairs

- problem solving

-

(and 1 more)

Tagged with:

-

We are installing the newel posts for our landing balustrade. Need to cut them down to level. We see that building regs require the handrail at a minimum 900mm above the floor. But commercial premises require 1100mm. We are interested in knowing if anyone has installed banister / balustrades (on landings, not on stairs) higher than 900mm in a residential setting. Any views on optimum height? Thanks

-

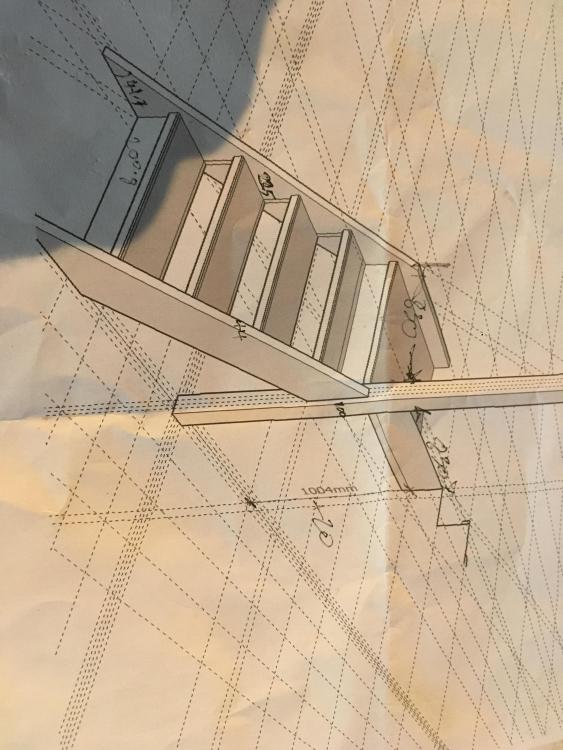

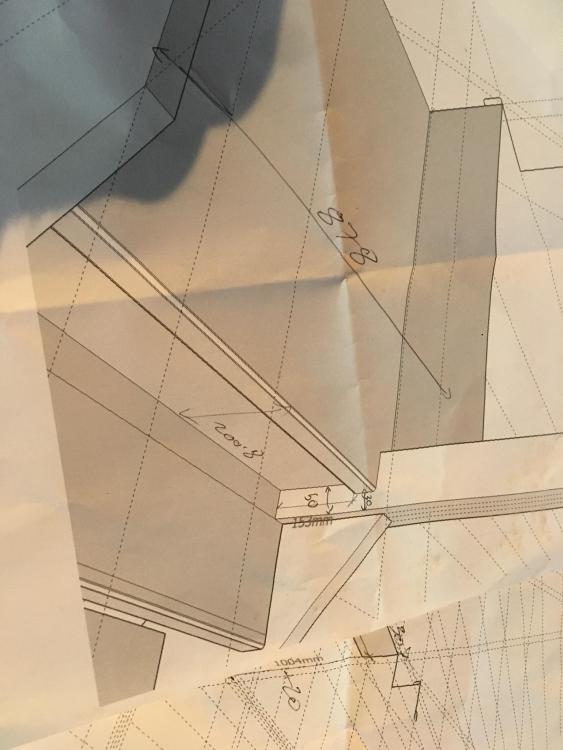

I was going to add this to the stage 1 thread but I feel it deserves its own thread. I am finally starting to make my staircase , all those years that the piles of rough sawn trees have been getting in the way are coming to an end. Yay. I should think some of you already know I started this project a good couple of years ago by cutting down a dead oak tree in the meadow. If not I will provide links to the beginning of the story when I get inside. But either way check out all the progress. The oak is starting out in roughly 55x600x3400mm planks that I slabbed with the chainsaw mill, From that they get laid onto some trestles and cut to useable widths with my skill saw and 3 rails connected together. i found these here little rollers very helpful when trying to get the full slabs into the rights place. Then I put under the little batten to stop it moving while I cut it. so we now have reasonable width 55mm oak planks. Most are over 300mm all have 1 straight side but otherwise they are very rough from the chainsaw. thats is how I left all but 2 lengths because I wanted to get my head around the newel posts. The 2 I put over the planer have come up very nicely so far, The strings treads and risers will be made from the oak if I can get enough out of it but it is looking promising so far. The newels and spindles will be ash. The ash started as roughly 120x600x3900 slabs so I am having to cut them from both sides with the saw but with the rails they are coming out rather well. as for converting the timber i have gone gone a little further with the ash. First job is to cut them to usable length. Then they get pushed over this overhand planer bow up until I get a consistent cut. Then I repeat the process on an adjacent side while making sure my new flat face is hard against the guard so I end up with 2 straight sides and one square corner. from there i take it and put it through the thicknesser useing those faces as references, this give a nice straight even thickness post. now I know what final thicknesses I can achieve with the wood I have I have started making the first jig for housing the treads in the strings. I say first because I will probably end up with at least 2-3 as the lower flight will have draws as risers. After the landing there will be a standard flight finishing with 3 winders at the top. I modeled it all on cad first to optimise the width so it finishes nicely after the winders. its all just lines on ply at the moment but I’ll be getting the router out soon, and thats about as far as I have got. I’d better get back to work

- 95 replies

-

- 7

-

-

-

- stairs

- homemade stairs

-

(and 2 more)

Tagged with:

-

Have a look at this please: The photo shows the joists supporting the (temporary) floor, and the Durisol wall which is at the head of the (currently temporary) stairs. The wall is 100mm short of the level of the top of the joists. I need to build the wall up to that level. There are three ways I can do so With Durisol alone With wood alone With a Dursiol base and timber 'bearer' built into the concrete. My concern is to make the level of the top of this bit of wall exactly the same as the level of the top of the joists. I ask because this is the head of the stairs, and so will be a high-traffic area. And, while I suspect that many of you will mutter ' There 'ee goes overthinking again ' , I'd rather have that than come on here wailing that (say) I wished I'd used a wooden bearer built into the concrete to support the chipboard floor..... The problem with Durisol alone would be that fixing the chipboard directly to concrete is not the best idea. The concrete would have to be perfectly flat and the perfectly level. Concrete shrinks doesn't it? So, it's an all wood bearer fixed into the Durisol as is, or a hefty wooden bearer concreted into some Durisol Wadja fink?

-

Hi all, just wondering whether anyone has sourced Oak stair treads and have any recommendations. I'm building my own open riser staircase and need 12 x 60mm treads. Have talked to a couple of local joiners down here (Devon) and have got wildly differing quotes or aren't interested in quoting which I find odd! thanks Alex

-

Hello! Our staircase is nearly in... I was so focus on head height and tread depth etc that I missed the building regs bit on max 100mm gap, which is an issue as we have open risers, which of course are about twice that. the stairs are powder coated metal frame with oak treads and side-fixed glass balustrades (toughened and laminated). So quite minimalist. I have seen a couple of possible solutions - sort of half risers attached to the underside of the tread, or a metal bar across the middle. Has anyone seen seen any other creative fixes? I’m keen to keep as much light as possible coming through as the stairs are right by a window. Thanks!

-

Hi, I need to buy a staircase for a barn (there is a mezzanine floor). It needs to be fairly sturdy so I'm thinking steel would be right. The rise is 3m and I'm imagining just a single flight, no turns or anything. Probably fairly wide at about 1m. Does anyone know a cost effective way to buy something like that? I could get someone local to fabricate it from scratch - but I would have thought there would be a way to buy a kit cheaper. Most of the companies I see online are about fancy expensive staircases for domestic or commercial settings. Also what kind of price should I expect to pay? thanks - reddal

-

Hi All Im just trying to work out what we're doing about stairs. After much deliberation we're not doing anything 'fancy' and will just go for a well made solid white wood quarter landing staircase. It's between two stud walls so not much in the way of balustrade either. So to my question: What's the accepted 'wriggle tollerence' when measuring up? 5mm all round?

-

Misses wants some fancy oak stairs, but these need to be fitted after plastering completed. Question: what is the normal practice to allow safe easy access to the second floor? A cheap set of stairs from ebay or just leave the trades struggling on a loose ladder?

-

Never mind floating shelves, our final stairs arrived today but there is a small snag.. We have a single staircase void for the three staircases (basement to ground, ground to first and first to loft). We chose this particular stringless stair design for the top two flights as the top flight is viewable from underneath and we want it to look the same as it does above. http://www.max-stairs.co.uk/?c=gallery&m=150 We went for more basic stairs to the basement. The stairs arrived as individual risers and treads - very substantial oak. They bolt together with hidden fixings and look very sharp indeed. However, when the installers arrive we find out that they expect to fix each riser through to the wall to prevent movement which in our case is tricky as there is just timber stud wall clad in OSB and plasterboard. We pointed this out in the survey but it was obviously overlooked. So we now have two options, first to have a single string under the wall side and second to cut out the PB and put reinforcement in the wall and make good. First option might be ok for the ground to first flight as the underside is above the basement stairs and is only visible when heading into the basement. Second flight would leave the stringer visible from the ground floor so that wall will need to be cut, strengthened and made good. Joiner is giving me a quote tomorrow - he thinks its quite straightforward, not much material required but a bit of labour. Question is whether I ask the stair firm to pay as they quoted and supplied us a design that by their own survey would not work. They are offering to make the new stings and ship over from Poland for free (guess that there is little cost in this for them) but we really want the look we were going for on at least one of the staircases.

-

I am trying to dismantle the stairs in a Victorian house so that the spindles and railings can be sent to a print stripping service (faster and not so expensive). The trouble is that I can see any screws and or nails and would not want to spend 2 months with a heat gun scrapping it down. Niether does the thought of ripping out and replacing appeal to me, feels wasteful to just replace them. Any idea or thoughts