Leaderboard

Popular Content

Showing content with the highest reputation on 01/12/18 in all areas

-

Cladding is going very well I am pleased I did a last minutes swerve from cedar to larch. Although you cant see it in this photo with the sun on it we do have a sacrficial coating of new age gris by Silva (we bought pre finished). It looks more grey without the sun directly on it. Still got to sort the leaking Internorm sliders!5 points

-

Today was d-day for us as far as planning permission is concerned as it was the decision deadline. Approved, no amendments, exactly how it was submitted. I had hoped for the best and prepared for the worst and got the former. Now the real work begins!4 points

-

There's a thread somewhere where I looked at this, might be on the GBF, as it was ages ago. I conducted several "post mortems" on blown LEDs and in every single case the LED itself was fine, it was the driver circuit in the base that had failed, always through obvious overheating. The smaller the lamp, the greater the failure rate for mains powered LEDs. What I have found is that 12 V LEDs are very reliable. I've had no failures at all running them on proper DC supplies, and we have loads of them. I did have a lot of early failures when using 12 V LED downlights, and traced the cause of this to the bridge rectifier in the 12 V MR16 failing. Every single failure was a bridge rectifier failure. After a bit of investigation, I discovered than the small 12 V "transformers" for downlighters had an output that was 12 VAC at around 20 kHz. The MR16 12 V downlighter design was originally intended to run on 12 VAC at mains frequency, 50 Hz. What was happening was that at 20 kHz the bridge rectifiers in the LEDs were just too slow, as they did not use fast recovery diodes. The result was overheating and failure. Replacing the downlighter "transformers" with proper 12 VDC supplies completely cured the problem and resulted in all the MR16 downlighter LEDs running a great deal cooler, too. Almost all the heat was coming from diode losses in the small bridge rectifiers, that were really struggling to work at the 20 kHz coming out from the standard miniature downlighter "transformers". I should add that these small "transformers" are absolutely fine with 12 VAC tungsten MR16 bulbs, the problem was purely with LEDs. One tip is to see if any LEDs are getting warm and where the heat is coming from. If the LED base is getting hot, then you can expect the LED to fail sooner or later when the driver burns out. There are a LOT of fake marked, far-Eastern made, 230 VAC LEDs around that are not approved to any acceptable safety standard and it's really hard to tell which are the decent ones and which are not. It seems even some of the big name brands have been caught with fake components, so even the name is no sure-fire guarantee that the lamps are approved and will be reliable. Some types of 230 VAC lamps are inherently more reliable by design. For example, the ones that have what look like fake filaments use a series string of LEDs that operate at high voltage, so they often just have a simple rectifier and capacitive voltage dropper in the base to limit the current. These tend to run cool, as they have no dodgy switched mode driver squeezed into the base. There are also some conventional size 230 VAC lamps around that use long chains of LEDs in series behind a diffuser and similarly they have no switched mode driver in the base and tend to run cooler and may well be more reliable.3 points

-

Hi everyone, The names AndyT and I work for Sunamp Ltd. - will not be selling on the forum but if you need information or advice I would be pleased to try and help. I have been in the renewables industry for 10 years - my 4 bed detached home with 4 adults is in W-s-M (hard water area) is used by Sunamp as a live test house. Robert Llewyllen (Fully Charged) filmed at my home - you can see the episode here https://www.youtube.com/watch?v=9upXeTMHUqE Economy measures added to this house originally built by Second City are; cavity wall insulation, 300mm of loft insulation, all external doors and windows upgraded, 3.5kWp Solar PV with excess generation diverted into a 5kWh SunampPV heat battery pre-heating hot water into an Intergas ECO RF30 with weather compensation and in-comfort control. My Miele dishwasher is fed with pre-heated water, I have Economy 10 off-peak and have monthly direct debits of £35 for electric and £10 for gas. You can view my dashboard here http://wattson.energyhive.com/dashboard/AndyT lots of interesting data. Also just started testing OpenTRV / Radbots and Loop energy monitoring. Looking forward to chatting. Kind regards. AndyT.2 points

-

I'm still digging out information. I've found a fairly specific NO2 sensor, that had a bi of hydrogen sensitivity, but should be OK for outside NO2 measurements: https://sgx.cdistore.com/datasheets/sgx/1107-Datasheet-MiCS-2714.pdf The bare sensor NO2 is around $9, so pretty cheap, I just need to find a source to buy one or two, preferably from a supplier that sells it at a reasonable price already on a breakout board. Using sensors like this together with any cheap flavour of microcomputer (I tend to use PICs, but you could splash out and use a Raspberry Pi) looks to be very easy indeed. It needs a real time clock, and I'm coming around to the idea that a single unit that includes a particulate sensor, NO2 sensor, perhaps a CO2 sensor, a relative humidity sensor and a temperature sensor, together with a small GPS module to provide time and position data for each sample, might be the best way to go. Adding a display, as I did on the temperature/humidity/CO2 air quality logger that a few here have borrowed, might be useful, too, as it's handy to see real time data as well as just recording it for later analysis.2 points

-

We put a bio ethanol fireplace in ours. Looks great, convenient, no smell, kicks out a fair bit more heat than expected and does heat the room up to borderline uncomfortable if the UFH has already been on. Probably does work out expensive as I just bought the ethanol from Amazon. However it’s only used as a feature when we have company. Dont believe any any of the fuel consumption claims, 1L lasts about 1hr30 in ours at full whack.2 points

-

Hi Liz, The cladding looks great. Things are really progressing fast now. I am so pleased for you after all the delays.1 point

-

I've found the same with the Screwfix ones, and interestingly they don't run hot, either, so I strongly suspect that they do not have a driver in the base. I swapped one over recently and the base was pretty cool, which suggests that they may well use a long series chain of LEDs with a capacitive dropper. I have a few spare and may well take one apart just out of curiosity.1 point

-

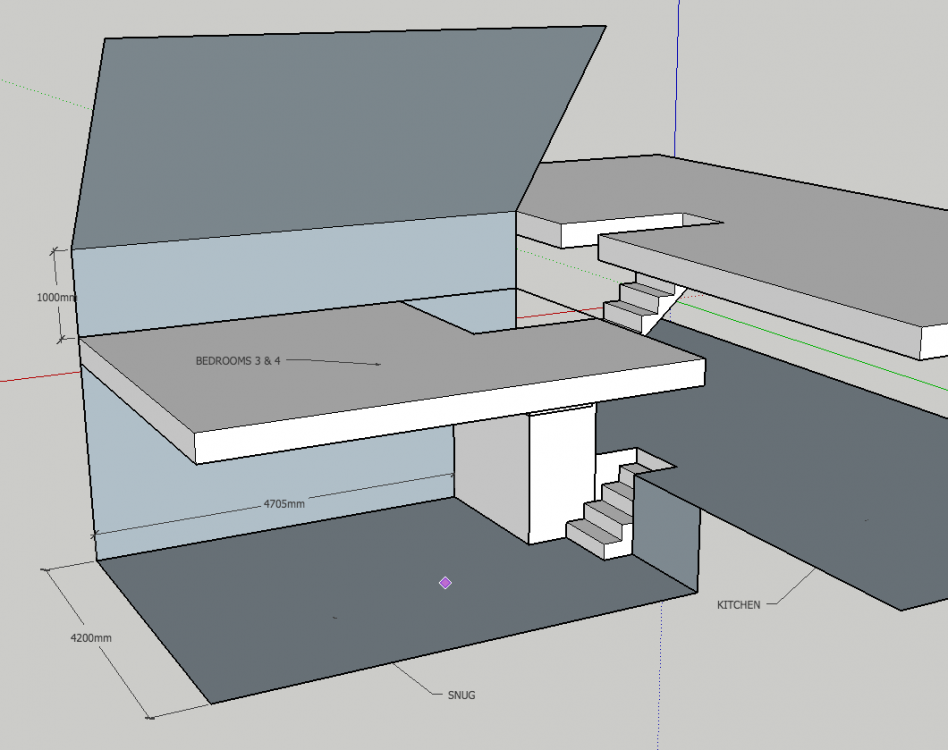

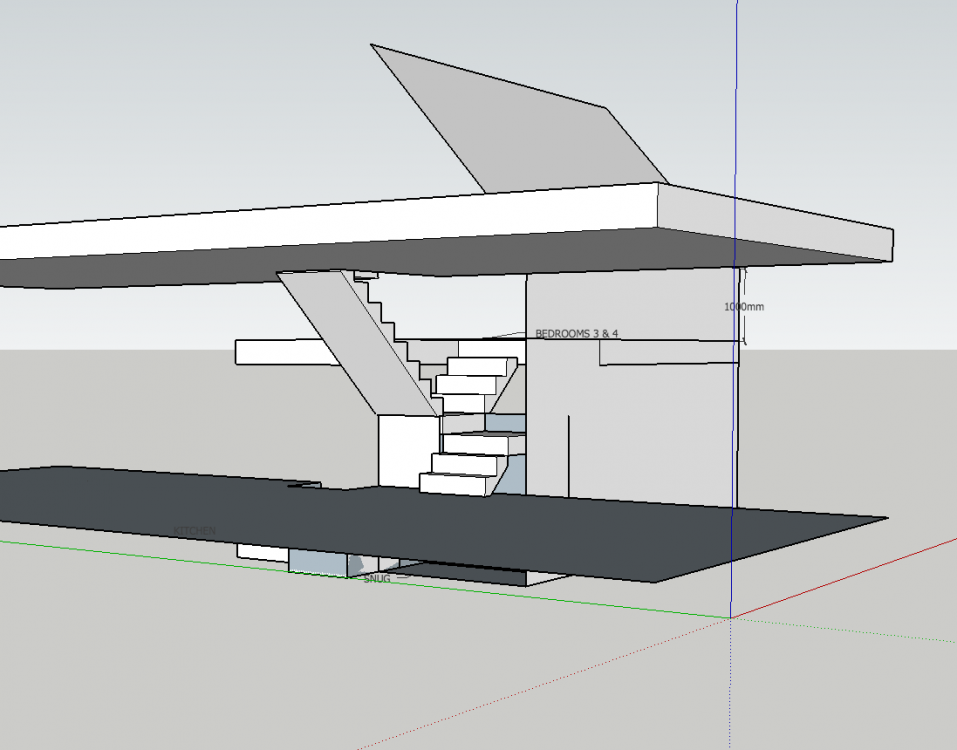

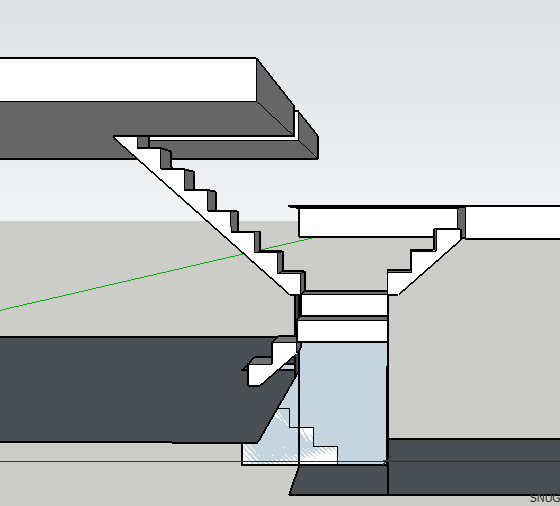

Thanks for your feedback @Ferdinand, it took a bit of pondering and head scratching but I think I might have got there with the stairs. Had to dust off my rusty SketchUp skills. The issue I had was that the upstairs wall in the Bedroom 3 and 4 area was only 1m high, so I struggled at first to get the required 2m head height. This is what I came up with and it works for me.... Uses 2 quarter turn landings rather than winders. As you suggested, using the dead lobby space next to bedrooms 3 and 4, takes the existing staircase out all together giving me a kitchen/dining/utility and study area largely unencumbered by staircases and frees up more space for Bedrooms 1 and 2. All good .... Hopefully the screen shots below will give some idea of how it looks. Undecided as to whether to make it a feature (i.e. glass, steel, open treads) or to, at least partially, box it in to reduce noise transmission to upstairs - that's a decision for the future, I think....1 point

-

I know somebody that put the BBQ next to the shed after use. An hour or so later his shed was on fire. Old wet scaffold boards are likely to be rotten. I lost about 20 of mine to rot because I stored them badly. Unlikely to be a long term solid base.1 point

-

Mine was an oversimplification, but the results being that the outcome is not necessarily the best result but skewed (sometimes significantly) in favour of an interested party, rather than general improvement.1 point

-

To say I'm thrilled is an understatement. Our architect gave me a call this afternoon to say that planning permission has been granted and with no changes to what we submitted. I was fully prepared for the worst and even had a plan B in place so that we could deal with the summer bat roost in the roof of the existing bungalow before it becomes active again at the end of spring, so I can set aside that bit of scheming now. I had some concern that the planning officer would object to the larger size of the new building or its increased height but my concerns were unnecessary. One of the main parts of our briefing to the architect was that we didn't want more rooms than we have in our current house (3 bed with a loft conversion), but we wanted larger rooms. Much larger. In this case, size really does matter. Anyhow, all's well for the time being so we best our game face on and start the hard work part of it.1 point

-

0ur site was not as challenging as yours appears to be but our plot does rise over 3m from the front boundary to the rear and slopes from right to left, looking up from the front. We had a lot of existing shrubs, trees and hedges that we wanted to retain from the existing house and the landscaping had to deal with this and the slope. We could not get our head around a decent design and engaged a landscape designer to produce a design. The landscape design wasn't cheap but my OH (who is the garden expert) insisted on it. In the event it was money well spent for the following reasons: As @JSHarris recommends, it allowed us to incorporate the landscape design in the Planning Application, though it was never included as a Condition in the Approval. All the work was VAT exempt from our contractor It allowed us to get good cost estimates and manage the work, with the groundwork contractor responsible for the ground clearance, hard landscaping, underground services and base for the passive foundation,. It allowed us to plan all the critical ground clearance and landscaping work that had to be completed with the heavy equipment before the foundation and underground scope was started. There was no way that we could have attempted this work after the house was built, as we could not any big equipment onto the site, except a small digger and it would been a long and laborious job. It minimised the amount of material that had to be taken off the site and eased the lorry movements (we had 69 lorry movements for this part of the project), which was important to us as we are opposite a school on a busy road and we wanted to have minimum impact from our build on the neighbours, including the school. In fact, we planned the major groundworks, including all the hard landscaping, except finishing the terrace and drive with paving slabs and Suds blocks, to be be executed in the school summer holidays. It was 4 weeks for the groundwork contractor and another week for MBC to install the passive slab. It allowed my OH to plant the garden before the house was finished, though the lawn elements were left until later. I believe that key for you is to get some ideas on landscaping including the retaining walls/terracing that meets your needs, incorporate the landscape design in your Planning Application/Approval and then it will give you a good starting point to execute it in the most effective manner as part of an overall plan for your project.1 point

-

Sorry to hear, but to check... Where does this requirement come from? We have 22mm engineered oak and I would say heat transferrance is not an issue. In one room we have a very large and thick persian rug over the 22mm flooring and that room also heats well. I doubt if there will be a massive difference in heat transfer between 15mm and 22mm, I would say more important is getting a good bond to the screed and minimising voids and air pockets.1 point

-

Looks like our spare room in our old house. I'm trying to clear it out as the house is going on the market but can't get enough access to get in there to get some of the stuff out. I don't have space for a skip, plus my number plate is still banned from the local recycling place, and I can't hire a van as the recycling place doesn't allow vans in now, either. Right now, the only way to shift stuff is to fill my car and drive to the next county to their recycling centre, around 20 miles each way. And they wonder why fly tipping is on the increase................1 point

-

And people wonder WHY some of us lost our patience with the way EU regulations have been formulated over the years........................ They start out with a laudable aim, to reduce energy use, but by the time the legislation has passed multiple times through the technical committee the original objective gets lost and replaced with a load of restrictive crap that will do little to reduce energy use. It's a bit like the EU regulations on electric bicycles. They set out, quite sensibly, to restrict the power and performance of these vehicles that did not require a driving licence, insurance, taxation etc. They then went through a process to develop a test method, and instead of just using the tried and tested UK British Standard that had worked well for years by doing a simple dynamometer test on the motor, they made up their own test. The result was that you can have a perfectly legal EU electric bicycle that massively exceeds the motor power output in the regulations. Why? Because the test is only a timed acceleration test over a set distance, and there is no stipulation on the weight of the test bicycle. This means you can get a pass with a very heavy person riding the bike, get the required approval, then sell an electric bike that has far more motor power than the regulations allow, and it's all OK................. PS: Please don't take this as an anti-EU rant - it is solely a rant about the very poor way some regulations are framed, nothing more.0 points

.thumb.jpg.84720b9262bdfdd639b2257471fce9e7.jpg)