Stabbed by the soil investigation!

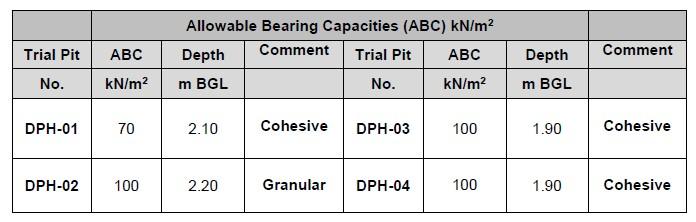

Well, everyone is back from holidays today and my Structural Engineer made a comment about the Ground Investigation Report I've been digesting all day. Turns out my soil is very poor despite hundreds of houses being constructed all over the rest of the estate 25+ years ago, I'm the one with a problem now! I'd have to dig / excavate nearly 2 meters of soil to reach sufficient bearing capacity which means my plans to start groundworks next month are almost dead. If you see results like mine....RUN!!

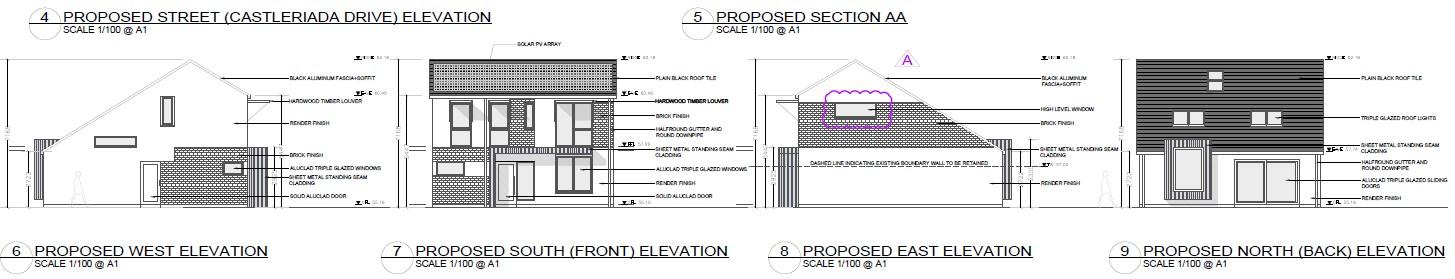

I've sent photos to the Groundworks lead as I've a house to one side 2.5 meters away which isn't too bad but the other side has a block council wall and would be 1 meter away, and 800mm where each of two buttresses are from the wall of the new house (see pics).

Anyway, I'll see what they come back with but the excavation would be 10m x 10m and 2m deep, risk of groundwater seepage, flooding, subsidence and having to shore up the walls to prevent collapse/damage would be required. I can see all those Grand Design houses coming back to haunt me!!

Piling / mini-piles are an option but with the close adjacency of several neighbours, are unlikely to be welcomed

A Kore Raft Foundation, a standard steel/concrete raft or strip foundations all require similar depth to get the bearing capacity from what I'm told.

Tip: If building get the Ground Investigation done EARLY!!!

I've reached out to a company that should be able to design a solution but their turn around due to workload is measured in months. I'll see if there are any other companies but screw piles are not common in Ireland, from the searches in this forum it's more likely in the UK to be required. But this would allow me to build a raft on top.

My house beside the site is up for sale, stuck on a legal issue currently and my planning runs out in August!! I'm guessing I'd be very lucky to get any foundations started before then and I've spent €15K on timber frame drawings and line loads to date. All expecting the site to sail through the soil test! At least I didn't try building after a trial pit and it subsides years later!!

I've asked the Architect for the cost of applying for new planning permission and I've an application in to extend the current one but that only allows you to continue building if you are up to wall plate by the deadline, expensive foundations don't count!!

I could probably reapply for planning myself at my own time and cost, just need to research a bit and hopefully am allowed use the original Architects drawings again. Either way the foundation costs are going to be more than I expected but plan B is to pull out of the house sale, sell the site or move elsewhere! I was thinking Thailand?! Anyone want to join me!!

47 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now