Search the Community

Showing results for tags 'the windy roost'.

-

Thought I'd do a short blog on the Polycarbonate tunnel we built. Our big field suffered with no storage, and location meant containers were very expensive to transport. so one option was to build a polytunnel, which we have planning permission for. again due to location, 500m from the coas...

-

Wow, we have finally started, and what a journey. The goal of the last 8 days was to try to make the the stars align. We had planned several meetings / connections deliveries all to happen the 1st week in April, and this was it, lets see what unfolds. Firstly, the plot, being located high...

- 10 comments

-

- 8

-

-

Had anybody had a steel building in my case 47 ft x 30 ft x 14 ft built and have the erection costs to hand? It will be 4 portal frames, timber perlins and metal clad. I've got package costs and kit costs and it seems like most things the sum of the parts have a big profit margin attached...

- 22 replies

-

- the windy roost

- caithness

-

(and 1 more)

Tagged with:

-

My initial plans were to have rainwater harvesting, build hub taught me no.. so with that scrapped I needed an alternative, soakaways are difficult due to bed rock levels. In addition to this we have lots of run off on the croft, and the track to the house floods. We have already installed a po...

- 6 comments

-

- 8

-

-

- the windy roost

- highlands

-

(and 2 more)

Tagged with:

-

HiMy initial plans were to have rainwater harvesting, build hub taught me no.. so with that scrapped I needed an alternative, soakaways are difficult due to bed rock levels. In addition to this we have lots of run off on the croft, and the track to the house floods. We have already installed a...

-

- the windy roost

- highlands

-

(and 2 more)

Tagged with:

-

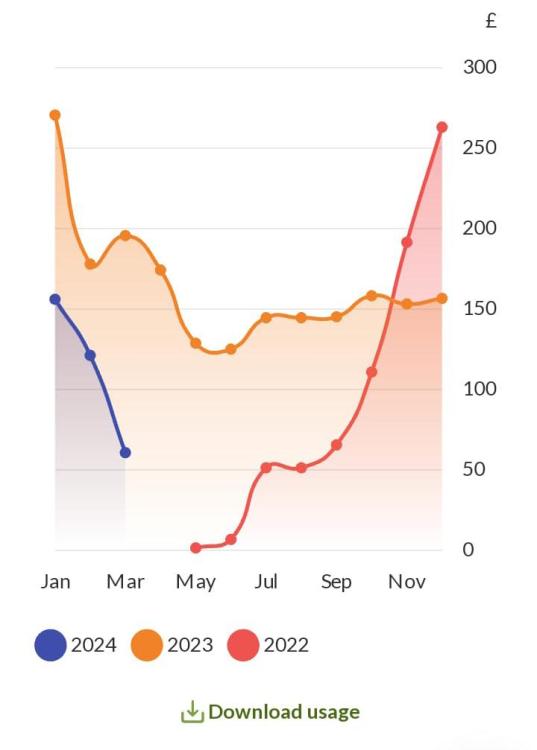

All the reading of posts on here at the design stage and the hard work implementing the experience of others on your own self build can be summed up / justified with just 1 image. Even when building on a very tight budget. This is my energy usage @ The Windy Roost since we...

- 5 replies

-

- 6

-

-

- the windy roost

- highlands

-

(and 1 more)

Tagged with:

-

Around 11 months ago, we started from a stripped site, the treatment plant was in and running the cabins / static so drainage just required connecting up. we had to wait for the warrant to be amended (change to the certificate of deign) this held us back ma month or so until the BCO just said "get...

- 6 comments

-

- 12

-

-

Just a very short blog to show the windy roost ( not fully finished, is a self build ever?) plant room. I'm quite chuffed I got it all to fit, and I think it's quite neat. It's full DIY and house's the UVC and combined buffer, UFH manifold, MVHR unit, inverter, consumer unit, network hub. All in 4M...

- 5 comments

-

- 8

-

-

- the windy roost

- caithness

-

(and 1 more)

Tagged with:

-

HI all. Would anyone with some knowledge like to give me an opinion on the AHP60 ASHP. Spec attached. its in conjunction with my other post, so run this to heat a 300L UVC for 2 camping pods. the money is good, brand new 3 year warranty. It is cheaper than the Dream units on ebay. and a...

-

It's been a while since my last blog, but we've not stopped, the days are shorter and the weather skipped autumn🍂 and dived into winter with a few storms and loads of rain. Our windows are budget friendly triple glazed UPVC, and composite doors. The external EPS was sealed a...

- 14 comments

-

- 14

-

-

- the windy roost

- icf

-

(and 1 more)

Tagged with:

-

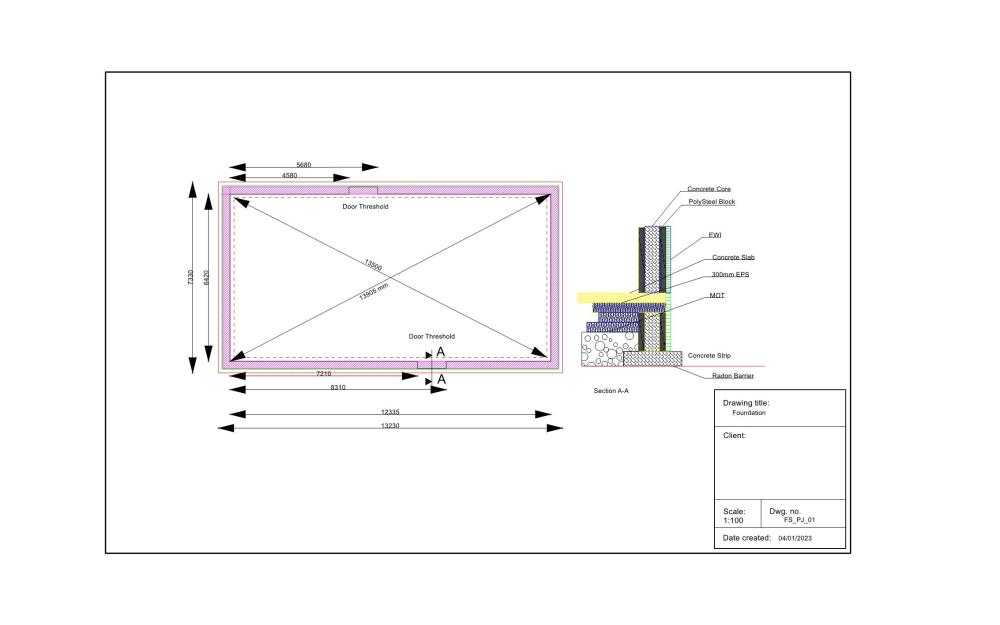

Day 31 of the build. (this is taken from the day we started shuttering the foundations) The weather up North has been spectacular for about 3 weeks, so we (Mandy and I) pushed to prepare and pour the slab before the weather changed, as I'm sure we will get a few weeks of low pressure, wet chang...

- 14 comments

-

- 6

-

-

- the windy roost

- icf

-

(and 3 more)

Tagged with:

-

Sunday in the Highlands, and the weather has a feel of changing, we've been so fortunate on the build so far, day 105 today, but the last week or so has been wet, windy, sunny, overcast usually everyday. So autumn is on the way. July and August have been busy with the 2 cabins with around 100 n...

- 4 comments

-

- 3

-

-

- the windy roost

- highlands

-

(and 4 more)

Tagged with:

-

With the great weather in the last two weeks, following on from the slab pour, we will endeavour to pour the walls of the house tomorrow. I'm thinking I won't sleep tonight. Mentally listing all the things I wanted to do, and re ticking them off. First 7 cube is arriving at 8.30. 🤞 I...

- 39 replies

-

- 8

-

-

- the windy roost

- icf

-

(and 2 more)

Tagged with:

-

Looking at one of these, haggling on price with City Plumbing and there 15% off using there APP. Anyone any experience with them? they do a Coastal protection option which has some appeal for me being 500m from the sea. They offer a control pack but at £500 I'm looking for alternat...

- 1 reply

-

- the windy roost

- caithness

-

(and 2 more)

Tagged with:

-

A short blog to show my Mini spilt Air2Air install, in the Windy Roost Static. I looked at installing a wood burning stove, but we have zero trees on site, so when I looked at the costs of twin wall flue, terminals, flashing, creating a heat shield and making the caravan tidy plus the hassle of...

-

Anybody got any quick tips to get my layout working. I downloaded a trial few weeks back and made a start but was struggling to make any progress. The weather has been ace, and if I can get a layout sorted, and ufh installed might be able to pour my spab by next weekend.

- 5 replies

-

- the windy roost

- caithness

-

(and 2 more)

Tagged with:

-

A busy couple of weeks and favourable weather has seen some progress at The Windy Roost. When in use the word I, or we, I mean Mandy my wife, and me. So far that's the only labour on the build. Mandy has worked office based for 40 years before we moved here, so this is an all new world for her,...

-

- 4

-

-

- the windy roost

- highlands

-

(and 2 more)

Tagged with:

-

I'm looking at options and prices for PV, with my build budget tight, I still want to add a 4KW array to the roof, Getting costs the only options I can find are GSE trays and there are coming in more expensive than the panels. Are there other systems out there or am I looking on the wrong place...

- 14 replies

-

- the windy roost

- highlands

-

(and 1 more)

Tagged with:

-

Finally made a start in earnest. The original plan was to stick build on site, but the cabin builds opened my eyes to the winds up here, and established concern for getting the house airtight. I priced ICF, and although the costs are higher in the begining I think, I can self build for similar...

- 13 comments

-

- 11

-

-

- the windy roost

- caithness

-

(and 2 more)

Tagged with:

-

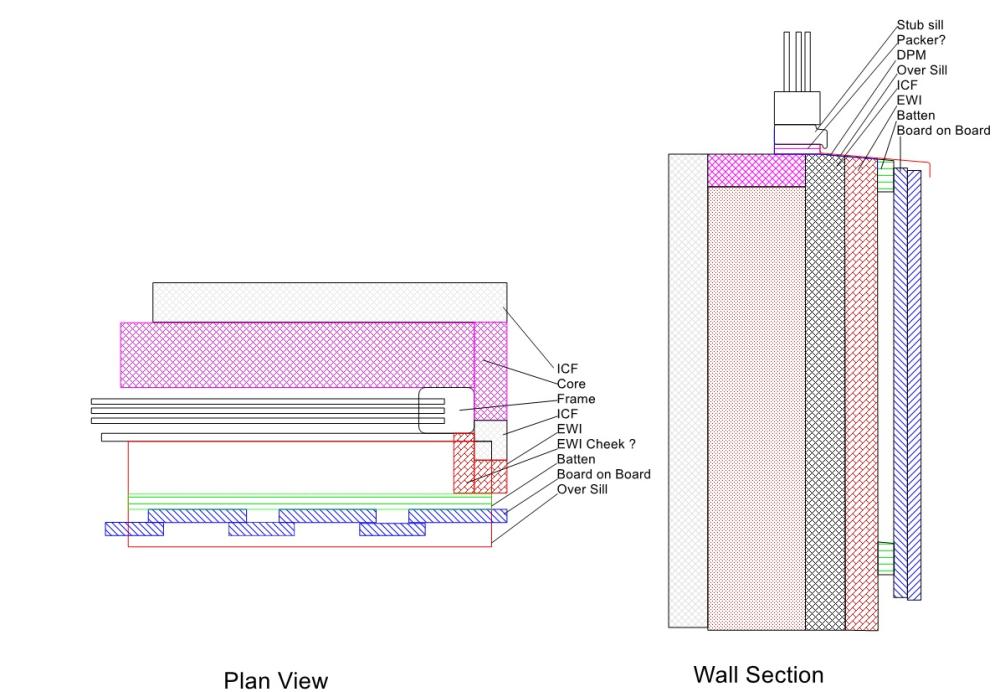

Following on from my Foundation post, I want to get the detailing correct on the windows, this is spurred on further by reading this post My build will be with PolySteel ICF, 50mm EWI, Board on Board vertical cladding. UPVC windows. I'm thinking of using a stub sill o...

-

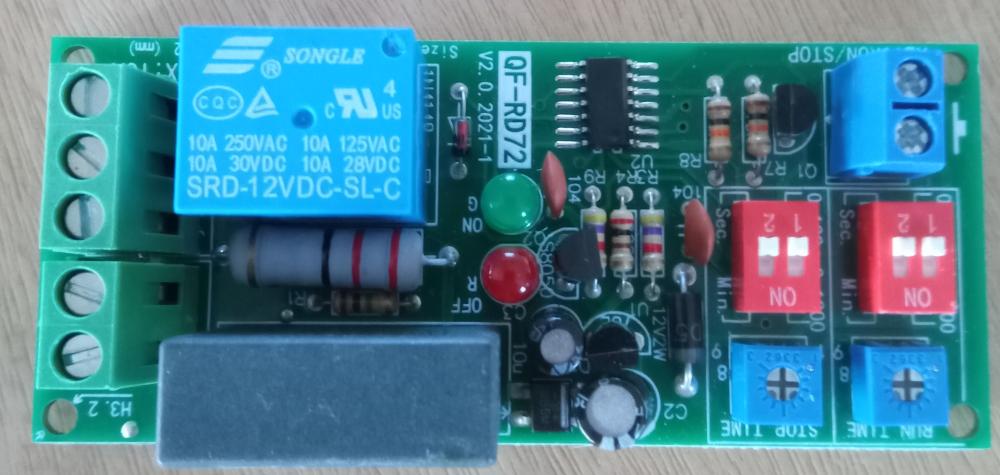

This has been discussed on here before. My treatment plant runs 24/7. That is the Compressor runs 24/7. I have read that switching it off there is a chance that water can syphon up the air tubes. SO I was wondering if I was to turn it on and off hourly I would reduce the risk of any damage by sy...

-

Since the last blog, a lot has happened in a relatively short time. The last blog was Stage 1 of the Amenity block, needing cladding and the roof, and as I'm sat here early in the morning , with the wind constantly blowing 20MPH, 2mm rain p/h. and a toasty 8 deg. inside the static, which is our hom...

- 17 comments

-

- 3

-

-

-

- the windy roost

- camping cabins

-

(and 1 more)

Tagged with:

-

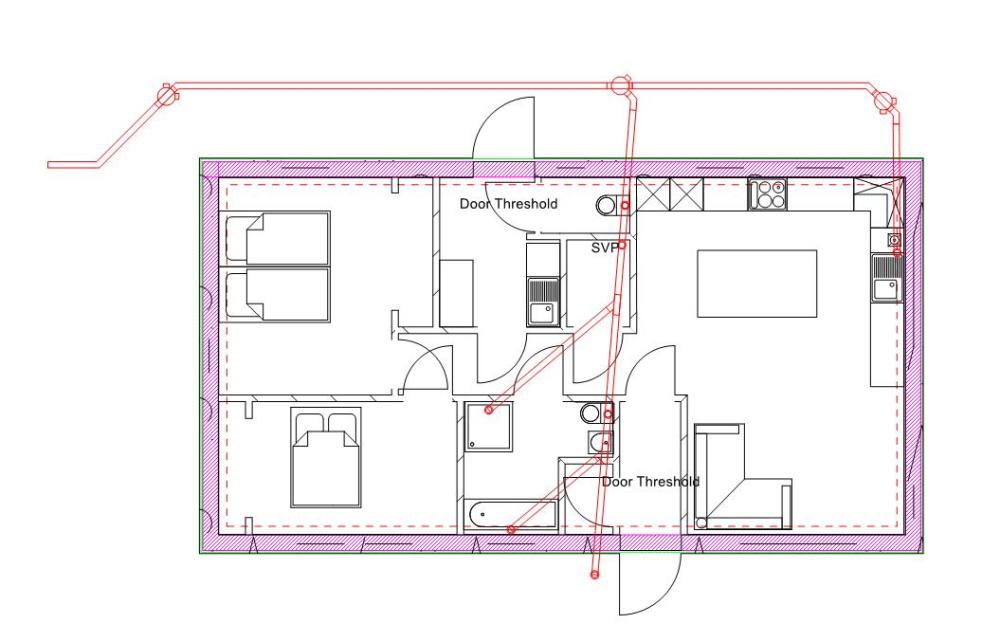

Could you please cast your informed eyes over my drainage plan, and tell me if I've missed anything. I've used a NHBC tech sheet for some guidance, namely if I use a rodding point (bottom of the diagram) I can then branch off the main run for Bath and Shower. The two WC's and SVP will be...

- 5 replies

-

- the windy roost

- highlands

-

(and 2 more)

Tagged with:

-

First of a few posts, Having lived in the Highlands for a long time, (5 months and counting), We have had a re-think on the construction of our house. The decision is two fold, firstly the increased cost of stick build and insulation, plus the delivery costs, secondly the Weather. Its windy a...

- 35 replies

-

I'm posting as a non Boffin, in search of ideas. I want to set up a weather station so in the future I can use this for weather compensation, but also want this information to have around the house. Additionally I have a project in mind that having wind speeds available, and being able to...