Search the Community

Showing results for tags 'retrofit'.

-

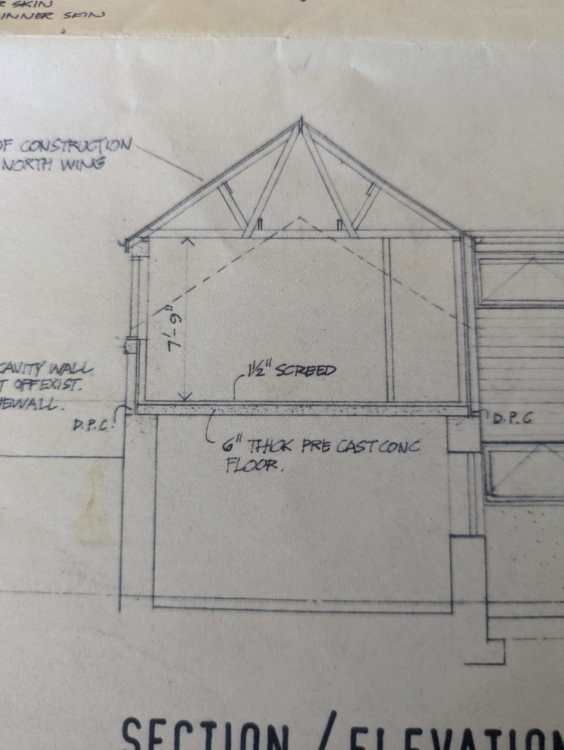

Hi all 👋🏼, I wanted to introduce myself and our project as I anticipate I'll be in hot pursuit of the forums thoughts, opinions and experiences in the forthcoming months. We purchased a 3-bedroom 1970's bungalow in August 2022 but had some planing complications due to a parish council policy that attempted to dictate that "a bungalow must stay a bungalow". 15 months later our planning application was finally granted, albeit with some compromises. Here's a few points on what we're attempting... Replace existing roof (& ceilings) entirely, building up the walls ~80cm, adding a new roof with 1.2m increased ridge height and steeper pitch Upstairs will accomodate two bedrooms, bathroom and "breakout area" overlooking hallway void Large single-storey flat roof side and back extension out to locate 65sqm kitchen/diner Complete re-configuration of downstairs layout Complete replacement of heating system (gas will be cut off entirely) New ASHP (current thinking Valliant Arotherm Plus, one-zone, no buffer) UFH all-round on ground floor (retrofit lo-profile UFH on top of the existing slab (Wunda?), insulated/screeded in new extension). Possibly fan convectors in bed-rooms upstairs Complete rewire I would assume MVHR (current thinking is a radial system installed through new posi-joists, manufacturer TBH but will get BCF to design) New solar panels, and battery (current thinking GivEnergy to unlock Octopus Intelligent Flux) New double-glazing all round (Residence R7 probably) also 2.7m high, ~8m wide sliding doors at rear (either Corteso Cor-vision or Minima) The biggest grey-area for us at the moment is how much to focus on/invest in improving the insulation and air-tightness of the existing exterior walls. I'll raise a separate thread for this in due course. Fortunately we were able to leverage a second mortgage and keep our existing home so we don't intend to live in the place whilst the majority of the work is taking place. The properties are only 0.5 mile apart so I am hoping I'll be able to keep a close eye on the build whilst I work from home. We are also intending to do a little of the work our-selves as possible (i.e. fitting MVHR, UFH, painting & decorating, airtightness membrane?, etc). Thanks for having me and in advance for any advice, Ollie Fleet, Hampshire Plans 24 OD - Amendments Combined.pdf Concept Images Existing Images

-

Hi, First time posting so apologies if I break any rules or social norms... We are looking to install a retrofit UFH system to our bedrooms which sit on top of an uninsulated/unheated garage space below. Current floor buildup is: - 150mm precast concrete beam floor - 38mm screed topping. No space to add insulation above the slab without having to raise external glazing that goes to floor so current plan is to insulate the soffit with about 150mm PIR (max. before restricting head height of garage below) and replace the 38mm screed topping with the following: - 20mm retrofit UFH (Wunda rapid response) - 7mm Wunda duoboard - 11mm UFH compatible carpet underlay - low tog Carpet I appreciate that this will likely mean a less responsive UFH system as it will be heating the 150mm slab but hoping the insulation below will still retain enough heat to make the system effective. Really just looking for a critique of the above plan, any thoughts or suggestions welcome.

- 4 replies

-

- ufh

- underfloor heating

-

(and 3 more)

Tagged with:

-

Hi everyone, I am looking at buy thing kit to install in my open plan downstairs area. https://underfloorheating1.co.uk/product/premium-xps-lowprofile-kit-50m2 I noticed in the install guide that the XPS panels need to be bonded to the subfloor with a flooring adhesive. I have seen other brands selling similar insulation panels that say this is not required when using using Laminate or Vinyl interlocking flooring on top. What are your thoughts on this, could I get away with out using a glue? Many thanks

- 1 reply

-

- retrofit

- floating floor

-

(and 1 more)

Tagged with:

-

I'm currently working on a listed house with original single glazed Crittall windows. We'd like to improve the energy efficiency of the house if we can, and would prefer not to go down the secondary glazing route. Does anyone know if it is possible to retrofit super slim vacuum glazing into existing metal windows? The only stuff I can find online is about retrofitting it into wooden sash windows...

-

Looking for wisdom from this forum on how to maintain an uninterrupted airtight layer between the ground floor and the first floor in our retrofit (solid brick mid terrace). The joists run front to back and on the front we have to do IWI (On the rear we’ll be doing EWI so my assumption is that we have a thermal bridge issue to solve on the front; but the rear won’t be such a challenge). I have seen a few different solutions proposed for this: i) rehang joists on joist hangers ii) create a new wall plate on which to rest the joists iii) support from below, leaving a complete gap between floor and wall iv) employ the “Tony tray” method Options (ii) and (iii) aren’t really suitable for our small footprint, bay window shape and structure. I don’t much fancy option (i) with a brick wall… so am extremely interested in the Tony tray option but haven’t been able to find an example of how to use it in a retrofit… is it possible? Can the airtight (breathable) membrane be wrapped around a joist in situ? And if so how…? Any pointers to diagrams, photos or videos extra appreciated! I can accept maybe not being able to achieve an airtight layer in it’s entirety, but what worries me is leaving the end of the joist getting damp in the brick area, which is beyond the insulation and airtight layer. I plan to use only natural breathable insulation, tho, so maybe my concern is unwarranted? thoughts extremely welcome!

- 5 replies

-

- airtightness

- joists

-

(and 2 more)

Tagged with:

-

Hi everyone I’d welcome your thoughts please, especially on heating. Wanted to reach out to you all as I’m finding it’s tough to get unbiased advice and personal experience. We’re just about to start a renovation and extension project to a bungalow. The existing building is a time capsule from 1979 with a stunning avocado bathroom suite so we need to do the works: heating, ventilation, electrics, skimming, new flooring etc. So we have a blank canvas. We’re trying to work out the classic air source heat pump vs gas, and UFH vs radiators conundrum. The existing property is 60m2 with a concrete floor (the very fashionable original self-adhesive tiles are below an equally fashionable retro carpet). Ceiling height is c.2.3m. We need to plasterboard the ceilings before skimming, so are losing a touch of height there. The extension will be 30m2. Attic insulation is going to be increased, there’s cavity wall insulation, and we’ll be putting in new windows. We’re looking at installing MVHR. The existing property’s radiators need replacing anyway and the pipes are all currently mounted on the walls, so if we went for rads here it would be a big job including all the pipework chased through the walls, etc. Even if we couldn’t afford a heat pump now, we’d want to make it as ‘heat pump ready’ for the future as possible by using low flow temp rads, etc. Because of the expense of this scenario, we wonder the actual cost difference with the alternative, which is a low-profile retrofit UFH system? I’ve been researching and awaiting quotes - I’ve heard back so far from Nu-Heat for their LowPro Max. I’m concerned with appropriateness for the existing building, cost, additional lost ceiling depth (although I’m pretty short!), and if there’s a building regs issue with presumably having no insulation with the original concrete floor. We’d like to do UFH in the 30m2 extension and have been quoted so far for Nu-Heat’s relevant system. The grant from April closes the financial gap between a heat pump and a new gas boiler, as if we went for old school gas there would be extra costs to replace the ancient combi as well as moving the gas supply (crazy money!), required to accommodate the new floor plan. So as there would be a relatively minor jump in cost to a heat pump, we’re wondering if the time is right now? And if so, how this would influence the choice of UFH vs rads in the existing part of the house? Would really appreciate your ideas, observations and experience. Big thanks

- 12 replies

-

- air source heat pump

- gas

-

(and 8 more)

Tagged with:

-

Still struggling with how to retrofit the DPM (on rough old solid concrete floor) and insulation etc Am not going to manage brilliant insulation as I failed to realise we couldn't take the DPM above the DPC ( at 150mm), even tho there is the head height. Am hoping for UFH in screed (supplied won't do 50mm, only 65mm). Would the retrofit UFH sort which goes over a floating floor be better? See BC full plans specification: there is a significant thermal bridge, so I would like to use Kingspan Kooltherm K103 as it has a better u value than Celotex PIR and also use it as an upstand. Does it have to overlap the DPC too (as the extern al wall insulation doesn't come down far enough)? Have been told to use sand blinding layer, but how should we protect the DPM from the rough wall bits, is a combination of 'paint on' OK? Would really love a Noddy's guide on how to do this ? Or at least which rules I need to follow...Thank you everyone Floor detail.pdf

-

Hi all Would love to get your views on this. We're upgrading our early 1970s detached house, with (as a minimum) cavity wall insulation, insulating under the suspended floor, upping the loft insulation and replacing doors and windows with triple glazing (Rationel / IdealCombi / Norrsken TBC). We may also insulate walls externally (subject to cost / budget). We're also building a kitchen extension which will be heavily insulated and airtight. We're now looking in to installing either a MEV or MVHR system. We've got supply only quotes from BPC of £2150 for MVHR and £575 for MEV, with extract from 3 bathrooms (upstairs, downstairs and en-suite) and the kitchen. We've got a young family and both work pretty much full time, so we're only really in the house at weekends and evenings. In summer / warm spring days the doors into the garden will be open, so lots of air will be drawn into the house. I know there's the thinking that MEV is throwing away money, extracting warmed air, but surely it would take a long a time for this to add up to the £1500 difference in supply cost, plus probably that again in installation cost. Heating is standard central heating from a combi boiler. My current thinking is that MEV would give the benefits of quiet extraction of moisture and odours from the bathrooms and kitchens and avoid the need for wall extractor fans, and its hard to justify the additional benefits of MVHR given our use of the house. It would be really good to hear from anyone who has a MEV system installed, or who upgraded from MEV to MVHR. Thanks!

-

Hello all. My six year old house was fitted with MEV by the developer but I’m planning to ‘upgrade’ to full MVHR. Although much MHVR goes on new build, plus some retrofit during refurbishment of older properties, I haven’t seen anything online about anyone upgrading existing MEV in this way. As background, my parents longed to do a self build, with MVHR oddly enough being one of the things mentioned a lot beforehand. It was installed in 2010/11, so I am familiar with such a system in practice. On buying my house new, the showhouses did have MVHR, but unfortunately all the others only have MEV. My original thinking was that I already have one half the of system in place, though perhaps I already get half the benefits. So while we get fresh air, humidity at reasonable levels and minimal condensation in the bathrooms, it galls me that trickle vents were cut into the frames of the triple glazed windows for supply and while I have two fans spinning 24/7, the heated warm air is just being pumped out. The extraction is not optimal – kitchen cooking smells permeate the whole house with the door closed, whether on boost or not. For some reason, only now are we getting some black mould in the en-suite bathroom. I have read up plenty since and so – as things stand – currently plan to go ahead. I’m also going ahead with an extension – highly glazed – and will need the SAP calc, so this is one of the few possible improvements I can make to the existing house if needed. (Loft insulation, firstly to building regs, though even better to the design spec, would be cheaper and easier so happening as well). The airtightness test result when new was 4.4 m3 /m2 hr @ 50Pa. Fairly average for recent new builds but certainly not spectacular. It’s below the figure where it should give some benefit, but above a level I expect some might think it’s not worth it. The extension will be built to a better standard, while there are some gaping holes in the existing house I am aware of and have filled or will do. Plus sealing up the trickle vents. Though at this sort of airtightness, I can’t justify a top end system professionally installed, it just will not pay back. Though I have acquired a good value unit and plan to do much work myself to limit expense. I don’t think I’ll necessarily use all that is currently in place. Rigid ducting was used for the extract and is not especially well sealed at joins where visible. The ceiling extract ducts were generally placed near the doorway, not at the opposite corner. The two existing roof extract terminals (there are two separate MEV units) are on the southern elevation but have insufficient free area to repurpose one as a supply and leave the other as extract. The manual boost switches might be the few parts I reuse. There is power to one of the MEVs that would also be the loft location – admittedly unheated – for the MVHR unit. I do have useful behind-shower voids at the front and back to enable semi rigid supply to all the ground floor rooms that need it, and back from the extract rooms. The doors already have sufficient gaps underneath. The reason for posting here is to ask a few queries on what I’m still unsure of. And if it does go ahead, perhaps be one of the few resources to document an MEV to MVHR upgrade. Savings are difficult to quantify at present. I would appreciate some hints on the following: Which of these positions, or something else entirely, would you put the external supply and extract terminals? A (Red): North roof through roof terminals, B (Gold): North roof soffits (might be easiest to install but need to watch the free area), C (blue): East gable end above the slightly lower roof. Overall I am trying to avoid the SW prevailing wind, be on the same elevation, far enough apart and be shaded in summer. I have seen a number of posts of DIY commissioning and producing the certificate for building control. As an alternative, there are a number of firms that can do testing, but is there a competent persons scheme for any of these testers? Reason I ask is that on speaking to building control they said it would be usual for installers to self certify as would be done for gas / electricity, in which case there is no BC fee. Though I have not found a similar scheme. If I have to pay the building control fee anyway, then I would probably test myself. Is this really worth going ahead with, or pulling the plug now? I am hopeful of getting this completed for under £2k all in for the parts, my labour counted as zero. One possible supplier for the large glazed doors for the extension wanted over £900 to add trickle ventilation. I’m not going with that firm, but whoever I use I avoid the need for those vents. Overall, I would hope to minimise the ventilation losses but have difficulty quantifying the payback. Non-financially, I would see benefits from input filtration (due to hay fever) and soundproofing from sealing the old vents. Sorry for the long post, and thanks in advance for any suggestions.