Search the Community

Showing results for tags 'dhw'.

-

I have an ASHP for heating and hot water. Unless I use the “luxury” DHW setting, my shower mixer adds too much cold water as it requires the thermostatic valve temperature differential to be 12 deg C. Does any one know of a shower mixer that will work with a heat pump hot water cylinder feed, i.e with DHW between say 40 to 45 deg C, rather than at above 50 deg C?

- 16 replies

-

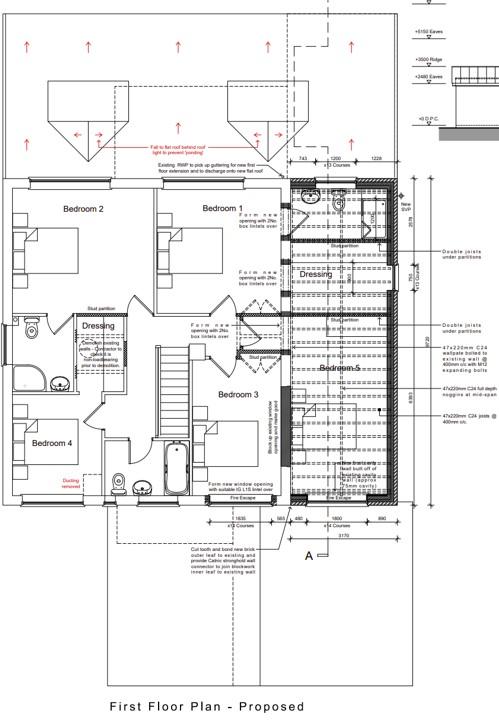

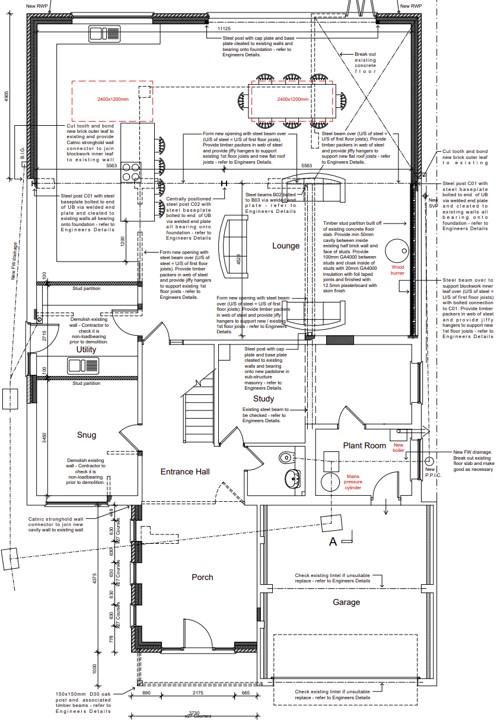

Afternoon all, I've been browsing the forums for a while, messaged a few users direct but as we are fast approaching water tight I'm after a steer from the group on all things plumbing...... Attached are a couple of pictures of what will be the finished ground and first floor plans. The existing house is/was heated using a warm air boiler (located in what will become a snug) ducting through floor to ground floor rooms and into the loft and into 1st floor via ceilings. hot water was previously provided by an electric hot water cylinder (i know $$$) located on the first floor. (Cold Water tank in the loft) Mains gas and water come into the house in the snug (it used to be the kitchen). The intention is to re-route the mains water/gas to a plant room accessed off the garage which will house new System Boiler Unvented Cylinder Water Softener Heating will be provided by radiators in bedrooms, snug, study (8 Rads) towel radiators in bathrooms/ensuite (4 Rads) underfloor heating in open plan kitchen/living room and porch This will be a completely new plumbing system with all existing plumbing decommissioned as the job goes on as we are still living in the house as while work progresses. The first floor joists run side to side (across the front) of the house, except the rear extension which runs front to back. Up until last week I was intent on using a branch/tee plumbing system for the hot water and central heating (because that's what I was familiar with) but I then realised how much more common the manifold systems have become. I've plumbed in plastic before when renovating our last house and I like the idea of using a manifold system because it gives a continuous run of pipe to the appliance/rad (reducing scope for leaky fittings at junctions/turns etc) but I also note the issues with having to empty fairly long sections of pipe before it receives hot water, to give an idea of scale the house is about 12m wide 14m deep. In terms of design my questions to you lovely people would be, should I Use one manifold in the plant room to serve CH pipe runs to all rads and towel rails and secondary manifolds serving the UFH? In respect of DHW and CW run a feed to each bathroom and install a manifold in each bathroom (therefore a using a shower means a significantly shorter length of pipe needs to be vacated for the sink hot tap)? Is running a manifold off another manifold a no, no in terms of maintaining consistent water pressure etc? In terms of manifolds etc, I'm familiar with 15mm, 22mm etc. but I'm seeing reference to 10mm, 16mm across some brands. Is there a preferred brand of pipe, manifold etc. you would recommend? I'll probably have more questions as we go on but I am actively scouting threads looking for answers etc. so thank you in advance for all the contributions

-

- renovation

- manifolds

- (and 10 more)

-

Hi all, We are planning a new-build that will approach passivhaus standards, and I feel that going for the typical ASHP+cylinder+UFH is engineering and financial overkill, especially since we like to have the house around 18-19C and cooler at night. Instead I would like to have minimal electric radiators (or even just electric blankets) and something like the Mixergy iHP* to provide hot water at COP > 1. I would like to set it up so that it has two inlet/outlet paths according to external weather: If solar gain > heat loss: extract from top of vaulted glazed area and return to bottom to provide cooling If solar gain < heat loss: extract and return from/to external environment The second case is to avoid having to run the radiators to provide hot water on days with no sun, which tend to be wet and not sub-zero where we are building. Does this sound feasible? We will be getting an MVHR, but I was hoping that by having only internal/internal or external/external config we would avoid interfering with it's operation. Are there any products out there that would allow a compact solution for changing the flow path? It doesn't have to be automatic or anything, but I want to avoid a mess of flexible tubing. Cheers, Diarmid * other products are available, I just like the look of the warranty and modularity of this one.

- 16 replies

-

Hi, I'm still struggling on! I need cheap electric options for my small stable conversion for the time being. I have space for an immersion heater so could use E7 but is it worth having a twin coil or even thermal store for the future? The builder's plumber won't/can't do a Willis heater and has advised a Heatrae Sadia electric boiler (not specified which). I would like solar thermal and an ASHP in the future, but it may be some time and I need to keep costs under control and move in quickly, but without stuffing up for the future, am I overthinking as usual?

-

Very grateful for any advice. it’s a new build property with a vaillant air source heat pump. the domestic hot water is set to a temperature of 60 degrees for which the air source heat pump manages around 45 degrees and then an immersion heater kicks in to get this to around 60. My question is how frequently should the immersion be used to obtain the 60. is this best daily or less frequent. 45 degrees is more than adequate for showers etc but appreciate the bacteria issue of not heating to 60. I’m wondering if it is acceptable to heat the water to 45 degrees 6 days a week and then have the immersion on for day 7. Many thanks

-

Hi. Firstly, not sure this is the correct place to post... never seen so many sub-forums in my life.... We're building a 245m2 passive(ish) house this year. South facing, plenty of solar gain when need (bris soleil and external blinds to minimise when not wanted). https://forum.buildhub.org.uk/topic/9228-hi-icf-project-in-holywood/ We're in a town and on mains gas, so it seems by far the most logical source of energy for heating and hot water. As much as I want to de-carbonise, a heat pump doesn't make sense in our case. So, that part is sorted. As we'll have triple glazing, ICF walls, large thermal mass, high air tightness, our energy demand will be low. I don't see the point in spending thousands installing a central heating system. Plus we'll have a wood burner - will be rarely used, so not fussed if there's a back boiler on it. Our initial PHPP assessment attached. I'm thinking plumbed towel rads in wet rooms and maybe 2kw post heaters (3x 150mm - one for each level - each with own control e.g. central warm water heater) Any issues with the above? Would also consider electric under tile heating mats for the master en-suite for my other half's chronically cold feet... My main query is hot water.... there's just the two of us and we both travel a lot for work so we've no regular routine. We have a combi boiler in our house which is great.... but hate the long delay for hot water to come out of the tap and the massive pressure and flow drops when somebody else flushes a toilet or turns on a tap. So I'm ruling that out. I'm also planning on a 3-4KW PV system with solar diverter to provide hot water in the summer... so that means some sort of storage. What are my options? In summary, we need instant DHW on demand, high flow rates, low running cost, heatable by gas and PV. Thernal store, unvented HW cylinder or sunamp type storage? Really unsure!!! Thanks

-

I am a new member at the planning stage of a new build house for our retirement and looking to make it as comfortable, efficient and maintenance free as possible. I am trying to get my head round the many and various heating options – things have changed beyond recognition since we built our current house 35 years ago. The plan is that we will have one large room incorporating living/kitchen/dining. This will be on the first floor with ceiling at roof height and extensive glass to S & W to maximise the views. I know this isn't ideal, but we love the outdoors and the views are spectacular. Bedrooms all ground floor. My current thinking is to have wet UFH in concrete screed floors on both levels; either GSHP or ASHP (current preference). Can the ASHP be located in an outbuilding to avoid noise issues? My main concern is solar gain:- Can I utilise this free energy to heat the lower floors/DHW in winter (MVHR)?? How do I keep it cool as we experience the ever warm summers we are promised? (MVHR/AC/??) Thanks in advance

-

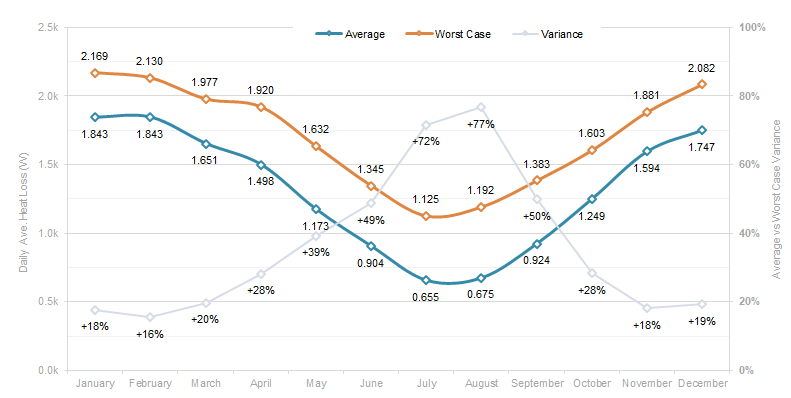

In this entry I'm going to discuss in more detail how I came to choose our heating and hot water system, and how it has performed to date. As other forum members have found, deciding which fuel source and type of technology to use in a low energy house, is a challenge given the different requirements each of us has. We had three stipulations – low running costs, hot water available on tap 24/7 and maintenance of the whole house at an even and constant temperature 24/7. Having calculated our heating demand, taking the impact of solar gain, incidental household gain, human occupancy and wind speed into account, I was confident that I had a good indication of the amount of heating I would need. I was also confident, based on historical use, of the amount of hot water we as a family use. Living in an area without mains gas, my options were somewhat limited to using either oil or electricity as my fuel source. LPG was initially considered but discounted due to the lack of availability in my location. As part of the decision making process, I spent a fair amount of time carrying out a cost comparison of both oil and electricity based heating and hot water systems, using 500kWh increments from 2500kWh to 5000kWh. I considered direct electric of various type, oil and air source heat pumps, both air to water and air to air. Solar PV was also considered and costed in terms of each method of heat and hot water delivery. In line with previous cost comparisons that I had carried out, I found direct electric to be the most cost effective in terms of capital outlay and running costs when both heating and hot water demand were less than 2500 kilowatt hours each year. As heating requirement and hot water requirement increases so the balance began to tip in favour of other technologies. Oil was quickly dropped from the list as it became apparent that any rise in fuel prices over then then low point, would significantly increase running costs. Having conducted significant investigation in respect of the viability of Sunamp units, although attractive in many ways, I found that the capital outlay and running cost was simply too high to be able to justify, given that the main benefit (low heat losses) were not as critical for me as they have been for others. Part of that decision was also driven by the cost of fitting Solar PV, which in our remote location was extortionate. I looked into a non MCS DIY install, but couldn’t make the figures stack up, the break-even point being around 17 years. Much as I wanted to install PV, it didn't make any sense financially. In time, I hope to revisit PV, if and when battery storage reduces the break-even point to a more realistic timescale. A wind turbine, given our location and the virtually constant presence of wind, would have been an ideal energy source and paired with Sunamp technology, probably unbeatable. The proximity of nearby houses ruled out that option in terms of planning permission. Air to Air heat pumps were ruled out based on my own experience of them and a road test at a friends house. Neither myself or my good lady found them particularly pleasant as a heat source. Having gone through the list of options, an air to water air source heat pump, paired with a large UVC and UFH for the distribution of heat, represented the best balance in terms of capital outlay, running costs and crucially, comfort and convenience. We opted for a package from Mitsubishi Ecodan, an 8.5kW heat pump and 300 litre pre-plumbed cylinder fitted with the Mitsubishi FTC5 control panel. Given our location, we opted for the coastal model, which is treated with acrylic resin for enhanced corrosion resistance. Whilst a pre-plumbed cylinder is more expensive than a bare cylinder and associated parts, after taking labour (plumber and electrician) into account, I found there was very little difference in cost. I sourced the package from a trade supplier, Secon Solar. I found their price list while searching online and having phoned the company, and perhaps fortuitously speaking to the managing director of the firm, found they were quite happy to sell me package at trade / installer price, the bonus being that delivery to my location was free. The package is configured for the UK market, the only difference to the system as sold in the rest of Europe (AFAIK) being that the cooling function of the heat pump is disabled so that the product complies with MCS approval for claiming RHI. It is however a simple task to activate the cooling function, by flipping a dip switch in the control module on the cylinder. Cooling can then be controlled from the master controller. As stated in an earlier blog entry, the heat pump and cylinder were fitted very quickly with simple connections on the plumbing side – flow and return from the ASHP, cold water, hot water and flow and return to the underfloor heating manifold. Electrical connections consisted of power to the ASHP, a cable from the ASHP to the control module and a plug-in controller. I had initially planned to have the cylinder in the utility room close to the ASHP Monobloc, but changed the location to a service cupboard in the middle of the house, to reduce internal DHW pipe runs. This does mean a 15 metre pipe run for flow and return to the ASHP, but as virtually all is within the insulated envelope, it doesn’t represent much of an issue, and does not appear to be having an adverse effect on performance. The ASHP Monobloc itself is located beside our back door, open to the elements. It seems happy enough where it is, despite the wind that traverses the space between house and garage walls. Locating the ASHP within the garage itself was an option but one I decided against simply on the grounds that I didn’t want to give up floor space within the garage. A timber housing for the ASHP is something we may look at in the future. We opted to fit individual room thermostats to all 3 bedrooms, to give us the option of being able to reduce the bedroom temperatures if we so wished. We have not used these and keep the whole house at one temperature 24/7, treating the underfloor heating as a single zone. At present I only have limited data as to how the heat pump has performed since moving in. On board energy metering (energy consumed and energy produced) shows the CoP for heating has ranged between 3.5 and 4. DHW is maintained at 47C-50C in the cylinder, boosted every fortnight to 60 degrees by the immersion on an anti-legionella cycle. To date the CoP for DHW is 2.4 As members know, heat pumps are best suited to the production of low temperature heat as opposed to the higher temperatures required for domestic hot water. Whilst the CoP for DHW is lower than that for heating, the cost per kWh of our DHW, based on a CoP of 2.4, is 5p, which is significantly better than an E7 electricity tariff. We may be taking a hit on efficiency, but in reality all of the other options would have cost us more. The 300 litre capacity of the cylinder means that we have plenty of hot water on tap and can comfortably run a full bath and still have sufficient left over for another person to shower. The ASHP is currently operating on a 24/7 basis, providing heat input to the UFH and topping off the DHW as and when it determines it needs to, at whatever flow temperature it determines. Whilst that does sound like a recipe for high bills and high flow temperatures, in practice, the heat pump delivers the lowest flow temp it can get away with to maintain our set temperature. If I so choose, the controller lets me set various parameters such as heating curves or set flow temperatures, or indeed a timed schedule for heating and DHW. However,as the system is operating efficiently on its auto setting, and providing the level of comfort we want, I see very little reason to mess around and create my own settings. If say electricity tariffs were to change from a single tariff to a dynamic tariff, then I would have the option of timing the heat pump operation to coincide with lower rate tariffs. After much thought, and indeed discussion on this forum, I opted for an 8.5 kWh ASHP over a 5 kWh ASHP, as I felt happier running a larger unit more gently than pushing a smaller capacity unit harder. A 5 kWh unit would probably have sufficed, and in time, may be what the current unit is replaced with when it reaches the end of its life. We haven’t yet had to activate the cooling function as any overheating (defined as internal temperatures over 23C) caused by solar gain, can, as modeled, be managed by natural cross ventilation. Neither have we found it necessary to constantly circulate the UFH to even out the house temperature / redistribute solar gain from one part of the house to the other. In the heating season, we found that there was sufficient circulation of the UFH during the heating cycle to maintain the house at an even temperature. Outwith the heating season, when solar gain is at its peak, the house zones itself, the bedroom section remaining slightly cooler than the public areas, very useful on a warm summers day. Overall I’m very happy and impressed with our system. It has, so far, delivered everything we have asked of it in terms of comfort and convenience, and the running costs are low. I have the capability to cool the house (via slab cooling) if I so wish, and the option to bolt on a second zone pack onto the pre-plumb cylinder if I ever found it necessary to install a second heating / cooling function – i.e. fan coil or duct heater / cooler. The one criticism that I have is about the controller thermostat function and its hysteresis - 1C increments only. A finer degree of control would have been preferable. Our installation was recently inspected by an MCS accreditor (our plumber is going through the accreditation process). In due course that will give us the option to apply for RHI, although that will be very much dependant on whether the figures stack up.

-

Having eventually got around to organising myself to change the bottom element on my E7 water heater, I have found it is leaking. So that takes one unknown away. So are all Vented, E7, DHW cylinders basically the same. To the best of my measuring, mine is 1.5m high, 0.5m wide and with about 40mm of insulation. The elements are both on the same side with the feed pipe going in at the bottom and a few degrees anticlockwise, the drain is opposite. There are some pictures below. I have been to a couple of websites and they seem to be around the £300 mark. Is that about right? I am hoping to just get a direct swap as that will save any mucking about with pipes, but I could, fairly easily, extend the top pipe downwards and re-jig the feed pipe. would rather not though. It would give me less heat losses, a slightly cheaper cylinder (though not much) and a larger airing cupboard (which might be useful). (edit, seems the website does not like .png files)

-

Our MBC passive new build has no conventional heating system. We are now embarking on plumbing. We want to make the right choices for a vented copper DHW cylinder needed for up to 4 - 6 people. The hot water will be needed for 2 gravity-fed mixer / pumped showers, 3 bathroom basins, a kitchen sink and a utiIity sink. We think we need 3 immersion- type connections on the cylinder: The energy from the solar PV will preferentially divert electricity into an 'immersun' type element (probably in the bottom of the cylinder?). The main energy source - when the sun isn't shining - is likely to be a conventional off-peak tariff immersion heater (again near the bottom of the cylinder?) And we think we ought to have a back up immersion for occasional use only, positioned near to the top of the cylinder. The two power showers will need to be fed via (2 no. ? twin) impeller pumps from the cylinder - probably (?) with 2 separate connecting points off or close to the top of the cylinder with some means of ensuring no risk of air bubbles into the pump in-feeds. We think we're probably looking at a cylinder in the size range of 200 - 300 litres. Having looked at a number of topics on the forum, we can’t find suggestions that address our specific queries, hence this post. We'd be very grateful for any advice and guidance on selecting the right type & size of cylinder & configuration of connections.

- 12 replies

-

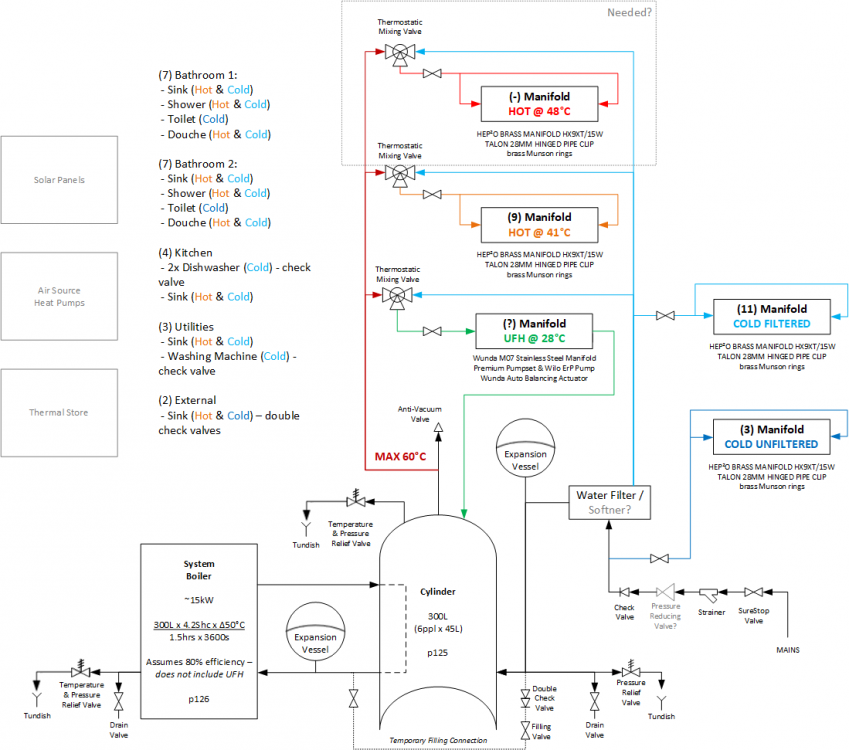

Due to some of the astounding quotes for UFH and DHW systems, I have decided to have a stab at designing and specing our own system! This is the first draft, possible due to this forum and the Building Services Handbook recommended by @curlewhouse - an awesome book, I've left in the page #'s from where I've done capacity calcs. Even so, a sanity check is very welcome! It's currently a bog-standard unvented system + system boiler that is scaled for the DHW only. You'll notice I'm one of the converted to @Nickfromwales's Hep 20 Manifold setup, though I'm not necessarily sure that the 2nd hot water at 48'C manifold is necessary for us. Principle question here is whether it's safe to pass the output of the UFH back to the main cylinder, or will that have to be discharged? We're unsure as to how we're going to supply heating however, whether we scale up the boiler / cylinder capacity, or whether we go via the ASHP or Solar Panels/Thermal Store. We're looking at ~2100 Watts for the UFH based on our heat losses during the winter here in Oxford. There'll be no other heating in the house save for some electrical UFH matts in the upstairs bathroom. ASHP with a good CoE running overnight to take advantage of the E7 scheme sounds grand, though we're concerned with the noise and another hole in our external wall for this. Could this be plummed directly into the UFH, or would a separate cylinder be needed to store the output? Solar Panels sound grand, but we're concerned the timing of the heating will be at odds with when we'll need to heat the floor. Also, the initial outlay appears quite steep so we'd likely need to install it retrospectively when we've the money. Scale up the Boiler to ~18kW to supply the UFH along with everything else FYI: I used MS Visio 2016 which has several Pipes & Valves stencil sets out of the box. Very useful! Heat Losses calculated thanks to @JSHarris's calculator.

-

Hi, Trying to complete the garage before returning to the house and an imminent decision is about how to supply hot water to the basin in the toilet and the two sinks (one downstairs in a sort of utility room and one upstairs in my man cave). These are highly unlikely to be used simultaneously and in fact won't be used that frequently so I'd prefer whatever device I fit not to store hot water. The garage is detached. A quick internet search has come up with the following: 1. Stiebel eletron type boiler. Seen these in work supplying sinks. Seem to work well enough and not seen one replaced yet (even in our relatively hard water area) 2. Domestic shower plumbed in 3. DAFI water heater (on ebay). I've tried to put links in this post but failed (frustrated by the tablet and my lack of IT). I suspect several of you may be toying with this question. Any comments gratefully received. CC

-

I'm trying to consider options for my DHW and have put my understanding of possible options into 5 broad brushstroke 'models' on the attached pdf, together with pros and cons. I've put these together from what I've gleaned reading on the forum, but as my experience of DHW is limited to a kettle (but later upgraded to an immersion heater) I may have got my wires crossed! I really need to get the big picture of what options are open to me and would appreciate suggestions. I have no mains gas, a low heating demand ('passive' type house) and low DHW demand (2 x push button showers + bath). I have no PV alas, but may ground mount a non FIT ~2kW array at a later date. I will be digging a well with a pressure vessel on supply so should have no problems with there, hopefully. I would be very interested to hear how others have or plan to cope with DHW supply, or comment on my listed models. Is it me or this a particularly difficult nut to crack without gas?? dhw & heating models.pdf