Nestor

Members-

Posts

760 -

Joined

-

Last visited

-

Days Won

6

Nestor last won the day on February 2 2025

Nestor had the most liked content!

Recent Profile Visitors

Nestor's Achievements

Regular Member (4/5)

350

Reputation

-

@Onoff It is such a great recipe, no need to purchase Evaporust.

-

Bit extreme but If you ever need to make up a large volume of rust remover this recipe works. I needed to clean some steel handrails which were covered in surface rust, in the end any rusty implement went in the bath.

-

MVHR. For sign off.

Nestor replied to Russell griffiths's topic in General Self Build & DIY Discussion

Most self builders on the forum had no issues with their BCO and MVHR. My BCO rejected my first self certifying report as the Anemometer had no proof of being calibrated, (used the Buildhub anemometer) I hired this :https://www.inlec.com/testo-417-vane-anemometer-with-flow-hoods Wrote a commissioning report with photos and had to be a little creative with the figures as our MVHR is slightly undersize for the volume of the house. Works perfectly though. -

Same size plant room here. No UFH fitted. It's 25.5C now but nothing is on. We use it as a drying room with a kitchen maid attached to the ceiling. I did consider putting a vent in the door to utilise the excess heat. Ecodan 300 litre HW cylinder. Consumer unit. UFH Manifold and wiring centre. Not in use as we have not needed to heat the lg floor. PV diverter. Has MVHR extract. You have a lot of kit in one room so 26C-27C to be expected. Congratulations on moving in.

-

I used https://www.howdens.com/joinery/skirting-boards. Consistent quality product, primed and a fair price. Easy to fill and sand, I fit with SticksLike or similar and use ovals pinned through. Tried Gripfill but not worked here. I scribed the internal corners, took a bit of MDF to master but worth a try. Robin Clevett here :

-

I made some concrete worktops and used https://www.atsdiamondtools.co.uk for polishing pads. Have fun.

-

+1 for Sigma. I purchased this https://www.protilertools.co.uk/product/montolit-63p5xl-masterpiuma-p5-power-5-manual-tile-cutter-63cm

-

Installing storm drain below public road

Nestor replied to Kevan Marshall's topic in Waste & Sewerage

Similar issues here on local lanes, Permissions and cost will be challenging going under the road. A bit crude but a trench excavated next to and under the hedge, large diameter pipe then fitted. That is 150mm diameter pipe in the photo. Only needs to be below the lowest point of the lane. Does get clogged up a few time a year which creates 50 metres of standing water, then cleared within a day. -

Why did you choose an air source heat pump?

Nestor replied to SimonD's topic in Air Source Heat Pumps (ASHP)

No mains gas and used oil in the past. New self build, air tight, MVHR, 3G etc. 275sqm. RHI was available so paid for kit and install. Our personal use for 2025 was 2700kWh for hot water and heating. However, I would not recommend ASHP in average insulated home with mains gas available if cost is a major factor. -

Yeeessss we bloody done it.

Nestor replied to Russell griffiths's topic in General Self Build & DIY Discussion

Congratulations Russell, looks amazing and do post a few more photos when ready. Similar here, started in 2017 and moved in after 3 years. 6 years later some minor tasks to complete.... -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

I have both the Makita and Milwaukee 18V oil driven impact drivers, the Makita is twice the price though quieter. 12V is probably enough for most tasks. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

I had the MAKITA DTS141ZJ, silly money but was a pleasure to use whilst building a house, very quiet. It did develop a fault after 6 years heavy use. Now using a Milwaukee M18 FQID, more torque, cheaper but not as quiet as the Makita. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

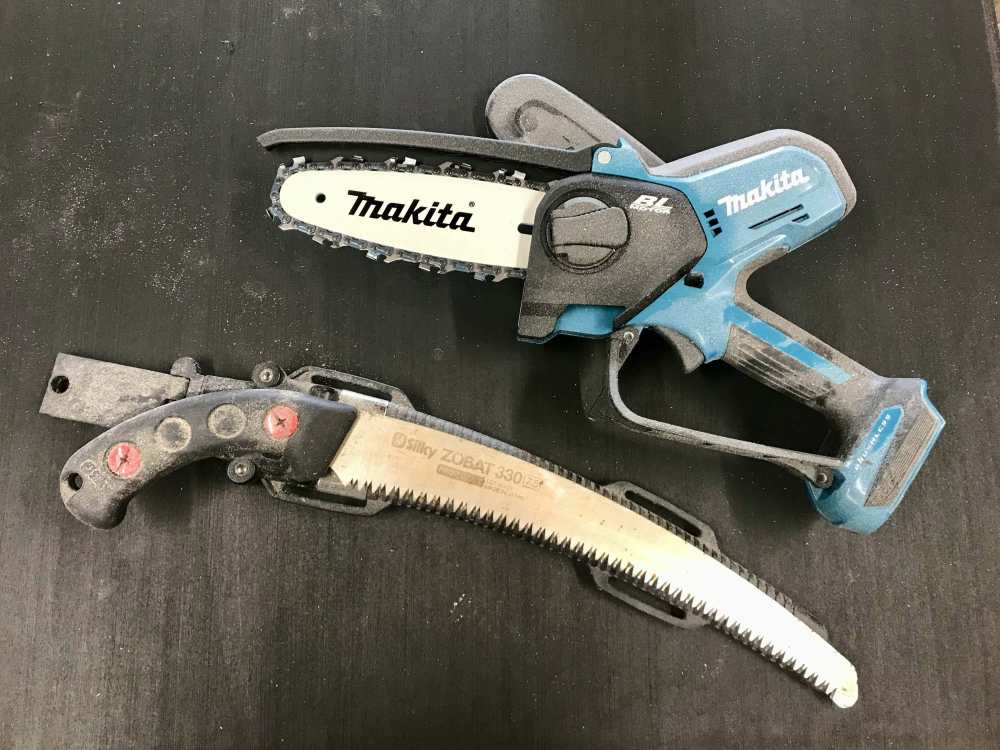

About to give this ago, DUC150Z for 50 metres of Devon bank medium hedge pruning / cutting back. Will let you know my thoughts in a few days Silky saw, no batteries required. -

What is this made of? Ceiling wood fibre board type stuff

Nestor replied to paro's topic in Building Materials

Looks like hardboard due to the staining but It could be a type of Sundeala board, wood fibre pin board originally. Is it slightly soft if you apply a little pressure to it from inside the loft? Very impressed with your clear up, proper job. -

Time for some new Makita goodies- any good deals on?

Nestor replied to Crofter's topic in Tools & Equipment

The Makita kit has been great. Just bought some 6.0Ah batteries from Toolden, always worth a search around for best prices. FFX now ITS https://www.lawson-his.co.uk https://its.co.uk https://www.powertoolworld.co.uk https://www.worldofpower.co.uk https://www.toolden.co.uk/tool-brands/makita/?utm_source=Klaviyo&utm_medium=flow&utm_campaign=Makita Cross Sell&utm_id=VXmYPi&_kx=iewy0UUI_HNqAKAOi3JbrAcYoka6HO07az6VLHTOI0U.WVZJJz