TerryE

Members-

Posts

3782 -

Joined

-

Last visited

-

Days Won

29

Everything posted by TerryE

-

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

TerryE replied to fatgus's topic in Heat Insulation

@fatgus I agree with your overall assertion that your design choices should be informed by through-life cost benefit trade-offs. You need to granularise to make doing this practice e.g. Wall U-value 2 vs 1.5 vs 1.2, etc. Also recognise that as-built might well vary from the design calcs due to mistakes in the design or construction quality issues: missing or sloppily fitted insulation, major leaks or missed thermal bridges. For example, our house works pretty much as design except that our slab losses are maybe 30-40% higher as build from a detail that caused edge bridging. So your heating / cooling system needs to have enough margin to cope with likely variations. Also remember that your heating / cooling system must be capable of adding / removing heat as needed. For example, we have a 3 storey house with only ground-floor in-slab UFH: no wall mounted rads and pipework anywhere; no heating on the top 2 floors. That is huge initial and ongoing cost-avoidance. See my blog for details. -

Interesting couple of days with the new heat pump.

TerryE replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

My friendly Gemini AI gives me 17 kWh/K so (1) is the right ballpark. However, I can't recall Mike giving details on his slab dimensions and profile. You need some assumptions about the profile, so mine has ring beams cross beams etc with a 10cm fill-in for the slab itself. If you simplify this to a cuboid slab with area 11×7½ then the average depth is 35 cm which is too high. I am at a loss as to where (2) comes from. If the slab is sitting on 20cm PIR then the downward loss would be ~ 120W for a slab at 25 °C sitting on a subbase at 10 °C, plus the edge losses which should be smaller. The amount going usefully into the house is ~ 7×A×ΔT which more in the 2-3 kW pallpark if is ~ 5°C -

Interesting couple of days with the new heat pump.

TerryE replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

No, that's me. 🤣 -

Interesting couple of days with the new heat pump.

TerryE replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Mike, one thing that you might try is get an idea of the time constant for the house at some point. Heat the house to some set-point and keep it at that for a couple of days, then tiurn off the heating for 24 hrs, say, and track how the house cools. We have low overall U-value loss, but high internal fabric total specific heat ("thermal mass"), so we lose maybe 1°C / per day with the heating off. This means that we can shift the heating windows to pretty much any time that the electricity costs are cheap and make maximum advantage of a ToD tariff. You might find the same, but some build techniques use a smaller slab volume inside the thermal envelope, plus low SH insulation so the time constant is shorter and the house loses 2-3 °C / per day. This impacts your best heating strategy, so it's a characteristic to understand. 🙂 -

Interesting couple of days with the new heat pump.

TerryE replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Mike, it looks very much as I'd expect, that is no surprises. I did warn you about the consequences of the 185s before you poured concrete but that conv obviously went into the information overload bin, but this falls into the 'it is what it is' category rather than something that needs fixing. The main consequence is that the flow speed is double what it would have been, with the increased circulation noise, and hit on your pump life. Your return temp is still 5°C more than room temp, so the avg slab surface temp is prob 7+°C warmer than the room env, and so you are dumping ~100W/m2 from the slab into the house, which seems to be heating the house by maybe 5°C per day. That's a hell of a lot for a passive class house, and you'll need nothing like that once the internal fabric is at target temp. You might want to experiment setting the house set-point to say 18°C and let the system reach equilibrium, leave a day or two; then step up the set-point another °C; rinse and repeat. That way you aren't going to be stressing anything too much. -

I've had ME/CFS hovering around in my life since my first collapse in my early thirties. Luckily I spiralled out into reasonably good health over the next year and for the next 25 years, albeit with the odd post viral wobble. However, I then had a second collapse in my mid 50s and was bedridden for more than a year and had to retire early. Again 8 years of slow recovery getting to a point in my 60s where we could take on the self build. This really was a sweet spot for us: we had the time, energy and enough capital to take it on. But TBH the build was gruelling and by the time we finished, I was "running on empty" so another ME collapse, and another year+ pretty much bedridden. So doing the build extracted a toll on my health and as I stretch into my 70s I am still dogged by fatigue problems. However we've downsized from an old stone farmhouse full of character (but also high-maintenance / expensive to heat and maintain) to a cosy and cheap to maintain modern passive-class home. At the same time we freed up some capital to help our kids on the housing ladder. So yes, it was all worth it, but it did have a life cost. I couldn't do this again.

-

+1 to Thanks for the update. We're all growing older. Jan and I are into our 70s now. We moved into our house a couple of months after you did. Overall we are delighted with our house, its environment and performance. We have made one change: we dumped the SunAmps for a decent UVC, and Jan is now keen to do a partial refresh of the kitchen, because some aspects of the design really grate. I hope all goes well with you both, all things considered. It would be good to get any further updates; A few of us are genuinely interested. 🙂

-

X3 Immersion heaters on a single radial

TerryE replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

You can get a range of contactors typically with 240VAC, 12VDC or 24VDC coil voltage. They all draw ballpark 1W to keep the contactor closed to the load on the control relay is ~40mA in the case of 24DVC, doubled for 12VDC, and a tenth of that for mains. I prefer using DC simply because all of the control stuff is low voltage which makes it easier to get signed off. -

None? We have 3 story passiveClass house in NN7. Lived in it for 8 years now. We have no heating on the top two floors. The master bedroom en-suite has a 60W towel rail on a Zigbee-enabled fused spur which automatically turns on overnight for about 6 hours in the heating months. We have an electric oil-filled rad in the hall well that outputs about 1kW and the CH system turns on as necessary in the cheapest (typically) 4-6 hrs on the Agile tariff in the winter months. This tops up the upper floors. Our master bedroom is about the coldest in the house and its at ~ 20°C ATM. It the house as constructed is truly energy efficient then you won't get a 10-15 payback on the installation costs of fancy solutions that you'll never use. E.g. that hall rad costs us maybe £100 p.a. and does the job. Do the math.

-

X3 Immersion heaters on a single radial

TerryE replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

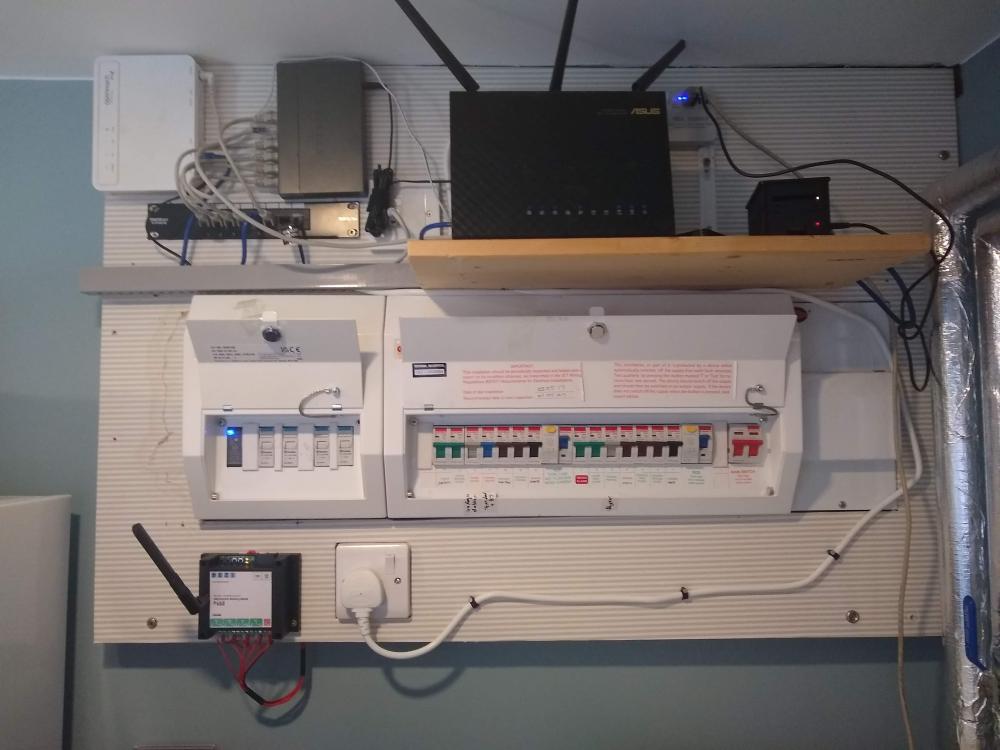

I use ½ blanks between my contactors, but a couple of W in a steel CU isn't really an issue. I had probs with my DIN mounted SSRs especially as my sparky had used an abs box. Luckily it was in a large closed cupboard so I could leave the cover off. I prefer my current setup. The RH unit was my sparky's work. The LH contains: 24VDC power, <gap>, contactor 1, <½gap>, contactor 2, <flyback diodes>, contactor 3, <½gap>, contactor 4 The 24V Tasmota 4×relay module is below. The red /black switch loom is all 24V. -

X3 Immersion heaters on a single radial

TerryE replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

@Mike, The power loss of SSRs is appalling IMO. The main issue is that the DIN rail form-factor ones get hot and this can cause oxidation on the power leads from the resistive heaters. Even with crimp covers the oxidation can cause probs. I haven't had any issues with the contactors. No you don't need snubbers on the resistive loads and I don't bother on the AC pump either as this only toggles ½doz times a day. No this issue is with your Shelly Pro 4PM which outputs 4 × wet 240 VAC signals for contactor coil switching. The inductance of the contactor coils is quite high so you can get field collapse arcing when they switch. I don't know if Shelley has internal snubbers, but this is something you need to check IMO -

X3 Immersion heaters on a single radial

TerryE replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

I moved away from using SSRs just under 2 years ago to an ESP32 module using 24 VDC to drive contactors. See p3 and 4 on this topic. My issue with the SSRs was that they had about a ½-1% heat loss in the SSR when on -- that's 15-30 W per relay. This caused real overheating issues with the DIN mounted SSRs. The contactor coil losses are a few W, so absolutely no overheating issues. I prefer using 24 VDC for relay control as this minimised safety issues in the microcontrolled modules. You just need to include flyback diodes to prevent the 24V relay contact arcing / wear. You really need to add snubbers for the 240VAC switching relays for the same reason. -

Thanks for poking me on this BTW @Nickfromwales, and I hope that you and the family have a good Christmas. Mike, Do a deep search on my posts on how I heat my slab etc., as I've covered this in depth elsewhere. A few comments / adjustments: As I described in my topic Micro-controller based power switching revisited in 2024, this showed my thinking and eventual rework of my UFH control and switching revised design. This was very much a discussion leading to final solution over the course of this long topic, so read to the end. But the key points were: I replaced the SSDs with DIN mounted CU-compatible 20A 240VAC contactors for switching all power circuits, e.g. Willis, pump, DHW×2. These have 24VDC contactor coils. (The parasitic heat losses of the Contactors are a few W which is a lot more enclosure friendly than 30+W of the power SSDs.) I use a generic COTS relay module powered by 24VDC and running Tasmota firmware; this allows me to use MQTT to drive all controls. These 24VDC outputs have dry contact outputs, which I prefer safety-wise so you should have flyback diode protection across all contactor coils, again see the topic. I use ESPhome firmware ESP modules with remote DS18B20 temperature probes on my Willis, loop out and returns, DHW top and bottom and central hall to aid my sequencing and control. I have my own DIY NodeRED app doing all of my CH sequencing and control, and I also use Home Assistant (HA) as my GUI (linked via MQTT), although the CH app is independent of HA and can keep the control regime running for days without HA input. The system implements various safety interlocks (e.g. the DHW Immersions are powered off once the UVC reaches target temp, the Willis heater is powered off if it gets above 40°C.) The Willis does UFH only, as the UVC is heated by Immersion, so I have no buffer tanks or low loss headers. The heating regimes are optimised for use with Octopus Agile tariff. I have a low-energy, high "thermal mass" house, so in general I (or at least my CH control app) pre-calculates the day-ahead heating requirements and then time-shifts UFH and DHW heating to the cheapest Agile time-slots in the day to buy the electricity at lowest prices, so last night for example we put about 22 kWh into our slab and UVC at about 3p / kWh so under £1 (and another £2 to charge our EV). As I describe in my blog ,the Willis OP gets dumped into our ~17 ton of insulated slab so this heats up slowly over the, say, 6 hr heating period by 5-10°C and the return goes directly into the Willis, so it never goes above 30°C in normal operation. Yes I do have a fairly complex NodeRED app controlling everything, but the electronics and hardware set up is all stack items and cheap as chips.

-

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

@Gus Potter I think that you should optimise any design within sensible engineering tolerances (say a 20% margin in the case of the thermal calcs for a self build, if you have proper review in the design process and QA in be construction). In our case, we split our quite large plot which ran parallel the the street and hence we had enough land to create a separate house plot with its own street access. This adjacency, plus being retired, and that we had previously completely refurbished our old farmhouse on the other half ourselves meant that we had enough knowledge and time to keep a close QA on the build process and to prevent any material off-spec deviations from the as-designed build. The as-lived-in performance of our new house as a system is about 15% lossier than the design and that was down to a single design thermal bridging mistake, which we didn't pick up during review, but did during construction and could therefore largely mitigate. As I said we peak at about 2 kW average heat loss mid winter (when the temperatures outside are below 0). I just can't see the point in having an UFH pipe layout that is capable of delivering 5× that or more. Our 3 loop ground floor UFH keeps our 3 storey house nice and warm, so we have no fixed upstairs CH at all. At some point we might consider an ASHP: I already have the pipework and dedicated 40A spur out to the target pad in place, but just not connected at the house end. We aren't eligible for the BUS and we would only net maybe £400 pa. in running cost savings, so we just can't make an investment case for installing one. A home battery is probably the next item on the wish list ATM. -

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

@John Carroll thanks -

The £250 is probably a fare cost of doing an assessment and writing up the report. "Free" means that they need recover the cost factored by win rate, say £1K, on the wins. I think the upfront cost is farer because those that decide to go with Heat Geek don't end up paying for spurious surveys.

-

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

Thanks for this, but I made a cock-up and hang my head in shame. I am getting a bit old after all. 🫣😨 I pulled the wrong pump photo from my house pictures. That was a pic of the pump in my old SunAmps which as you say is PCM controlled. My house is 2,000 miles away and I pulled the wrong pic. It's working fine at the mo, so this can wait until I get back on the 12th. I will update then. Sorry guys. PS I think it is a UPS2 25/40-60 130. This has an 240VAC input and H/M/L selector for speed control. 😨 -

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

John, I pressured the UVH to 1 bar on commissioning and topped after initial dissolved air bleed off. I haven't needed to top up since. I chose 1-bar because the Pump spec called for a min ½ bar and I could see any advantage in going above 1. The circulation is on the lowest pump setting and this seems to circulate the water fast enough. A good safely check is the willis temp as this rapidly climbs if the pump isn't circulating the water through the slab, and I do have a safety check on this. -

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

@Gus Potter, I agree with you in many respects, but also take an opposite view on some. I had just turned 65 when we moved in. Doing a self-build was only feasible for us at this stage in life when we had enough capital and time and effort available to take of some of the trades and jobs ourselves to reduce cost. You mention a 50-60 year objective, but we optimised for about 30 years, as I doubt we'll be around much longer than that. We put a lot of thought into our design and material choices to ensure that the house would be pretty much zero maintenance for that sort of time-frame, but the house should be good for at least another 30-50. If you are talking about a 50 year horizon, then the other key point is that the house has to be electric only -- which it is. The number of UFH loops is just a small design detail that should be matched to the house characteristics. In our case we need to put about 2kW (coldest midwinter) into the slab to keep the entire house at a cosy 22+°C, so 3×95m loops controlled as a single zone works fine for us. The UFH tail length (if long enough) is pretty irrelevant. I feel that your position about automation is about similar to the argument that our predecessors might have had 100 years ago about replacing gas and paraffin heating and lighting by electricity. Technology moves on, so reject it and get stuck in the past or accept and embrace it: this is a personal choice. In my case, our design choices reflect some principles (like all-electric and near zero maintenance), but beyond this they were largely driven by return on investment (RoI) criteria: I have minimised our running costs, and we won't invest in "improvements" unless the discounted savings over a 10-year per period exceed the net investment cost. BTW, I wrote my first computer program 57 years ago and my career was spent in IT so I am very familiar with programming and approaches such as integrated logistic life cycle management. This is why, for example, my CH system is independent of my Home Assistant (HA) stuff; why at a component/module level everything is pretty-standard multi-source commercial off-the-shelf, and i keep enough spares to be able to do cold-swap repair in less that 24 hrs. Putative new buyers could rip out all of the HA system and its IoT devices, but this would leave them a working CH and HW system. They could replace the entire CH / HW control system for under £2K if they stuck with resistive heating, or by then Octopus will probably have a bundled deal to install an ASHP with demand-side managing your CH, HW and EV on some flat-rate tariff. -

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

I do VPN into the house routinely to keep an eye on things. I've also got email alerting of any errors like this so I don't miss something on my TODO list. I do cycle the pump for 6 mins every 3 hrs - mainly so that I can log the slab temp, but doing this routinely cycle the UFH and stops any crud selling out in the pipework or pump over the summer. BTW, the Elec Installation sec of the pump manual warns that the pump can have an inrush spike of ~8A at on/off, so advises that any relay should be rated to handle this i.e. have AgSnO contacts (e.g. a contactor) so you might have cycle life issues with the Shelly causing it to fail after a few years. As to spinning these up, it's a two min job and there's even a YouTube howto on this. Next time send the customer a link and say this is a routine home owner job - or charger a hefty call out fee. BTW if you are passing the MK area and need an overnight / nice meal then give me a shout - so long as we are in country that is. 😄 -

Grundfos Pump Occasionally Stalls on Willis based UFH system.

TerryE replied to TerryE's topic in Underfloor Heating

It's a Grundfos UPM2 15-70 CIL2 that runs at about 40W. Easy to bump start manually except that I am in Greece at the moment and my house is over 2,000 miles away in the UK, but back home in just over a week. In the meantime, I've downloaded the manual for this model and will read it. I will also monitor the HA system to see if we get any more stalls. The water is inhibited but there is little scope for electrolytic corrosion: no rads; just the PexAlPex going into the Wunda manifold and a short loop-back through the Willis. The expansion vessel and fill input is T'd off this. I need to give my live-in son some basic plumbing and home automation lessons. 🤣 -

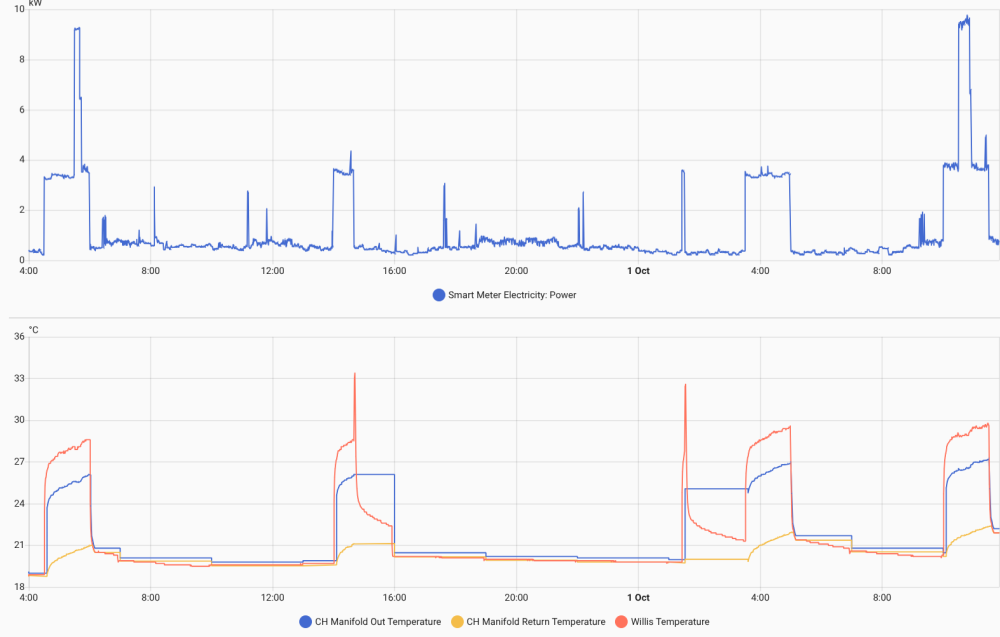

Short version: We have an 8 year old passive-class all-electric house running on and optimised for the Octopus Agile tariff with electrically heated wet UFH. We made the house ASHP ready, but didn't install one during the build, instead using an inline Willis heater as a "temporary" solution to allow us to size the ASHP on actual house performance. In practice the running costs are low enough that we've never made the RoI case to install an ASHP so here we are 8 years later and still using the Willis. One of the major advantages of my design is that it has very few moving parts so pretty much no servicing maintenance is needed: some CU mounted contactors, some commercial ESP based modules, the Willis and the UFH pump. I keep cold-swap spares for the relays, modules and the Willis. But now the pump has occasionally stalled. Is it time to get a cold-swap spare or should I just have done and replace it? @Nickfromwales you are the oracle on such matters. Longer supplementary. My CH control system is a NodeRED based app comprising about 1K lines of JavaScript and some NodeRED flow including maybe 50-100 other NodeRED nodes -- a fairly small app by NodeRED standards. This uses MQTT to talk to the ESP modules and to share data with a Home Assistant instance which I use as a general Home automation interface. My basic strategy is to move any time-shiftable electricity loads to the cheapest Agile tariff time slots: white-goods, EV, HW and CH heating. This is workable because the thermal capacity of the house is so high that it doesn't really matter when I schedule heating so long as I top up enough each day overall. Each day just before tariff roll-over, the system calculates the heating required for the day ahead and allocates a heating schedule so that we do this at the cheapest price. So our typical electricity use is a base ripple of stuff that can't easily be time shifted, plus big blocks of power draw at the cheapest prices that day. See the graph below which is an extract for 32 hours starting 4 AM yesterday. The top plot is our spot energy use taken from our smart meter; the bottom plot is the Willis temp, plus the average out and return flow temps from the UFH loops. The cheapest price slot was 04:30 - 06:00 so that was when the main UFH heating slot was scheduled (the spike to 9kW spike was when the HW immersions also kicked in) ) You can see the typical UFH heating curve: The Willis quickly heats to ~27°C with the average out flow to the UFH a couple of degrees cooler and the return at 19°C (the overall slab temp); these all slowly rise together by about 2½°C over the next 90 mins as the heat transferred warms the slab around the UFH pipe. This pattern happens on four heating cycles during this period. BTW, the out & return flow temperature readings are steppy because these thermometers are only read if the circulation pump has been running for at least 5 mins, because these rapidly settle to the ground-floor ambient temperatures without circulation. The pump is cycled for 6 mins every 3 hours to enable the slab temp to be tracked. Note that some went wrong at 14:41 and the following 01:31. Here the Willis suddenly started heating rapidly until the 35 °C safety trip was exceeded and the CH system turned off the Willis. The system log shows that the pump relay was still on but the water wasn't circulating: it had stalled at 14:41 and was still stalled when it came on again at 01:30. What is odd is that it started correctly at the 3:30 heating slot, so the stall is intermittent . Very odd.

-

BTW the little <> icon in the post form can be used to insert code, e.g. try: dt = parse_ts(s) assert dt.tzinfo is not None and dt.utcoffset().total_seconds() == 0 print("OK ", s, "→", dt.isoformat()) except Exception as e: print("FAIL", s, "→", repr(e)) It also does nice syntax highlighting. You can also use the TR ... icon to edit previous posts and add code formatting 🙂

-

Fabric and ventilation heat loss calculator

TerryE replied to Jeremy Harris's topic in Heat Insulation

@flanagaj IMO this is in the noise. JSH's sheet is an approximate indicator for general sizing. Yes, you could net off the fenestration area, but then again windows etc. typically have ~10× the U-value of decent wall profiles. Also you also get additional edge-effect heat losses where surface meet such as where walls meet and where fenestration meets the surrounding wall. This is roughly of the same order as this netting out, so I wouldn't bother. This simple model is a useful tool but will always be maybe a 20+% under estimate because of this edge effects and bridging losses that always creep into as-built houses.- 204 replies

-

- 1

-

-

- heat loss

- ventilation

-

(and 4 more)

Tagged with: