hb1982

Members-

Posts

40 -

Joined

-

Last visited

Everything posted by hb1982

-

there is an acoustic benefit when using heavy rockwool insulation in pitch-roof construction.

-

first of all need to understand which noise you would like to reduce, the high pitch or the low humm or the vibration. Then pick a good quiet washing machine; run in night mode; good floor construction. Locally sound proof the surround of the washing machine Lastly good solid wall from top to bottom (ceiling void and floor void well sealed) with high density construction.

-

Rega Vent MVHR Reviews

hb1982 replied to bob the builder 2's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Have you asked them what material is used in the heat exchanger core? Not sure how much it costs but you are buying: 1. no SAP rating 2. no leakage class tested 3. no summer by-pass damper 4. questionable condensate management (tray / fall / material) 5. single skin construction 6. no filter protect the heat exchanger -

Saw this, whatcha think?

hb1982 replied to CalvinHobbes's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Remove air pollution from sources. If outdoor air is polluted, we install suitable air filter to remove pollutants before drawing air into the indoor space. If there is pollution sources within the house, we remove pollutants locally, e.g. fume from cooking and moisture from wet rooms. We only install air filter when there is a reason. -

air from recirculation hood is only as good as the filters permitted. I believe premium brand products could perform better but you can never tell until you have the system purchased and installed (and no turning back).

-

that is like an highly insulated box. sounds like the cold could be from air infiltration or generally the room is not heated?

-

The delta T was based on 12C (30degC in UFH vs 18degC in non UFH) as you suggested in previous post. The BEV/ICE may not be a good example but that is not really the conversation here. As a home owner, there is no harm to go with better insulation as long as the decision is informed. £800 is cost difference on the insulation only. There will be extra due to extra digging and removal of earth subject to your site condition. Subject to your location, the carbon payback could be questionable as well. My original reply, to be honest, was trying to answer the OP question, i.e. if 75mm floor insulation is sufficient. My answer was/is yes from the building regulation perspective. Solid slab U-Value calculation is different from suspended floor calculation. If the P/A ratio is right, 75mm PIR in the said sbuil-up could meet the building regulation requirements.

-

For a 50sqm area, the 0.07W/m2K difference is going to give you around 40W extra heat losses theoretically. For a ground slab, it could be less or more subject to the ground temperature fluctuation. We may all have different perspectives on this. From a builder perspective, 75mm PIR in a 0.4 P/A ratio scenario, it meets the building regulation and he saves £800 on insulation material and more on avoiding extra digging / grab lorries / time. From a homeowner perspective, it will take a lot of heating hours to payback that £800 + £ xxxx costs. It is a similar conversation like if electric cars are more eco-green considered that huge amount of lithium is required to be dug from ground.

-

The floor buildup suggested is a solid concrete slab on ground (not suspended) in a house extension. If you check out the Kingspan Insulation Calculator 75mm Insulation (PIR) - 0.40 P/A ratio (e.g. 6m extension for a 8m wide room), the resultant U-Value is 0.17W/m2K. For 150mm insulation, the result is 0.10 W/m2K, that what I consider as an overkill (at least from the builders perspective) https://www.uvalue-calculator.co.uk/calculator/floors/ground floor/solid concrete - insulation below screed/0.4/75/

-

probably same principle of using breathable membrane in suspended floor insulation application (rather than just chicken wire), to avoid wind washing.

-

U-Value for floor, in solid slab on grade, is subject to the perimeter to area ratio. 150mm in general is an overkill. Regards

-

MVHR UV Filters

hb1982 replied to Dave Jones's topic in Mechanical Ventilation with Heat Recovery (MVHR)

if the filter is out of air stream (min. pressure drop) and the air velocity within the chamber can be achieved (to meet the UV filter spec), there is no reason not. The question is why you want a UV filter in your MVHR? We, human being, should be exposed to some degree of germs/bacteria/virus in air and water to maintain our immune system. super clean air and water is going to do more harm than good in the long term unless you have other medical reason. -

Controlling MVHR preheater

hb1982 replied to markocosic's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Heating Typical domestic installation would use electric heater with integrated control, to maintain off-coil temperature at 3 to 5 degC. In your case, with hot water source, you can: 1. Buy the right heater (I supposed you can buy a 150mm / 200mm dia. circular heater easily online), plenty of option on the consumer market 2. Connect to the brine circuit 3.A simple solution is to use a TRV (Thermostatic Radiator Valve) with remote temperature probe. Put the probe in the off-coil position and to turn the set-point to minimum (may be 10 degC)? Otherwise, you may need to install a proper valve with actuator linked with a PI (Proportional- Integral) controller Cooling More complicated. You cannot use a heating coil for cooling. I would install a dedicated cooling coil in this instance to make your control and piping easier. For control, you will need a PI controller with duct temperature sensor. Alternatively, you can get hold with a 4-pipe FCU (Fan Coil Unit) controller, you can use a single controller to control both heating and cooling. -

The one from Victorian could be the same as those on ebay at half the price. (not here to promote the use of unbranded product) Grohe / Crosswater / Travistock are all more expensive but you have the comfort of quality and less likely require repair / replacement in the future. A lot of job lot discount on ebay to be honest. Trade can get those products at like 40% of RRP.

-

Plumbing pipes - copper v plastic, different sized pipes

hb1982 replied to Porthole's topic in General Plumbing

Good quality plastic if installed properly should last as long as copper. When installing plastic: 1. Use as few fittings as possible. use cold form bend fitting where possible. 2. Support and clip pipe as per instruction, usually every 800 to 1000mm 3. Only use pipe and fittings from the same manufacturer 4. Remind to install one size bigger in plastic installation. e.g. 15mm copper is (I.D. 13.6mm); Plastic 15mm (nominal) - I.D. is 11.3mm. 5. Press fit is better than push fit but not usually available in domestic contractors 6. PEX pipe is far better than grey PB pipe. -

Is my house suitable?

hb1982 replied to jayc89's topic in Mechanical Ventilation with Heat Recovery (MVHR)

For clarity I supposed that is for side wall installation, at high level as close to the ceiling as possible? -

MVHR cooker hood idea

hb1982 replied to woodman's topic in Mechanical Ventilation with Heat Recovery (MVHR)

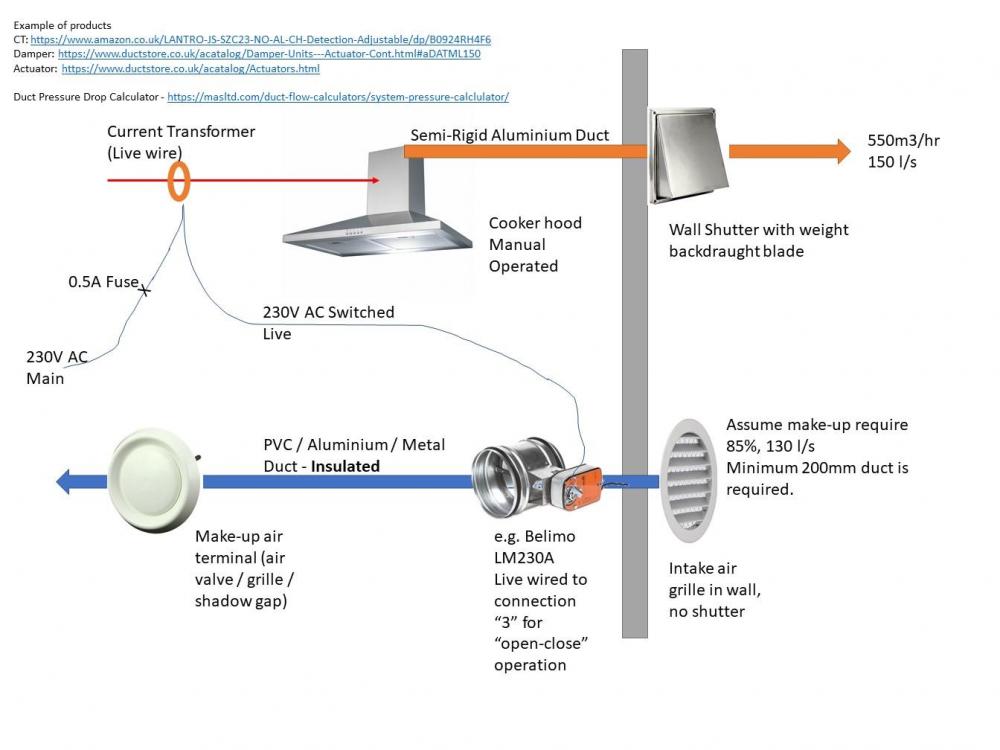

I hope the attached makes sense to you. A standard hood extraction of 150l/s (good quality 900mm hood) is not small for an air tight house. 200mm duct is recommended, 150mm is the absolute minimum. -

MVHR cooker hood idea

hb1982 replied to woodman's topic in Mechanical Ventilation with Heat Recovery (MVHR)

That was a specification for high-end residential to avoid recirculation hood. TBH it sounds like a commercial type installation but could be DIY. A 4"/6" motorised damper with belimo actuator, normally closed, drive open. 230V AC power supply, a current transformer to sense the extractor operation and give power to drive open the Belimo actuator. May be around £ 200 to 250 on materials? A less sophisticated version is a weighted shutter to control the make-up air. Make sure the mark-up air duct is properly insulated to avoid condensation. Your kitchen extractor should be fitted with wall shutter with weight backdruaght damper in external wall face as well. Blauberg sells some good looking stainless version (I used plastic only in my house extension but added weight to the shutter to make it less flippy). I don't have MVHR therefore rely on make-up air via trickle vents. -

MVHR cooker hood idea

hb1982 replied to woodman's topic in Mechanical Ventilation with Heat Recovery (MVHR)

How air tight is your house? Otherwise can you provide make up air via trickle vent; openable windows or dedicated air valve ; weighted damper etc. In some high end residential I specified, we put in automatic make-up air damper triggered by the extractor via a current transformer. -

your structural would state on the drawings that when digging and filling the trench foundation, you may need to do that in 2 steps (although most builders would ignore that). Are you planning to build right against the neighbour garage wall without gap?

-

MVHR flow rate - safe to reduce it ?

hb1982 replied to ollie's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Objectives of ventilation are - provide clean outdoor air - maintain CO2 level to acceptable level - remove humidity - remove other harmful pollutant CO2 is the metric used normally for occupied space. 1,000ppm was the gold standard but modern building design target a range around 800ppm. 660ppm (suggested by another poster) is very hard to achieve as the atmosphere CO2 level is around 430 ppm (it was 370ppm when I was in my first year degree 20 years ago). to achieve 1,000ppm, you need 10 l/s per person. to achieve 800ppm, you need 15 l/s per person. Both are based on steady state model, no matter how big your space volume is. Figure 2 here illustrates it. https://www.cibsejournal.com/cpd/modules/2014-10/ Do typical MVHR installations provide sufficient ventilation in an air tight house under "work from home ; 24/7 stay at home" scenario? I very doubt it. Open windows if you have a chance! -

Insulating a pebbledash solid wall and damp concerns

hb1982 replied to Ben Weston's topic in Heat Insulation

In my case, 1930 semi detach with original pebble dash, I applied 100mm EPS and K-Rend, normal plaster on internal faces. Loose pebble dash was brushed off and retained. EPS stick on retained pebble dash surface plus mechanical fixing. Bottom EPS layer supported by a track system. I did my own IES fabric analysis and I was satisfied there is no predicted condensation risk. All wall DPC was checked carefully and the suspended floor ventilation had been retained. Good breathable paint is used for all surfaces (including external wall below DPC) The house is ventilated internal with mechanical extraction, trickle vent air make-up. I am not a fan of MVHR in general as I have seen too many MVHR failure in my working life. -

Death of MHRV unit

hb1982 replied to DaveAndAnnaUK's topic in Mechanical Ventilation with Heat Recovery (MVHR)

with the amount of mould growth I would imagine the heat exchanger inside is gutted. hate to say it but mould spore is hard to remove from duct surface. Physical brushing / cleaning / wiping is required in my experience. -

Is a cooker extractor necessary with MVHR

hb1982 replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

£159 for two black filter blocks... I wonder what they are made of.... -

Is a cooker extractor necessary with MVHR

hb1982 replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I am a strong believer that grease, smell and moisture should be discharge to the atmosphere in the most direct way. If recirculation is preferred to match with MVHR installation in an air-tight house, it should be done again to minimise pressure drop; discharge air to open air (avoid damp); best possible filtration with regular maintenance.