Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/17 in all areas

-

3 points

-

How about a length of st/st Unistrut? Plenty of pre drilled slots. If you fitted it toes up you could hook over the edge.2 points

-

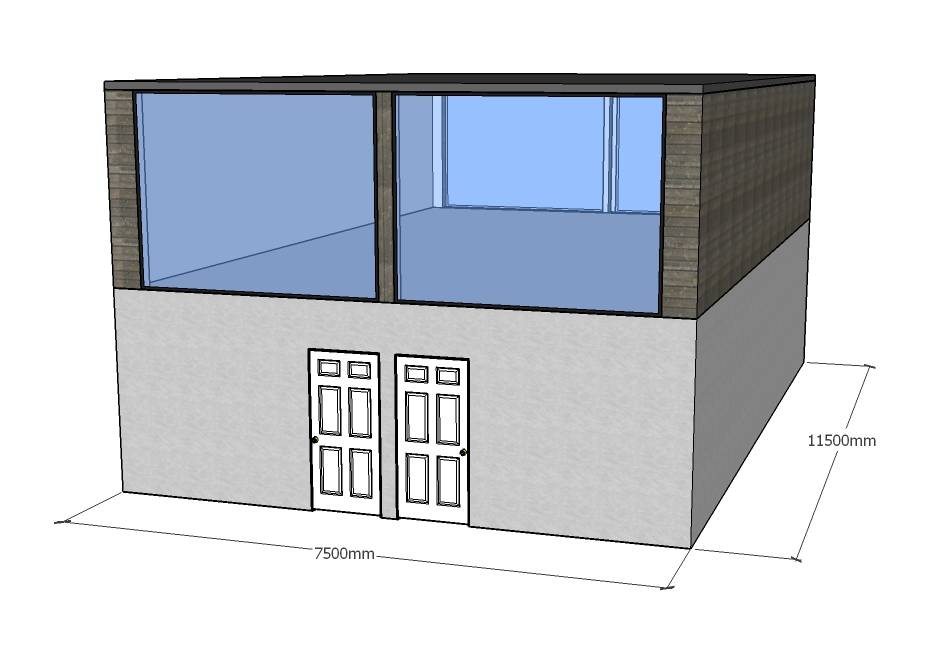

Hello I'm going to build a one storey garden house with basement this summer. I haven't really build a lot before so I would appreciate an advice here. The site is very tight and one of the objectives of the project is to utilise as much space as possible efficiently, so every inch of the wall width counts here. I'm going to build it mostly myself with one assistant builder and have to squeeze the project into a lowest possible budget. The building plan as very simple being effectively just a box of 7.5m x 11.5m with basement and 1st floor both 2.5-2.7m tall. There will be one internal non-bearing wall and a flat roof. 1) Basement walls and ICF ICF blocks seem to be hugely advertised nowadays by I'm not sure is there real value behind it? Self-building seems pretty straight-forward especially after studying manuals. I'm considering the possibility of building either basement walls of ICF and first floor of SIP and frame or building both basement and first floor of ICF. Does anyone here have experience with them? Should I really be using them especially in terms of saving precious centimeters of the wall thickness while achieving sufficient U-value There are quite a few ICF suppliers on the market, which ones are cheaper and still good quality? I've requested a quote from Nudura (and studied their docs quite thoroughly) but expect the quote to be quite high If not ICF that which other options should I consider for basement walls? What would be your opinion on the thickness of these walls. I know people are mostly using 8" and more thick concrete for basements, by do you think it would be technically possible to go with 6" by adding extra rebar? Or even 4". I just must save every extra inch, that's crucial 2) First floor walls, roof and SIP I was thinking maybe I should build everything higher than the basement of SIPs? Including the roof. Am I right that I wouldn't need vertical steel supports for SIPs in such a case? Which other ways for building first floor and roof should I think of? It should be space efficient. Also I'd better save on extra labour in favour of pre-build units like SIP. I'd be glad to provide any additional information needed.. Thanks!1 point

-

I wrote this on Ebuild. "The weyrock comes in a 600x2400 format so they'll generally be laid at 90 degrees to the joists. You'll then have around 6 joists (if the joists are at 400mm centres ) per board to fix into. Over the 600 width I always fit 5 screws, 1 in each end 50mm in and 1 in the middle of the board. Then another 2 screws in the remaining gaps. PU ( polyurethane ) glue ( or 7 day glue as I call it as that's how long it takes to get off your hands !) is an expanding glue similar to expanding foam bought in a can but is applied like a liquid/pva glue. This stuff starts to cure within 60 seconds or so of being open to atmosphere so never glue up more than one board at a time!!! Dry cut and lay your first row of boards, and mark the joist with the outline so you don't put down more glue than you need ( I stop 50mm short of every board as the glue typically expands to the end anyway and it saves cleaning of excess cured glue when on the next dry run). Lift the boards, appy glue to joist tops and lay your first row of boards to suit, gluing the 600 tongues but NOT the long tongues. Have a dry full board handy at this stage and span it across the joint of the first two boards, as this will tell you if the first run is nice and straight. Only then start screwing the first boards down. NOTE, the glue goes off in about 5 mins, so don't hang about. You need to be on your toes with this and have all things needed close to hand. Screw, glue and repeat as required ! :-)The screws need to be 2" or 2 1/2" No.10's ideally, which is what I use, as No.8's tend to have a small head and pull through the boards. The important part is NOT to use a screw which us fully threaded ( has thread from tip to head ). The ones I use are part threaded with about 1/2" of clear shank before the head. The reason for this is fully threaded screws tend to promote 'jacking', which is where the screw goes through the board, hits the joist and then lifts the board slightly before the screw bites and pulls into the joist. Unless you ram the screw half way into the wayrock to pull this gap closed ( bad thing to do ) then you will be left with gaps and that point of the flooring being supported by the screw. :-( Screw the part threaded ( flooring ) screw into the board and stop when the screw head is just under flush with the top of the wayrock. Don't keep tightening as most good cordless drills, particularly impact drills, will happily pull the screw right through the wayrock, and out the other side. The fact that the screw head starts to pull through and countersink itself tells you that the board is tight against the joist so stop there!Speed is of the essence here as the glue is great, but goes off really fast. Before laying your next row of boards, check under the previous tongues for any excess cured glue and remove if necessary, as that'll stop the boards fitting snug into the next groove. A good idea is to have a can of gun grade foam 'cleaner' handy to keep tools and hands clean as this glue is a bugger to clean off when cured. I @!## you not :-@ don't apply more glue than needed as this will expand about 20 times its original mass, less is more. If you see a lot of uncured glue oozing out of the joints when you bring the boards together you've used too much! Seeing expanded cured glue coming out after is normal though and means you're joints are solid. Regards, nick." The rest of the thread is here.1 point

-

Well my floor was laid by my builder and supplied as a kit, the 22mm polythene protected flooring sheets were glued only to the Finn joists with foaming D4 glue ( don't know what brand) and my builder has been doing floors this way for years and never had a problem or a reported squeaky floor ( my pet hate).1 point

-

Re. the roof in SIPs. I got some quotes for mine, supply only, and they were eye watering. Regardless to say I won't be using it.1 point

-

Cant disagree with that. What you have to keep at the front of your mind is that this is a holiday let, and all guests will care about is that it is warm and cozy. They are not going to care how that is achieved, and the simpler / more automated it is, i.e. the building is always at a constant temperature so they are not having to fiddle with controls, the better.1 point

-

1 point

-

I vill say zis only once....SPAX: http://www.wickes.co.uk/Spax-Chipboard-Flooring-Screws-4-5-x-60mm-Pack-300/p/140812 This is 22mm on 400ctrs. No glue, just butted tight. SPAX screws in the middle of the board and on each edge. Solid as a rock and no squeaks whatsover.1 point

-

If you are going for tiles then the advice I have received has been 18mm ply both ways with a lot of screws to make it rigid. Alternatively I have seen them just filled with ashphalt. We got rid of a step down into a room that way. But out if you have a concrete base below tiles I am not sure what all that wood is about. Why not just put a DP membrane down, then insulation down - your 75mm celotex, then fill it up with self-levelling concrete, then tile on that. Is 35-40mm concrete cover enough in these circs, @PeterW ? Or use a screed instead. You could put wooden floor onto concrete directly.1 point

-

1 point

.thumb.jpg.4eacb68daaabfa619e8d69fcda06e560.jpg)

.thumb.jpg.f9421cb0de2ce9c8aaad1785112cef63.jpg)