Search the Community

Showing results for tags 'solid walls'.

-

I’m renovating a small mission hall on the Isle of Lewis in the Outer Hebrides. Due to it’s already small internal size (7.500 x 4.500), I was thinking of looking at external insulation rather than internal? Its a solid wall construction (approx 500mm+) currently with an external pebbledash finisish. Any thoughts or recomendations?

- 19 replies

-

- solid walls

- stone walls

-

(and 3 more)

Tagged with:

-

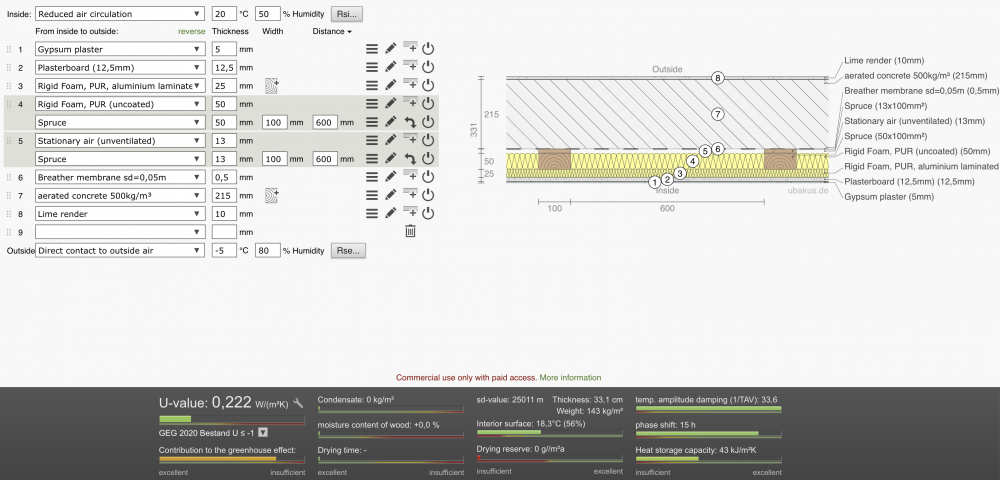

Could someone please sense check this insulation for a solid wall for a garage conversion. I have asked building control but they said they weren't interested. Things I'm not sure about. I have a very small air gap but I think this is countered by the breather membrane, does this make sense? Using uncoated PIR (thinking this General-Purpose-Polystyrene to save quite a few pounds) between the battens because the outer layer of PIR will be coated and act as the vapour barrier. Apologies have asked this question before but slight change here in the makeup so want to make sure I get it right. Thanks in advance

- 8 replies

-

- solid walls

- insulation

-

(and 1 more)

Tagged with:

-

I'm in the process of planning a detached garage conversion. The wall will need to hold some pretty heavy and important things like: Boiler Consumer unit Wall mounted server cabinet So strength of fixings is going to be important as well as insulation and U/R values. Reading up it looks like fixings for insulated plasterboard are a bit of a pain and don't get great reviews so leaning towards Stud walls with PIR between and plasterboard on top making sure I have extra timber where needed. Given the construction (from planning permission history) is rendered 200mm lightweight block-work. How do I go about calculating the construction for insulation? I seem to be reading conflicting info on whether you need a void depending on whether you have a vapour barrier or not so my initial thoughts from outside-in are: Render 200mm block-work Damp Proof Membrane (any reason why not?) 100mm studs filled with 100mm foil backed PIR Vapour Barrier 12.5mm Plasterboard Skim Layer Is this going to achieve the 0.30 W/m²·K to satisfy Approved Document L - England, Existing Buildings - Refurbishment requirements? Block-work looks like this currently

- 6 replies

-

- solid walls

- insulation

-

(and 1 more)

Tagged with:

-

Hello, Can anyone help with the positioning of bifold doors within the thickness of a solid wall aperture please? (i.e. towards the room side, middle or exterior side of the aperture). I can see there are various considerations, although I can't find much advice online for solid walls. I'd like to maximise the internal space in the room if possible, whilst maintaining good thermal properties, rain resistance etc. I've attached a screen grab of my architect's proposal (plan / overhead view). He has the exterior glass of the bifolds inset 225mm from the exterior face of the brick, thus the overall bifolds unit is closer to the room side of the aperture. Note the blue steel column / I-beam immediately adjacent to the frame. I'd like to move the bifolds a little towards the exterior side if possible to maximise the internal room space - I'd appreciate any thoughts anybody might have on the various implications of that please, thermal or otherwise. Thanks.

- 1 reply

-

- bifold doors

- solid walls

-

(and 1 more)

Tagged with:

-

I'm trying to find out what insulation options on a solid walls I have and which ill choose so advise or suggestion's insight in any way would be welcome i have been told they are grants for this work this could even be a factor when making my choice

- 10 replies

-

- insulation

- solid walls

-

(and 1 more)

Tagged with:

-

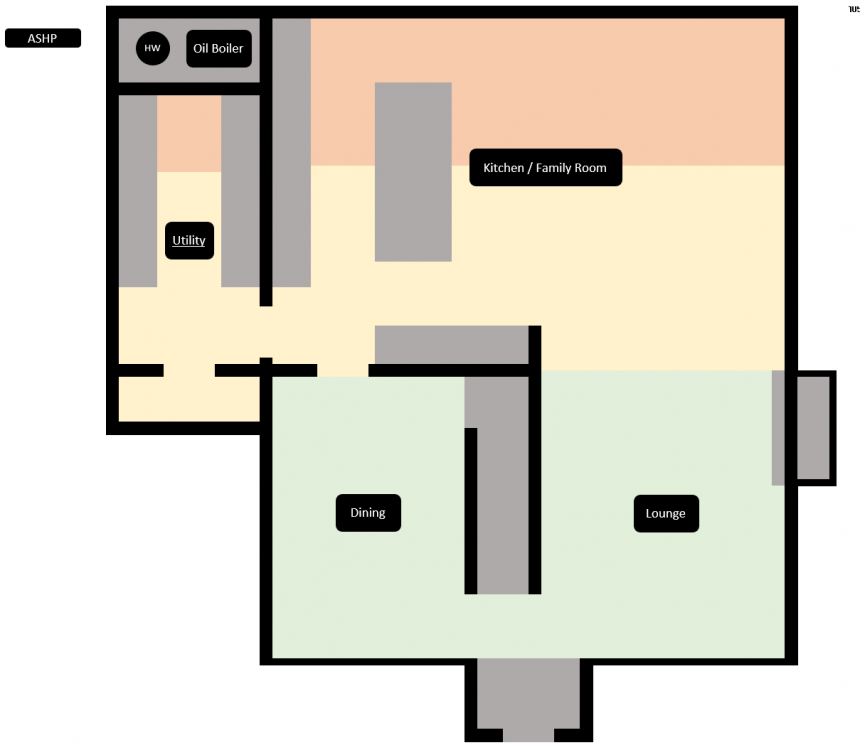

I'm in the early stages of the refurb of a 1917 property in Kent. The rough downstairs floorplan is below - The floor is a real hotchpotch of suspended floor (45% - Green), Previous extension concrete floor ( 35% - Yellow) and New proposed extension (Orange 20%). The current EPC is a horrible 23 and we're looking at using a combination of internal and external insulation to improve this. This may be an opportunity to seal the house (replacing floorboards?) Trying to bring all the potentially different technologies and solutions together is a challenge and every choice seems to lead to a particular specialist supplier that may have a particular axe to grind/product to sell. There is a wealth of knowledge and experience on this forum that I am very glad that I have found. Regards Tet

-

- ufh

- solid walls

-

(and 2 more)

Tagged with:

-

Hi All I am about to embark on a renovation and extension self build for the first time. Very daunting. The property is a 1920s solid wall construction and I hope to build the extension using 7nm block laid flat to provide a 220mm solid wall. The whole building will then be wrapped in external wall insulation and faced with brick slips. A MVHR system will control the air exchanges in the completed property. I'm sure that I will have lots of questions along the way so look forward to receiving you feedback both positive and negative but all hopefully constructive. Existing and proposed plans attached. Regards Mark Plans.pdf

-

Just getting my head around wall construction and the balance of vapour, heat and draught resistance and how they work together. I'm planning to renovate my walls (internal, as neighbours in the terrace aren't necessarily enthusiastic) house-wide - the solid double-brick victorian design (basically just bricks with plaster on it) has some significant room for improvement. But there are a dizzying array of options and configurations for internal wall insulation and it seems like information "out there" hasn't quite kept up with our developing understanding of water vapour and airtightness. Here's my current understanding, am hoping folks can correct me where I'm wrong (from outside to inside): 1. The air outside: The weather here in the UK is rarely on average over 21C, so the inside of the house will almost always be warmer. So the design needs to address water vapour that is *leaving* the house, getting cold and turning to condensation at some stage during its exit from the inside rooms. Not much reason to worry about water vapour coming in from outside. 2. The outer structural layer, that is in my case a solid double brick layer has a Vapor Resistivity, N s/(kg m) of 45 - 70 (got that from here: from here: https://www.engineeringtoolbox.com/vapour-resistance-d_1807.html). This means that it is "semi-permeable" 2b. Leaving on plaster (or not): Most of my walls have plaster (in some cases lime plaster, but haven't done an exhaustive survey), which I gather is straight-up "permeable". I can't see a consensus as to whether it's better to remove or not remove plaster, but I gather it may be necessary to remove (a) so that one can assess damp problems in case they aren't fully permeating the plaster to the inside layer of the wall (to show on paint etc.) and (b) so as to install some sort of membrane, or (c) obviously to address where there has been damage, and it seems to make more sense to leave it off if it's already off. But it seems like some folks like to save time and energy by leaving it on if there aren't mitigating situations. I'm about 70/30 leaning towards removing paint and plaster to expose the brick and check things out properly. 3. Air gap (or not): I've noticed some disagreement as to whether an air gap is now necessary. I gather an air gap is needed so that air can circulate vapour so that it can evaporate or vent out through the brick wall rather than condensing as it might in a tighter space without air. For the air gap, I can do battens over walls - and it seems that wood and stainless steel are the likely options here, nailed or screwed. Steel is more expensive, but will avoid rotting better than wooden battens (though damp proofing should ensure this isn't happenning!). Seems like Damp Proof Membranes are also an alternative, but a bit of overkill for my purposes here as it's not a cellar and all walls are above ground. But then the 4. PIR boards. I'll get these with foil backing, as this has an astronomical Vapor Resistivity value (4000), putting it on the very high end of "vapor impermeable". But it seems that some folks prefer the more labour intensive but easier-on-battens-long-term "warm battens" approach, where a insulation is split into two layers (a) a membrane is put down with half or more in layer of foil-backed insulation and then (b) an inner layer of battens with more insulation boards inbetween. This keeps warmth around the battens and ensures that moisture will condense further out in the wall. This seems reasonable to me - and I don't mind the more challenging job if there's an efficiency to be gained. What I'm not sure about is whether to use a membrane or foil-backed insulation boards for the vapour membrane at this stage. And if I use a membrane can I skip the air gap? 5. Plasterboard. "semi-permeable" here, skim on some plaster and ready to go. With regards to thermal transfer and insulation performance, here's what I've got: 1. Air = cold 2. Brick wall has u-value of 2 W/m²K or so 3. Air gap will reduce this slightly 4. PIR boards have a very low U value, which is why they'd be preferrable in walls to various wolls, cellulose, or other good options. I'm aiming for 70mm PIR or more (if possible) to try and get as close to or lower than my target U-value of 0.30. 5. Plasterboard adds a bit here too, but not much. Compliments of diydoctor, here's a diagram of what I'm doing: Option 1 (keep plaster, cold battens): Option 2 (warm battens - ignore blocks in picture): Option 3 (with service void): So questions are: (1) Is there a way of adding internal wall insulation on a solid double brick wall using new "tech" which will enable me to skip the air gap? (2) Should I strip plaster off the wall? (3) What's the best material for battens? (4) Any tips on how/whether to do a service void? I'm going to wire the whole house with ethernet and rewire electrical, so this wouldn't be out of place. (5) I've noticed comments elsewhere by @Jeremy Harris regarding a need to do graded vapour permeability, starting with (as he suggests): "the least vapour permeable and the outermost layer is most vapour permeable". This approach seems to be pretty difficult with internal wall insulation. Or am I allowed to ignore the plasterboard for the purposes of this kind of calculation? Would love to be enlightened. Note: this was quite helpful: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/658604/BEIS_-_SWI_Innovation_Final_Report_-_FINAL_Approved.pdf

- 7 replies

-

- vapour control

- pir

-

(and 4 more)

Tagged with:

-

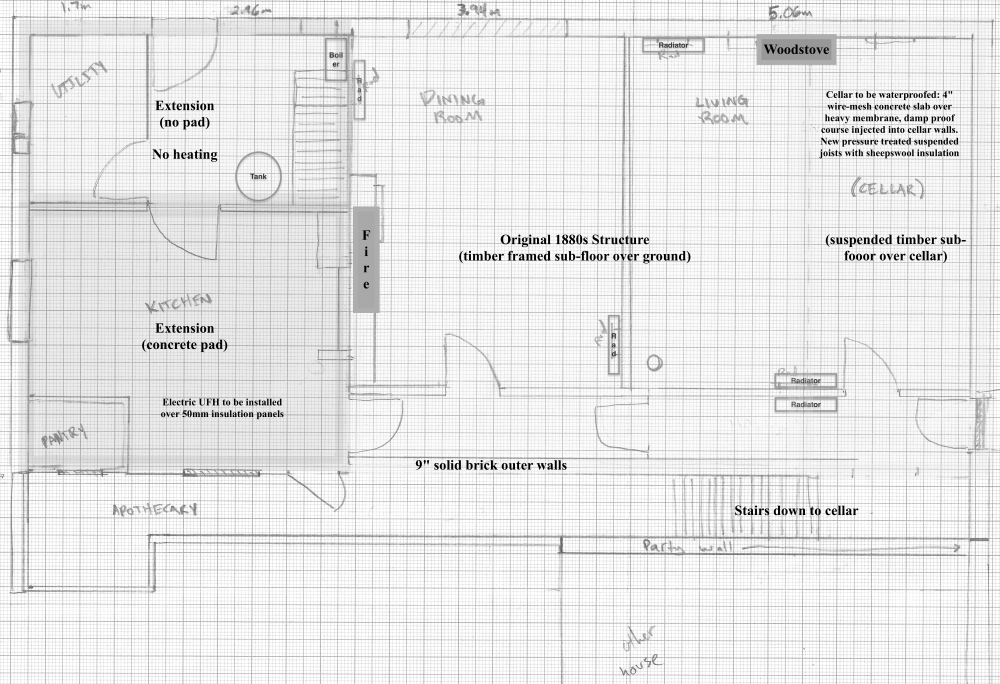

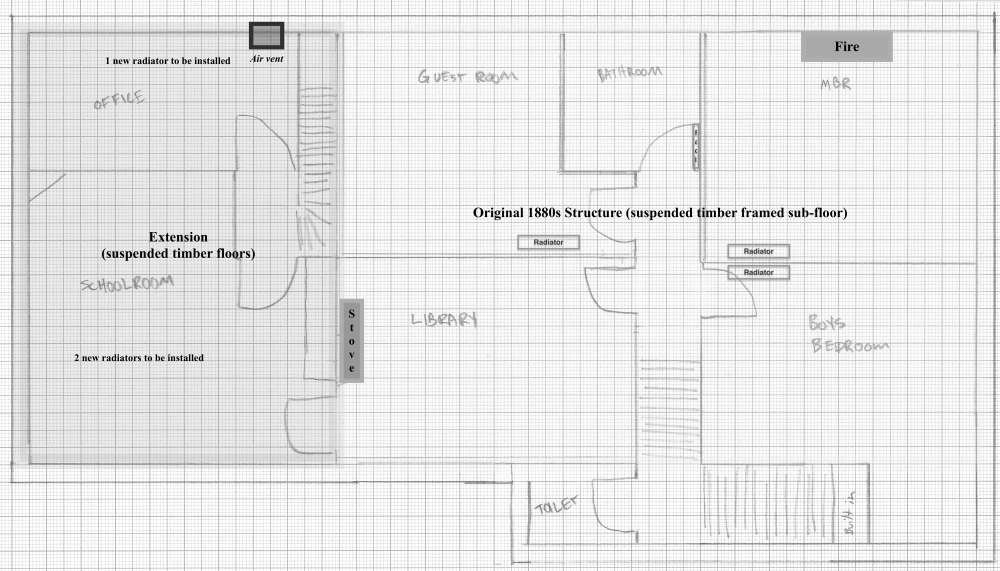

I'm renovating an 1880s Victorian semi-detached house. It's largely unmodernised, which means single-paned glass, damp cellar, damp walls, leaky chimney, vented hot water system with a cold water cistern in an overly large closet in the middle of a central first-floor room, unburied electrics etc. The upside is that it's a bit of a blank canvas and I'm looking forward to building up some self-building skills by doing a lot of the work myself. At this point I've browsed forums here and consulted with a few experts and have received some conflicting advice. I'm wondering if some experts on here with some simillar experience might be able to give my current plan a glance and poke holes as appropriate! Images incuded here are hand-drawn (I work on a screen all day, so working with pencil and paper has been therapeautic) but drawn to scale. I've tried to annotate with some indications of underlying structure and heating I have planned. It's a reasonably big 5BR house, about 2k square feet in total, and rather drafty, with as-porous-as-one-might-expect solid 9" brick outer walls. There's also a cellar underneath half the sitting room (indicated on the diagram) with some dry rot in joists and sub-floor I'll be replacing after I can get it properly waterproofed. There's also some damp coming down from chimney in the first-floor room marked library, on which I'll get brickwork repaired and walls replastered. There's a 24kw Worcester boiler feeding 7 radiators. Half the first-floor has no heating at all and seems to have been largely unoccupied for the past several decades. I'm planning to remove gas stoves from the five fireplaces, remove the current 1980s layers, restore the fireplaces to their former glory and install wood-burning stoves in several of them. I'm aware there are differing opinions about stoves, but I'm pretty set on installing at least 2-3 of these. It's worth noting that sustainability is a key concern for us, so I'm not tied to the idea of offsetting costs invested in the heating system with energy bill savings 1:1. I do want to balance outlays across the different elements of the house, so can't dump £10k into an exotic hot water system or GSHP, but getting off fossil fuel inputs as much as possible is a key concern, thus my plans to install solar thermal or an ASHP eventually alongside use of biomass in the woodstoves. My provisional plan for the (21x8') cellar is to excavate to get a flat floor (there's a good bit of rubble and the remnants of old brick flooring), put in a heavy membrane, 2" or so of sand and then a 4" wire-mesh reinforced concrete floor. I'll inject a damp-proof course into the walls, tank the whole thing, and to improve air flow put in a moisture extractor and probably also a humidifier to get moisture in there under control. I'll have zigbee / wifi humidity & temp sensors in all the rooms, so I will be able to monitor progress on this with some level of precision. I'm thinking we'll remove the radiator from the kitchen, which is the "indoor" part of an extension which has a concrete pad installed, and replace with electric UFH on top of 50mm insulation boards. Above the extension on the first floor are two rooms without heating installed. There I'm thinking I'll install a few radiators. Plan for bathroom upstairs is to completely gut and replace the bathroom upstairs, and install a thermostatic mixer shower and an electric towel heater style radiator. One key question is how to drive the heating in this overall design. On one hand, it seems like the most efficient choice would be to put in an unvented hot water cylinder (250l) and have a plumber replace the hot water plumbing to be a 22mm pressurised system. I've seen good advice on here to get extra insulation installed and it seems like I'll probably get a Telford cylinder and get an extra 50mm of insulation added to minimise thermal loss. I'm also thinking I'll get a cylinder with connections for thermal solar as I will probably add solar PV and thermal water heating when we replace the slate roof in 3-5 years. But I'm also wondering if it may be better to install a thermal store. They seem reasonable in cost, and also a bit easier to add in new inputs for heat. Ideally, I will add thermal solar and perhaps get boilers which feed in from the wood-burning stoves to store energy being generated while they are running. Hot water demand will be moderate - one bath a day for the kids and two showers for adults, which can be spaced out. There are five sinks in the house and the usual appliances. I don't need a million gallons per minute coming out of the shower, but do want to get away from the many years of combination boilers in the houses we've occupied which get cold every time someone turns on a sink. In terms of insulation overall, I've got insulation in the ground floors as a mix of insulation boards in kitchen and sheeps wool (probably in the main rooms). I'll add a bunch of mineral or sheeps wool to the roof to get that up to 330mm. And we'll replace all the windows with proper double paned. I am also wondering if, since we'll be renovating all the walls and floors and the house will be unoccupied while I do initial work, if it would be worthwhile to install internal wall insulation. This seems to be a bit expensive, and time consuming. It seems like the green home grants aren't coming any time soon to Wales either. I'm resigned to the fact that it is unwise to convert a Victorian solid wall home to a passivehaus, but also wondering if this might, conversely, be a good way to get away from that "cold drafty house feeling". If anyone on here has done internal wall insulation as part of a renovation, I'd love to hear more about how it worked for you, especially in terms of wall dampness and overall warmth improvement. Sorry for any rookie errors here - I'm still definitely learning how these systems all work together and thanks to anyone who has wisdom to share. I'm also happy to share photos of the house if that's useful.

- 25 replies

-

- damp

- waterproof

- (and 7 more)

-

A bit of a spinoff from my other thread. I am replacing a back galley kitchen in a 1900 terrace house due to damp over a decade having stained the back of 2 base units. Date is approx 1960-1970 (based on different bricks from house and knowing when my local council did grants), so probably a mix of solid wall and cavity. The plan is to strip out the kitchen, and do some protection against what I expect to be rising damp ni the walls. I can see 2 options: 1 - Strip plaster at bottom and Inject DPC. 2 - Do not strip plaster, and attempt to seal with eg "Damp Seal". My inclination is to do both 1 and 2, but I will not have the option of leaving the walls exposed inside for more than 24 hours to dry out as it has tenants in situ. I get a clear week to work but more will be awkward. Potential problems: 1 - One wall is external, one is party. Are there difficulties injectnig a DPC into a party wall? Do I need to do a PWA notice etc? 2 - I would like to insulate the external wall as much as is practical, but what is the method? I reckon I can lose only perhaps 25-30mm off the kitchen width, and I really don't want to take it all back to brick even on one side. Can I bond PIR or PUR backed plasterboard directly to the existing plaster? Any comments are welcome. Ferdinand (Aside: may be off line for a bit due to antipodean holiday, or may check in if the marsupials are boring).