JCB400

Members-

Posts

13 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

JCB400's Achievements

Member (3/5)

1

Reputation

-

Our local council appears to be close to making our area a conservation area - they just sent us a letter saying the final "consultation" closes at the end of January. It is not clear if or when the conservation area will come in to force, although the letter suggested the council wanted to do it and it was reasonably imminent. If the conservation area came in, permitted development rights would be restricted and any change to the roofline would require planning permission. We are in the initial stages of organising a hip-to-gable loft conversion under permitted development. The loft is currently not converted and we need the conversion for the house to work as a family home. We are having trouble getting a straight answer on what the position would be if the conservation area comes into force before we have finished the build. Or what happens if e.g. we have the Certificate of Lawful Development but have not started the build. We have various enquiries running but does anybody have any experience of this please?

-

Does anybody know of any windows with a heat recovery ventilator built into the frame please? I am looking at the Internorm KV-440 with I-tec IV40 ventilator - any other options? I'm aware of the separate through the wall units which are available - I'm particularly looking for a window frame unit. A whole-house MVHR is not an option. Thanks.

-

The K103 spec sheet states "Where multiple layers of insulation of different thicknesses are used, the thickest layer should be installed as the outermost layer in the construction."

-

Large pane bifolds: Schuco ASS 70 FD.HD or Express Bifolds XP Vision?

JCB400 replied to JCB400's topic in Windows & Glazing

Thanks for the replies all. We elected to go for the Schuco ASS 70 FD.HD bifold in a 3-pane config - this is a newer large leaf version of the regular ASS 70.FD, which can take up to 150 kg / 1.5m wide / 3m high per leaf. We are within the weight limit for triple glazing and went for that. As Conor says, the higher glass to frame ratio is better as the U-value for the glass is better than the frame. As you know, there are pros and cons to all options - 3-pane sliding, 3-pane bifold and 5-pane bifold. I'll report back with my thoughts when they are installed. -

Large pane bifolds: Schuco ASS 70 FD.HD or Express Bifolds XP Vision?

JCB400 replied to JCB400's topic in Windows & Glazing

Yes, both Schuco and and Express Bifolds (Alumil product) do panes up to 1.5 metres wide. -

Does anybody have experience of or thoughts on either of these bifold door products please? We have a 4200w x 2450h aperture - we'd like 3-pane bifolds for it and the options are a bit limited for the required pane size. I have the usual comparison spreadsheet running but would really appreciate hearing from anybody that owns or has experience of either product, or knows of another option. We've been through the sliding vs bifolds pros and cons in detail and are set on bifolds. Cheers.

-

Yeah, the EOLO L stuff is at the top of my list at the moment but I'm open to further suggestions.

-

I'm designing the ventilation arrangements for my landlocked utility room. I'll be using as much rigid duct as possible, but it's inevitable that I'll need some sort of flexible duct in the system. The flexible ducting options do not appear to be great. Generally it's either the very thin white helixed PVC stuff, which is poor for airflow and not robust, or the semi-rigid / semi-flexible aluminium duct, which is also not terribly robust and prone to tearing / denting etc. The proper semi-rigid duct used for radial MVHR systems would be great, but it's only available in the smaller sizes used in those systems. I have feelers out with some ventilation suppliers, but does anybody have any knowledge or experience of any decent options for 125 mm flexible-ish duct please? I'm looking for: As smooth a bore as possible for airflow Robust (e.g. vs tearing, mice, denting etc.) Good longevity Reasonable flexibility Available in 125 mm (sometimes 127 mm) and able to be make an airtight connection to normal male 125 mm spigots and connectors in the rest of the system (e.g. can it be squeezed tight with a jubilee clip) Thanks.

-

I'm looking at kitchen options at different price points for our renovation - we need options due to contingencies with the budget etc. One thing that annoys me intensely is the way some kitchen companies don't give customers access to the specs, dimensions and options for their units. It's all a big mystery and you are reliant on the knowledge and skill of the designer, their awareness of the different units available etc. That might work for some people but not for me. I'm not sure I could be comfortable buying a kitchen without access to some sort of brochure showing the details of the units available (rather than just a vague glossy coffee table brochure). Can anyone recommend decent kitchen companies who provide such details please, from their own experiences? So far I've found the following companies who do: • Nolte • Nobilia • Howdens • DIY Kitchens Thanks.

-

I got this one: http://www.cem-instruments.com/en/Product/detail/id/926. It was £69 on Amazon and has been decent (no longer available on there though). Having owned one for a while, I wish I'd spent more and got one with a battery power option so I could use it more easily and in other places (e.g. the car). I get quite high CO2 levels in the rooms in my house if they are occupied with the doors closed - this is in an unrenovated, supposedly leaky Victorian end of terrace. We reached over 4000 ppm overnight in the bedroom - we now leave the door open as a result, until we renovate. 2500ppm in the living room. One of the problems is that curtains etc. occlude trickle vents. There's a good article about it here: https://www.cibsejournal.com/technical/build-tight-ventilate-right/ The research paper the article was based on is here: https://www.researchgate.net/publication/273588438_Building_tight_-_Ventilating_right_How_are_new_air_tightness_standards_affecting_indoor_air_quality_in_dwellings (it's free to download - just click on the blue "Download full-text PDF" in the top right) My experience has been consistent with the above articles. I gather CO2 can be an issue in cars, which isn't great if it results in drowsiness etc. - hence it would be interesting to measure in your car if you get a battery operated version.

-

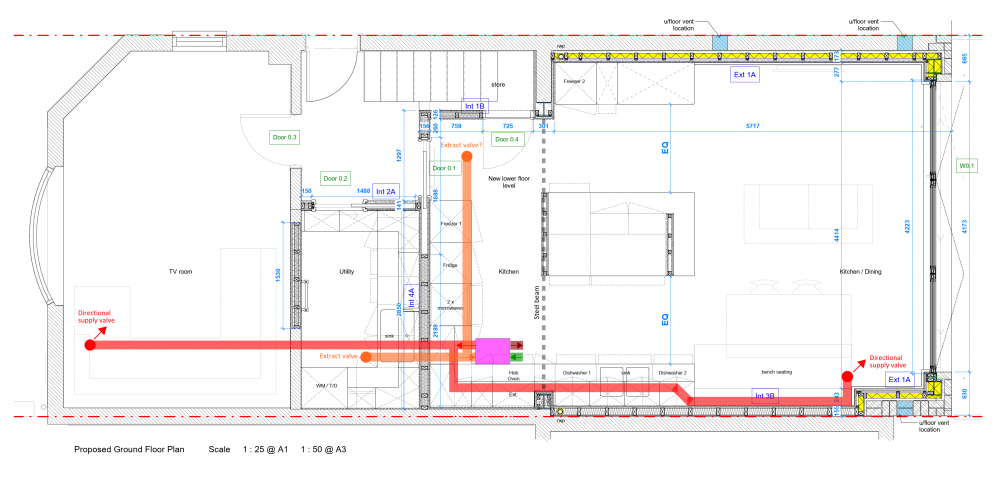

Hello, We are installing a small, basic ground-floor MVHR (Blauberg D-105A) as part of a side-return open-plan kitchen extension to our 1910s terraced house. A full-blown MVHR is beyond the scope of the project. I'd really appreciate any comments on the attached design. A few notes: • North is at the top of the page. There is a steel beam running north-south as shown. We can just get some 125mm duct underneath where it meets the column to the south as shown, boxed off above the kitchen units. The beam is otherwise impassable (within the scope of the project). • East of the beam, the south third of the kitchen has a pitched roof with Velux windows (usual London side-return extension). This also limits valve placement options to the area of the bench seating as shown (hence the proposed directional supply valve to avoid draughts). • Valves can otherwise be placed anywhere in the kitchen ceiling west of the beam. It is not possible to place valves east of the beam other than close to the south wall as shown. • The extension is being constructed with best efforts on the insulation and airtightness front but not to a certifiable standard. My main ventilation priority is the utility room, which will have a condenser tumble drier and be used to dry clothes on hanging rails. I have a CO2 meter and CO2 levels in the house are already poor in occupied rooms. The house does not "officially" need an MVHR, but I would like to ventilate in an energy efficient manner and improve air quality. • The kitchen will have a conventional extractor hood over the hob, vented to outside. Given this, I am questioning the need for an MVHR extract valve in the large open-plan kitchen space and wondering whether having an extract valve solely in the utility room would ensure it is well-ventilated without providing excessive airflow to the 2 supply valves. Would the supply valve location in the south east of the dining area, coupled with the utility room extract valve, set up a drift of fresh air towards the kitchen door to ventilate the kitchen, with the conventional extractor hood used for cooking as required? Such that an extract valve in the kitchen is not needed? • If a kitchen extract valve is needed, where is the best location for it? I thought next to the door so as to be diagonally opposite the supply valve, although I'm concerned this might work against the utility room extract valve. Thanks. JC MVHR GBF.pdf

-

Hello, Can anyone help with the positioning of bifold doors within the thickness of a solid wall aperture please? (i.e. towards the room side, middle or exterior side of the aperture). I can see there are various considerations, although I can't find much advice online for solid walls. I'd like to maximise the internal space in the room if possible, whilst maintaining good thermal properties, rain resistance etc. I've attached a screen grab of my architect's proposal (plan / overhead view). He has the exterior glass of the bifolds inset 225mm from the exterior face of the brick, thus the overall bifolds unit is closer to the room side of the aperture. Note the blue steel column / I-beam immediately adjacent to the frame. I'd like to move the bifolds a little towards the exterior side if possible to maximise the internal room space - I'd appreciate any thoughts anybody might have on the various implications of that please, thermal or otherwise. Thanks.

- 1 reply

-

- bifold doors

- solid walls

-

(and 1 more)

Tagged with: