Search the Community

Showing results for tags 'concrete slab'.

-

Hi All, We are embarking on a self-build and the ASHP was installed yesterday and we are awaiting the commissioning engineer tomorrow to turn on and start heating. I was a little alarmed by the our ASHP supplier planning to just operate the ASHP at its standard operation rather then operating a thermal cycle. From what I have read on line this is important for the concrete screed performance and any floor finishes installed later. I spoke with our tile installer and tile adhesive supplier and they have recommended the following regime which is more or less a 14 day cycle that involves, 5 days of gradual heat increase (2-3C per day) , maintain at expected operating temp for a further 4 days, before a 5 day gradual decrease in temperature. My question is with regard to the expected operating temperature, which I presume is the outflow temperature of the ASHP (45 degree), that the underfloor heating pipework's will be supplying to the screed for these 4 days. My understanding is that the thermostats will be overridden temporarily for the commissioning and the slab will be consistently heated with this 45 degree water - am I correct? If this is so then theoretically will the house be extremely warm for a few days as the slab should come close to the 45 degree temperature?

-

Hi all, I am an unwilling renovator! I have an issue with my German style house, comprising of proton blocks, Lime plaster with a porothon ceiling topped with a slab of concrete. One of my issues is that the concrete ceiling appears to be causing a crack in mainly the gable end walls. My first question is - does a inside first floor concrete slab need to have expansion joints in it? The size of the slab ie 14 m x 8 m. Also it appears that the Lime render applied was not suitable for the driving rain in Donegal and that I may have to replaster some sections of the house. I would love some expert advice before I ask local builders who will be unfamiliar with my building materials. Thanks so much for looking here

- 31 replies

-

- concrete slab

- lime render

-

(and 1 more)

Tagged with:

-

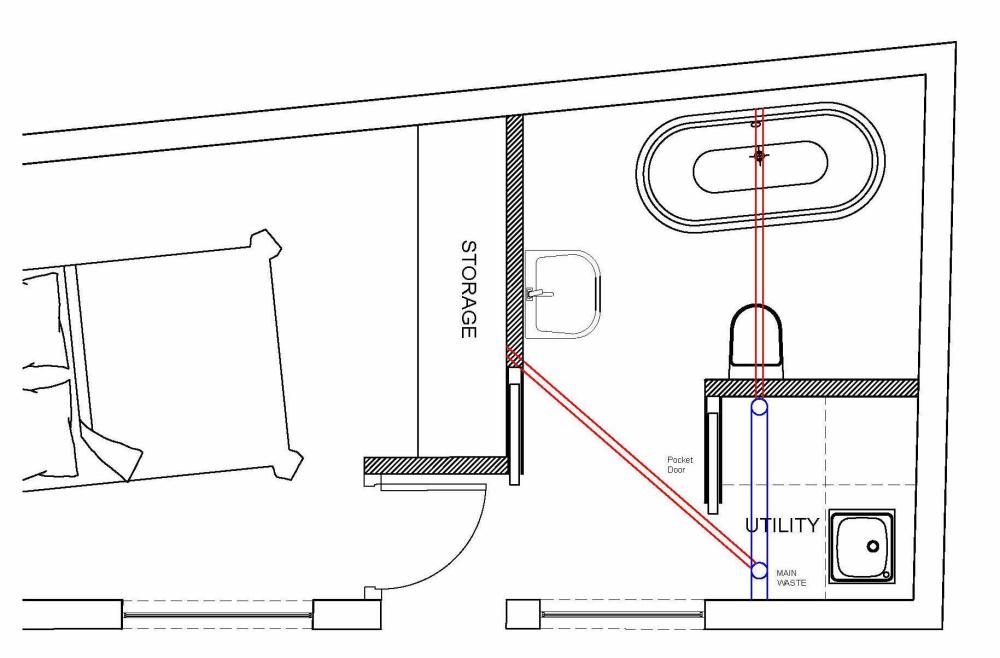

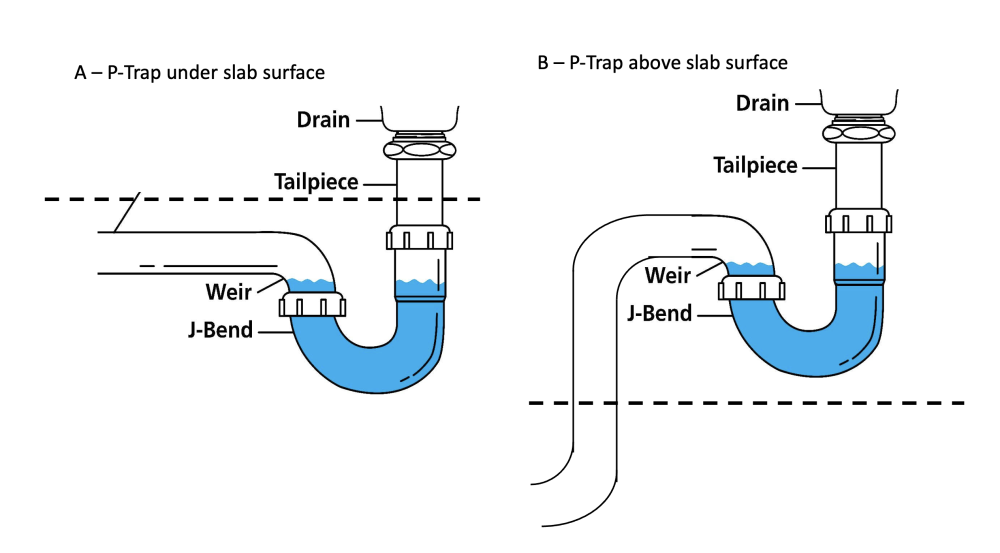

I'm in the process of slowly converting a garage into living accomodation. The garage currently has a concrete slab floor which will need to be insulated and screeded etc. One part of the garage will be the master bathroom. I have a basic layout and know that I will have a freestanding bath so would like to chase the concrete for the drainage as I will need to hire a floor saw for another job so may as well get this chased at the same time. Layout of the bathroom is below (red lines show 50mm waste, blue 110mm waste): My question is regarding a P-Trap for the bath waste. Is it advisable/recommended to have the P trap burried in the slab so I have max wiggle room above to connect to the freestanding bath or would you just poke a 50mm though the slab (with a 90 degree bend) and have the trap above the slab? i.e. A or B in this picture?

- 7 replies

-

- trap

- waste pipe

-

(and 1 more)

Tagged with:

-

Hi All, I was hoping to run past you all our situation with our first floor 200mm concrete slabs. We are being recommended liquid poured TLA insulation on the floor from our builder mainly due to the slab being at some parts ever so slightly uneven, so the poured insulation will work to level out the floor before the screed goes in place. I have on my notes that the architect mentioned with the 200mm concrete slabs you don't need insulation, just lay the UFH pipes and screed over them - which I may have noted wrongly. What have you done on your upstairs, or from experience what would you recommend for depth of insulation and screed? Thanks and as always, I appreciated everyones feedback. This forum as helped me so much in the last few years from an non-subscriber to now a member.

- 19 replies

-

- ufh

- first floor

-

(and 1 more)

Tagged with:

-

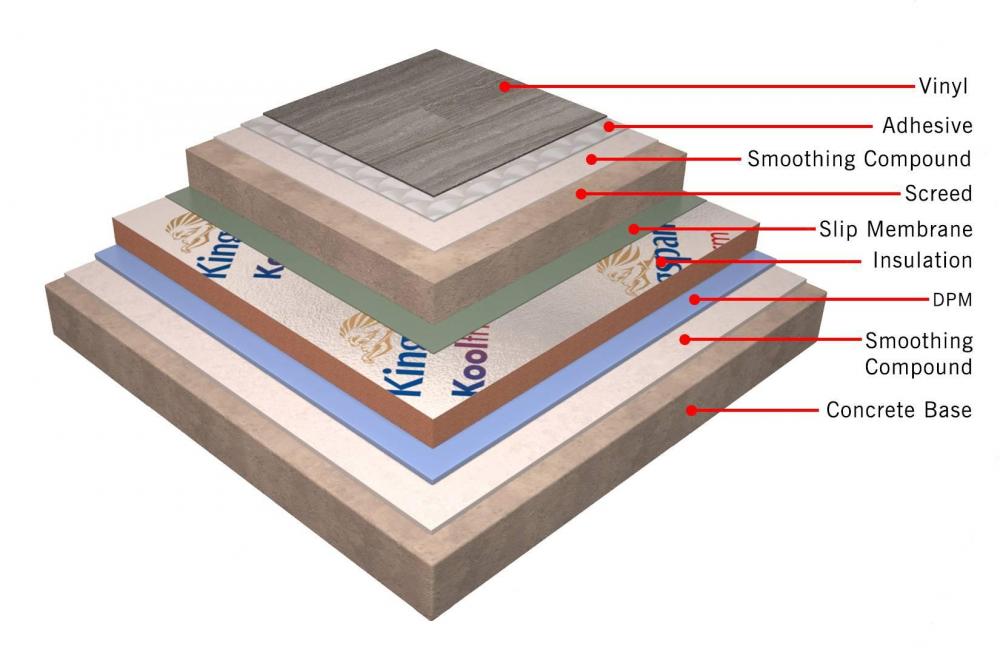

We have a detached garage which we are looking to convert to living accommodation. Whilst trenching for utilities we noticed that the damp proof course has been bridged by the concrete slab. Just wondering, should I be concerned about this? What could I do to remediate? Do I need to dig out the slab, excavate and re-lay or is there a simpler/cheaper option? Original plan was to follow this up to the screed layer. Is this still applicable or do I need to deal with the bridged DPC first?

-

Hi All My first post here, hope you're all well Just after some advice pls. I'm preparing a base for a wooden (cedar cladded) insulated garden room (4.2 m by 3.02 m) So far we have cleaned and levelled the area and put down 4 inches of Mot, we plan to put down a 4 inch concrete base However I'm getting mixed reports and opinions from tradesman / friends etc.. that 4 inches is either enough or its not enough and I should go for a 6 inch with re-bar The room will contain me, a small sofa, desk, some music equipment, you know typical man cave / office type set up Not being an expert in this areas you can imagine I'm a bit undecided and worried I'll make the wrong decision. I just wondered if anyone has done a similar project and if a 4 or 6 inch base is best etc..? Many thanks in advance :)

- 8 replies

-

- garden room

- summerhouse

-

(and 1 more)

Tagged with:

-

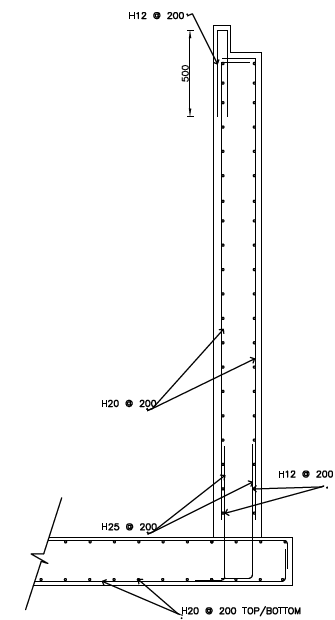

Hey, I am building a new home with basement. My structural engineer has specified a 400mm thick sl ab, and the slab reinforcement is 100% H20 rebar. This is to support a 5 bed property over ground, 1st, 2nd floor, meaning the basement walls are structural. I assumed that the slab would have been mainly made up of steel mesh, and H20 starter bars for the walls. Instead, over a 240m2 base there will be 8259 linear meters of H20 top and bottom. The wall starter bars are specified H25. Does this H20 and H25 sound overkill? £16k + vat worth of steel in the slab alone. If you know groundworks well, I would be interested in your thoughts Thanks

- 37 replies

-

- basement

- concrete slab

-

(and 3 more)

Tagged with:

-

Hi all, I have today attempted my first concrete slab. It isn't a big room about 2.75m by 3.5m . We are replacing a suspended timber floor so the walls are already built which made things difficult. It was a day full of choice language and despite the best efforts of myself and the ministry of fun we have made a bit of a mess. The result is a slab that rises and falls by up to about 15mm in places. I am thinking that I could go over it with a thin screed or self levelling compound but don't know if this is a good or bad idea. the slab will be covered with 150mm of celotex and a final screed so won't be seen but i'll always know that it isn't level. Is there a product that I can use on a newly laid slab to level it and cover imperfections. Your help and suggestions will be greatly appreciated.

-

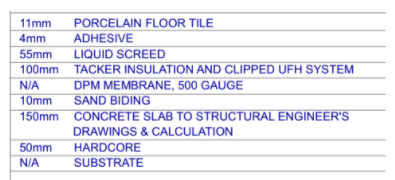

Anybody have any comments on this build up of my ground floor (we've taken out the original timber vented subfloor of a 1930s semi and are going to have a concrete slab instead). Any tweaks or improvements? (I don't have any more space, so any increase in insulation would have to be balanced out by a decrease in something else.)

- 2 replies

-

- subfloor

- concrete slab

-

(and 1 more)

Tagged with:

-

I've had a concrete slab poored today and just found out from the contractor that he did the following. 100mm 40mm to dust compacted with a a dpm (visqueen thick guage) layed straight on top lapping up onto the inner skin of blockwork. HE DID NOT USE A BLINDING OF SAND instead he layed another layer of dmp on top of the insulation but not lapping the wall. Then he poored the 100mm concrete slab. In short Crusher run compacted Dpm lapping inner skin Insulation Dpm Concrete Am i likely to suffer damp issues? Fortunately its quite dry round with sandy conditions and great drainage. Sorry to be long winded in my description.

- 4 replies

-

- dpm

- concrete slab

-

(and 1 more)

Tagged with:

-

Hi everyone, Thanks a lot for having me I value your feedback! The other question I have been wondering (and need to decide on before applying for planning) is about the groundwork. The structural report says that it's sound and doesn't need underpinning. However, the barn is quite short. I think it's 4m tall, not at the top of the gable - I couldn't get my tape measure up there. It used to have a first floor and has the holes where the beams used to go. We'll be wanting to put the first floor back in. I had originally thought I would raise the first floor so there's more head room downstairs, and upstairs will be fine as we'll have it open to the ridge inside. However, as we'll be hoping to put on an extension, and will need to be doing some insulation and slab laying in the main barn anyway, would it be better to lower the whole floor level? If you're already doing groundwork, how much extra would I expect to pay if I wanted to lower it 30cm or something? I think I am leaning towards just raising the first floor level. I personally don't mind the walls being a bit lower than the top of my head, as there's so much extra space that will be open from keeping the roof open. But worried I am missing a trick that might not cost much more!

- 9 replies

-

- concrete slab

- barn conversion

-

(and 1 more)

Tagged with:

-

Admins, please move thread to another area if this isn't the best area! Okay, I had contractor to come and dig up my old slab (100mm) and then proceed to remove a further 375 of soil. They then barrowed back in 150-160mm of type 1. They proceeded to compact it with their wacker which IMHO was too small for the job. But they kept going....and of course they didn't get to the required 100mm compacted level. I spoke to the contractor and he said he would be back today (early!!!) and would come back with a decent whacker that they use for roads. I thought they'd use a roller for that, not a whacker but who am I to say what's best.... Anyway, looks like the £250 retainer that I kept back wasn't enough to get him back to finish the job off. The bar steward has not showed up and is not answering my calls. Should have retained a bigger amount but I stupidly trusted the man. And the two barrows and rake they left behind aren't going to make up for things. I could be livid, but I'm fairly used to it in this country that homeowners get shafted like this. It's a way of life. Just look at the TV shows that rely on these 'cowboy' trades. And trying to take things up via the small claims court is just not worth the effort and expense. So rather than get angry about it, I'd like to channel any negative thoughts into getting the job finished. And rather than get someone else in, I'll probably tackle the 88sqm myself. The small whacker they had was clearly not up to the task of crushing the 160mm down to 100mm. Think they used a 450mm plate (83kg). What do I need to get this done? In most places I will need to go down another 40-50mm. Would this baby do the job? http://www.jewson.co.uk/tool-hire/compaction/plate-compactors/products/2530/reversible-plate-compactor-500mm/ Do-able in a day? I need to go down another 50mm as otherwise I won't get sufficient EPS under the new floor slab.And that was the whole flamin' point in going down do deep in the first place Mr R. BlXXXMAA of AXXXFXXW, you !"£%^&*()_+ !!!!!!! Can't wait to write up my review on MyBuilder...... red pen = excavation level, white marker = 100mm compaction level, red marker = top of hardcore bloody uneven too!! not really clear, but room centres are a lot higher too. Ideally I don't want to remove any hardcore and then compact and then add a bit back in, compact...... Advice, options? No replies on cowboy tactics, my gulliibility etc pls. That's another thread-starter....

.jpg.75c67145b50e2e2c0d389a7e99dbac60.jpg)