Tin Soldier

Members-

Posts

258 -

Joined

-

Last visited

Everything posted by Tin Soldier

-

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

Well I got to the bottom of it There was very little water going through the inspection chamber I basically did as above and ran gallons and gallons of water down every outlet at the same time, very little making its way out 5 mins later I heard something slowly moving down the pipe outside like a rat crawling down it, until... Well you don't want to know what it looked like, Needless to say it was massive, it was brown and it stunk.. It spewed our of the inspection chamber base broke up and was followed by a torrent of water Diagnosis Baby wipes, bits of plaster, bits of plastic all probably places there whilst pipes were open and kids could get to them I am smell free! -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

Poo -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

I can't test the svp behind the false wall without a lot of destruction ? I just can't understand how everythings Been fine for months and this week it starts stinking -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

Hmmm replaced aav with a spare Question is should I be able to notice the diaphragm withing it moving at all when toilets are flushed -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

fingers crossed -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

interesting so another question is If all the traps are full, and the pipes sealed how does the smell get out? does it force its way passed the seals in the soil pipe or? -

unbearable stench - what have I done wrong

Tin Soldier replied to Tin Soldier's topic in Waste & Sewerage

theres only two traps in the bathoom, one is the shower, which has plenty and I've run litres into, the other is the toilet, which is fully functional Like I said the sink waste doesnt have a trap, but an airtight bung in the kitchen, theres the kitchen waste trap which again is full -

New build large extension - completely separate drain/waste from old system until it meets well outside to go into septic tank Kitchen and bathroom have been plumbed in for months and months Kitchen has 1 waste will trap, thus no smell Bathroom has three waste points 1. toilet is plumbed in to 2. sink is almost plumbed in to 3. SVP leading to an AAV in the loft the sink has a 40mm pipe solvent welded to a reducer in a 110mm pipe, it comes upwards and out of the wall and is bunged at the end with an airtight bung. it was awaiting the wife painting the upcycled vanity unit (still bloody waiting) It was set up this way for months, no smell I put up a false wall, no smell I tiled the false wall, no smell months pass. unbearable stench seemingly coming from false wall. My thinking was one of the kids had slammed into the 40mm waste pipe broken the solvent weld, thus a small amount of gas is leaking. Last night, I punched a large hole through the wall, cut the waste pipe to sink, and replace it brand new, this morning I woke to a godawful smell again any ideas how/why this has started months after installation? my plan for tonight is to go up to loft and check on AAV, but I doubt that's it

-

great thanks, all sounds non scary to me I've already plumbed up the pumphouse opposite to change over to the 32mm so its a two minute job to disconnect from old pipe and connect to new one, and vice versa, so I could have just tried and see what happened but you know what like - better to ask If I'm honest, I was thinking of just running the water through the pipe for a good while, and not bothering disinfecting, but wouldnt tell the wife that

-

Hi there, Probably another ridiculous question, but I'll ask anyway Old (private) water main is a copper 1/2" pipe that runs under my track into from the pumphouse on the other side into the old kitchen, Theres a stopcock under the sink connected into 15mm copper pipework that I assume routes to all the cold water outlets (as theres water at them) and the thermal store as its full of water. probably about 6 months ago I ran a 32mm mdpe pipe under the track whilst I had the change, and terminated underneath the window where the new utility room sink will be, if it ever happens / at the moment there is a washing machine there, which is supplied by 15mm pipe so questions 1. 32mm through the wall or downsize before taking it through? 2. Is it just a question of teeing in a stop cock to the 15mm pipe where washing machine is (as is a sink is there) and the cold water will magically find its way to the right place 3. do I need to worry about where about in the pipework it is connected to 4. the 4 m or so of mdpe has been there for 6 months, albeit capped - how best do I disinfect this before I connect everything up?

-

What ya building.

Tin Soldier replied to Russell griffiths's topic in General Self Build & DIY Discussion

What does my SIPS build count as, Timber Frame? -

Should I plane my own Cladding/decking ?

Tin Soldier replied to Tin Soldier's topic in General Joinery

I've now planed 100 lengths x 3m Getting there slowly The boards are not all totally flat, so in order to get a good finish I need to plane them to 30mm Look great once planed Still tonnes of work to do though -

Should I plane my own Cladding/decking ?

Tin Soldier replied to Tin Soldier's topic in General Joinery

Blades coping ok, I changed it round after 40 lengths (they are double sided) I have two spares, so 4x more uses My wifes sisters are taking the shavings for hens bedding or something free to uplift -

Should I plane my own Cladding/decking ?

Tin Soldier replied to Tin Soldier's topic in General Joinery

This was a mistake most of the larch averages 38-39mm thick Thicknessing down to 30mm is a chore. so far I've done 45 3 metre lengths, and all the window surrounds(window surrounds down to 22mm) and filled 22 bin bags with shavings. -

Never mind pinged my Brother in law a message who works for a local company that sells all sorts of bits and pieces £66 inc vat for 1500 stainless steel screws- he says ' yeh the markup on fasteners is pretty large' - pretty large? try 10 fold.

-

Holy Moly the price of stainless steel fixings.. I simply cannot believe it, I need circa 2000 of them - face fixed Is there any reason deck screws cannot be used? Similar to these https://www.screwfix.com/p/timbadeck-double-countersunk-stainless-steel-decking-screws-4-5-x-75mm-500-pack/26316 https://www.screwfix.com/p/deck-tite-double-countersunk-stainless-steel-decking-screw-4-5-x-75mm-200-pack/52019 Also can coated screws (ugly green things) be used on the boards behind - that are unseen https://www.screwfix.com/p/timbadeck-double-countersunk-carbon-steel-decking-screws-4-5-x-65mm-1300-pack/23160#product_additional_details_container

-

Should I plane my own Cladding/decking ?

Tin Soldier replied to Tin Soldier's topic in General Joinery

I'm nearly ready for starting this job, Bit of an odd situation in that the timber I ordered doesnt match what I ordered I ordered 900 lm of 30mm siberian larch 154 lengths at 3m 90 lengths at 5m What was delivered was 154 at (minimum) 3.2m 90 lengths at 6m all approx 33-34mm - so I've ended up with a lot more wood that I bargained for Real heavy, thick wood - going to be great for the decking, but very chunky for Cladding which is either gonna look great/unique or ridiculous. Planer to be built tonight, -

rendering, Timber cladding

Tin Soldier replied to GrantMcscott's topic in Bricklaying, Blockwork & Mortar

Also splash zone If the woods too close to ground level the rain will splash up and ruin the ends. -

Very quick question attaching 30mm thick larch barge board to rendered blockwork What fittings to use, hammer fixings? drill through, wall plug and stainless steel screws?

-

If its to be painted, couldn't you get cementitious board like cedral which looks the same but doesn't need painted?

-

any recommendations on fixings attaching battens/counter battens to building (timber) Screws or nails? attaching face fix larch cladding - screws or nails?

-

have you asked Ali? at rationel for a discount? I managed to get some off when I asked nicely

-

Pressure Test Length / Pressure Dropping

Tin Soldier replied to jamesmonk83's topic in Underfloor Heating

Hi, I assume its just cold water that you are putting in the loops at start of the test? -

Verge Coming back to bite me?

Tin Soldier replied to Tin Soldier's topic in Roofing, Tiling & Slating

@JSHarris panic over, kytun pvc and aluminium both have retro fit options Thanks once again! -

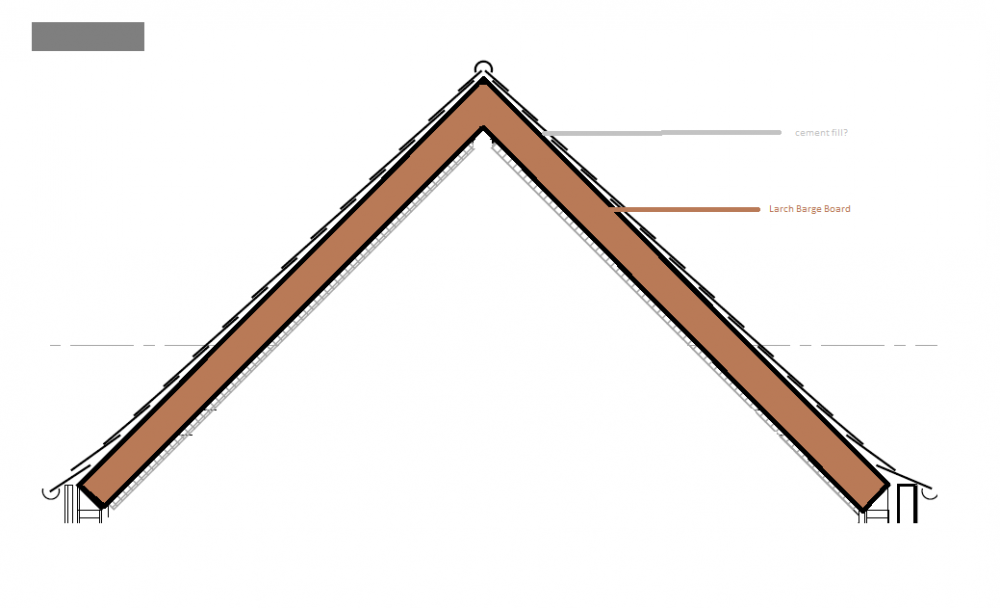

Hi there, I've got a standard slated roof (sarking board underneath) and now that I'm coming to think about timber cladding, barge board, soffit etc I'm looking at the edge detailing (verge?) of the slates and wondering what the hell to do. I hate soffit/fascia/barge board boxy overhangs so I had planned to keep them to a minimum. Currently there is a 9 cm slate overhang at the gable(6cm of it includes sarking board overhang), and nominally I thought I would. 1. Attach treated timber to wall, circa 4cm thick, trim back sarking so its level with this board 2. Attach Siberian Larch barge board to timber batten, circa 28mm thick, butted up to slates, leaving a 2-3cm overhang of just slate 3. somehow magically fill in the gap between barge board and slates. the slating, other than labouring is the one area I didnt pay any attention to, Now reading about it now, I should have installed some sort of dry verge? too late to easily retrofit, using only my diy skills? is there other options? wet verge- pointing with cement?