-

Posts

79 -

Joined

-

Last visited

-

Days Won

1

Everything posted by deancatherine09

-

We did, and it was fine - but we went from a less expensive build to a more expensive, and so the end value went up and naturally the bank were happy. I'm not sure how it would work if you plan to apply for permission for a smaller / more affordable house? We were with Ecology Building Society who were flexible

-

We are really pleased with our MBC house. The installation team did run over and it took almost 7 weeks in the end but it was quite a complex build.

-

So here's what we did; 1) We specified a separate return duct so all the outside lights and plug sockets go out of the building under the slab, then get routed behind the exterior cladding in the service cavity. 2) We have a specific duct in for the data and CCTV camera wires 3) We have two outside taps, one is teed off before the water pipe enters the house but the other one we ended up drilling through the house from the kitchen as it made sense given the location. We did all the airtightness taping etc and insulated the pipe. You don't want to mix data and power cables in the same duct so map out what you want coming in and out, and go from there. MBC didn't charge us extra for the additional conduits we wanted but we did supply the pipe.

-

Go to the NSBRC if you can and play around with the exhibits there, most (if not all) suppliers mentioned on this thread have displays there. We were 100% set on a set of sliders until we tried some of them at the NSBRC. Same with windows, lots of the 3g ones have very thick frames. ETA Nordan windows are awful - they have them in the Scotframe exhibition house in NSBRC. They are a significant cut below the other manufacturers IMO.

-

Timber Frame arrival & erection!

deancatherine09 commented on mike2016's blog entry in The Fun Irish (House)

The size of the windows was the biggest surprise for us too! Progress is looking good! Love the window seat idea -

Is it ok for builder to leave pipes like this?

deancatherine09 replied to nmh's topic in Waste & Sewerage

That's very poor Ours are all clipped at 600mm centres and fully insulated. -

We've got Velfac - have been very happy with the windows and doors but they've only been in 1 year. We chose them as they have the thinnest frames and also offered the bi-parting slide door (which suited our requirements perfectly). However, performance of the approved installer with regards to manufacturing and fitting the cills has been a different story.....

-

It really isn't clear. After posting here I went on the BuildHub guide and on there it seems to suggest otherwise. I think, to be on the safe side, I will buy everything pre completion cert. For us its things like patio materials, tiles etc - things that are not needed to be finished for Building Control completion but would be allowable on the VAT reclaim.

-

We've always had a F&P double drawer dishwasher and love them. For us (a couple), they are excellent as you only have half the space to fill and so it means we are not running a half empty dishwasher. It also saves a lot of bending when loading / unloading the top drawer (which is the one we use most often). We got ours several years ago and paid £800 in the sale.

-

We love the style of Steel Crittal windows / doors but were building a passivehouse, and the two don't really mix well! In the end we went with Velfac 3g units in black with glazing bars, which look really nice.

-

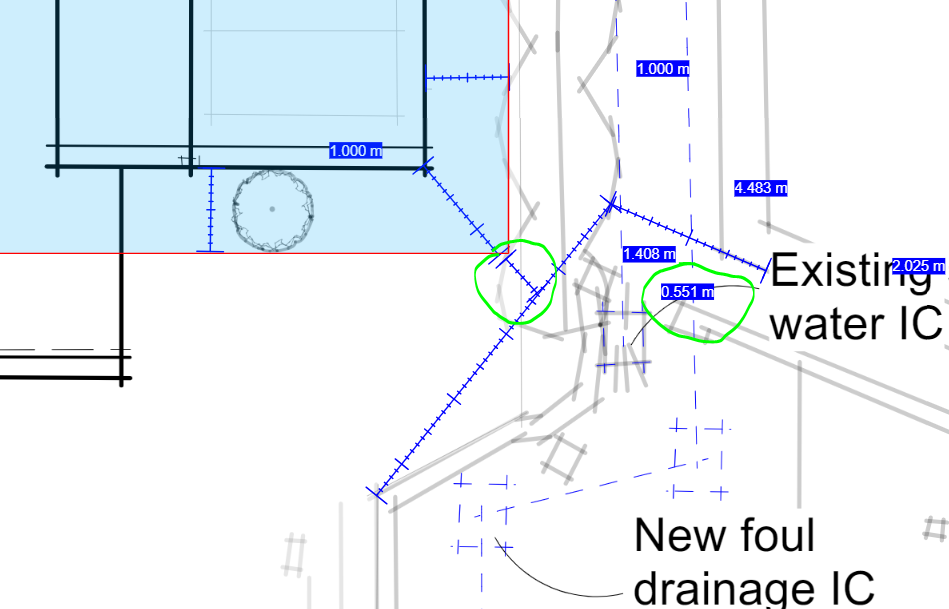

Diagram below shows house, red line is hardcore. Second pic is aerial view of what they have dug, green line original retaining wall.

-

All So we are 75% through the build of our house (MBC twinwall with passive raft). Doing exterior cladding & first fix at the moment. Relations with neighbours were great until planning went in and then they immediately stopped talking to us and started creating problems. They have now, I feel, come to the realisation that no matter what they try to do to us, we ignore and carry on so they have started trying to separate themselves from us (great as they are nutcases!). As part of that, they started to erect a fence on the boundary line, however in doing their preparations for such fence, have removed a retaining wall on their property and excavated 1-2m of earth (retaining wall on their property, so obviously they want to erect the fence at the lower level & at the boundary). The retaining wall was about 0.8m high, ish and retained the soil on our property. Problem is, where they have excavated is within 0.5m of our compacted hardcore under the EPS base, and 1.8m from said EPS base. It's lower down than the founds. I don't believe they are planning on replacing the retaining wall further back as they have dug fence post holes right next to boundary line. I think their intention was to just put up the fence and tell us the soil retention was our issue? When we realised we immediately sent them a cease & desist letter requesting that they stop the work and follow the Party Wall Act. No response (although they have seemingly stopped work on that area). This happened on Tues 15th and we delivered letter Weds 16th by hand, with another copy send via post. We are also following up with a surveyor. My quandry now is, should we tell insurance company (Protek)? Technically there is no visible slippage of the soil etc, no visible structural damage to the frame / foundations and thus no actual damage to claim YET but I am sure they would be interested?

-

Planning committee Related query

deancatherine09 replied to Achu's topic in Garage & Cellar Conversions

We had this. 6 objections and 3 repeat objections (orchestrated by our neighbour, most of the objectors didn't live near us and were their friends & family). Went to committee with support of the planning department - my partner & I spoke for 3 minutes. Objecting neighbour spoke for 3 minutes, PC 3 minutes and local councilor 5 minutes (all against us, but it was clear the PC and the local councilor had been fed lies by the neighbors and they came across as fairly incompetent - spouting off reasons why we shouldn't build a house there when we already had permission for a different design). One person abstained to vote (think the PC had got to him) and all others voted in support. One lady even chastised the neighbours for objecting - saying we should be actively encouraging sustainable developments like ours not trying to stop them. Another said the new design fitted in much better with the street scene and there were murmurings of support when he said that. It was awkward and stressful, and I nearly cried with relief when it was voted for approval, but it's important you attend I think. I think one of the things that helped us was that we were there and spoke, so the committee could see we were a couple trying to create a home and not a developer, and also how much we cared. When it was voted for approval, neighbours got up and left. Can't tell you how good that felt! Best of luck and please come back to update us with the outcome. -

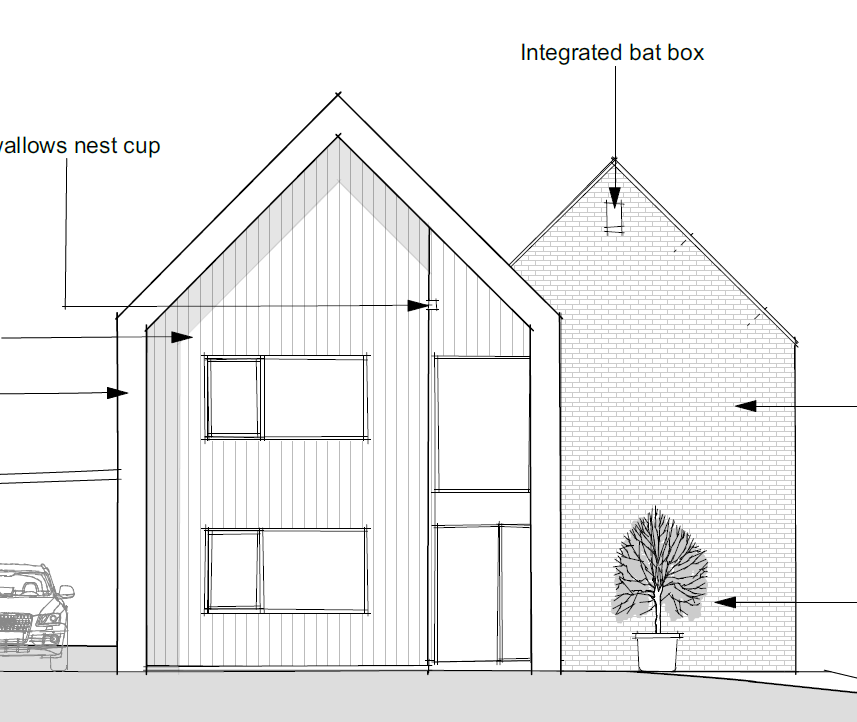

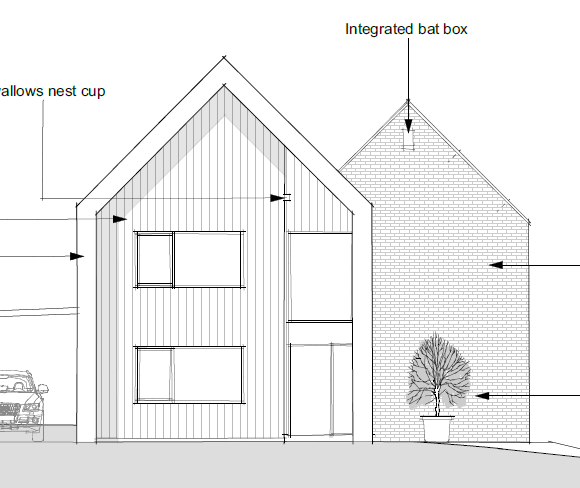

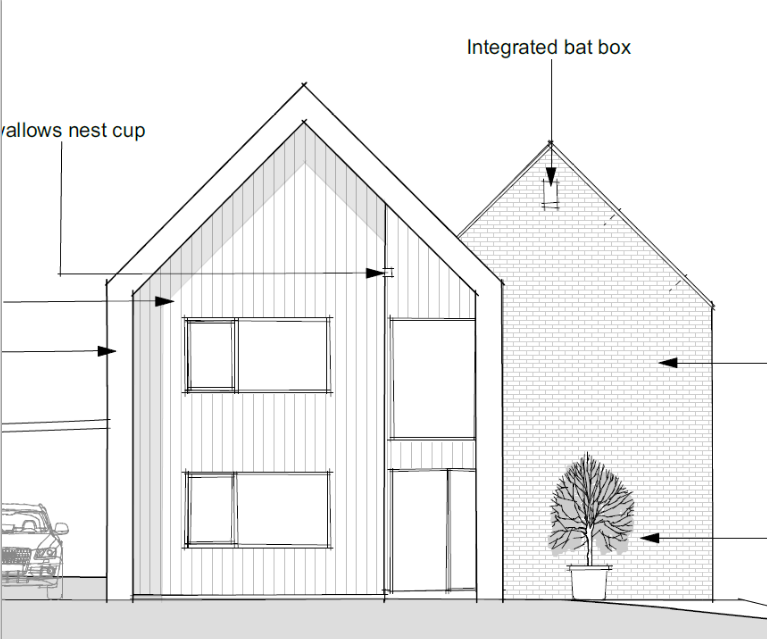

Larch or Brick? - a Cladding Dilemma

deancatherine09 posted a topic in New House & Self Build Design

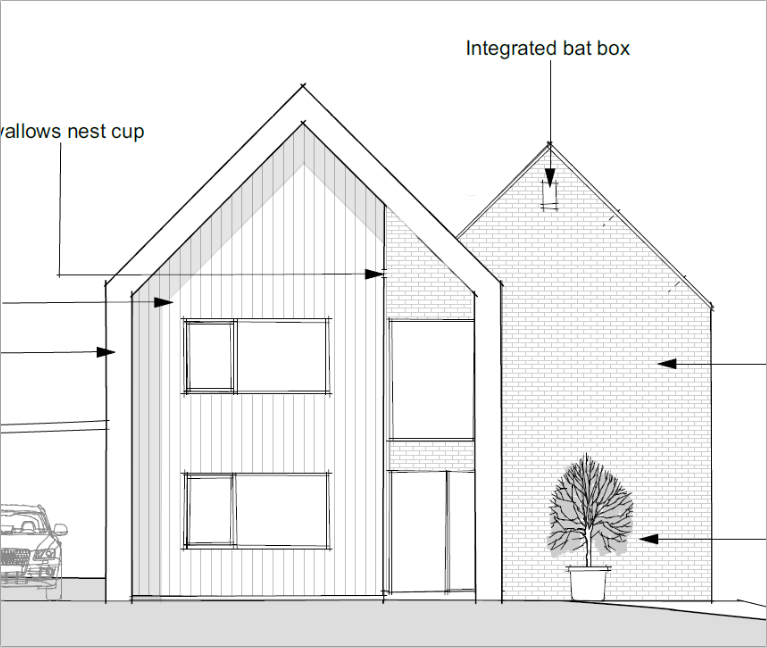

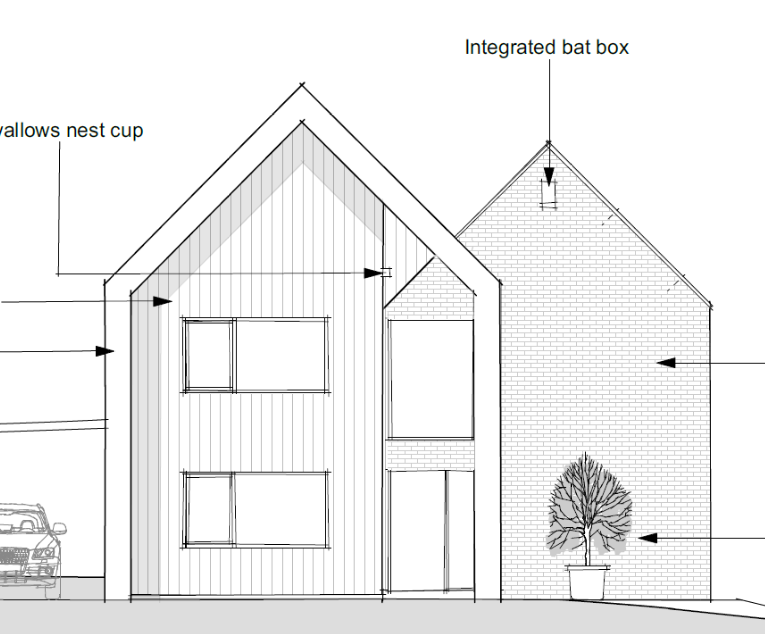

Now that our frame is up, we have started the exterior cladding work. Our house is designed as two joined volumes, a larger primary volume, which will be clad in vertical, rain screen larch. With the smaller secondary volume clad in red brick slips. We have reached a dilemma around the porch/front door where the two materials meet, and thought we would reach out for wider opinions! Our porch area is made by having a section of the larger volume removed, and the roof continued to create a shelter external area: The architects have shown the internal faces of the roof wood clad, along with the wall above the landing window/front door. Our dilemma is that this is actually the same wall/elevation as the brick section of wall on the right, due to it being set back. So our thoughts are to: 1 - Clad this area in wood, and have a join between wood and brick sitting to the right of the front door in the 'middle' of the wall 2 - Continue the brick onto this face and have the wood / brick join at the corner of the walls to the left of the front door, but this would mean having brick cladding up the gable of the larger volume beyond where the smaller gable would exist 3 - Combine the two claddings on the wall, following the roofline of the brick clad gable through into the porch, and fill the gap above with wood from the larger gable Please cast your votes and share opinions -

Hi all, I've had a little look through some similar posts, and then done some calculations to try and back up my thinking! We are building using MBCs Passive Twin-wall system, with passive foundation and Triple-glazed Velfac windows. We had a SAP calculation done for us, and sent this out when requesting ASHP quotes. We got quotes back from multiple companies, and all seem to specify 15/16kW ASHPs, but we can't shift the feeling that this is massively oversized. My calculation was as follows: (Data from SAP report) 8. Space heating requirement Space heating requirement for each month, kWh/month December = 1702.24kWh 9a. Energy requirements – Individual heating systems including micro-CHP) Water heating Fuel for water heating, kWh/month December = 82.86kWh So taking the calculation from another thread, December needs 1785.1kWh, which is 57.6kwH per day, or average of 2.4kW (24/7) And assuming it is running for half the time, 4.8kW requirement from the ASHP? Am I missing something obvious in the SAP report that means we actually need a 15kW ASHP? - as several companies have told us we need such a huge one? Revised SAP Documents - Burbank.pdf

-

We went with MBC - they finished putting the frame up last week. Apart from one issue we've had with the wrong membrane being fitted (we spec'd a fire rated breather membrane on one elevation) they have been great. Back in May to do the airtightness works.

-

DPC under stud wall on insulated slab foundation?

deancatherine09 replied to BotusBuild's topic in Timber Frame

We have MBC on site at the moment and they have put DPC under all stud walls even though there is a DPM under the concrete in the insulated raft 🙂 -

Hi - this is what we used - for our temporary standpipe insulation. SHalloduct Water Service Pipe Insulation - 835 x 32mm - 19170 (bes.co.uk) 110mm Blue Twinwall Duct x 3m inc coupling (tradepipes.co.uk) It was a bit tricky to bend in a hockey stick shape, but we did manage to manipulate it into position with the help of some metal straps.