Oz07

Members-

Posts

3246 -

Joined

-

Last visited

-

Days Won

4

Everything posted by Oz07

-

Massively depends. A subby bricky may or may not supply a mixer likewise a laser too. Don't discount someone just because they don't supply these things they may be a skilled tradesman. Now if they start saying they haven't got a trowel or a level that's when you've got to worry. Not sure why but joiners usually supply everything they would need and are usually anal about their kit

-

I think potentially you'd only need one. I'm sure some people have said not every house even needs one. One at the end of each of those runs won't hurt

-

110mm into access chamber when no spare inlets

Oz07 replied to Mattg4321's topic in Waste & Sewerage

Is it? If you have to start featuring something with the access chamber. Couple of slip collars and a y branch jobs a goodun and its legit. -

110mm into access chamber when no spare inlets

Oz07 replied to Mattg4321's topic in Waste & Sewerage

Just y off an existing branch -

What does 'High Specification' really mean.

Oz07 replied to SteamyTea's topic in General Construction Issues

Id say marketing gimmick used for the bling elements. -

This is why when I plumbed it into AI it was basically saying 3g will never pay. Excluding any comfort factor 3g may afford over 2g. How much are the units are they roughly 50% more expensive as half armchair glass again? The u value difference between 1g and 2g was alot bigger than 2g vs 3g

-

MVHR. For sign off.

Oz07 replied to Russell griffiths's topic in General Self Build & DIY Discussion

I had a guy come out and commission mine 2 years later as wasn't happy with my job never used anonometer. The guy was reccomended by firm who supplied the gear. Complete chancer. Used a hot wire tester or whatever it is with no hood. The cert he issued me balanced up the sums but was missing a room supply terminal. When I told him this he just added that into the figures and then it didn't balance. He had just made up the numbers I think. Needless to say he wasn't paid. -

Whats the average lifespan of 3g units?

-

MVHR. For sign off.

Oz07 replied to Russell griffiths's topic in General Self Build & DIY Discussion

Just a printed spreadsheets with flow rates that tally up. Maybe a word document stating you've commissioned it as per manufacturer's instruction. Job done. Did you use an anonometer? -

You will find span tables online for joists if needed.

-

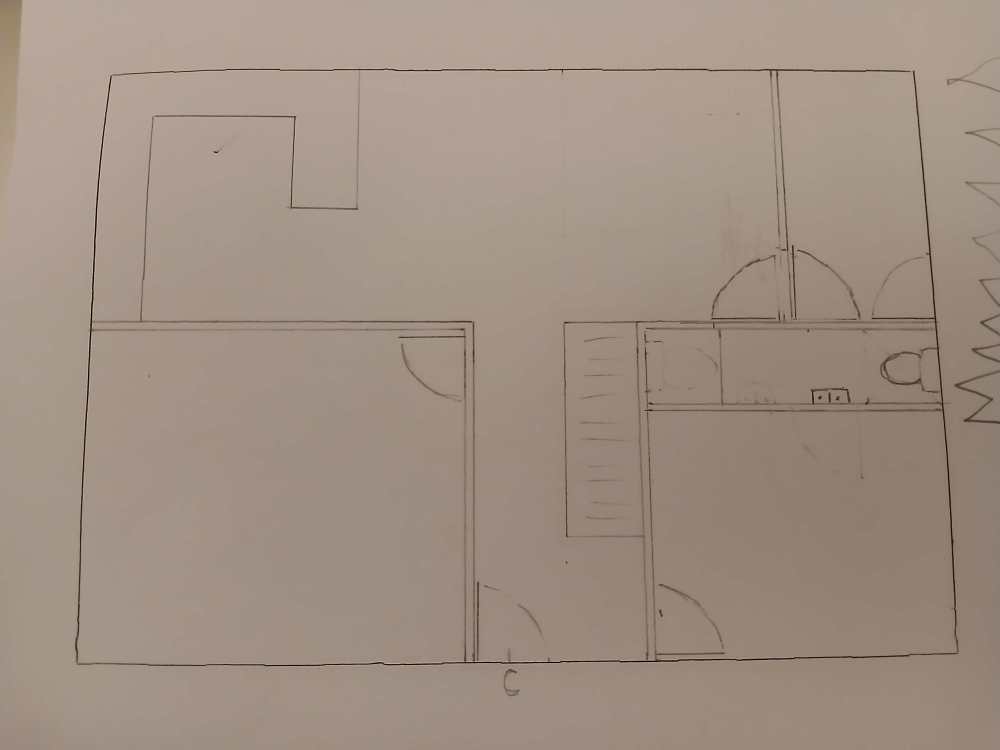

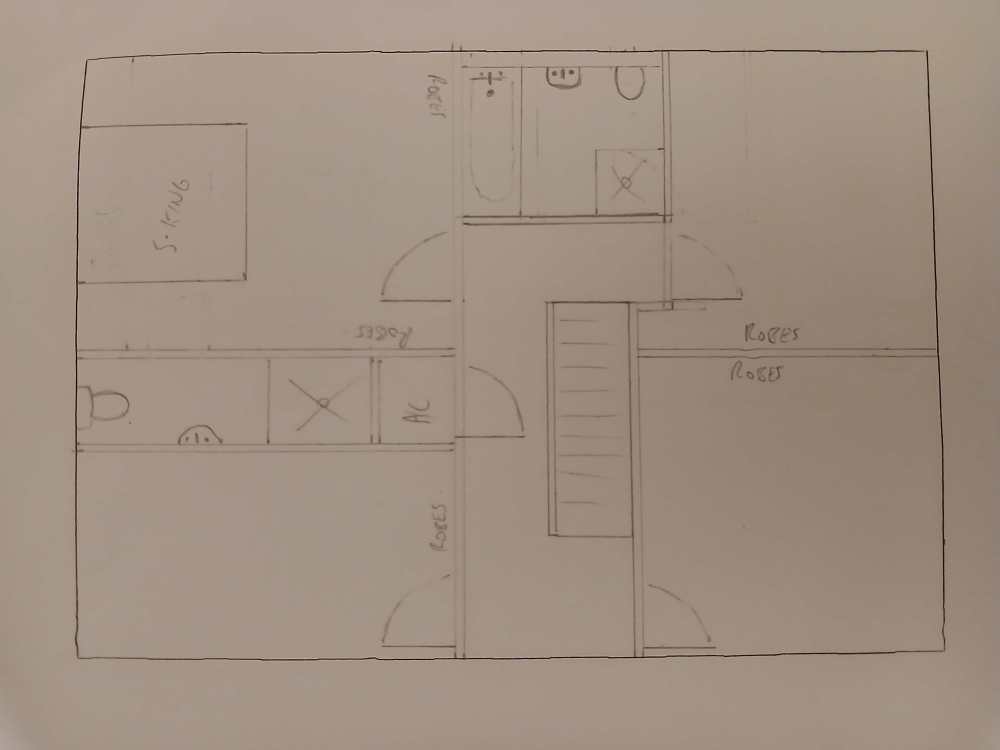

Reason I ask about ufh manifold is because gf cloaks is a bit long. If I squeeze the length 3 or 400mm I could gain a good central cupboard accessed off halfway behind shower. Basically ensuite and gf cloaks is carbon copy then can just order 2 of everything.

-

Would uvc actually be better in ac or plant room? Guessing plant room but not much else to do with that space. Getting ahead of myself not but ufh manifold better in plant room?

-

B1 feels a bit boxed in there

-

Yeh blue area probably absorbed into robes so not an issue. Or I could pinch 600 odd mm of bed 2, split in in half and have half robes for b2 and half for b3. Evens out the bedroom sizes then. Ensuite door not great but keep in mind could be 686mm if swinging. There is 800mm between that bed and wall. Tbf pocket door prob a better option as I never shut any door when i shower or use the bathroom anyway. Door would just be in the way when open

-

Here its just gf cloaks unless things have changed. Yeh I would deffo have a glazed door there at end of hall, possibly a pair as I like the thought of keeping understairs open for spacious feel. Nice view from front door to garden then.

-

Working with an existing footprint so want to keep the same size. 7.25 deep x 10.25 wide after dry lining internally. Want to keep front elevation symmetrical although not particularly fussed on elevation till I get floor plan sorted. Keeping option of 2nd floor open although highly unlikely will be used. Kitchen diner 3.2m x 8.4m Utility 3.2 x 1.8 Lounge 4.5 x 3.9 Office 3.5 x 2.8 B1 4.5 x 3.6 B2 3.6 x 3.5 B3 3.6 x 3.2 B4 2.4 x 2.5 Rear is south, probably have big central doors in middle of that kitchen diner. Utility / plant room on opposite side of kitchen not ideal but dont actually go in there that much in current house for cooking related tasks. More to put washing on or get dog lead etc. Would likely jack and Jill downstairs cloakroom and put a shower in then would likely use b4 as study and gf study as b4. Handy for elderly relatives and keep guests out the way. Maybe need a pocket door? I'm pretty pleased with it at end of the day I think there's only so much you can do with a 1600 odd sq ft box. Had planned to show robes in planning drawings for vat reclaim. Will likely exclude gf shower so planners don't think I'm going for 5 bed. Any other planning tips that you should show in drawings so can claim back?

-

is there a better kind of roofing / cladding batten?

Oz07 replied to Alan Ambrose's topic in Building Materials

How dry and light were the battens? Wetter the better when it comes to not splitting timber. Usually when I've had a pack of battens delivered they are heavy and soaked. Were probably still a tree the week before. -

what i should not have done when installing solar

Oz07 replied to scottishjohn's topic in Photovoltaics (PV)

So much of the case for buying all these expensive batteries has always seemed based on gimmicky tariffs to me. -

No problem exceeding 1.40 with pvc pipe they removed max gradient from regs

-

I understand its pretty good to use aircrete as the thermal break and keep them dry with a dpc. Perform pretty well for lot less £

-

I got 1.2 m3 hr whatever that is in ach. Masonry cavity build with dot and dab. Large coated blockwork internally

-

Try and get away from aircrete. I think you can get .18 with medium dense and 150mm cavity from memory. Maybe dot and dab improves the score slightly

-

Are the regs super strict now with walls having to hit .18? I seem to remember this being the case and swapping some cavities from 100 to 150 in 2015. Saying that new build sites round here still plugging away with 100mm cavity albeit with thermalite blocks. Now I'm thinking maybe you can exceed .18 if you offset elsewhere.

-

4m max potentially get it down to 2m with different svp position. Nothing set in stone yet. When i read the regs its asking for 18mm in 1m for fall

-

Interesting. Just at very early planning stage so nothing concrete yet. I think the wall hung wcs have that 82mm soil pipe from memory? Can you come out of a normal wc pan into 82mm without problems? So my option is smaller waste or less fall. Max run would be 4m, prob a bit less. I'll have to remember to feed waste pipe in when putting joists on. I did it last time with a 2" pipe and small joists centres saved having to try thread it in after.