Mr Punter

Members-

Posts

8238 -

Joined

-

Last visited

-

Days Won

24

Everything posted by Mr Punter

-

tiling over trench blocks below dpc?

Mr Punter replied to Ajm's topic in Bricklaying, Blockwork & Mortar

Yes you can tile these. I am not sure why they would need to "breathe". -

Ventilation under & above windows

Mr Punter replied to Space Race's topic in General Construction Issues

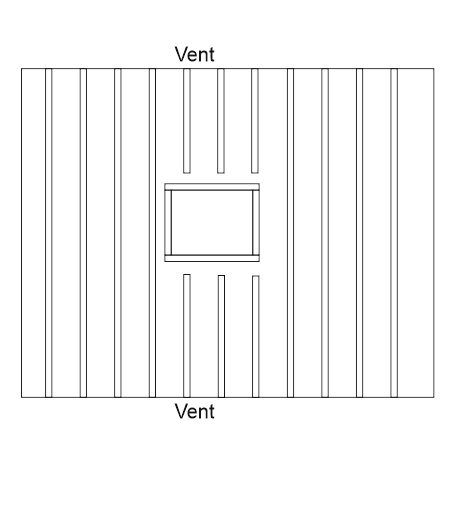

Normally you will leave the battens short of the window opening so the air can flow round. Like this: -

Tee off the below ground. Come up to near finish level and use a 110 to 40mm reducer for your sink waste.

-

It’s coming out the hole

Mr Punter replied to Pocster's topic in General Self Build & DIY Discussion

A plate like the one holding the hinge, so it has more than one fixing and they are spread out. -

110mm into access chamber when no spare inlets

Mr Punter replied to Mattg4321's topic in Waste & Sewerage

If this is just surface water you can pretty much do as you please. -

This is why it is important to identify the wires with the correct colour sleeving.

-

The south facing units are the ones that die quickest.

-

Recommendations for a Structural Engineer - Scottish Borders

Mr Punter replied to Stewpot's topic in Building Regulations

@Gus Potter of this forum is a structural engineer. You could pm him and see what he suggests. I have not used him but he is based in Scotland. -

It depends on the inspector. Since this is for your own occupation it won't come back to bite them so they could be OK. You may need to properly cap off the waste pipes sufficient to do a soil pressure test. Do you need warranty approval / mortgage drawdown? They may be a bit more picky for this. You need electric completion cert and you will also need an airtightness test so see what state they will accept.

-

No, but I remember a fair amount of effort on my part. Probably a Euroscrubby and some Bar Keepers Friend.

-

Vaillant ashp (my battle with).

Mr Punter replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I put him on ignore a few years ago as I thought he was trolling. -

Use the fattest stud that will fit through the holes. Use the plate as a template. 100mm depth in the concrete should be fine and 2mm bigger diameter than the studs. Either a blow out tool or a hose to clean the holes.

-

Measure the holes in the rollers. Your stud should be snug but not tight. It is probably M12.

-

+1 Ensure stud, washers and nuts are corrosion resistant (stainless or galv). Clean the drilled holes thoroughly.

-

The Party Wall notice engages the Party Wall Act and once issued, you need to follow through, possibly instructing a surveyor and perhaps also paying for the adjoining owners surveyors surveyor. You will need plans and sections, together with Risk Assessments and Method Statements from the piling contractor. Allow 2-3 months. If your neighbour does not give their written consent to the proposal, they will be deemed to be in dispute and 2 surveyors will normally be needed to draw up a Party Wall Award - all paid for by you. If you chose not to issue the notice and just carry on, you run the risk that the neighbour could issue an injunction preventing you from continuing, but they would need to do this at their own risk and expense. If their injunction is successful, you would be liable for their legal costs as well as any damages. If they do not issue an injunction there is nothing else that can be done.

-

Where we are you have to have an accessible ground floor WC with outward opening door that can be made into a shower room. Probably 1.6m x 1.8m. Better not to have the kitchen open to the stairs, so add a door.

-

We had an Ebac and it really heated the room up which was not good. The Meaco is much better. Less than 200W. I have a couple in a basement rental, with permanent drainage, and they keep the damp at bay.

-

We have a Meaco dehumidifier for clothes drying. Very cheap to run and dries brilliantly.

-

Raised Tiles on Fibreglass roof Balcony

Mr Punter replied to Robbb's topic in Roofing, Tiling & Slating

I have done similar but with 600 x 600 tiles 18mm and a pedestal in each corner. Make sure they are non-slip. There is not much room under so you will need to set the pedestal heights and positions spot on as you won't be able to adjust them later. Laser level may be useful. The fillet under the sliding doors looks a bit awkward. -

is there a better kind of roofing / cladding batten?

Mr Punter replied to Alan Ambrose's topic in Building Materials

I have used plastic lumber for below ground. Over twice the price of timber and may not have good fire rating for cladding but it does not rot. -

OK to cut excess window fixing straps to help airtightness taping?

Mr Punter replied to Gaf's topic in Ventilation

Yes, 50mm concrete screws are your friends here. For a 7.5mm screw drill a 7mm hole and clear it out a bit so the screw goes in tight with an impact driver but does not lock up before it is home. -

OK to cut excess window fixing straps to help airtightness taping?

Mr Punter replied to Gaf's topic in Ventilation

One nail per strap looks a bit stingy. Often see screws and plugs or masonry screws. No issue with zipping off the surplus strap with a grinder and thin blade.