-

Posts

57 -

Joined

-

Last visited

Everything posted by StructuralEngineer

-

DIY Insulated Foundations

StructuralEngineer replied to Triassic's topic in General Construction Issues

Thanks for the cost breakdown. Did you have professional fees on top of that? I'd be very interested in how the SE did the sliding calculation -- did they have a coefficient of friction between the concrete and insulation? -

Millennial don’t need living rooms!

StructuralEngineer replied to Triassic's topic in Housing Politics

Actually I think the whole point of the article is that planning and other government interventions need to be relaxed. You might like the article. -

Millennial don’t need living rooms!

StructuralEngineer replied to Triassic's topic in Housing Politics

Here's the full article: Only Capitalism Can Solve The Housing Crisis Makes very interesting reading. Essentially he seems to be saying that the housing crisis is basically an "affordability crisis" and that market forces should be let loose on this rather than government policy artificially keeping house prices high by setting minimum space requirements. -

Timber frame or brick & Block

StructuralEngineer replied to Ian D's topic in New House & Self Build Design

Thanks @Declan52 for an enormously candid and valuable insight! I'm trying to understand the source of how this went wrong for you. A standard Celcon block weighs 8kg, which usually should be well within the capabilities of someone to lift consistently for a few hours. Also at £2.50 or so per block, they could even be bought ten at a time and transported in the boot of the car, if money was coming in slowly. Am I missing something here? Again, thanks for the insight, and any further details to help me understand this would be much appreciated! -

Timber frame or brick & Block

StructuralEngineer replied to Ian D's topic in New House & Self Build Design

A big piece of the debate is about labour -- you can get a brick/block wall built for a reasonable day-rate and no supervisors to pay. At the end of that day you can see what's been built, can fire or retain the brickie, pull it down and start again tomorrow if you want. So there's a level of control there. Everyone more or less understands what a masonry wall does and what it should look like. It's also the ultimate modular system when you think about it -- 440x215x100 units that can be lifted by one person and glued in place. Having said that, I'm no fan. Having every measurement in multiples of 225mm procludes any form of standardisation/repeatability or off-site manufacture, and for me that's a big deal. -

Timber frame or brick & Block

StructuralEngineer replied to Ian D's topic in New House & Self Build Design

With SIPS you get a weather-tight frame in no time, and the manufacturer does the design for you if you provide general sizes. For a self builder those two things are a big deal, I think. Trying to tackle a timber frame yourself without being an apprenticed joiner would be pretty much impossible -- or at least a protracted and painful learning experience. Steel is similar -- you decide what you want and someone else takes design liability, delivers and erects it. You then have a stable, plumb and level structure to build your floors & walls around. In comparing timber frame with blockwork I'm assuming the self-builder is the builder, so to learn to put up blocks and then get a satisfactory end result, is achievable. With timber frame, even if you have someone else design it for you, you still have to cut, join, and get it erected plumb. Possibly your experience has been with a timber frame "turnkey" solution provider, and I assume going that route is expensive and akin to getting a kit home? -

Timber frame or brick & Block

StructuralEngineer replied to Ian D's topic in New House & Self Build Design

For a self build there's no real benefit in timber frame. Blockwork is much more durable and forgiving, and you could build quicker with block than timber anyway for a single dwelling. Housebuilders use timber frame because they can throw houses up quicker on big sites. Personally I would go with SIPS or a steel frame, or a combination of both, and I would seriously consider not having a brick outer skin. -

I'll take of 20%, so you save a quid per hour.

-

Sounds like a plan. Everyone round here seems to hire them from Ireland.

-

You might balk at my hourly rate

-

I used to design steel balconies and never, ever, powder coated structural steels. One coat primer, one undercoat and one top coat, or a combination of specialist paints should be fine. Powder coating tends to chip and also loses its gloss. As it's plastic it might fade in the sun too.

-

Looking to begin my estimate

StructuralEngineer replied to Youngredders's topic in Costing & Estimating

I'd +1 on getting spons price book. From what I understand, when you get builders quotes they'll just be using this. The big benefit is that you can then look at contrasting options for each item. Be aware though that this covers only relatively tried and tested building methods. That's £1200/m2. If you don't mind me asking, if you have that size budget, could you get an architect and contractor to handle it all? -

An 11kv line will give off significant EMF radiation, and if you are under this wire you will no doubt be receiving well above the guideline amount. If you ring/email the national grid emf helpline and ask them to tell you what the EMF radiation level is at your property, this might set in motion a process whereby you can get it moved asap.

-

Does the drive need to be "permeable" as you stated? If laid to a slight fall you could go with tarmac or patterned concrete, and introduce ACO drains where necessary. Permeable drives tend to block up anyway.

-

Hello and yes, it's a renovation blog.

StructuralEngineer replied to AdamSee's topic in Introduce Yourself

Looks to me like it's only carrying some floor joists and no masonry. This end of the beam looks better than the other end you showed us before. If you're having BC round at some point anyway, just get them to look at it. They probably won't ask for padstones if it's clearly part of the original build and is only carrying floor joists -- and the brick is well bonded below it. -

Meeting architect for first time

StructuralEngineer replied to Youngredders's topic in Surveyors & Architects

I'd take a step back here and think about fundamentals first. If you haven't worked with them previously: Can you see his three most similar projects to the one you're proposing. Can he provide three names and contact details for references should you need them. Are they RIBA / ACA registered Will they provide Building regulations issue drawings, or just planning (the difference is enormous). WHich RIBA stage will they be working up to. What form of contract. Will they project manage. What form of construction are they comfortable with. Have they tried modern forms, or have only done two-skin masonry. Then if they haven't got nervous answering all those, move on to discussing your design. Hope it helps, and hope you get what you need. -

Loadbearing baths

StructuralEngineer replied to StructuralEngineer's topic in Bathrooms, Ensuites & Wetrooms

Thanks all. I'll take a look at Trojan and Kaldewei. -

We're getting a new bath with shower over, and the builder says we should get a decent bath that will take the weight of someone standing in it -- not something cheap and flexible. Seems to make sense. Does anyone have suggestions for a decent brand to look out for?

-

Hello and yes, it's a renovation blog.

StructuralEngineer replied to AdamSee's topic in Introduce Yourself

That beam seating doesn't look good. It's at the edge of the wall without a padstone, so if one brick goes, everything goes. I'd suggest you get a structural engineer in to take a look asap. You mentioned a door frame sticking. If it's the opening adjacent to this beam -- I'd stay out of the building for now -- as it indicates progressive movement, so the wall (beam bearing) may be failing. -

If you take out the section in red you will need to reinstate a full length rafter at the location in blue. Also you'll need to fix the trimmers at the locations where you have now cut the supporting rafter (in green). Keylite have an engineering department -- have you given them a call? They might be able to advise on an easier solution: https://www.keyliteroofwindows.com/help-centre/after-sales-support/

-

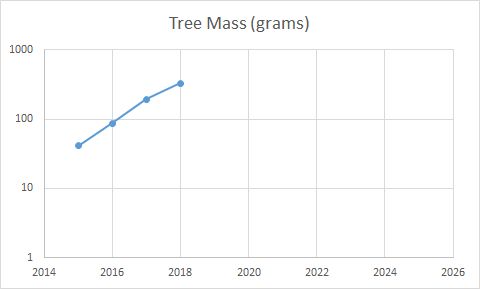

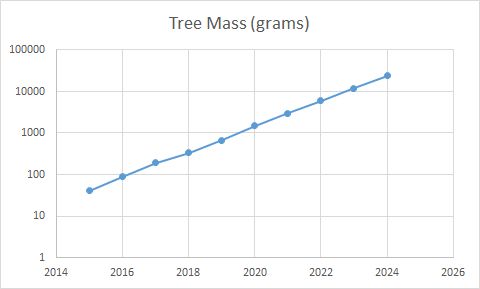

Looks to me that this is increasing exponentially. Plotted on a log scale it looks like this (almost a straight line): So if that's the case, in ten years you could have a 24 tonne tree (24,000 grams).

-

Which is worse, heave or subsidence?

StructuralEngineer replied to epsilonGreedy's topic in Foundations

You'd usually have insulation over the slab if it's concrete or beam and block. For Timber you can have it between the joists. A gap allows for air circulation which generally is a good thing (especially if radon or methane is present. For a cast in-situ concrete slab you would have void formers, so no air gap as such. -

Which is worse, heave or subsidence?

StructuralEngineer replied to epsilonGreedy's topic in Foundations

What a sight that must be! @epsilonGreedy Ground heave is more difficult to remediate once it's happened, for sure. Ground dropping away can be dealt with by underpinning (if a foundation) or resin injection (if a slab). If a slab is lifting, more invasive interventions could be needed such as breaking out the slab and reinstating -- not cheap, not easy to design, and very time consuming (while the home owners have to move out). This is one more reason why a suspended ground floor is a good choice at design stage. -

Garage construction advice needed

StructuralEngineer replied to Kgthomas's topic in Garages & Workshops

Hi @Kgthomas. It sounds to me from your description that you have a steel portal frame structure and that your steel sheeting acts as the building envelope to keep rain and wind out. traditionally with this form of construction you might wish to span a steel or timber "header support" between the posts and build a blockwork wall of about 1.5m to 2m under it. If you fasten the blockwork wall at the top to the header, and at the sides to the steel columns, you should have a robust wall for your workshop. -

I'm racking my brain trying to think what the SE wants straps for. The sole plate should be fixed down to concrete anyway, and the top plate should be connected to the joists.