-

Posts

12029 -

Joined

-

Last visited

-

Days Won

174

Everything posted by JohnMo

-

A problem or not a problem?

JohnMo replied to MikeGrahamT21's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Dodgy temperature reading to me, or you have the wrong identity assigned to each gauge? So rubbish in, rubbish out. You seem to making an issue from reading from a £1 gauge. -

The other way to it, is borrow ideas for the Adia system and simplify. Have heat pump on its own loop, CCT and additional pump for secondary loop, flow rate and match flow rate with secondary pump. Choose pump with enough head to go through existing pipes as required. Use flow setters on the existing rads at a dT to suit room and flow temps. Heat pump will modulate as needed to meet the heat extracted from the primary loop. Primary pump pulling almost zero Watts as no real head is needed. Whether you actually need to include the CCT is questionable, you just install an additional pump on the piping to produce the additional head required on fixed duty (then there is no fight with 2x modulating pumps), to push though the existing pipes. Then do what you normally do to the system.

-

And domestic cats kill way more - every year. But no-one complains about that. Don't here any slogans "stop the wind farm and neuter/ban all cats"

-

Are you not just arguing for the sake if it? No one one says (well maybe a few some ill informed are) that we must stick with hydrocarbon energy sources. NIMBY's are complaining about anything and everything, even if happens 20 miles from them. If we can get all our energy from renewables (which doesn't include nuclear) let's fill our boots. Distribution of said electric needs to happen, more NIMBY action there. In the time to bring renewables on line oil/gas needs to back fill. All very simple.

-

Panasonic, Daikin, I'm using a Myson iVector. You need one with adjustable water flow temp fan start permission. Some only really designed for gas boiler so have a fan start permission of say 45 degs - which is no good. These fit in the none adjustable fan permission category, in most and are designed to allow cooling.

- 41 replies

-

- mvhr

- ashp and dhw

-

(and 2 more)

Tagged with:

-

Think it's there to cover all bases. Use the installed pump of the ASHP to overcome heat exchanger and piping to house. The secondary pump is there to push though micro bore if you need to. It's a one box to cover a lot of situations. Still not seen anything on how it works with UFH. It says one flow temperature systems including UFH are doable. But not seen any details.

-

They can't, almost no country can, it's a global market. It's what I mentioned previously, it shouldn't be a binary gate, each fuel, renewable or hydrocarbon has a part to play. Trouble is the environmental activists, demonstrate, with their plastic tents, plastic drinks bottles, fleece jackets, nylon ropes, and don't understand all that vanishes with no oil. The point should be what mix of fuel and energy sources leads to best self reliance. A grown up discussion needs to be had, but British politics, the press and the money, will never let that happen. You need people power to revolt and standup, but most couldn't give a stuff or cannot or not interested enough to understand the issues or possibly solutions. In the round renewables is the way forward, but for a long time hydrocarbons will have a big part to play, especially in England, Scotland way less so.

-

It's sold on the basis that no radiator or piping changes are needed. After a few weeks of capturing data, the home owners gets the options - stay as you are, and possibly upgrade radiators, for a given cost v cost saving on running cost. Suppose the idea is for £4k plus a day or two labour you get a heat pump. If you have a cylinder already they can use that as well.

-

Self Build Heating and Cooling Strategy

JohnMo replied to Havkey100's topic in Other Heating Systems

I installed two units in our house, self installed, well under £2k all in. Ebay can be your friend - if you accept warranty is unlikely. But in the UK you don't need pre heat or enthalpy heat exchangers, you don't need CO2 sensors and really once setup, and running, you don't even need boost very often - we last had boost on (manually) over a year ago, auto boost just isn't activated. Manual boost outside bathrooms and in kitchen, or manual boost in kitchen and humidity activated elsewhere. -

I've seen that way of doing things mentioned several times and the real world a lot of building could get away without much in the way of radiator changes. VAT, include a contingency (deposit) to return assess and make x pre priced changes - fully refundable, less second visit service charge? Explain you could remove that charge, but full VAT, plus any grant funding, that was too have been included, would be payable for the second visit.

-

Self Build Heating and Cooling Strategy

JohnMo replied to Havkey100's topic in Other Heating Systems

Keep it all simple and functions separate First ventilation is ventilation, it isn't heating/cooling. Separate the ventilation keep it a stand alone item. Cooling via MVHR is an expensive folly and in the round doesn't work as flow rates are too low. Why oversize the heat pump - bad for SCoP due to cycling. Plus Vaillant don't do cooling out the box and cost way too much So is that 3kW or less? if so heating bey direct electric isn't going to be cheap - 3 x 24 hrs is 72kWh. Direct cylinder are fine, not sure I would pay the premium for an OSO A rated one. Slightly oversize for house and heat to 50 degs. Low tariff charge not from battery, use battery for other stuff, not worth the round trip losses when you can charge direct, without going via battery. I would do Decent no frills MVHR, if you want a Passivhaus certified one, fine, but leave all the optional extras on the shelf Stand alone small heat pump - A Haier 4kW is £2100 from Wolseley incl VAT (you can reclaim) Telford Tempest 250L direct cylinder £610 UFH to ground floor, £1k - fully open system, no room stats or actuators, flow direct from ASHP circulation pump Or direct cylinder and a good quality A2A heat pump for heating and cooling Option 1 - no Option 2 - no, almost but not quite - £10k for MVHR are you mad? Options 3 - no -

Just found a price, £1500, smart but... if offsetting getting new radiators, new plumbing and paying for an engineer to optimise your system, then small beer. New build where you should know exactly wall, floor and roof buildup and get heat losses quite accurate and your installing new piping and radiators anyway, not really needed. But would idiot proof a lot of installs, assuming heat pump is massively oversized.

-

Choose a product specifically with certification for what you want. Kingspan Nilvent comes to mind, but plenty of other available. Look at the certificates and approvals. Doesn't Allow two way humidity movement as it's a smart membrane? If so not sure you want unventilated roof space, but with correct roof membrane you still get plenty of air movement as they are vapour closed and air permeable. Get you ducks in row and the BBA certificates, then you should have no issues

-

That's an interesting bit of kit A video here https://youtu.be/9sHmHa5ha_4?si=mir2dQesUXf0Aqgn

-

It does external and assumes 20 deg internal.

-

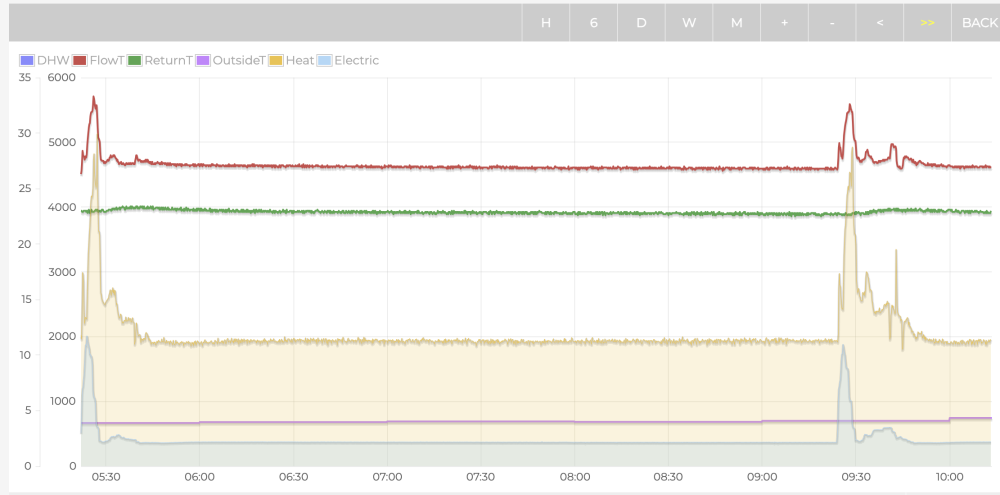

Everything relevant via Heatpumpmonitor So plot of all the data so far, included hybrid running, ashp on it own in heating and cooling modes. I can go in to each day and see a 20 sec resolution on all the datapoints, instantaneous CoP, flow rate, flow temp, return temp, electrical input, heat output etc

-

Certainly does, out the box I would suspect a sound SCoP of 3.5 to 4.0. Without monitoring gear, no-one would see the modulation that was going on in the background, not even the installer. I am fully expecting a SCoP in the 5s

-

Plot of the last 5 hrs, one thing I have noticed is, every 4 hours it does a full load spike. Not sure if thats to test the sensors are all still working, adding a little heat to the lube oil to stop refrigerant saturation or combination of all these, plus some others. But seems part of the hardwired DNA of not wanting to stop running and cycling.

-

Had a week so far since startup. Seems Haier run two different algorithms one with a buffer and one without. The one without buffer seems to look for immediate response to changes, really suited to radiators or fan coils - not a massive slab of concrete. If it doesn't get response it expects, it seems to chase about trying different things and leads to the erratic running I posted a couple of days ago. I tried running in buffer mode (no actual buffer installed), reintroduce the volumiser and this calmed everything down for quite a number of hours, but then things went astray a little. The heat pump seems to hardwired to do anything other than shutdown. Opening up the target dT to 5 really calmed everything down. So far I have tried, fixed dT control at 3, 4 and 5, fixed speed circulation pump at various speed, volumiser in and out of circuit (while running various modes), buffer and none buffer mode (without an actual buffer). Settled on volumiser in circuit, running buffer mode, and circulation pump set to control at flow and return at dT 5. So far today outside temp has been between 4 and 4.5, average CoP today has been 5.0, the last 30 mins 5.2 and flowing 26 degs. The other day during some steady state running I was seeing a CoP of 6.2 over a number of hours at an outside temp of 7 degs. Over the last week with trying things, a fair few starts and stops and 3 defrosts, the average CoP was still 4.5, the month previously had a average of 3.6. So looking forward to a much better CoP, so lower my actual heating bill by a 25-30%.

-

Loft hatch or no loft hatch

JohnMo replied to Selfbuildsarah's topic in New House & Self Build Design

I would have one, get an insulated and air tight one, with ladder - make a raised landing area above the level of the loose insulation and maybe a central pathway. You can never have enough storage space! -

Unless he wants 3 phase?

-

https://acwservicesltd.co.uk/electrical-services/solar-assisted-heat-pumps/

-

Thermal Mass is just a common way of saying thermal capacity - The SI unit for thermal capacity (or heat capacity) is, joules per kelvin (J/K) or joules per degree Celsius (J/°C). Heavy stuff like concrete the value is high, air the value is low. But Harris and Steamy through the teddy out the cot because it "Not the Correct term" to use, but ha-ho. They exist in science they are just taken from a differing view point, an example cut and paste The centripetal acceleration is the acceleration a body experiences in centripetal motion (moving in a circle or along an arc). Centripetal acceleration always points towards the centre of the circle, hence the direction of the moving body is constantly changing (since its velocity is always tangent to the circle). On the other hand, the centrifugal force is a fictitious (imaginary) force the object experiences during circular motion. The direction of this force is opposite to the direction of the centripetal acceleration. The best example to visualise this difference is to imagine being in a car. If the car takes a sharp left turn, the passengers experience a thrust towards the right (the centrifugal force), whereas the friction between the road and the tyres results in the centripetal acceleration allowing the turn to take place. So they are equal but opposing forces.