-

Posts

21023 -

Joined

-

Last visited

-

Days Won

206

Everything posted by Onoff

-

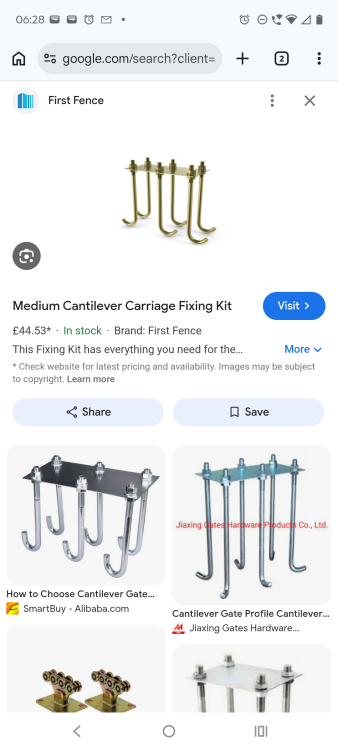

Again, J bolts hooked under reinforcing mesh or some similar design of holding down unit with plates and long studs. Windage against a gate and offset loads will just worry chemical anchors out over time. With something locked into the concrete you're trying to "worry" the whole, large concrete footing.

-

I'd cast in J bolts for that as a "holding down unit". Hooked round mesh going down into the concrete. Don't get me wrong I love chemical anchors.

-

Try this before cerium oxide: https://www.ungerglobal.com/uk/products/rub-out

-

Jewellers rouge aka cerium oxide works a treat to bring up scaled glass. We used to use it to get cement stains off glass. It comes in different grit sizes. We once used coarse to fine getting burn marks out of glass that some lad had caused with angle grinder sparks.

-

Low points: and how to get out of them

Onoff replied to ToughButterCup's topic in General Self Build & DIY Discussion

Plus you can look back to that point where you had perfectly flat, boarded walls and think "If I'd have "turned right" and accepted a mate's proffered help on the tiling..." Guess who turned left and had a go himself? 😡 -

-

-

-

Greasy cockup - don't read this before eating.

Onoff replied to ToughButterCup's topic in Waste & Sewerage

& you've been caught! -

ESP32 S3 m5Stack Cores3 swmbo friendly watering system!

Onoff replied to Pocster's topic in Boffin's Corner

Print in tpu. -

More gone east than West then?

-

Big in Japan apparently.

-

Yes. Fit stainless screws and black screw caps. https://www.screwfix.com/p/timco-4-9ga-100-pack-black-plastic-screw-caps/378kf

-

I fell off my bike, so I'm ravin' mad ....

Onoff replied to ToughButterCup's topic in General Self Build & DIY Discussion

Is that für ze tanks? -

Yeeessss we bloody done it.

Onoff replied to Russell griffiths's topic in General Self Build & DIY Discussion

Fantastic! Can we see some more pics.....maybe close ups of the locks and security measures? 😉 -

You have absolutely no idea how close to the truth you are. Buildings either side of that street have seen a fair bit of Police activity over the years. For what you're getting at is a couple of streets over.

-

Stainless Steels in warm, damp and chlorine environments.

Onoff replied to SteamyTea's topic in Boffin's Corner

Hasn't A4 80 roughly the same tensile strength as Gr8.8 mild steel? -

I spy a huge box of tissues on the right... 😉

-

That's a good shout actually. I've a cable tray setter I made when at college, that might do it.

-

Thinking to fire up the plasma in the morning and cut a say 16" circle out of some thin stainless sheet I have here as a start. Maybe drag the torch round an old wheel rim. Thinking won't a flat plate be noisy in the rain? Is a conical cowl necessary? I've no method either of rolling a downturn/lip on said disc.

-

All I got from that was "hands free".

-

Stainless Steels in warm, damp and chlorine environments.

Onoff replied to SteamyTea's topic in Boffin's Corner

I know using stainless electrodes for electrolysis isn't a good idea as it produces toxic hexavalent chromium, Cr6+ at the anode. It does work mind as I've tried it. -

Stainless Steels in warm, damp and chlorine environments.

Onoff replied to SteamyTea's topic in Boffin's Corner

Grade A2 nuts and bolts, by the sea, end up like a Swiss cheese. A4 is what you want. -

.thumb.jpg.984fda65500c69c5abcdfc1b38e63366.jpg)

.thumb.jpg.ed84bf409e8b67125d99b94bb9bde8e7.jpg)