-

Posts

2858 -

Joined

-

Last visited

-

Days Won

5

Everything posted by joth

-

Earth Neutral bond for hybrid inverter (again)

joth replied to jimseng's topic in Photovoltaics (PV)

An alternative is to have automatic switch over to backup power, but with a long (multiple seconds) blackout period on grid loss before reenergising from backup. This way most heavy power users will automatically stop and not restart on power restore thereby shedding most the excess loads. All modern, digital controlled ones would; Certainly my ovens, microwave, washing machine and dishwasher, heat pump and hob all do. The immersion is the exception if hard powered on, but if on a PV diverter it's also taken care of. Even power tools probably power off too (as operator would have chance to release the trigger before the backup returns) -

Time for some new Makita goodies- any good deals on?

joth replied to Crofter's topic in Tools & Equipment

I just ordered 4x 6000mAh Li-ion batteries from AliExpress -- £5 each! They claim to be genuine Makita, of course they would wouldn't they, but I've had pretty good results from bulky NiCads I previously bought there so thought worth a punt Been really enjoying the pruning chainsaw I bought recently. -

Interesting - even knowing this, i can't find any references to it whatsoever. (I don't do YouTube videos willingly though) The Apollo msr2 is the same thing going (has an optional temp sensor, but totally unreliable) and I've struggled with the same issue in devices I've built professionally in the past so i sympathise with their struggle. It's annoying some projects we struggle to get one temperature sensor per floor, others we have 4 per room 😂. Like London buses eh

-

Looks like they have a Pro edition in the works with PoE, which is nice to see. Odd they don't have Temperature + humidity in an "everything" sensor. That, plus and a nice flush-mount recessed housing, it'd start to look like a good solution for install throughout a build. Also, funny story: late last year I mis-remembered this thread, saw a discount on Apollo MSR2. Bought 2 and guess what? They're just as useless as the mmWave board I built myself (as using the exact same LD2450 as I was. I should have double checked what you wrote here before ordering LOL. Also interesting the Everything One/Pro also use the troublesome LD2450 , but coupled with PIR and another longer range mmWave SEN0609. Sounds hacky but I guess don't knock it if it works. Anyway I'll certainly stay clear of their Lite as it's LD2450 only and I now know for sure that's a disappointing result, exactly as you said here 12 months ago. Have you put custom ESPHome firmware on the Everything One? That is one thing Apollo got right - very easy to take control of it. I specifically wanted to adapt it to make HTTP request (or send UDP) to my server on every state change, to avoid polling state or having to use the HomeAssistant API. That'd be a nice thing to have built into the stock firmware like Shelly do (aka Webhooks)

-

My Starlink works fine at ground level so long as it has clear view of sky, although since then I've now mounted it on the roof of the campervan. I also setup a dedicated VPN from the campervan router to my home router, so there's minimal Starlink / USAian involvement in the datapath. I'd now much rather not be sending money with that man or his empire, but we are where we are - at least I can minimise the visibility of my traffic as it passes through his patch.

-

A couple thoughts on this: KNX is not a smart home solution, it's a communication protocol. If you want automations and phone or voice control, you need a home server / controller of some sort to run the Smarts, and it can use KNX as one of likely a number of protocols of varying levels of standardisation to control devices. (Dali, DMX, Modbus, 1Wire, and wireless things like Zigbee, Bluetooth, Thread and of course Wifi/IP are all possible) Once you've selected the smart home controller, and figured out what use cases involve it talking to the ASHP, the integration with the ASHP may be via KNX but I'd be happy to bet that's an uncommon and awkward pairing compared to having the controller talk something more natively supported by the heat pump (most often modbus RTU or eeBus) As others say, the use-cases for integrating the smart home and heat pump are not that compelling so it's definitely not something I'd prioritise over getting a robust self-contained ASHP install from a reliable installer. Here's a few things I do do in my install, but they're all in the nice-to-have bucket: Load compensation, SW tuneable weather compensation based on a forward looking forecast, TOU optimization, automatic "away" mode, automatic DHW boost when more people are staying in the house, remote monitoring and error reporting with automatic fallback to immersion and resistive heating when the ASHP fails (needed more often than I'd like; see above comment about prioritising a robust installation!), energy & COP monitoring. The one thing I *do* value is having the controller (Loxone miniserver in my case) coordinate the heating and cooling requirements across the house to avoid systems fighting each other; this can cover shading, passive stack ventilation, active boost & MVHR bypass ventilation, aircon, UFH, etc. But this doesn't need a very deep level of integration with the ASHP, on off control (and a way to switch heating/cooling mode, if supported) is sufficient.

-

DM sent, thanks

-

Well, another year, another L9 ecodan flow rate failure, this time it's the other flexi-pipe, I think. I've replaced it with the other one of the pair I bought, but being 750mm long it's ended up with a tight bend to get it in place, and I'm still only seeing 7 l/min not the 12 I used to have. Anyone got tip on where to buy 1" BSP x 28mm compression flexi for a reasonable price? I don't need "pre-insulated" MCS approved as I now have plenty of spare external insulation from the failed hoses. I *do* need something with a bit of longevity though, as I'm getting tired of all the maintenance these hoses introduce.

-

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

Sorry i lost track but is he still assuming a flow temperature of 40°C or something? If you're running low and slow, any rooms that are already over 24°C simply won't take any more heat from an emitter that is barely any hotter than target temperature. Whereas rooms that are (significantly) colder will have a steeper temperature gradient and hence transfer more heat. This is one of the great advantages of low and slow in a low energy home: it's largely self balancing and so you can jettison all the complicated controls as @JohnMoand others evangelise so well here -

One thing I'd add is the secondary (output) side of the driver must be 150V d.c. or so, which is definitely not SELV and enough to give a fair belt. So take care handling it and maybe one reason replacement driver would be hard to find. Do you know how many watts the fitting (i.e. The LEDs themselves) is rated as? Here's a 150mA driver which will be fine current wise, but only 6.3W which is likely (but not obviously) too low https://www.aliexpress.com/item/1005009676981309.html Edit: 12W, maybe getting closer https://www.aliexpress.com/item/1005008654656151.html

-

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

No, it was oversized to facilitate fast DHW reheat times, and because the MCS installer was skeptical our enerphit would succeed. PHP said 4kW demand but we installed 8kW. This supporting the fast cheap rate heating cycle is a happy coincidence, as in 2019 I really wasn't specifying this based on the existence of such deals. -

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

To get best energy efficiency you'll want to use weather compensation, so you set a curve of flow temperature for given outdoor temperature. Perhaps 35 or more on vary coldest days tapering down to around 20 when the outdoor temperature approaches 20. The only downside of running a very low flow temperature is risk of the heat pump short cycling, which reduces its efficiency greatly, but a large ufh area makes this very unlikely so long as most looops remain open. -

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

It's controlled by Loxone with load and weather compensation, but during periods of very cheap energy i push right down the turn on threshold, bump up target temperature very slightly, and boost the curve based on the difference between the floor slab temperature and target temperature Means i can squeeze out a day's heating demand in about 4 hours operation. The DHW schedule is a bit more hard coded as I want that to happen last thing during the cheap rate block -

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

Even with a 10kWh battery we find Fast and Furious ashp program is still a cost saving in winter, because the battery is fully used time shifting the rest of our demand. (2 people working from home, with compute heavy work). For sure a larger battery would change that, but it's not a good capital investment for just a couple months a year. YMMV, but designing to work low and slow is surely the sensible starting point -

Buffer tank and secondary pumps. Do I need them?

joth replied to jimseng's topic in Air Source Heat Pumps (ASHP)

Not to contradict this, but this is specifically true for energy efficiency. Some folks talking about efficiency actually want running cost efficiency. With TOU tariffs, in a low energy home, running the heat pump fast and furious for 5 hours of overnight cheap rate electricity can be much lower cost than the low and slow mantra has you believe. So some consideration for higher flow temperature and potentially controls to avoid specific room overshoot can be helpful if chasing low running costs. All that said, to the OP this doesn't really impact the choice of a buffer tank or volumizer, such items are less necessary for short cycling reduction if running the ashp hard, and don't help at all in effective TOU shifting of demand. (An oversized UVC however can be useful if chasing low cost tariffs) -

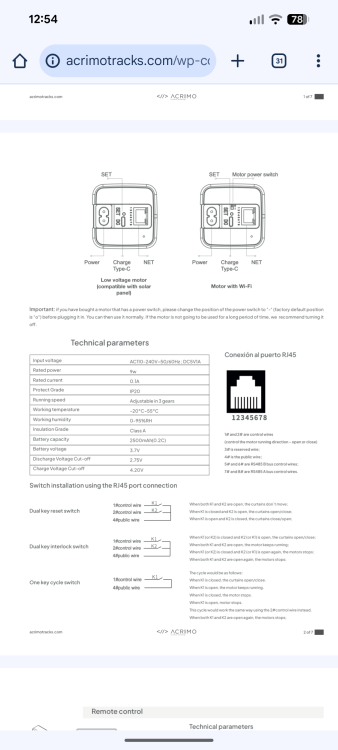

Got it. I expect it's a Tuya motor, extrapolating from their App support info: https://acrimotracks.com/wp-content/uploads/2024/04/Folleto-motor-wifi-EN.pdf A quick search suggests Tuya RS485 is generally running modbus. Dooya is perhaps another brand using Tuya and there's some info on it here https://community.home-assistant.io/t/dooya-curtain-motor-rs485/140398 (inc links to other pages with some code that has position read back support https://github.com/chuanjiangwong/RS485/blob/665bc856cff307b876acc519dcc02d17ec1dec1d/app/rs485d/src/device/curtain/doya/doya.c) so that's what I'd probably start poking around with (either using that code, or more likely using a generic modbus read/write tool) There's also A-OK curtain motors that have a different RS485 (non-modbus) interface, but I think Tuya is the place to start for reasons mentions.

-

Is it not this device? https://acrimotracks.com/wp-content/uploads/2024/05/Product-manual_EN.pdf Connect pin 1 or 2 to pin 4 for open/close. It has a 220V ac input connector (figure-8 style) to bypass the solar/battery gumpf. I wouldn't bother with RS485 as i doubt it offers anything more than the dry contact input controls. (It'd be lovely if it reported back current curtain location, especially if it supports tug to open, but I doubt it would)

-

No, you'll appreciate having the wire when the battery (or motor) in these fail and you can't get a replacement. I'd always use wired power and control if I can. Does it not have any option to bypass the battery? In most cases you can use a couple "dry contact" relays to trigger each direction. Electrically equivalent to having a up/down momentary switch to control it. It's just a case of figuring out the pinout on their rj45. If it wasn't that expensive perhaps worth a shot opening it up and tracing the PCB a bit. Or email the manufacturer and ask?

-

Anybody using Eon NextDrive Tariff ?

joth replied to mk1_man's topic in Air Source Heat Pumps (ASHP)

Looks like the Eon honeymoon is over. My one year renewal arrived: Import cheap rate is down from 7 to 6 hours. Price up from 6.7 to 7.5p Export is switching down from 16.5p to 6p per kWh!! Apparently as I'm on a TOU tariff i can't renew export to the higher paying Exclusive tariff. Despite the original renewal offer saying that's what I'd move to As expected they make the list of options complicated enough it's a maze to navigate in the hope you'd give up. Probably back to the even bigger maze of Octopus for me -

Air monitoring thingamajig

joth replied to Russell griffiths's topic in General Self Build & DIY Discussion

CO alarm is best kept separate to CO2 monitoring If CO too is high you need a loud alarm to wake you up and get you out the building. (Things that combust continuously, like a boiler, are biggest risk) CO2 is most interesting to see long term graph off, correlate any spikes to activity (house party is classic) or equipment performance. So suggests a cloud or App connected device of some sort You don't need an alarm for it to save lifes in the same way, even in a very airtight build -

ASHP with large thermal store (for load shifting)

joth replied to apesort's topic in Air Source Heat Pumps (ASHP)

Link? +1 to that. If keeping the TS I'd just heat it from the 6kW immersion and have the ASHP bypass the TS completely and directly feed the rads (and DHW, if zoning allows). You can then heat the TS to 80degC to increase its capacity using cheap rate at a slight saving vs running the ASHP on expensive rate (savings would increase if the cheap : expensive ratio increases in future, or be wiped out if the difference reduces - who knows). Personally I'd be on the side of removing TS altogether, for simplicity and maintainability. But I'd love to program an intelligent control system for it, just for funsies. -

Loxone recommend budgeting 10W per speaker for normal installs https://www.loxone.com/enen/products/audio/install-speaker/#:~:text=Power supply planning,to safely cover power peaks. Also bear in mind that on a 40m run, no all the current will be drawn along the full distance. It's a ramp function, so on average you can model the full current at the midway point (or half the current the full distance). You can also run it as a ring and feed the power (but NOT DATA!) cores from both ends if you really want. That halves the average current again. I typically run data buses, even strict buses like 1-wire, as a ring back to the node 0 anyway, and only connect one end, as it makes it easy to test for continuity, diagnose issues, and even split the ring into 2 separate buses in case of any issues (cable damage or interference).

-

It's the difference between test voltage limit and application voltage. The data sheet actually rates the insulation up to 5500VAC ! https://pim.loxone.com/datasheet/100606-audio-cable But also has this clumsy wording (probably clearer in the OG Deutsch) "The power wire with 2 x 1.5 mm² can be loaded with 230 V, but the data wire must not be connected to a 230 V circuit. Before connecting the data conductors, the entire circuit must be limited to a maximum of 25 V." i.e you can use it for 230V if you want to, but then you can't use the data cores for anything because that needs to be SELV. As an example, you could run this and put (only) mains down it now, but installing it as a future proof to switch over to 24V + data in future. For light switches, maybe? (Why you'd want to do that with audio cable is anybody's guess; my guess is this is the spec for the Tree cable and they've just changed the jacket colour) (also the 25V reference is weird, pretty sure all Loxone components are rated upto 30V input from PSU)