-

Posts

1493 -

Joined

-

Last visited

-

Days Won

5

Everything posted by marshian

-

Yeah 100% this is something I see and most people wouldn't notice it It's more common between 4 and 8 deg C - after 10 deg it doesn't really happen It hasn't done it for a couple of days since I've changed my strategy for heating and my current WC curves are to to be frank bloody weird......... I'll post them up later but in summary I now have 3 WC curves, one for below zero, one for zero to 10 deg and one for 10 degs and above and I swap between the curves with the target room temp

-

Well Viessmann technical have washed their hands of the boilers behaviour - their conclusion is that it is normal behaviour for a heat only boiler running weather compensation I'd done a few videos showing the boiler behaviour and shared them with the technical team hoping that this would help to point me in the right direction if it was a set up issue Seeing as they are adamant it's not a boiler issue as such I'll share one here Basically attached a remote microphone to the boiler because the phone itself can't pick up the sound change when it ramps up or down and then filmed the Vicare app on another phone which shows flow temp and modulation level so it's as dull as a dull thing from a content perspective The commentary to go with it is in the description but I'll put it below as well 9.7 Deg Outside Air Temp - Target Flow temp ~25 Deg C Timelines (so you can skip the boring bits) 00:00:20 Boiler Starts (Initial Purge and Burn followed by ramp down) 00:02:12 Boiler at "Minimum modulation" 00:02:47 Running thro the settings (Weather Comp Curve Slope and Level) 00:03:22 thro to 00:15:35 Boiler stable running at min (flow temp slowly rising from initial 27.7 Deg C to 29.2 Deg C) 00:15:37 Boiler modulation increases driving flow temp higher faster 00:17:43 Boiler modulation decreases and then rises again 00:20:18 Boiler modulates back to minimum - flow temps drop to 30.5 Deg C 00:21:45 Boiler shuts down (due to flow temp exceeding target plus 5) 00:21:16 Running thro the settings (Weather Comp Curve Slope and Level)

-

What numbers do I need to size a heat pump?

marshian replied to Selfbuildsarah's topic in New House & Self Build Design

In an attempt to understand my errant boiler behaviour I recently tried to heat a tank of HW with a 16kW boiler when range rated to 4 kWh - it's only a 115 Litre tank to say progress was glacial was an understatement - a bigger tank would definitely be little and often -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I compare it to bashing your own head repeatedly into a wall It's nice when you stop............. -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

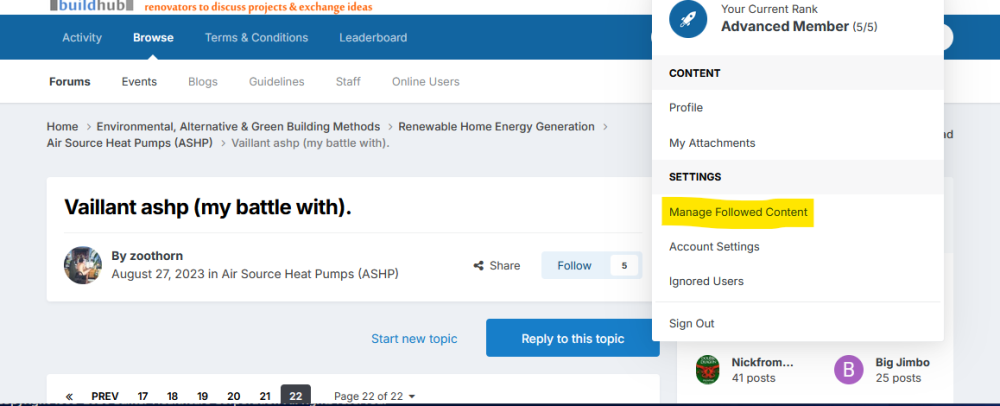

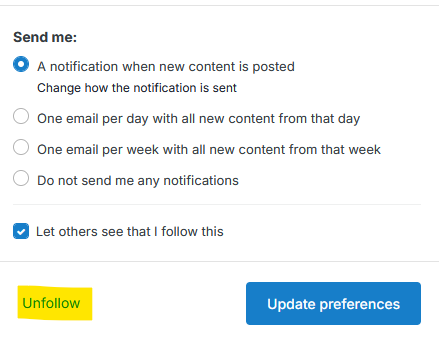

@saveasteading @Nickfromwales@SimonD Alternatively go to your profile Manage followed content Find the "Unfollow" this thread and update preferences -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Ahh I wouldn't mind betting we are of a similar era - Good old Fergal I was gonna say @-rick- bravo for persistence but possible you on a hiding to nothing - good luck -

Our Meaco when on full Laundry mode is 700 watts but it's very effective and wouldn't be without it

-

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Christ this is hard work - my BH user id is Marshian - You know like from another planet - oh maybe the planet Mars - my better half - Mrs "Alien" (You know like from another planet) I know it's not spelt like that!!!! -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I'm just saying start low (ish) and work your way up if the house remains cold - I have this irrational fear that you will start high, pronounce the house too hot, can't sleep and turn it off again People tolerances are different - I'm "hot" above 19 - Mrs Alien - different kettle of fish less than 21 is freezing!!!! Well we can start there - what size and type are the rads and what sizes are the rooms - we have enough knowledge on here to start piecing it all together and come up with a reasonable punt I have a gas boiler and I'm running it like an ASHP - CH 24/7 low flow temps (between 25 and 35 Deg C based on weather comp) - when doing HW it raises the flow temp to heat the tank. I could replace it with a 5kW HP tomorrow and know it would work perfectly - this was the point of my rad upgrades and insulation improvements - get HP ready without leaping into it and then finding all my calcs were wrong and I've got a problem. -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

No point saving money with a lower flow temp if the house remains freezing 😉 We don't want @zoothorn cooking though do we 😉 I'd start in the middle (35 Deg) and see where the house settles - increase or decrease accordingly -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

What Flow temp you need is simple - the lowest flow temp required to heat the house with the rads you have My house with a gas boiler is between 25 and 35 depending on outside temp............ But I did fit big rads so that I could do low flow temps -

My neighbour had a bloody great conifer in his front garden - far to big for the space - completely blocked the light to his front room. He never pruned it or even topped it. I asked him several times to trim it but he refused. It also meant my side gate and his side gate weren't visible from the road and a low lifer decided he'd gain access to my back garden and break in thro the French doors. As a result I pointed out to him that his house would probably be next and he'd probably need to get a better back gate. shortly after he had it removed but not before the cheeky bugger asked me if I'd go halves on the cost

-

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Absolutely - flow temp and the size of the rad are fundamental to the heating ability of a radiator Example T22 800 x 600 (so this is a double panel double convector rad that is 800 long and 600 high) Supplied with a flow temp that results in a mean rad temp of 50 Deg output is 1.205 kW Supplied with a flow temp that results in a mean rad temp of 30 Deg output is 0.366 kW So a 20 deg drop in mean rad temp results in a reduction of 70% in heating output -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

You can have both when it's not dragging round 2,000 plus kgs I was fixing headlights so bumper had to come off -

Greasy cockup - don't read this before eating.

marshian replied to ToughButterCup's topic in Waste & Sewerage

Nice Boomtown Rat Reference -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Because he's been told it cannot work by an "expert" - therefore it cannot work - doesn't matter what anyone else says because "not experts" It's not suitable for anything other than heating water and that's the end of it............. -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Do you sleep in 3 different bedrooms? Do you spend time in the kitchen and sitting room overnight too? That's what you are doing now - how is that working out for you?? I just checked not a full moon till 3rd March. HTH -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

It’s meant well if you are lost on the roads sat nav will get you home - but if you ignore it and decide you know better you can end up lost. the contributions here regarding zoots ASHP are well meaning so think of it as sat nav directions…,.. zoot can chose to ignore it…… -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

It means literally - want a warm house in the day you need to allow it to trickle heat in 24/7 Want a cold bedroom - turn the bloody rad off overnight and back on in the morning -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Sat nav works for roads....... ASHP not so much -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Exactly........................................ -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

If you are using low heat levels to cover the heat being lost - you run the heating 24/7 - you can add a little setback if you want to bedrooms at night or fit trvs and cap the bedroom temps that way but the issue with setbacks is you need to run a higher temp to recover from the setback period My house bedrooms are at 18, living areas 20 and bathrooms 21 - all other areas are between 16 and 19 house is far more comfortable than heating am and PM in timed slots and the cost difference for me is an extra £60 a year - I’m happy to pay that because I can do that on a good night on the beer!!!! -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I can go along with that I didn't want to go down the route of explaining what ON means for my house but since you've pulled me up on the word ON Outside temp sensor tells the boiler how cold it is - based on this temp the weather compensation curve sets the flow temp At outside temps below minus 2.5 the boiler pretty much consumes energy all the time at a rate of 4 kWh (so peak consumption when it's that temp outside in a day is 96 kWh (plus a 4 to 5 kWh for HW) This means my peak cost is £5 a day (100 * £0.05) When it's not bloody cold the boiler cycles - puts in some heat "on a burn" - circuit cools down "on a coast" Depending on the outside temp the burn can be as little as 20 mins or as much as 60 mins and the coast can be as little as 10 mins or as long as 3 hours - All I am trying to do is replace the heat lost and that heat lost is directly related to the difference between warm inside house and colder outside house - I'm not trying to heat the house....... It is a comfortable temp all the time because the boiler is putting back what the house is losing PS I have no TRV intervention - they are there as absolute room temp limiters in the event of solar gain Each rad is sized to the room heat loss No UFH (all rads) Flow temps range from 25 deg to 33 deg C - no rad ever feels warm!!!