sam

Members-

Posts

51 -

Joined

-

Last visited

Everything posted by sam

-

How acid is your rainwater? Does it matter?

sam replied to sharpener's topic in Rainwater, Guttering & SuDS

I treat my acidic spring water with a cylinder containing a product called Juraperle. It needs topping up every 6 months or so. I've not found universal indicator strips particularly useful but when the drinking water starts to taste a bit metallic its a sign I need to top it up. -

I agree with your calculations but straw is a by product. Until recently often a waste product. The primary crop is the wheat (or other cereal). The observation that solar panels are more effective, by land area, use of land than growing biomass to burn for electricity is unsurprising. They are also significantly more capital intensive. Drax is another interesting comparison because the wood harvested is often from land which would be difficult to use for other purposes, such as solar. Although the reality of important biomass from North America is questionable. The potential to capture the co2 and be carbon negative adds another dimension. Straw is plentiful and produced near house building areas so an interesting building material to explore.

-

Sleaford Renewable Energy Plant is a straw-fired plant, I think the largest in the UK. 240 thousand tonnes of straw per year produces 38MW.

-

Wholesale prices are currently below £100/Kwp for really big projects. Pricing depends somewhat on which parts of China you want them to be made in as many of the larger buyers are restricted by their ESG rules.

-

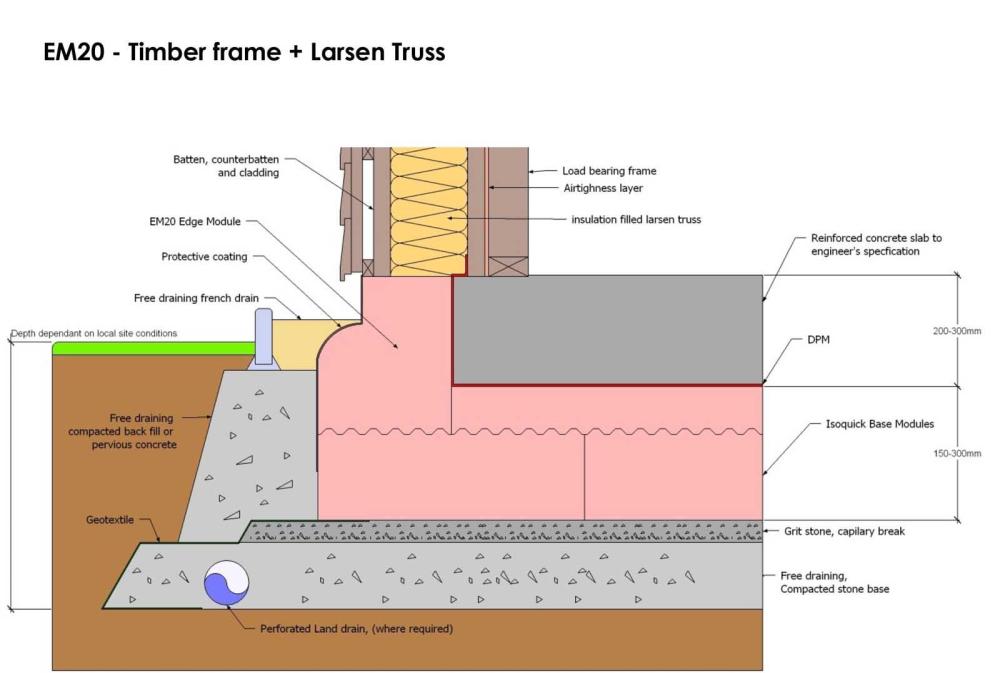

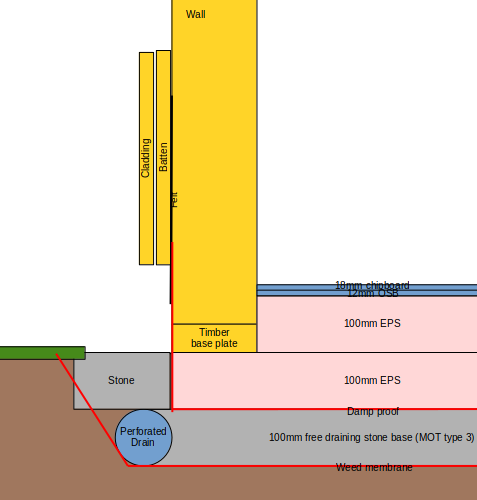

Thanks all - some really interesting points. The building will be an insulated garden room - for a garden office or children's play room. Building control would not be required. I can get a digger on site but not ready-mix concrete. It is on a slope, but I don't that overly relevant for this discussion. A suspended floor design (on pads or ground screws) would be the simpler solution and is what I designed and got approved for my planning permission (in order to be taller than permitted development allows). For aesthetic reasons I'm keen not to bring the building up higher than I need to, hence exploring other options. I come on this forum because the wisdom should put my mind at rest that I've tried and failed to find a better solution or to give me the confidence to proceed! My question is also partly theoretical. I'm aware of 'passive foundation' designs (diagram below) which are very similar to my diagram above but with the addition of a reinforced concrete slab above the insulation - even if access was easy is this necessary? It adds rigidity to the base of the the building (preventing lateral movement but I don't feel this to be an issue) and adds mass (reducing rocking/lifting, which might be an issue). I am concerned by the lifting/rocking issue. I don't think the increased rigidity of this concrete slab would help, as the weight would still be on a point if it rocked. It would add mass but only about 6 tonnes if 100mm thick - so not sure it would substantially change the situation.

-

I've read what I can on this and did ask on the forum some years back but shall now try on my own thread. I want to build a smallish (c. 4 metre square) garden room, single story and timber construction. This style of building is often built without conventional foundations, maybe on 'shed base' or paving slabs. I'm curious about the following design which has no concrete. I’ve consider the potential issues with this design which might not be present with conventional foundations, a passive slabs or a suspended floor. I've identified the following potential issues: The floor is unsupported: This is a somewhat standard floating floor arrangement and might have a little bit of a spring to it. The EPS under the walls could be compressed: It takes 45kn/sqm to compress EPS100 1%. The 145mm wide base plate around the perimeter has a surface area of 2.2sqm so if the building weighed 10 tonnes this would reach that level of pressure and compress the 100mm EPS to 99mm. I think the whole building will be significantly lighter than this. I know passive slabs often specify higher grade EPS but that would seem unnecessary for a light weight building. The walls could distort laterally: This is the same as a timber frame building on dwarf brick walls. Additionally the top EPS layer would prevent the walls moving inwards. If this was considered a risk the walls could be fixed to the flooring or the base plate could be connected to a strap between the EPS layers. Am I missing something - why wouldn’t this be a good idea?

-

Insulated Concrete Slab Garden Office - Questions

sam replied to Ticky's topic in Garages & Workshops

In the context of a small single story lightweight timber frame and lightweight roof, what would be the purpose of the concrete ring beam? I note viking-house have many examples where the ring beam is separated from the floor slab. I also like Moonshine's suggest of flooring directly onto insulation. I'm wondering if it would be possible to put the timber frame directly onto EPS and do without any concrete. -

How to go about a refund from builder?

sam replied to johnhenstock83's topic in General Self Build & DIY Discussion

Do consider what happens after you win the court claim. You need a real address for the defendant and he needs to be able to pay you. Bad builders often aren't rich. I'd pay land registry £3 to see if he owns his house before starting on a court case. I learnt the hard way. You don't want to throw good money after bad. -

How to retrofit insulation at intersection of cavity and ceiling

sam replied to sam's topic in Heat Insulation

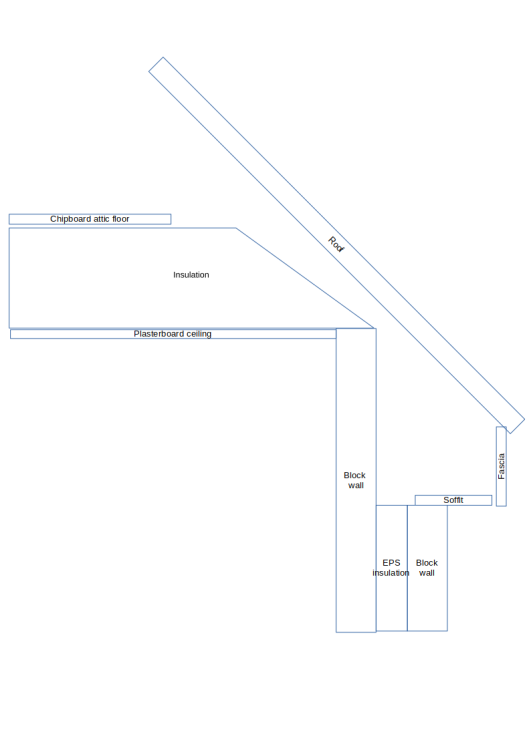

Thanks for the suggestions. I came to discover the issue as I intended to improve the ventilation into the attic, so agree that I need to address these together. -

When I put my gshp in the rhi helped the decision. You would have to do the sums now. In response to the earlier post, you should get the same cop all year if the system is sized appropriately. My kensa says (on the display when it's running) it gives cop of >5 for heating (38 degrees) and >3 for dhw. How does that compare to a new ashp? Noise is slightly worse than the freezer.

-

My 1950s block-cavity-block two story house had EPS beads injected into the cavity. I've recently discovered that the outer wall is c. 400mm shorter than the inner wall and the cavity is open to the eaves void and the loft. This means that the top of the wall is not insulated. Is this common? Any suggestions for insulating this area? The gap between the inner wall and the roof is small (c. 50mm), meaning it's hard to access this area.

-

I thought I'd find this with an easy search but I've not managed to find anything useful here or otherwise online. What are the advantages and disadvantages of using Eaves Felt (5U) vs using Felt Support Trays? Eaves Felt is slightly cheaper (c. £25 for 16m) than cheap Felt Support Trays (c. £2 for 1.5m minus overlap). There appear to be much more expensive Felt Support Trays but I can't see anything obviously better about these. My question is general but for context or if there is anything specific I should consider, I'm roofing a steep (45 degree) garage roof using fibre cement slate tiles and a breatherable membrane (135gsm Cromer Vent 3).

-

It becomes even more complex if you have off-peak (e7) electricity as well! Do you set the heat pump to come on in the day when there might be solar generation or in the night when electricity is half the price?

-

I stand corrected - this is in the FAQs for RHI. I cannot find the actual legal terms and am curious how this is detailed. I know I'm being pedantic, but to comply with this an applicant would appear to need an EPC produced after the heat pump was installed!

-

Subsidies are designed to incentivise behaviour rather than to be inherently fair or logical. In your example the RHI has encouraged the installation of a heat pump which may not have been installed otherwise. The other option may have been to install an oil boiler and not improve the insulation at all. I believe it to be legitimate under the OFGEM rules and not fraudulent. The requirement to install basic insulation (eg cavity wall insulation) before hand and to cap the total KWHs go some way to prevent the most extreme 'playing the system'. A related but different example: it would be ridiculous if you were obliged to pay back (or stop receiving the RHI) if you were to improve insulation after the RHI claim (i.e. during the 7 years) as this would disincentives later insulation.

-

No. The RHI payment is based on the EPC but the system is sized based on the MCS calculations. I believe that it is quite legitimate to improve the building (eg new windows) between the EPC and MCS.

-

We have an AEG induction hob (model HK854320FB) which is mostly very good but does have a few issues which are annoying me. I don't know if it's a faulty model or if this is behaving as standard and we are misusing it. It often beeps and deactivates itself. Frequently this coincides with the surface getting too hot, mostly when we are using heavy cast iron pans so I'm curious to know if @JSHarris has the same problem when using Le Creuset pans. Often it deactivates when the surface is not hot. Reading the manual suggests this may be due to something being put on the 'sensor field' (the control panel?), which I'm not aware of having done. Has anyone else had this problem or have any idea if the relevant sensor can be replaced?

-

As far as I can tell this is acceptable within the RHI rules. Key is to get the EPC first (showing a high heating demand), then improve the insulation, then get the MCS installation sized based on your new lower heat requirements. In this case the RHI is appropriately incentivising you to improve the insulation in your home and install renewable heating. If you get the same MCS company to install the insulation for you then you may get it at the lower VAT rate, but it still may well be cheaper to do it yourself or get another contractor to.

-

Yet there have been some grid scale subsidy free PV built in the UK and there will likely be many more to come. Onshore wind is marginally cheaper but with planning near impossible PV is currently the cheapest form of generation. Cost effective sites are under £500k/MW to build. The market for building on your own roof top (either residential or industrial) is distorted as 'private wire' avoids the grids distribution charges but this is likely to change soon. Yes - off shore wind is still being subsidised with CfDs. I was recently involved in financing an almost 1 GW project which is now under construction. That's about right: £450k-£500k/MW (or MWh as most are just over 1 hour) for containerised batteries. These are currently being built almost subsidy free given National Grid's Capacity Market is almost negligible for batteries.

-

Thanks for the useful post @ProDave. I'm trying to work out how to position the current transformers. Am I correct in thinking that your first current transformer (which delivers "house_current") measures the house load 'gross', i.e. if you are consuming 4kw and producing 3kw this would read 4kw, rather than the 1kw you would be drawing from the grid? If this is the case I think I'm going to struggle as my PV production is fed into the consumer unit. Have other people found ways of doing this? I've considered using a Elster a100c meter, as this can measure the current direction, but I would prefer to use current transformers as this feels less invasive. On a separate point, my immersion heater has a dedicated supply back to the consumer unit. Is there any reason not to put the SSR near the consumer unit even though this is some distance from the immersion heater? Obviously I would have to remove the current timer/programmer next to the immersion heater.

-

Floor insulation perimeter installation? (block build)

sam replied to JamieM's topic in Heat Insulation

EPS is more compressible than PIR so you may want EPS to allow for expansion of the screed. -

Thanks again for the useful posts. Where in the system is the official meter used for FIT and Export payments? Is it possible to use this data or is it not in a useful format or sufficiently real time for this? The Ginlong Solis inverter (and many others I believe) has a RS485 interface and a 'COM' interface. A wifi (or ethernet or GPRS) connector can be purchased. Does anyone have experience using this to get production data or again is this not in useful?

-

Thanks for the useful replies. At this stage I'm wondering if there is anything which is sensible to install at the same time as the panels and inverter. Can you recommend the meter chip? I'll read up on your code but at the moment my actual coding and immersion/heat pump controller side of things can come later!

-

Thanks @ragg987; what I'm hoping to do is be able to access the data to program other devices, rather than just view it. Do you know if that is possible with the solaredge setup?

-

I'm expecting to get PV installed shortly and wanted advice on anything sensible to install at the same time to assist with production monitoring. I'd like to be able to monitor the PV production and export in order to maximise my usage. I know that there are commercial systems to control immersion heaters but more likely I'd build something using Arduino (or something similar) like I think @ProDave and @JSHarris have mentioned they have done. At this stage I'm asking if there is anything I should consider installing near the inverter or meter to be able to capture the necessary data. I know I could get a clip on power meter which could easily be retro fitted but I was wondering if some kind of meter was more useful or easier to export the data from in an accessible form. I currently have a digital E7 non-smart meter and expect to have a Solis inverter. I know that Solis sell a wifi or ethernet adapter but I'm not sure if the data from this is accessible.