Original house contained cheap UPVC windows that were ill fitted and would not match the new windows in the two extensions. So the decision was made to fit new windows throughout with the original plan to go for alu-clad wooden, nut resorted to UPVC due to cost and worries on how some of the alu-clad windows were constructed. Surprising how difficult it was to get quotes that were in an affordable category. Some companies needed numerous follow-up calls which was very frustrating in view of the fact that I would be spending approx £20k on their product. In the end, although I would have preferred to buy local, I ended up sourcing windows from abroad which ended up costing a lot less than anything UK-sourced and also meant they were passivhaus certified! Pity how many sectors in the UK shoot themselves in the foot by atrocious service which is partly down to them not wanting to deal with end clients/self-builders.

There was a lot of email ping-pong, but I think that would have been the case with UK windows too, but they were at least keen to do business which didn't seem to be the case with many of the UK ones. The only area I was hesitant about was measuring the window openings which was further complicated by the fact that I was using special EWI brackets which would position the windows outside of the window opening itself. So I had to take into account the bracket measurements in addition to the window openings. I must have measured each opening at least 15 times before submitting my final order. Glad to say everything seems to fit (just 3 doors to fit now).

Unloading some of the units was a bit precarious especially the 800kg 4.6x 2.3m slider using a standard forklift and then travelling 200m down the road! I got a local window company to help me fit the windows and of course they had no clue how to fit them with the EWI brackets. It took a while for them to admit that the client knew best in this case as he'd actually read the bloody instructions. Means I'll have to rectify their first window later on.

External view:

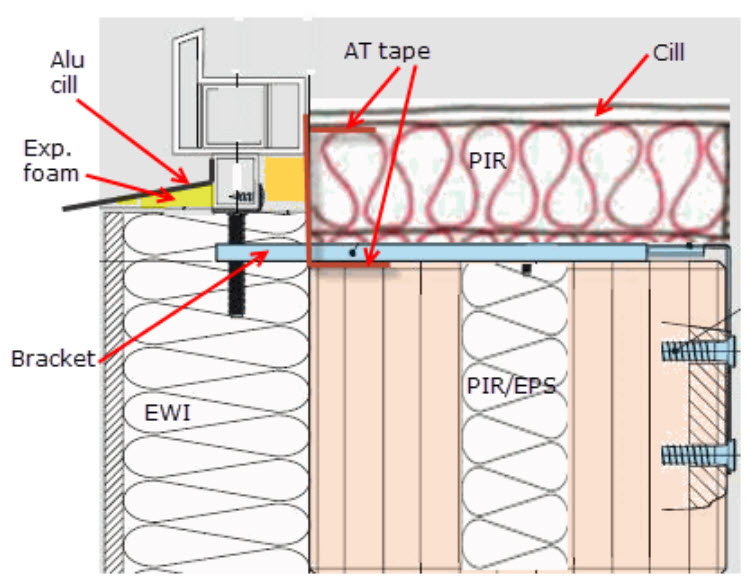

Next stage on the exterior, is to EWI all walls with circa 100mm insulation. Note the brackets above (this is the first window and the bottom bracket aren't fitted correctly, so will need to be fixed before EWI). The brackets will cause minimal thermal bridging at least and certainly be better than having a timber frame constructed all round the window frame. The external aluminium cills (sourced from Germany, cheaper and thicker than UK suppliers) will fix onto that bottom mini (grey) cill at the bottom.

EWI will tuck in under frame (well all sides of frame of course):

and will marry up with the insulation I plan to add under the internal cill also:

My next job is to get started with the internal plastering, so I'm looking at how to detail the internal reveals and cills. My plan is to insulate under the cill also. Cavity wall will most likely be filled with PIR where I can force it down or EPS beads (with a bit of PVA). I'll then fix 60mm PIR board to the now insulated cavity wall using PU adhesive. I'll have to channel out a bit of the PIR to accommodate the window brackets so the board sits flat:

I should have enough clearance then to fit a wooden cill on top of the PIR. Not sure how best to affix that to PIR. Maybe the plasterboard reveals will sit on top of the cill and help pin it down.

Probably overkill with the EWI, but my intention was to also insulate the reveals (see grey EPS example above) with 20-25mm PIR board and then plasterboard over the top. Just need to leave sufficient space to get at the internal beading in case the glass ever needs replacing (sons and footballs....).

The other consideration is to decide where to stick the air tightness tape. Initial thought was to stick that on face of window frame and onto brickwork before I stick down the PIR board. But how well does the stuff stick to clean brickwork? I could add a further layer of tape from window frame and stick to top of PIR board before the final cill goes down.

I'll try and post some drawings up here later on.

Not great, but some of the intended detail:

-

3

3

13 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now