In this entry I'm going to discuss in more detail how I came to choose our heating and hot water system, and how it has performed to date.

As other forum members have found, deciding which fuel source and type of technology to use in a low energy house, is a challenge given the different requirements each of us has. We had three stipulations – low running costs, hot water available on tap 24/7 and maintenance of the whole house at an even and constant temperature 24/7.

Having calculated our heating demand, taking the impact of solar gain, incidental household gain, human occupancy and wind speed into account, I was confident that I had a good indication of the amount of heating I would need. I was also confident, based on historical use, of the amount of hot water we as a family use.

Living in an area without mains gas, my options were somewhat limited to using either oil or electricity as my fuel source. LPG was initially considered but discounted due to the lack of availability in my location.

As part of the decision making process, I spent a fair amount of time carrying out a cost comparison of both oil and electricity based heating and hot water systems, using 500kWh increments from 2500kWh to 5000kWh. I considered direct electric of various type, oil and air source heat pumps, both air to water and air to air. Solar PV was also considered and costed in terms of each method of heat and hot water delivery.

In line with previous cost comparisons that I had carried out, I found direct electric to be the most cost effective in terms of capital outlay and running costs when both heating and hot water demand were less than 2500 kilowatt hours each year. As heating requirement and hot water requirement increases so the balance began to tip in favour of other technologies.

Oil was quickly dropped from the list as it became apparent that any rise in fuel prices over then then low point, would significantly increase running costs.

Having conducted significant investigation in respect of the viability of Sunamp units, although attractive in many ways, I found that the capital outlay and running cost was simply too high to be able to justify, given that the main benefit (low heat losses) were not as critical for me as they have been for others. Part of that decision was also driven by the cost of fitting Solar PV, which in our remote location was extortionate. I looked into a non MCS DIY install, but couldn’t make the figures stack up, the break-even point being around 17 years. Much as I wanted to install PV, it didn't make any sense financially. In time, I hope to revisit PV, if and when battery storage reduces the break-even point to a more realistic timescale.

A wind turbine, given our location and the virtually constant presence of wind, would have been an ideal energy source and paired with Sunamp technology, probably unbeatable. The proximity of nearby houses ruled out that option in terms of planning permission.

Air to Air heat pumps were ruled out based on my own experience of them and a road test at a friends house. Neither myself or my good lady found them particularly pleasant as a heat source.

Having gone through the list of options, an air to water air source heat pump, paired with a large UVC and UFH for the distribution of heat, represented the best balance in terms of capital outlay, running costs and crucially, comfort and convenience.

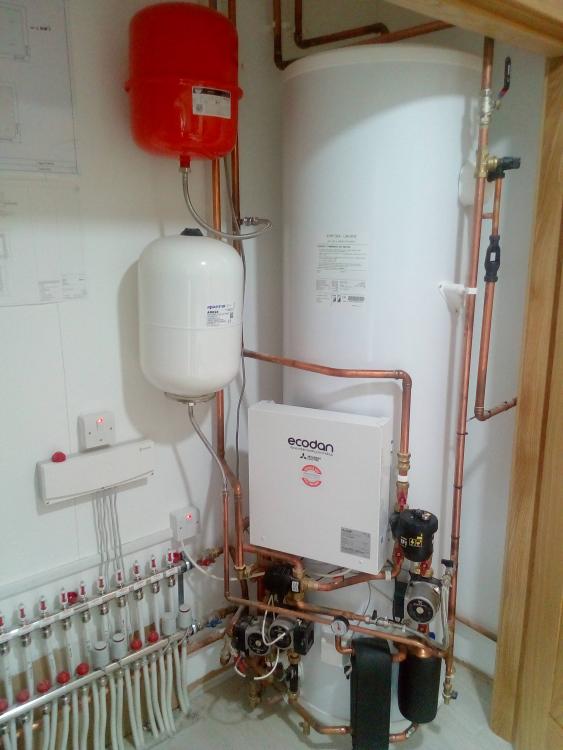

We opted for a package from Mitsubishi Ecodan, an 8.5kW heat pump and 300 litre pre-plumbed cylinder fitted with the Mitsubishi FTC5 control panel. Given our location, we opted for the coastal model, which is treated with acrylic resin for enhanced corrosion resistance. Whilst a pre-plumbed cylinder is more expensive than a bare cylinder and associated parts, after taking labour (plumber and electrician) into account, I found there was very little difference in cost.

I sourced the package from a trade supplier, Secon Solar. I found their price list while searching online and having phoned the company, and perhaps fortuitously speaking to the managing director of the firm, found they were quite happy to sell me package at trade / installer price, the bonus being that delivery to my location was free.

The package is configured for the UK market, the only difference to the system as sold in the rest of Europe (AFAIK) being that the cooling function of the heat pump is disabled so that the product complies with MCS approval for claiming RHI. It is however a simple task to activate the cooling function, by flipping a dip switch in the control module on the cylinder. Cooling can then be controlled from the master controller.

As stated in an earlier blog entry, the heat pump and cylinder were fitted very quickly with simple connections on the plumbing side – flow and return from the ASHP, cold water, hot water and flow and return to the underfloor heating manifold. Electrical connections consisted of power to the ASHP, a cable from the ASHP to the control module and a plug-in controller.

I had initially planned to have the cylinder in the utility room close to the ASHP Monobloc, but changed the location to a service cupboard in the middle of the house, to reduce internal DHW pipe runs. This does mean a 15 metre pipe run for flow and return to the ASHP, but as virtually all is within the insulated envelope, it doesn’t represent much of an issue, and does not appear to be having an adverse effect on performance.

The ASHP Monobloc itself is located beside our back door, open to the elements. It seems happy enough where it is, despite the wind that traverses the space between house and garage walls. Locating the ASHP within the garage itself was an option but one I decided against simply on the grounds that I didn’t want to give up floor space within the garage. A timber housing for the ASHP is something we may look at in the future.

We opted to fit individual room thermostats to all 3 bedrooms, to give us the option of being able to reduce the bedroom temperatures if we so wished. We have not used these and keep the whole house at one temperature 24/7, treating the underfloor heating as a single zone.

At present I only have limited data as to how the heat pump has performed since moving in. On board energy metering (energy consumed and energy produced) shows the CoP for heating has ranged between 3.5 and 4. DHW is maintained at 47C-50C in the cylinder, boosted every fortnight to 60 degrees by the immersion on an anti-legionella cycle. To date the CoP for DHW is 2.4

As members know, heat pumps are best suited to the production of low temperature heat as opposed to the higher temperatures required for domestic hot water. Whilst the CoP for DHW is lower than that for heating, the cost per kWh of our DHW, based on a CoP of 2.4, is 5p, which is significantly better than an E7 electricity tariff. We may be taking a hit on efficiency, but in reality all of the other options would have cost us more.

The 300 litre capacity of the cylinder means that we have plenty of hot water on tap and can comfortably run a full bath and still have sufficient left over for another person to shower.

The ASHP is currently operating on a 24/7 basis, providing heat input to the UFH and topping off the DHW as and when it determines it needs to, at whatever flow temperature it determines. Whilst that does sound like a recipe for high bills and high flow temperatures, in practice, the heat pump delivers the lowest flow temp it can get away with to maintain our set temperature.

If I so choose, the controller lets me set various parameters such as heating curves or set flow temperatures, or indeed a timed schedule for heating and DHW. However,as the system is operating efficiently on its auto setting, and providing the level of comfort we want, I see very little reason to mess around and create my own settings. If say electricity tariffs were to change from a single tariff to a dynamic tariff, then I would have the option of timing the heat pump operation to coincide with lower rate tariffs.

After much thought, and indeed discussion on this forum, I opted for an 8.5 kWh ASHP over a 5 kWh ASHP, as I felt happier running a larger unit more gently than pushing a smaller capacity unit harder. A 5 kWh unit would probably have sufficed, and in time, may be what the current unit is replaced with when it reaches the end of its life.

We haven’t yet had to activate the cooling function as any overheating (defined as internal temperatures over 23C) caused by solar gain, can, as modeled, be managed by natural cross ventilation.

Neither have we found it necessary to constantly circulate the UFH to even out the house temperature / redistribute solar gain from one part of the house to the other. In the heating season, we found that there was sufficient circulation of the UFH during the heating cycle to maintain the house at an even temperature. Outwith the heating season, when solar gain is at its peak, the house zones itself, the bedroom section remaining slightly cooler than the public areas, very useful on a warm summers day.

Overall I’m very happy and impressed with our system. It has, so far, delivered everything we have asked of it in terms of comfort and convenience, and the running costs are low. I have the capability to cool the house (via slab cooling) if I so wish, and the option to bolt on a second zone pack onto the pre-plumb cylinder if I ever found it necessary to install a second heating / cooling function – i.e. fan coil or duct heater / cooler. The one criticism that I have is about the controller thermostat function and its hysteresis - 1C increments only. A finer degree of control would have been preferable.

Our installation was recently inspected by an MCS accreditor (our plumber is going through the accreditation process). In due course that will give us the option to apply for RHI, although that will be very much dependant on whether the figures stack up.

-

8

8

-

1

1

23 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now