Search the Community

Showing results for tags 'subfloor'.

-

Hi all and a very merry Christmas - I hope you are all enjoying some time off. I was hoping to gain some advice/feedback on ground floor insulation over our ground sub floor. We are hoping to go with a polished concrete floor which our architect noted the minimum depth would be 75mm, leaving 150mm of insulation to work with (total 225mm to work with)... Our contractor advises 100mm for the concrete to be polished above the UFH (I am waiting until the concrete company and the floor polishing company opens to chat to them directly also in the new year). This would only leave us with 125mm of board insulation which from reading the forum and any reading I have done I am seeing a 150mm as the recommended depth of insulation - I am keen to get this right and to limit heat loss through the ground. The aim was to achieve a u-value of 0.13 or better (figure from architect); our initial plan was to have liquid poured insulation but that has changed as we don't have the depths available to achieve the u-value with this method along with the polished concrete floors we would like. I was hoping someone could advise on the insulation/concrete combination or steer me in the right direction as I would be very grateful. Many thanks, Joe

- 25 replies

-

- polished concrete

- insulation

-

(and 1 more)

Tagged with:

-

Converting a 3 bed very dilapidated 1930s semi into a 4.5 bed modern home. EVERYTHING is being gutted except the joists. Quotes are way over budget, particularly for the underfloor heating. I had specified wet underfloor heating throughout all three floors of the house (ground = 800 sqft, first = 750 sq ft and loft = 450 sqft), with the ground being imbedded into screed and the first and second floors being laid within some high performance extruded polystyrene boards made by Cellecta called XFLO. XFLO is quite expensive, about £26 a square metre, but the reason I had specified them is that they provide good insulation to make sure the heat goes up, are CNC drilled by Cellecta to meet any pipe layout requirements we specify and also feel quite firm underfoot. The other advantage of the XFLO is that you can lay the finished floor directly onto it. Underneath those XFLO boards, I had specified a 6mm dense rubber matting (which comes as a 10m by 1m rolled product, so pretty easy and quick to lay) to absorb impact sound, and underneath that 18mm tongue and groove ply which is nailed directly onto the joists (whereas the rubber and XFLO are just floating). In between the joists I was going to have mineral wool to mute airborne sound travel, and underneath the joists I was going to have the ceiling attached using resilient bars (with market name "Genie clips") to isolate the ceiling from the joists to further prevent sound transmission. The whole system is to be zoned as 9 zones, including one zone for the 3 towel radiators (which will be the only radiators in the house, one for each bathroom), although I'm going to provide Tado thermostats, one for each of the 8 UFH zones and a Tado smart valve for each of the towel radiators. One builder has quoted about £25k plus VAT for all of the above, and the other about £28k plus VAT. These quotes don't include the thermostats (I'm providing those). When I have challenged each of them on why this is so expensive (I was expecting about half the cost) they have said different things. The first builder has said that I could save £2,500 to £3,000 money by losing UFH in the loft and in most of the first floor, and instead having radiators there. The second builder doesn't agree that would save any money and is also trying to respect our reasons for having UFH. Instead he just thinks the system I've specified for the first and second floor is overkill and that I could make two changes which would save about £4k in labour: First, instead of 18mm ply plus 6mm rubber matting plus the XFLO boards (which are about 28mm thick) I should just lay a product sold by theunderfloorheating store calledProWarm ProFloor 22mm pre-routed chipboard. I've looked this up and I see the benefit. Like the XFLO boards, you attach it directly to the joists and it comes routed (though with standard not bespoke routing) and enables you to fix the finished floor directly. It costs roughly the same as the XLFO, but it saves the builder the trouble of having to lay the rubber matting and the ply, so the saving is in the cost of the matting (£6 per sq metre), the ply (about £14 a sq metre) and the labour to fit those two layers. Second, he says that in the bathrooms, I should just lay electric UFH rather than wet. He accepts it's dearer to run, but he says I can have smart timers on it to make sure I only have it on when needed and as there will be wet towel rails in there, I really won't use it that often. I think I'm willing to accept his second point and fir the electric UFH in the bathrooms, but I'm concerned about the disadvantages of the first point, which I see as follows: 1) I lose the impact sound protection provided by the 6mm rubber - is this such a big deal given I have an isolated ceiling and the mineral wool between the joists? If so, can anyone think of a way of combining a fairly cheap but effective sound impact layer with the 22mm pre-routed chipboard? It would only ever be my kids running around, so impact sound is not a major issue, but I want some protection. 2) Chipboard is not as durable or as strong as ply. Although both will feel similar at the outset of their lifespan, what will they feel like in 12 years time? I plan to be at the property for 12 years at least, but hopefully longer and I don't like springy floors. 3) no bespoke pipe channels like Cellecta offer with XFLO. But is this overkill? Maybe I don't need bespoke pipe layouts. Builder says that the 22mm pre-routed chipboard just has channels at 200mm pipe centres and that is a standard construction for first and second floors. Although most of the rear of the house is being extended, so it will have insulated cavity walls, and the loft will also be well insulated, the rest of the house has no cavity walls. Keen to hear your thoughts on the above. Thanks for your time!!!

- 34 replies

-

Hi, I have an extension built on my home which my Dad, who has since passed away, built in 2011. The extension has always been very very cold compared to the rest of the house. The rest of the house is built on solid floor. We had tight site access so my Dad decided to do a suspended floor rather than a solid thinking it would be easier to get materials on site. I always suspected the floor was the problem as the air gap underneath is about 600mm deep due to the ground level that connects it to the rest of the house. But also upon opening the floor I found it was built on posi-joists. The architects drawings I found stated that it needed to have 100mm of PIR board between each joist, which they did install - but at the top of the joists. As the joists are about 200mm deep this mean it left the bottom 100mm open and allowed the cold air to directly reach the top chord, which is 47mm thick. Effectively this would be like having your outside wall made of 47mm thick wood and then just having plasterboard directly on top. No wonder it was cold! So now I need to figure out a 'safe' way to insulate the joists. What I wanted to do is push the PIR board to the bottom so it was level with the bottom chord - possibly use gapotape too (though that might be unnecessary in this idea) effectively creating an air tight seal at the bottom. Then I was going to put sheep's wool insulation inbetween the metal fixings of each joist - making them full. Finally a sheet of SuperQuilt on top to act as a vapour barrier, an air tight seal for the room and foil to reflect the underfloor heating back - it would also have an air gap between the top of the PIR board and the bottom of the quilt and from the top of the quilt and the chip board subfloor. My biggest question is that in doing this the top chord of the posi-joist would effectively be sealed off from the fresh air void below by the PIR boards. Could that cause any issues with damp/rot? Or does it just mean the top chord is now part of the warm room? (though sealed off from the main room by the vapour barrier) If so I don't see any real way to fully insulate away the issues but also keep the top chord access to the fresh air. I think the only way I can think would be to move the PIR board up so there's a gap just above the bottom chord, but keep it full of sheep's wool so that it's got nearly 200mm of insulation before meeting the top chord - it at least will be in theory then "breathable". The top and bottom chords on the joists are 122mm wide and 47mm thick on 600mm centres. I suspect there will be a school of thought in the best way to go about this. I could find little to nothing regarding insulating posi-joists online with such a large cold air gap below. The architects specified Wolf easi-joist WS200 - I asked them this exactly insulation/breathability question and included the photo. That appeared to be a mistake as apparently whilst identical, these are not official Wolf easi-joists, so he wouldn't answer the question, even on an "in theory with this type of top/bottom chord split". Look forward to hearing thoughts.

- 3 replies

-

- posi-joists

- subfloor

-

(and 1 more)

Tagged with:

-

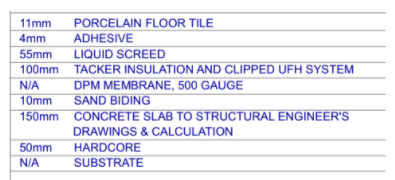

Anybody have any comments on this build up of my ground floor (we've taken out the original timber vented subfloor of a 1930s semi and are going to have a concrete slab instead). Any tweaks or improvements? (I don't have any more space, so any increase in insulation would have to be balanced out by a decrease in something else.)

- 2 replies

-

- subfloor

- concrete slab

-

(and 1 more)

Tagged with:

-

Getting prices back on a tender for a full refurb of a 1930s semi, together with double storey rear extension and loft conversion. Big variation in price for upgrading the the existing subfloor of the first and second floors (the second floor being the floor of the loft). As much as £10k +VAT difference. I had specified that first and loft floor joists should be inspected and only replaced if necessary, and that the joists should be reinforced with noggins and additional joists in one of the bathrooms (because heavy stone bath tub in that bathroom). Although those joists will be 90 years old, there is no damp/rot (as far as I'm aware), and so I don't see why we should necessarily replace them. One builder has said that in his experience joists this old always need replacing and given the amount of changes I'm making to the floor layout (I'm moving the stair case, for example), it's going to be easier to rip everything out and start again with new joists. He therefore thinks I should budget for this at the outset, rather than work off provisional sums depending on what is revealed when we expose the subfloor. A separate point is that the "subfloor" is already exposed in the loft, so if he wasn't being lazy he could just go up there and show me why he thinks the existing joists aren't good enough. Thoughts anyone?

-

Hi All, I’ve just had 2 rooms tiled with oak effect ceramics and I feel a little disappointed with the final result. The tiler used self-leveller to even the floor prior to laying but I feel that this should have been done with more care, and that many of the subsequent problems are a result of this… I’ve used the closest thing I have to a 2m straight edge to check the flooring and I’m finding regular deviations of around 5-6mm. Offering up the skirting has highlighted a couple of areas far worse at 10mm & 14mm. The tiler has offered to rectify these two areas but I still have my doubts about the overall quality of the job and feel it was rushed. He spent no more than a few hours on the screed and then 3 days to lay both rooms totalling over 30 sq.m. I worry that in correcting these local defects with extra adhesive or whatever, he simply creates new problems elsewhere. There are also several areas of lipping affecting at least half a dozen tiles in each room of 2,3 & 4mm. The British Standard BS 5385 seems to say that 1mm is the tolerance for such narrow 2mm joints? The standards also seem to suggest a tolerance for levelness of 3mm over a 2m edge? I’ve only garnered this info online and haven’t actually read the specific standards but I’m wondering to what extent I could use this as a stick to beat him with? I’ve already paid £1000 in labour for the job but frankly I feel it isn’t justified. I know he’s legally entitled to try and rectify it but short of ripping it all up, I can’t see me getting a result that’s compliant with the relevant standards? I feel the best outcome for me would be to get him to fix what he can then attempt to get compensation for the rest.. Sadly I’ve already had to sue someone for a failed floor in the past so I’m all too familiar with the small claims process! Any help much appreciated., please see attached photos

-

Would you be kind enough to run your eye over this, please? The list below is gleaned from a mixture of YT videos, the LABC and NHBC standards and several flooring threads on BH : thanks to @ProDave, @Big Neil, @Simplysimon, @Hecateh, @PeterW, @Mr Punter, @Declan52 , @bassanclan @Oz07 and others. I have 46 sq meters of floor to lay on the first floor on joists which are laid at 400 centres: you know, the ones that de-bagged me Since the floor is a structural member, and the roof is on - we are dry, the sensible choice seems to be 22ml chipboard T+G, (although 18mm will do for 400 centers) laid at right angles to the joists, long edges at room perimeters must be fully supported on either a joist or a nogging in any case, noggins must support the short edge laid ' brick-bond ' (to ensure minimal waste and maximum T+G contact) D4 adhesive : gloves to prevent contact with the glue (thanks, @Declan52) screwed every 300mm, screws 50mm long (at least double the depth of the board) and at least size 8s with a 10ml gap all the way round vertical abutment(s) leave a small loose panel in each room so I can fish wires through later (thanks @ProDave) I'm using sheets that are 2400mm by 600mm and my BM is charging me £8.88 / sheet. Missed anything? As every, many thanks in anticipation. Ian (PS, forgot to ask about screws spec: are there any screws that are specially for boarding out?)