RobLe

Members-

Posts

231 -

Joined

-

Last visited

Everything posted by RobLe

-

Prioritising battery discharge over PV self consumption

RobLe replied to Dillsue's topic in Energy Storage

We hve the equivalent of this. We have an Ohme car charger via a henley block prior to our CU. The CU has a 3.6kW sunsynk hybrid inverter, and the CU feed has the CT measurement on it. So the car can charge whenever IOG likes, and there will be no interaction with the hybrid inverter which is generally neutralising house loads. If our car charger were your PV+inverter, it would again have no impact on the CT nor hybrid inverter. Our system is actually more complex than above, with lots and lots of PV😁; the complexity is just confusing to explain with text though, and not relevant to the above point. -

Prioritising battery discharge over PV self consumption

RobLe replied to Dillsue's topic in Energy Storage

That depends in the inverter generally. A way to definitely achieve this no matter what inverter, is to have separate inverters for PV and battery, the battery one connecting to the main CU and it's CT sense coil clipped to the CU feed. Any PV then connecting via an inverter to a henley block before this main CU. We have a sunsynk; this is a hybrid inverter, and defintely cannot do as you wish if it has both batt and PV connected to it. The software it comes with is designed for sunny places with a grid with frequent power cuts; so it is designed to always first charge the battery, then export. Other hybrid inverters may by default allow PV export first. -

The below U-Vacua works out around £75/m2 from digikey - I think they’re expecting to sell to fridge freezer type applications rather than construction tbh. Centre panel lambda =0.002W/mK, 10x better than PUR, the one linked is just 15mm thick. I guess need to be super careful about construction, to make sure it doesn’t and can’t get punctured. https://www.digikey.co.uk/en/products/detail/panasonic-industrial-devices-fbd/cnrzzb98400/9558509

-

I’m impressed, required insulation values are pretty good these days - that’s a big house for a 5kW heatpump. How confident are you that the insulation and airtightness will be done right? Is there an airtightness test, and consequences if not met? Who checks thermal stuff is done right? Any guarantees kick in if the heatloss actually is double the design value?

-

Shade is fantastic for keeping lofts cooler - a free unsung advantage of PV! Roof tiles can get to 50C+ quite easily in the sun otherwise, but will just be at ambient air temp if shaded. I totally agree about the decrement delay - so a better roof construction in available space would be be: tiles with well ventilated air gap behind (ridge and soffit vents), celotex type insulation with good air tightness, three layers of plasterboard.

-

We used to have one, had a regular wood stove put in 15 years ago, it is more efficicient. In retrospect though a bit of a waste, we hardly use it. Anyway, the underground bucket bit was removed, hole filled in, tiled over. The brick opening was widened out, and a new lintel put in, single lining and the woodstove. The baxi had air vents on both sides of the house that ran through the slab I think, into the old baxi system - seemed like a source of heatloss to me, so I filled both of them in. Since then we’ve had EWI around the house, the chimney bit with rockwool just in case. I expect the thermal bridge of the woodstove chimney loses more heat over the year than we get out of the wood we ocaisionally burn. Ah but Mrs Robl likes the ambience, so it is all worthwhile:-)

-

ASHP + Solar PV + Battery - Choices

RobLe replied to Diarmid's topic in Air Source Heat Pumps (ASHP)

Re the battery size: For comparison we are an all electric house, and use 2000kWh of electric/year for house and hot water heating (via a heatpump). I think you’ll be similar or slightly higher than us. We have a 15kWh home battery, it copes for all but 5-10 days a year, on those days we have to import a few kWh of expensive electric, the rest of the time we’re on IOG electric. -

Of the eight 3/4“ hose tails for our gshp groundloop connections, two had completely failed within three years, and four were showing visible signs of a crack forming. They’re all replaced with plastic now 🤞🏽

-

Uhhhh, it happened again the other day. That is, another brass coupler cracked for no obvious reason (which I guess means fatigue failure after 3 years of 15C ish hourly temperature cycling), a litre or two of water+(non toxic) glycol came out, and the heatpump stopped. Took me a day to notice (there’s lots of insulation at our house), Mrs RobL didn’t notice at all (even tho she’s sensitive to the 🥶 ). I had already bought enough of the plastic 6bar rated fittings, so I’ll change them all over this weekend rather than one at a time as they fail…

-

(ASHP-based) Hot water tank gets cold surprisingly quick

RobLe replied to puntloos's topic in Boilers & Hot Water Tanks

That’s a big tank! We heat our 220l tank at night with gshp to 50C, then for 30 minutes with a 60C immersion cutout just at the top - again at night, all in the ‘go’ time. Used to do the immersion once a week, but that 50C drops - and Mrs Robl starts the day happy when the water is super hot, never really noticed myself. Some battles are not worth fighting 🤗 -

I think BTU is just used for heat energy, and it does have one advantage - its a quantity not a rate as kW is. So BTU avoids the ‘rate trap’ that kW gets people into, persuading them to use kW/h. Having said that, a bit of Googling shows btu and btu/h being used interchangeably, oh well. So those rads at 50C could produce 4.6kW if on at 50C, which would heat two of our home on a cold day. As others have indicated, there’s still more to it: what’s the U value of all the walls, floor(ok 100mm celotex), glazing, and what is the heat source hence temp (gas/heatpump) ? If it’s all new spec and gas heated, then almost certainly yes. But we would all aspire to a heatpump one day…

-

I think that's a fair assessment - for a straight gas/oil -> ashp swap, the running costs are similar. And changing a functioning heating system is somewhat of a risk. There are ways to improve matters though which you cannot do with gas/oil; if you have a house with PV, you get some cheaper electricity effectively. If you've a low heating requirement, then getting rid of the gas standing charge is noticeable. There are lots of time-of-use tariffs now that allow for something more creative - especially if your house has a long thermal time constant. Our house rises or falls about 1degC/day in winter with/without the heating on, so it would be possible to turn off the heating at certain times of day without noticing. If you have an elec car, you could get intelligent Octopus Go, giving extra cheap timeslots which also allow cheap heatpump operation - I expect more of this to occur in future, using heating as a cheap "battery" when the wind blows. And of course the battery option - there's differing opinions about whether it "pays for itself" yet - but there's no doubt in my mind that battery prices will continue to fall.

-

Thanks for link, expect I’ll get some. For now I used one of the other brass ones as it was easy to get, but I’ll get pressure rated ones - it’s annoying when stuff breaks. The outdoor ground loops and the indoor rad system both have header tanks - so there’s no pressure to speak of by the way. I’ve been running with 3 groundloops for a couple of days rather than the usual 4, the system has to try a bit harder and the heating COP dropped from 4 to 3.7. This is the worst time of year for the cop - the ground is cold, even though the air is starting to get warmer.

-

Found this alternative part: And this is a new picture of the original: Will the top one be any stronger? It cost a little bit more, maybe that helps🤔

-

Any idea why this bust yesterday? The picture shows where the gshp groundloop pipe converts to thinner pipe so I could easily connect them at a manifold. One of the 3/4” bsp to hose tail brass converters has now a crack in it - It’d been there for 3 years, never moved, probably cycles between -5C and 5C every hour with glycol+tap water, and suddenly broke - why? I added a zoom in as well, the crack is almost all the way around. Am I too strong ?😁 Will the others fail?

-

I think at least one drain hole is needed to vent to outdoor air that is usually lower absolute humidity than indoor air.

-

I think there should be an air gap all the way around the double glazing seal(the one built into the sealed units) and that air gap should vent outside at the lowest point. It’s both to vent liquid water that gets in, and to ensure that you don’t get condensation on the dg seal that will eventually make the dg unit fail. It’s true for all dg windows as far as I know.

-

Given any experiences you have had, what would you choose tomorrow

RobLe replied to Makeitstop's topic in Windows & Glazing

If you’ve got pre 2000 uPVC windows that are in good nick with internal beads, I think it’s worth replacing the U=2.7 glass units. We did this 15 years ago - our frames are 35 years old now, but with newer planitherm one glass and diy foam filled frames(make sure that water can drain). It’s a tough decision to not change the whole window for a more expensive ‘eco’ one; we could have afforded it - I just hate skipping perfectly good stuff. Plastic is a problem - throwing a window frame away doesn’t help. -

Help in raising the COP on my Samsung 5kw ASHP

RobLe replied to Suffolk peasant's topic in Air Source Heat Pumps (ASHP)

That COP is so low, that I think something odd is happening, as opposed to the usual high flow temperature at the ashp. I think ostensibly it suggests an average COP of (124+38)/124 =1.3. This may or may not include the weekly immersion use. You don’t complain of a cold house; in this weather if the COP were actually that low I’m surprised the unit can actually warm the house sufficiently. Has it always been like this? Suggestions to try: I note that 124kWh elec in a cold week is not insane - can you calculate your heat loss in kW, see how it compares to an hour of the generate+consumption at the design external temperature? Fit an independent mid-certified elec meter to the ashp, and also a heat meter - more effort this, but will give a believable COP. Eg opentherm. -

Heat Loss through Double-Glazed Windows

RobLe replied to windowproblem2025's topic in Windows & Glazing

You can figure it out from a thermal conductivity (U value) ratios, based on a known value: Indoors, in still air, a vertical boundry air layer has a U value of 8W/m^2/degC. That is from the centre pane glass surface, to the air temperature in the middle of the room. The U value of the glass represents the heatflow per m^2/degC through the glass, based on the air temperature in the middle of the room and the outdoor air temperature. So, if you measure the values below with the same IR thermometer pointed at a bit of tape stuck on the glass etc: Tindoor = the indoor air temp Toutdoor = the outdoor air temp Tglass = indoor centre pane glass temp Uglass = 8* (Tindoor - Tglass)/(Tindoor - Toutdoor) I can generally get the answer within +/-20% of the expected value when it's cold outside. That's good enough to tell if the units are just glass, or have a coating on them.- 15 replies

-

- heat loss

- double glazing

-

(and 1 more)

Tagged with:

-

Heat Loss through Double-Glazed Windows

RobLe replied to windowproblem2025's topic in Windows & Glazing

Your walls likely don’t have CWI (cavity wall insulation); you can usually see the pattern drilled into them if it’s been done. Typically 25mm dia holes into morter, every 500mm or so over the entire wall. Suggest taking a photo of the brickwork (regular, not IR), and we can likely tell.- 15 replies

-

- heat loss

- double glazing

-

(and 1 more)

Tagged with:

-

Heat Loss through Double-Glazed Windows

RobLe replied to windowproblem2025's topic in Windows & Glazing

It’s most likely that your DG windows are U=2.7W/m2/degC, or thereabouts - that’s what you get from two panes of glass with a 16mm air gap between, as happened until around 20 years ago. It’s possible to measure the U value of a window. Now there’s a metal low emission film applied, a warm edge spacer, and ‘heavier than air’ gas inside the cavity. The obvious thing to check first is if you e had your cavity filled yet? You can generally tell from the brick pattern outside. I say this as the wall looks cold too.- 15 replies

-

- heat loss

- double glazing

-

(and 1 more)

Tagged with:

-

Question about DNO approvals and inverters

RobLe replied to Beelbeebub's topic in Photovoltaics (PV)

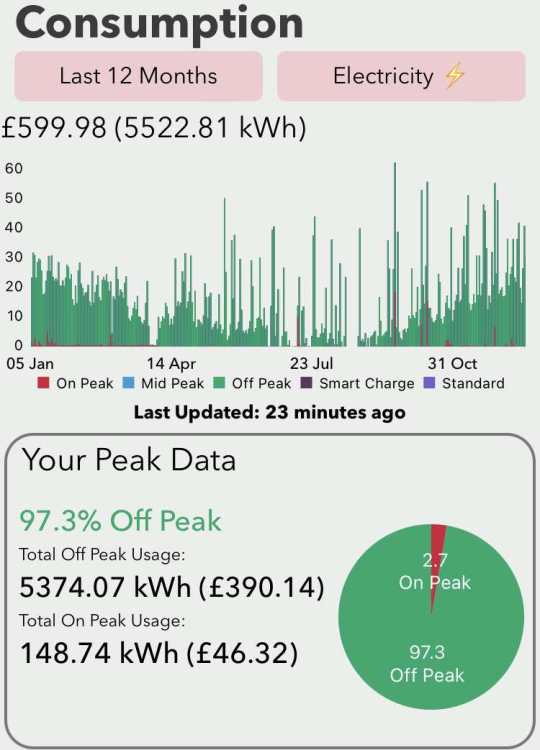

While I agree you can draw over 3.6kW in a home, in practice I believe it’s sufficient for most people. We have 2+2 people here, and don’t make any attempt to limit our combined appliance useage - kettle/cooker/washing/gshp(v small) whatever. Cars charge and dhw heats at night on the cheap rate. Our 3.6kW sunsynk +15kWh Seplos batt system charges at night in the winter, and gives us 97.3% cheap rate elec useage. The most significant aspect I found for improving the cheap rate useage has been getting the CT coil noise related offset working well. pic below ignoring export: -

Question about DNO approvals and inverters

RobLe replied to Beelbeebub's topic in Photovoltaics (PV)

Yes. eg a sunsynk 3.6kW Ecco, will allow 2 strings of 425V*13A max. It can charge a 16cell LiFePo4 batt at 90A while sending 3.6kW to grid. Or get an even bigger unit that is g100 certified, and get the overall grid export limited to 3.6kW. -

There might be an issue with a heatpump being force fed super hot water into its heat exchangers, which a gas boiler could do. Doubt an issue in practice, but let’s say you pushed in water at 90C then the refrigerant pressure might end up above the heat exchanger design pressure. Maybe. We ran with a heatpump and a gas boiler for a year and a half, until Mrs RobL was convinced the new fangled (diy) heatpump was ok. The electrics totally switched one or the other in with a 4 way rotary switch, the water flow was magnetic filter->gas boiler->heatpump, and the heatpump flow & return could be closed off and bypassed. The gas boiler was eventually taken out, as it was never used, gas meter gone, no standing charge.