-

Posts

23 -

Joined

-

Last visited

Recent Profile Visitors

1977 profile views

Daedalus's Achievements

Member (3/5)

2

Reputation

-

Many thanks for the replies chaps. pfft.. I don't think my other half knows where the kitchen is. Tsk Tsk! Can you get pyrolytic steam ovens? Other hard advises that with NEFF and Miele it seems to be one or other. Both gave advantages so we need to weigh up. I think the steam one wins as we cook a lot... I did read about this and some which give off a horrendous smell during a cleaning cycle. Not really sure how true it was or if I've missed a discussion on here about. I think the steam ovens I looked at have a different cleaning feature similar to what Bitpipe mentioned where you have a water cartridge and cleans with steam as opposed to simply incinerating the residue into ash.

-

Technically yes, in reality a BCO could ask for the ticket and if you have a non RC spec with reinforcing then you may have an issue. Not that I want to have a disagreement with anyone but there's not really a technically about it.. The suitability of concrete from a specifiers perspective is that strength is the only really important parameter. The RC in front of the 30 is only a suggestion and does not mean that all other concrete's are inferior etc etc. There's really no such thing as an RC spec concrete is what I am rabbiting on about. Use a scabbler if required to prepare a surface prior to casting I'm still waiting on the SE but I will check and double check before I order any concrete +1 trust nothing you read on the internet

-

Sorry but that's not really true. RC30 and C30 should technically be the same strength and both (depending on the situation) should be perfectly suitable for use with reinforcement. RC30 is whats known as a 'designated mix' with certain properties such as cement type, content and water / cement ratio already specified (in BS 8500). Its basically like an off the shelf product, although some things can vary. Other examples of designated mixes are usually have either GEN FN or RC before them with the 30 in this case being its compressive strength. C30 concrete is a concrete with a compressive strength of 30 N/mm2. if this was specified on a drawing for instance, certain properties should be specified else where on a separate specification. Although they normally aren't and it doesn't really matter either way because the concrete supplier will assume something reasonable and you'll probably end up with the same product anyway.

-

As per the title.. Anybody got one of these and can they comment on whether it is worth it?

-

I am loathe to give this sort of advice over the internet but... You can get away with a 215 thick brickwork wall (bonded together) with a half decent strip footing can retain 750mm. A good google search can provide some standard details little brickwork retaining walls.

-

Always am ... ...

-

You seem to have a lot of openings in some sections of the wall, are these full height? If so its probably so the walls can take a wind load along that face? Just a guess mind. +1 to attic trusses being cheaper and easier, although you would lose that nice vaulted roof look at the end.

-

Not sure where your based but near me we've had a number of high profile soakaway failures in the past few years. Basically the Engineer has designed a large attenuation tank to deal with the stormwater on a medium sized development, the Client and Architect moaned about the cost and suggested / insisted ground infiltration / soakaway solution. A single (isolated) infiltration test was carried out which showed a half decent infiltration rate. Soakaway installed, next big storm, property floods etc. etc. Said Engineer's PI takes a hit ... Not surprised your guys being abit twitchy

-

Structural Engineer problems - who to turn to?

Daedalus replied to Ness's topic in Introduce Yourself

A ground bearing capacity of 25kN/m2 seems very low. Is this not a typo on the ground investigation report? Your SE would normally estimate a bearing capacity of 50kN/m2 based on traditional footings (which he has). Anything less then this would normally be piled. Please don't take this the wrong way but your problems with your Engineer are probably caused by the following ... He's probably spent his fee and is now is unwilling to spend anymore time on your project. If you're not getting the service you want approach another Engineer, without knowing the circumstances the timescales seem a bit ridiculous. Hope that helps. -

piling Piling: Preparing for the Quotes 1 -piling method

Daedalus commented on ToughButterCup's blog entry in Salamander Cottage

Out of interest, can I ask how the Surefoot price compared to generic piling quotes? Looks to be a good system for some lightly loaded bases which I am dealing with. Pilling mat is easy. Your SE should sort this out no problem, there is a design guide by the BRE. You are looking at a min 300mm of stone over the site however depending on the size of the rig. Is this included with the price?- 10 comments

-

- due diligence

- spons

-

(and 1 more)

Tagged with:

-

surface drainage Surface Drainage: advice please

Daedalus replied to ToughButterCup's topic in Waste & Sewerage

Some small watercourses are the responsibility of the LPA's now with regards to surface water management. Whilst discharge from a disgester will normally always be the EA's responsibility. Surface water discharge is then dealt with by the local SUDS guy at the council. In my experience you are only allowed to discharge surface water directly to a stream if both conventional SUDS are not an option and there is no suitable surface water drainage around the property. Then ... discharge to the stream should be limited to greenfield runoff rates. Of course this is superfluous for one property therefore see what you can agree with LPA / EA. You should be able to find out if this is under the EA's jurisdiction if it is listed as a 'main river' here: http://maps.environment-agency.gov.uk/wiyby/wiybyController?x=357683.0&y=355134.0&scale=1&layerGroups=default&ep=map&textonly=off&lang=_e&topic=floodmap#x=374881&y=400113&lg=1,2,10,&scale=1 Be aware however some very small trickles are still run by the EA so its best to check. -

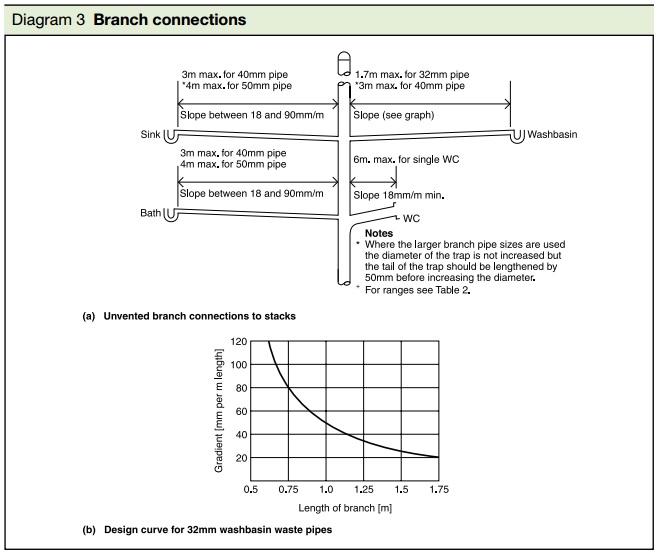

Externally you've got no problems. Distance between IC's is between 40 - 90m allowable. I would just make sure all the points are rod-able, especially at the base of the stack. I though the length of branches was limited to 3m for a 40mm pipe although this might only be without an additional AAV (see attached). Although I've just installed an internal shower waste which is around 5 ish meters to the hopper and no problems yet.

- 3 replies

-

- 1

-

-

- underground

- sewerage

-

(and 1 more)

Tagged with:

-

Porcelain and I've got about 2 dozen holes to do throughout the bathroom once the tiles are eventually finished. I'll give the cheaper arrow shaped ones recommended by Dave a quick go and see how far I get.

-

Yikes! I should have clarified that my price was Per pile (in 5m lengths) not per meter. I've just gone and double checked that number and it was actually £220 per pile, i.e. £44/m/pile. with an EO of £45 per m if the piles need to go deeper. Also, not sure what your scheme looks like but getting your piles and ground beams done by the pilling company is always (alot) more expensive, although it is easier!

-

As above. Any recommendations? I've got the general principals just wondering if its worth shelling out for some of the diamond bits or just those arrow shaped tile/glass drills. Thanks in advance