Search the Community

Showing results for tags 'joinery'.

-

Hi all, I have already posted a similar question in another forum but I decided I'll ask here as well. I would like to get to know as much as I can about building houses and extensions etc. I am looking for the most comprehensive resources (mainly books) that are available on the market. I want to learn as much as I can from arriving on site and clearing the site, digging the foundations, the civils, the waste, the storm water, the water connections, pouring the foundations, the rising walls, floor slabs, blockwork, brickwork, dry lining, skimming, plastering, plumbing, electrical, joinery, roofing, and everything in between. Any recommendations?

- 6 replies

-

- books

- house building

- (and 10 more)

-

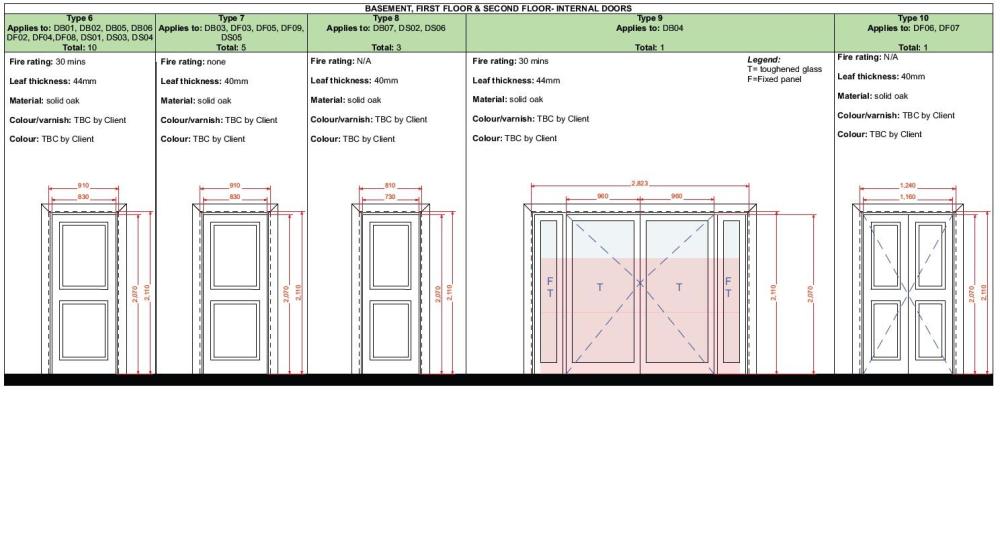

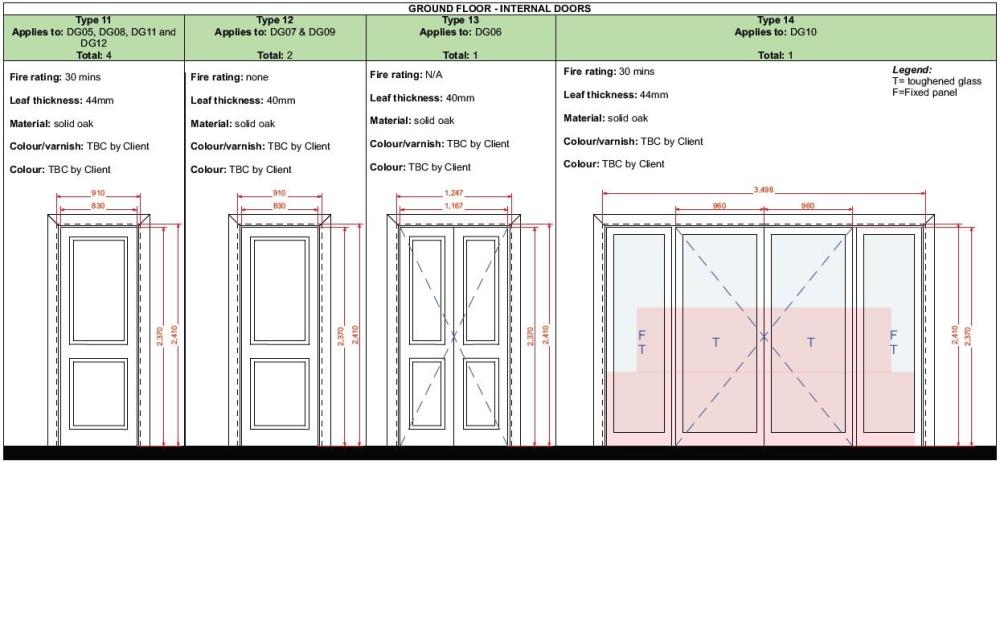

Hi, looking for some advice on my Architects chosen door sizes on my new build. I am comparing some of the sizes from the single doors attached and not really finding an easy match. Just about to have the openings built with blockwork so would appreciate any advice. Block to block is 910mm and the 810mm one is a smaller toilet door under the stairs. Heights vary on the images depending on what floor the door is on, 2110mm high to blockwork opening in the basment which will have 2400mm high ceilings. Do you think I will find it easy to buy doors without them having to be made bespoke sizing? Would I purchase a door frame kit for these openings or just have them made up to suit? Thanks C

-

Hi, I am just looking for some advice and wanted to see if anyone had any success in soundproofing their house from neighbours in a Semi Detached house. I am not the most savvy at Construction and Building work so I’ll try put as much detail as I can! I have recently moved into a Semi detached property and am experiencing a lot of intrusive noise from our neighbours. Couple with 3 young kids who run around and scream like maniacs. Constantly hear them running up and down their stairs and on the landing. Can also hear everything the family do in their kitchen as it backs onto our lounge. (Cupboards closing, appliances, switches/sockets being used). Can hear all of this clear as day as if it’s a hollow wall separating us. Can also hear them walking up and down the stairs and slamming doors. (Hard to tell whether they are slamming and stomping or if it’s just poor insulation or work between the properties). We have a breeze-block party wall with a layer of plasterboard on our side which I believe is Dot and Dab. Downstairs we have a lounge and kitchen along the party wall with the stairs going up through the middle separating the two. Then upstairs we have our landing and two bedrooms along the party wall. So currently we are going to look at getting the lounge, bedrooms and landing done first and then potentially the kitchen in the future when we get a new kitchen! I am in the process of looking for quotes for this. I want to get the best soundproofing possible on our party walls to block out noise this way. Does anyone know what the best soundproofing method would be to block out the noise coming from them stomping up the stairs and upstairs rooms, as this is the main contributor. Would it be a case of soundproofing under our upstairs floor boards between joists? Want to get professionals in to sort this properly so am happy to pay for the best solution possible. Just wanted to know if anyone has been in a similar situation before and had soundproofing installed and if had much joy? Any information would be appreciated! Thanks, Jack

- 7 replies

-

- soundproofing

- insulation

- (and 7 more)

-

I need to get quite a lot of bespoke joinery done. We are having bespoke doors on our kitchen, as well as a few bespoke wardrobes, two pieces of bespoke cabinetry and quite a bit of cladding and concealed storage. My architect has designed it all in meticulous detail and we are now sending out his drawings to tender. Some of it will be CNC machined, but a lot of it will be hand made. Any recommendations for really good joiners that don't costs the earth gratefully received. Thanks.

-

We always thought we’d make our under stairs area look neater by putting a cupboard door in. Now we have a window of opportunity with most other indoor jobs done so here we go. Thought we’d make our own to get the size right to fit the space and have a very large door to fit a human in easily. It’s about 700mm wide. I bought some 6mm oak boards. Thought we’d stick them to some mdf to make a door and build a frame. Is this a ridiculous idea? Will this door make up work? If so, would 20mm mdf work or thinner? And should we face the door on both sides for balance? Any joiners willing to offer advice please? And please feel free to shoot the idea down if it’s rubbish! Thanks

-

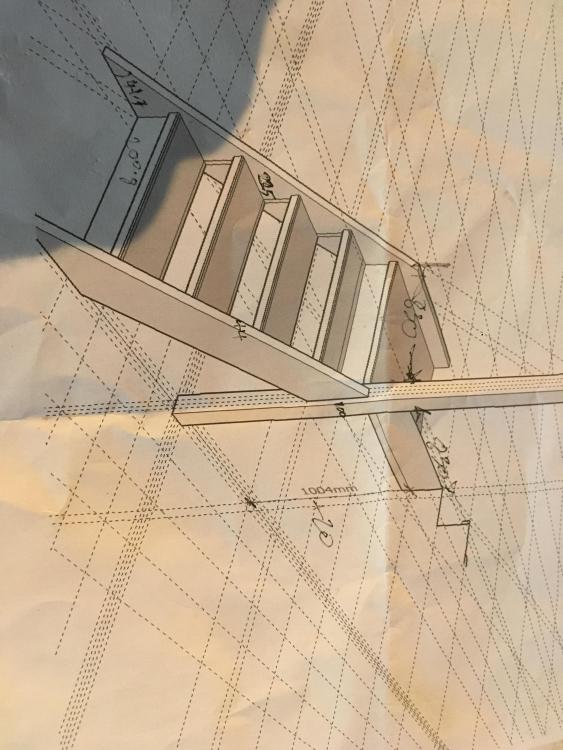

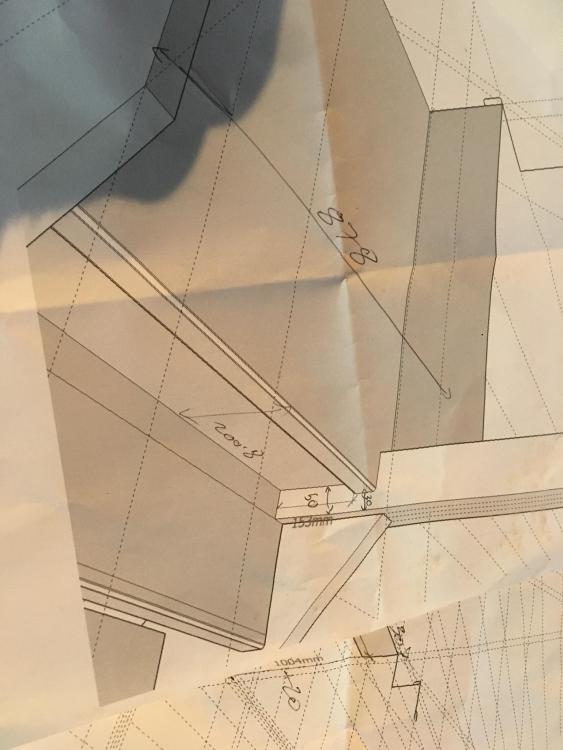

I was going to add this to the stage 1 thread but I feel it deserves its own thread. I am finally starting to make my staircase , all those years that the piles of rough sawn trees have been getting in the way are coming to an end. Yay. I should think some of you already know I started this project a good couple of years ago by cutting down a dead oak tree in the meadow. If not I will provide links to the beginning of the story when I get inside. But either way check out all the progress. The oak is starting out in roughly 55x600x3400mm planks that I slabbed with the chainsaw mill, From that they get laid onto some trestles and cut to useable widths with my skill saw and 3 rails connected together. i found these here little rollers very helpful when trying to get the full slabs into the rights place. Then I put under the little batten to stop it moving while I cut it. so we now have reasonable width 55mm oak planks. Most are over 300mm all have 1 straight side but otherwise they are very rough from the chainsaw. thats is how I left all but 2 lengths because I wanted to get my head around the newel posts. The 2 I put over the planer have come up very nicely so far, The strings treads and risers will be made from the oak if I can get enough out of it but it is looking promising so far. The newels and spindles will be ash. The ash started as roughly 120x600x3900 slabs so I am having to cut them from both sides with the saw but with the rails they are coming out rather well. as for converting the timber i have gone gone a little further with the ash. First job is to cut them to usable length. Then they get pushed over this overhand planer bow up until I get a consistent cut. Then I repeat the process on an adjacent side while making sure my new flat face is hard against the guard so I end up with 2 straight sides and one square corner. from there i take it and put it through the thicknesser useing those faces as references, this give a nice straight even thickness post. now I know what final thicknesses I can achieve with the wood I have I have started making the first jig for housing the treads in the strings. I say first because I will probably end up with at least 2-3 as the lower flight will have draws as risers. After the landing there will be a standard flight finishing with 3 winders at the top. I modeled it all on cad first to optimise the width so it finishes nicely after the winders. its all just lines on ply at the moment but I’ll be getting the router out soon, and thats about as far as I have got. I’d better get back to work

- 95 replies

-

- 7

-

-

-

- stairs

- homemade stairs

-

(and 2 more)

Tagged with: