flanagaj

Members-

Posts

1105 -

Joined

-

Last visited

-

Days Won

2

Everything posted by flanagaj

-

Can anyone provide guidance on achieving a U value of 0.18 W/mK with a 7.3N block outer leaf and 150mm cavity and 32 Dritherm cavity batts. Do I have no choice but to use expensive aircrete blocks? I am now wondering whether a 90mm T&G PIR cavity would enable me to use cheaper blocks and therefore come in at a cheaper £/M2 for the masonry walls. Any builders on here able to provide some options for achieving the required 0.18 U value and how costs compare for different options?

-

They seem to vary widely. https://materialsmarket.com/building-materials/bricks-blocks/engineering-bricks

-

So I'm going to purchase some engineering bricks for below ground and for a couple of courses that will be behind the wood cladding. What I'm struggling to understand is why you'd pay £1.50 for some class A glazed, when a 22N concrete brick is £0.50?

-

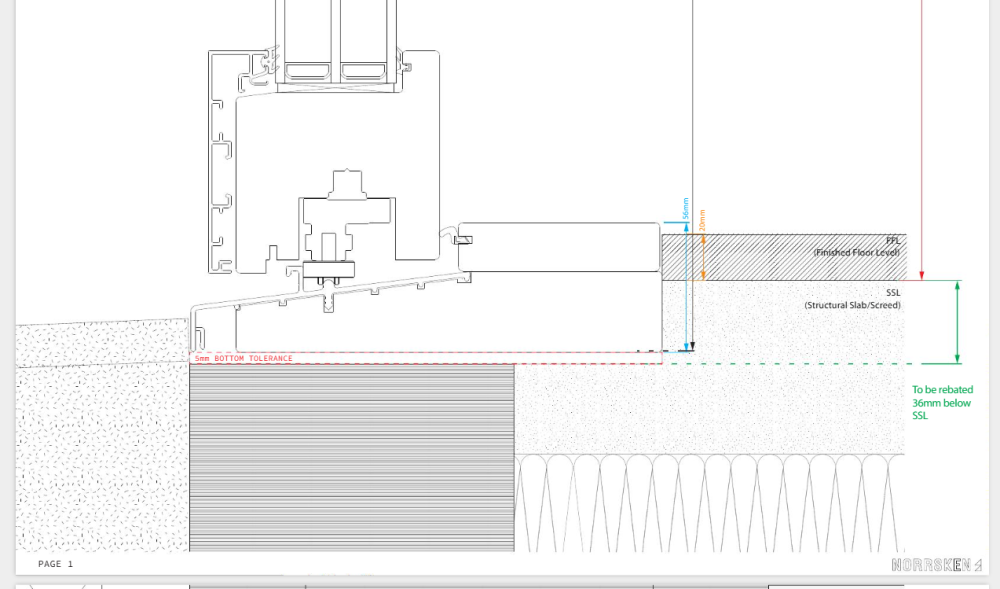

So I receive the below from Norrsken as I am trying to understand the required build up for the sliding doors. Front edge to back edge dimensions of the cill is 204mm. This will therefore mean, that the back edge of the door will sit directly over the 150mm cavity. I am not sure whether the detailing below is for the European market, but the outer leaf is clearly not brick as it is > 1/2 the width of 204mm. Does anyone have a cross section detail. I am keen to understand how the insulation / screed and inner leaf brick / block course is adapted to get a 'level' threshold.

-

I wrongly assumed that regs drawings and construction drawings are the same thing. This is because my brother in law used the same chap for his drawings. Just for my own understanding, how do construction details differ from building reg drawings? when I gave our drawings to an SE, he just did calcs for the steels. He didn’t make any mention of what concrete blocks …

-

But isn't that what the technical architect is supposed to do? Building control have signed off the drawings, but still so many questions. Now I'm beginning to understand why the original architects wanted 10k and this guy only charged 2k

-

Our vague regs drawings just state the walls will achieve a U value of 0.18W/m2k and consist of high strength 7 concrete blocks. I went back to the TA, who wasn't much help and he said "when you know what blocks you you are using, I'll run it back through the SAP calcs". I can't be bothered with the faff and want to know if 7N blocks can be used across the whole build. Thermalites are expensive and will they really reduce the U values, or would another layer of insulation in the loft offset their better thermal performance. I need to get materials ordered as footings are scheduled to be pulled in 3 weeks time.

-

Using ACO drain for guttering downpipe?

flanagaj replied to flanagaj's topic in Rainwater, Guttering & SuDS

I also like the idea of a large tank as if the soakaway ever failed, I could simply fit a submersible pump into the tank and sneakily pump it out onto the road, which then flows down to a very large pond which always has loads of capacity. Hoping it would never be required, but it's a useful backup. -

Using ACO drain for guttering downpipe?

flanagaj replied to flanagaj's topic in Rainwater, Guttering & SuDS

I still need to size it, but thinking 5000 litres. -

Using ACO drain for guttering downpipe?

flanagaj replied to flanagaj's topic in Rainwater, Guttering & SuDS

I dont' think the TA even though about that 😞 A sump before the tank makes a lot of sense. -

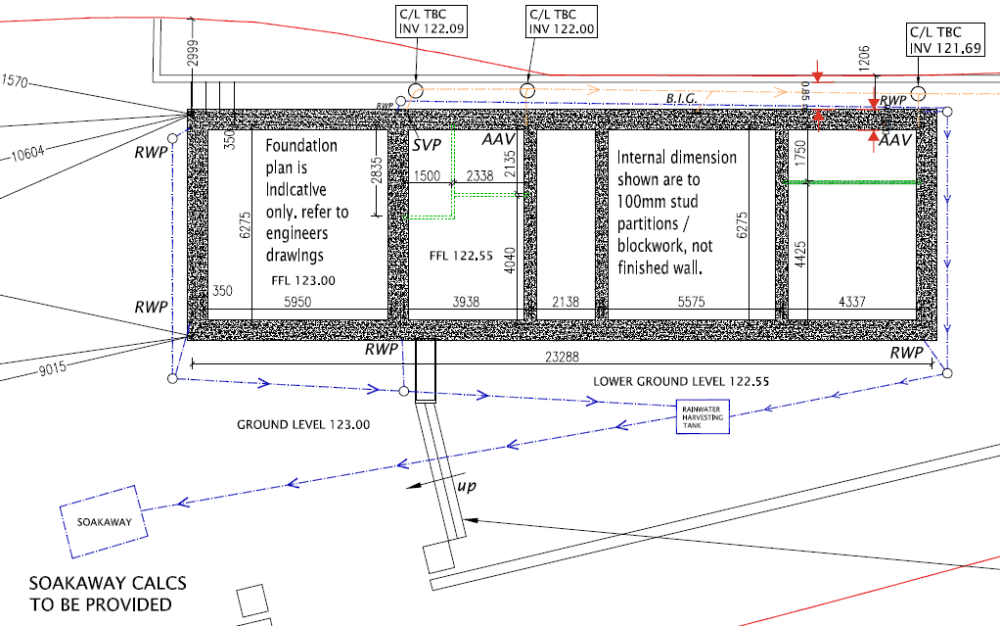

We have a level threshold around the whole house and therefore we need to install ACO drainage. As space is tight down the back of the property, I was wondering whether the downpipes from the guttering can feed into the ACO drain, instead of having to have a separate pipe system for the guttering downpipe. The tech architect who did our drawings has drawn an ACO on one drawing, but then seems to have drawn standard underground 110mm pipe for the guttering.

-

So that is quite straightforward should I need / decide to go down that path?

-

Ok, I think I was over complicating matters, by thinking I could run the UFH above dew point and run the fan coils at a much colder temperature to really make the bedrooms cool, but I suspect that running it at 16-17 degs is perfectly fine and will create a nice cold room for hot summer weather.

-

This is exactly what I had recently with an ASHP installer. With regards to your configuration. Do you run your fan coils at a different water temperature to that of your UFH when you are in cooling mode?

-

Can I ask those who have done whole house ASHP for DHW, heating and cooling who did your system design. I have decided that I want UFH downstairs and ceiling mounted fan coil cassette units upstairs, but I want to install the system myself, except the ASHP or the parts that I cannot install myself. I suspect that if I simply give my plans to a ASHP company and get them to supply and install, it's going to cost a fortune, hence why I am keen to get a system designed, so I know what is required. I could be over analysing this, and it's a simple case of understanding the heat loss calcs for each room and then simply purchasing the appropriate fan coil unit and running the pipework to the unit from the plant room and if appropriate putting in condensate drains.

-

I've put in a oak sleeper retaining wall. The sleepers are installed so that they'll slightly below the gravel path. The will allow me to put hardcore / gravel underneath them so they are not sitting in soil. I keep hearing that I should install a french drain behind the sleeper, but as you can see from the images below, that is nigh on impossible due to the boundary and hedging. If I was to excavate a trench between the steels and fill that with rubble, would that suffice? I was also contemplating putting a 6mm steel plate behind the sleepers so I could bolt (stainless) each sleeper to it to help keep them inline and reduce the possibility of bowing. I wasn't sure whether the centre plate should also be concreted into the ground? The was is not very high, but just don't want it looking a mess. In hindsight, I wish I'd just ripped the neighbors 'hedge' out and had a block wall installed, especially given it's down the back of the house and future access with an excavator will be nigh on impossible.

-

I've been asleep at the wheel on this one and should have realised I need to put in another VoC. Due to a pain in the xxxx neighbour, I put the steels in for our retaining wall set forward 400mm to avoid ripping out all of their hedging to the boundary. This has meant that to maintain a reasonable width path (900mm) on the far corner of the property, I need to pull one corner forward 400mm. At the same time, I'd like to raise the ridge height 200mm so that FFL is a bit higher than the surrounding ground level. The houses on the land are all orientated differently and set back from the road by different distances. So I don't suspect it will be refused, but I suppose I don't have any options but to wait the 8 weeks for it to be processed, before making a start?

-

I'm curious how the banana links can wear as they are fixed to the pin so in theory can't? Mine have a lot of play, but assumed that was normal. The same goes for the quick hitch. The pins are pretty loose in those holes too. I'm only fettling as the weather is so xxxx and thought I'd spend a few quid getting my new toy ready for action.

-

Pressing the new bushings in should be straightforward using a threaded bar and a socket. I could be wrong and it requires way more force than I'm thinking it does.

-

Thanks all. I did look at the cold chisel option, but it looks like the lip on the inner edge is only a few mm and as a result it will be difficult to get anything to stay in contact without slipping off when you hit it. I didn't know whether a blind bearing puller will do the job, or whether the bushings are so tight, that you won't have any chance of being able to get them out with one.

-

The excavator I recently purchased is a bit slack on some of the bushings and I want to replace them. I don’t have an oxyacetylene torch, welder or means of cutting them out. Does anyone have any experience of doing this. It looks like a job that could be a right xxxxxxcx if you don’t have the right tools or do it via a specific approach. it’s a 1.8T machine and uses 30mm pins.

-

Is anyone actually building at the moment?

flanagaj replied to flanagaj's topic in General Self Build & DIY Discussion

I am most likely going to use a man and an excavator. Just so things can get moving and trenches are not left open for too long. I am now wondering whether to go with a beam and block floor over a ground bearing slab. Given I am binning having a power floated floor and am going with conventional screed and then either tiles or wood, it might be quicker and might be better suited to DIY installation of the radon membrane. -

Is anyone actually building at the moment?

flanagaj replied to flanagaj's topic in General Self Build & DIY Discussion

Some good points there Nick. Haven't really planned any of the stuff you mention, but now is a good time. -

Is anyone actually building at the moment?

flanagaj replied to flanagaj's topic in General Self Build & DIY Discussion

So I am not alone in waiting. The sound of the heavy rain on the metal roof of a static caravan is akin to being waterboarded and remaining positive is hard work. -

We have been in our static caravan now for nearly two months and haven't even started our self-build. The weather has just been so rotten. It's been either very cold, or throwing it down with rain. Are people literally just carrying on in the rain and pumping out filled trenches .... to enable things to progress?