Tetrarch

Members-

Posts

170 -

Joined

-

Last visited

Everything posted by Tetrarch

-

Ducting fumes from ventilated induction hob on a kitchen island

Tetrarch replied to Smallholdertoo's topic in Ventilation

We've had our 900mm Neff Downdraft I98WMM1S7B for over 18 months now. Our MVHR has a double extract (almost) directly above the hob. The outlet vents through an open vent in the plinth, it has a 90-degree vent on floor level but isn't even ducted to the opening. I took the picture attached just now and took the opportunity to remove the vent and check the opening. There is absolutely no presence of any grease build-up or residue there. The MVHR vent is also grease-free as far as I can tell Regards Tet -

Allocating your precious resources on the horizontal surfaces is (IMO) the way to go Your island will absolutely be the focus of your new kitchen. It is what you see and what you notice, it will become your social centre, your prep. area and the focus of your kitchen. I would suggest that the surfaces are more important than the cupboards to some extent You definitely should actually go and see the products themselves. Our kitchen supplier got us in to see the supplier of the slabs in their raw polished full-slab form. After a decision was made we managed to negotiate with the quartz finisher/installer to get the splashback in the same material at a discount and one waterfall edge thrown in for free from the initial quote I've since been back to the quartz installer to get window sills made up. Regards Tet

-

Both my digital showers were an early design choice (thanks to my builder's recommendation). It seemed to be a good idea to co-locate all the plumbing sources. They are both located in the cupboard where the megaflo, the CH expansion tank, CH pump and control centre are located. All the wet stuff (except from UFH) is here Regards Tet

-

Our downstairs 2m x 2m bathroom is cold. It has slightly less UF heating than I wanted. Our upstairs bathroom is too warm as it has the non-TRV escape from the heating circuit. I'd like to change the escape rad to the downstairs bathroom Problem: I have no side or floor access in the downstairs bathroom. The only way to run pipes would be from above Has anyone got any recommendations how to install a top-fed towel rail? - I can get an 1800mm one that will help to minimise the visible tails Regards Tet

-

I had a concealed Aqualisa valve explode in a wall - never again Surface valves are OK - Grohe or Hansgrohe for me Digital showers are (IMO) the best way to go. Permanent access to the rainfall head and a single pipe in the wall must be the way to go. Then you can put your controls wherever you like I've got two - a Vado and a Mira I prefer the shower head of the Mira and the wireless control but I prefer the aesthetics of the wired control buttons of the Vado. I would never recommend anything else Regards Tet

-

I love Para 4. - burn! I am interested in why you don't lead with the factual error as it taints the entire decision. The rest of your points are opinion-based and could be challenged but para 4 is a real humdinger. From a weight of argument point of view I would be tempted to start with the most fact-based and work my way down to the most opinion-based Regards Tet

-

Any love for CCT (i.e. changeable white) LED strips?

Tetrarch replied to Alan Ambrose's topic in Lighting

I've got CCT's everywhere downstairs I have way too much lighting anyway. I have 17 RGB downlights that are actually not on very often but are great for a party I have CCT LED's in three skylights and under the kitchen cupboards all wired to the same wireless switch so that they all work together. We use the different colours frequently, sometime to soften the light for the evening and sometimes just aid close work over the island We also have three pendant ring lights that have CCT functionality - again these are really good for mood setting of an evening Regards Tet -

Thanks to the OP for this thread. My daughter has been asking the same question and I am leaning toward Drayton over Hive (that I have) The Drayton BF sale has prices even lower than Screwfix (marginally) and free delivery https://wiser.draytoncontrols.co.uk/pages/black-friday-2025 I'm looking at a package for a combi boiler with 5 TRV's for £250 Regards Tet

-

Downdraft extractor or over-hob?

Tetrarch replied to Lincolnshire Ian's topic in Kitchen & Household Appliances

We* use our Neff Downdraft every time the hob is used. It has a setting that adjusts automatically to accomodate the amount of steam that is being generated. Ours is on an island with a large rooflight over part of it, so keeping the ceiling clear was very important to us aesthetically We actually went to the Siemens demo kitchen to see the identical downdraft hob in action and it has proved as effective in practice as it was in the showroom. THEY ARE NOT CHEAP, but this was an early line item in our budget and we got a great cashback from Neff by buying multiple items in their annual Autumn offer. We had them in boxes for nearly 8 months before they were installed. JohnMo is dead right about the MVHR and humidity. Our MVHR inlet is positioned at the left-hand corner of the pic below. It has two extract pipes in it. We would use the "boost" function but I haven't found a way to make my Alexa+Shelly switch work yet and it seems to work perfectly well without Regards Tet -

Dependent on how big your pantry unit is I would seriously condider one of these: https://www.amazon.co.uk/dp/B07WMRJP8R?ref_=ppx_hzsearch_conn_dt_b_fed_asin_title_3 It's a usb-rechargeable mini led strip that gives out a ton of light and the sensor works well (not perfectly, but well). I have one for the cupboard under the stairs and it is perfect for that Regards Tet

-

We have the Neff downdraft and it copes absolutely fine regularly with four pans on the go. The balance between the occasional lingering smell and the aesthetic appearance of no hood, (plus the theatre of the downdraft) means that we are happy with our decision A consideration may be the volume of the room the vent empties into. Whilst we only have one (double piped) vent directly over the island, the kickboard vent empties in a large space, so the effects may be mitigated somewhat Regards Tet

-

Bath fillers - Mira, or Aqualisa

Tetrarch replied to crispy_wafer's topic in Bathrooms, Ensuites & Wetrooms

I was vetoed on these suggestions as a showerhead was a requirement, but if you are going full minimalist... Overflow filler: https://www.heatandplumb.com/acatalog/sagittarius-minimal-centrafill-bath-filler-waste-wa-486-c?msclkid=2fe061b79e891f53b0b108a635d67fc7 Ceiling filler: https://www.amazon.co.uk/Kohler-Laminar-Ceiling-Filler-Polished/dp/B0013423IY Regards Tet -

I've got three x 2.2m blinds for a 6.5m door. The supplier/installer (I was too chicken) recommended that 2 x 3.25m would be too big. I had all the blinds run on a single motor with the mechanisms linked so that they all move in lockstep. To the right I have another 1m blind on a separate motor I have Somfy blind controls that link to Alexa The all in cost for the blinds was £3,500 of which £900 was labour (survey and install) Added to that was the cost of the blindboxes - they were £1,500 on their own but they are very discreet and hide the blinds and the mechanism beautifully. These were a pain in tp fix as they were so long Regard

-

Real World Report I posted above in Jan '24 and we had the Neff Downdraft installed in September '24, so we've had a year's full use The reason we chose the downdraft in the island was to avoid having an extractor above the it. I have MVHR and we have a double-extract actually over the end of the island with the hob and this seems to take care of the extra humidity from the recirc. extractor It copes very well with all sorts of cooking and, with its auto function takes steam from the front of the cooking surface. The Neff Griddle plate is exceptionally good for steak and burgers https://www.neff-home.com/uk/en/product/accessories/hobs/cookware/tepan-yaki-grill-plates/17000339 Regards Tet

-

Which house cladding option

Tetrarch replied to Amateur bob's topic in New House & Self Build Design

Ah! - a quandary indeed Regards Tet -

Which house cladding option

Tetrarch replied to Amateur bob's topic in New House & Self Build Design

Ooops - apologies If you want an opinion, then definitely don't paint. Let the wood go through its full shrinking/drying/colour-changing cycle and see how you feel afterwards. Regards Tet -

Which house cladding option

Tetrarch replied to Amateur bob's topic in New House & Self Build Design

If you want maintenance-free then you could do a lot worse than Millboard. I used Cedral on a prevous house (both outside and as a bath panel) and it is a great product, but is definitely "just a concrete board" https://www.millboard.com/en-gb/composite-cladding-collections/board-batten/golden-oak/MCBF360G The millboard cladding is astonishingly realistic, and is really good for mitre-ing. The only downside is that it is NOT cheap. Other cladding boards are available,but when you compare them close-up the Millboard is a cut above. My critical criteria was waterproofing as I wanted to add a rain chain and they do splash a bit. I attach some during and after installation photos Regards Tet -

Hob extractor in a passivehaus? (or nearly, at least)

Tetrarch replied to Great_scot_selfbuild's topic in Ventilation

We have recirculation with a Neff Downdraft. The MVHR was designed with this in mind and there's a double extract almost directly over the hood - we've not used the boost Regards Tet -

Mounting frame of recessed light gone in ceiling - can't get down

Tetrarch replied to Question's topic in Decorating

You'll have to fold both springs down. I'd try to bend both down, using a screwdriver to wedge them against the bottom and then use a zippy-strip to hold them in situ - that should let you get the whole thing out Regards Tet -

Thank you for the candid feedback. Fat finger: That deflection is 16mm not 160mm This is entirely my typographical error - for which I apologise One piece of hitherto unprovided information. The North/South beam is 8m long, so there is a significant load on the centre of the East/West beam. This install will definitely need significant professional input. I would still like to know the answer to my original question though...... Regards Tet

-

Hi Nick, The beam required to span the gap was ~800kg. The deflection is 160mm which is significantly more than the door supplier specifies I understand that I am out of my depth, but my intuition is that there are multiple compromises with a single beam which can be entirely offset by a single compromise of a single supporting pillar IF I am correct, then the size of the pillar becomes the entirety of the compromise - hence my question. I'm only interested in the comparison between vertical supports Regards Tet

-

This must be a common situation but I'd like some comment on alternatives. The below picture is just to illustrate the install and there has been no structural calcs yet so the proposed steels are not to scale. The plan is to open up the back of the house and install a 6.5m fully-opening patio door and remove the internal wall the currently runs North/South. It's a two-storey house so both beams will be replacing supporting walls above. Accepting that some kind of vertical support will be needed. Aesthetically, my view is that a circular pillar (indicated by the yellow circle) is far less obtrusive than a square or raw I-beam. Is there a way to find a comparison between round, square and circular vertical supports cross-section vs compressive load. The actual numbers are not as important as the relative cross-sectional area Regards Tet P.S. Asking for a friend.

-

I would suggest that trying to slide this upstairs sounds attractive, but sounds hellishly dangerous for the guys UNDERNEATH I like the idea of a genie. The trouble with a genie is the weight transfer when you try shift it laterally. I had a large problem trying to move a 75kg skylight through its own "hole" - up was fine - it was just the transition from vertical to horizontal that was a challenge. Removing the glass would make things enormously easier. You can then genie the whole bath and fix some scaff boards across the diagonal to take the weight straight off the genie Very best of luck Regards Tet

-

They're all different FH Brundle do a great range and very keen prices. Big fan of the company, their products and their flawless customer service https://www.fhbrundle.co.uk/handrailing-and-balustrade/frameless-glass-balustrade?via_sb=true Regards Tet

-

Leak coming in around roof light EPDM issue

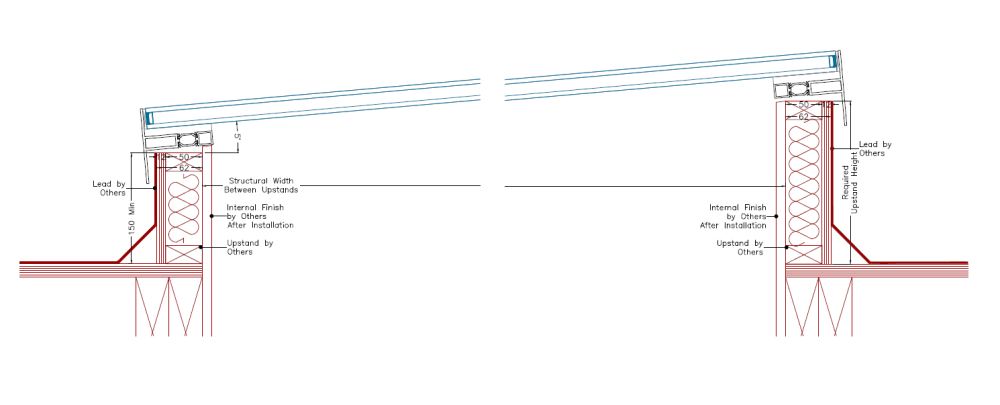

Tetrarch replied to nmh's topic in Roofing, Tiling & Slating

That detail looks very odd. My spec was 100mm of waterproof upstand as a minimum (see below) I used EPDM rather than the architects lead spec and they (generally) don't use 45-degree flashing anymore for EPDM. I would wholeheartedly agree with the other critics of your roofer's advice. In my experience traditional felt roof guys are always only really happy with felt, some rave about liquid coverings, but most rail against EPDM. I'd get an EPDM specialist to have a look at your particular install and go from there Regards Tet