BotusBuild

Members-

Posts

1180 -

Joined

-

Last visited

-

Days Won

10

Everything posted by BotusBuild

-

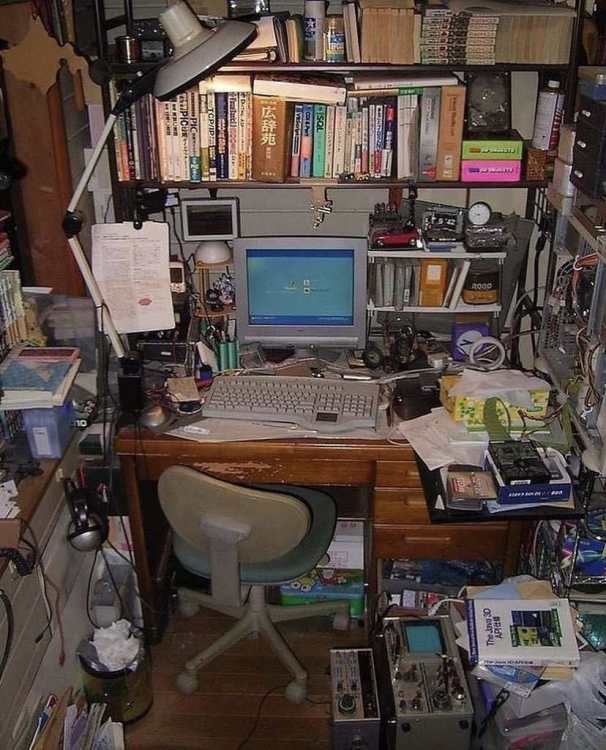

The only room finished in his 10 year build?

-

-

Mat Wells yay or nay and if yay what mat?

BotusBuild replied to Beau's topic in General Construction Issues

We have one of these, albeit outside, but I dont see any reason it won't work in a mat well. A good shake occasionally and it's clean. Would work in an internal entrance/boot room. https://musthaveideas.co.uk/products/dirt-defender -

I don't know why, but I don't like the idea of those pipes under the stud walls of the two right hand bedrooms. Also, I don't think there is any need to have the pipes so close to each other near the manifold - the vertical bit of the blue kitchen/dining loop and top of the hall loop can be removed and then spread out the pipes from the utility, WC, bathroom and left bedroom to fill that space. Spirals probably a reasonable request in the bedrooms. As you have 3 loops in the kitchen/dining the heat distribution will be reasonably even

-

Glass balustrade fixing to Glulam beam

BotusBuild replied to BotusBuild's topic in Windows & Glazing

Nuts and bolts and big washers behind the wood? -

Glass balustrade fixing to Glulam beam

BotusBuild replied to BotusBuild's topic in Windows & Glazing

Happy Days. Made2Measure (link in JohnMo's message above) has wood connection certification with M8/80mm long at 200mm spacing (400mm with no wind loading) using Fisher FPF-WT YZP (https://www.fischer.co.uk/en-gb/products/screws/wood-construction-screw-powerfast/powerfast-fpf-wt-zpp) -

Glass balustrade fixing to Glulam beam

BotusBuild replied to BotusBuild's topic in Windows & Glazing

Certification/Accreditation only mentions concrete and steel. I have messaged them about fixing to the glulam beam. -

Glass balustrade fixing to Glulam beam

BotusBuild replied to BotusBuild's topic in Windows & Glazing

Thanks, I shall take a look -

Yes, and no. Yes, replace all FF generating capacity with non-FF alternatives and you can then price electricity accordingly. I'm really not going to respond to any comments on that statement. It's just not going to happen overnight, but I think we all agree on that. No, because while we are interconnected and other countries use gas (bought on that global market) we are beholden to the price of electricity of those other countries. Don't misunderstand me, I believe we should be investing to remove our dependence on using FF to create electricity, or find ways to remove the harm caused by using FF. There is no silver bullet, but it does not preclude us from doing what we can while remaining economically viable in a global economy. It's not easy. Out.

-

@Beelbeebub, before I say what I'm here to say, I agree with the overall sentiment of your POV of the OP. Now, do you understand that the auction is not just a national thing? As we are interconnected to Europe for electricity, that auction involves international suppliers. Behind all that is the global gas pricing market (a much bigger thing). Yes, it sucks, I agree. But all of that makes it a damn sight more difficult to change the system - just look at how long things take for the EU to reach agreement on anything as an example. By all means suggest the change, but keep in mind the diplomatic, economic, and geopolitical matters that would be brought to bear in trying to do so. I'm not saying its impossible but good luck trying to make it happen, or finding a political party that you can vote for who will make it happen.

-

Look carefully under the second step. Haven't hidden the wire to the camera yet 🙂

-

@-rick-, note that none of the milled wood is in the staircase, thats just in the breakfast bar. The wood for the staircase was about £2200

-

Low points: and how to get out of them

BotusBuild replied to ToughButterCup's topic in General Self Build & DIY Discussion

I have a perfection streak (maybe OCD) like many "hands on" self builders, and I hear what you're saying, Ian, about being less lenient with your own work than others. I think we see more detail because we did the work ourselves. Could we have done better at the time, with the right tools, and maybe more time? Now we may have done the same thing multiple times, and through experience got better, sure, we know that first one is not as good as it could be. If you can fix the "bad" one, go for it. If not, accept it as a lesson learned. Has my perfection streak disappeared? Absolutely not, and I'm still fooking it up every so often. Ian, be kind to yourself. What you've achieved overall with your selfbuild is monumental. You know this to be true. Try to put the little things in context against that, one little thing at a time. Hope this helps you a tiny bit -

Just shy of £10k

-

Osmo oiled 👍🏻

-

Low points: and how to get out of them

BotusBuild replied to ToughButterCup's topic in General Self Build & DIY Discussion

Differing levels of annoyance require different responses. Severe annoyance, for me, means remove and replace or whatever will correct it to my satisfaction. Anything else is dealt with by the phrase "it is what it is" which kind of sums up some of things @SimonD states more eloquently above. In summary - fix only that which you can at reasonable personal and/or financial cost. Everything else is a lesson learned. FYI - the phrase comes from someone who worked for me many years ago. He used this phrase in daily worklife to describe situations that were not fixable or in some cases would cost far too much (time/money) to put right, but in themselves were not terminal, unlike his final medical diagnosis, at which point his phrase hit me square in the face! I now use it at appropriate times to remove stress from my life. -

Three men and a rope. The two spines are separate pieces.

-

It is (part K). It'll get done sometime before completion signoff 🙂

-

Dusters on the toes of our slippers 😀