-

Posts

5549 -

Joined

-

Last visited

-

Days Won

16

Everything posted by MikeSharp01

-

Best pipe insulation and where do I need it?

MikeSharp01 replied to MikeSharp01's topic in General Plumbing

Yes so you pump hot water round the house with take off points at each sink, shower etc returning it to the tank. Its much more common in commercial buildings but if you have it it means the Hot water is almost instant at your tap! It is costly in energy terms and if you have it then very good insulation is needed for the pipework especially in a highly insulated house. -

Exploring the ratios and losses between building elements

MikeSharp01 commented on SteamyTea's blog entry in Energy Ideas

Two things arise in my head from this - I may have missed something as I did have some wine last night. Firstly, if it is a big problem why has it not been sorted out - stupid to ask I guess but hey. Secondly, if you do have a blower test result then surely the leakage must add to the MVHR losses and be a calculate fraction assuming the MVHR holds the pressure difference roughly constant. From this it must follow that you can reduce the MVHR setting by the pressure test ACH when you are setting up the MVHR as part of the ventilation strategy. Might this then go some way to explaining why people find that when using MVHR they can back off the flow rate and still be comfortable because all they have done is got to the regulation ACH flow rate including the fabric losses. -

Shocking Snagging Inspection Finds at NEW BUILD HOMES....

MikeSharp01 replied to MAB's topic in Housing Politics

They think they are getting a trouble-free house with no work to do, the horror stories won't happen to them, and anyway, there is a 10 year guarantee. What they don't know is that the guarantee is mostly worthless, the horror stories happen everywhere, and the house will be poky and the same as the one next door without any character. -

Why did you choose an air source heat pump?

MikeSharp01 replied to SimonD's topic in Air Source Heat Pumps (ASHP)

We started the build as a Passive House but gas fired, we had the gas laid in and ran the track pipe (which is for sale in the market place now.) through a duct from the gas meter. I had looked at ASHP but felt gas was a safer bet, this was at the planning stage in 2017 - we wouldn't need a cylinder so the heat loss into the building, which @Jeremy Harris had shared with us all would not be a problem. I had a very good plumber / gas fitter so fitting the boiler would have been no problem and it should have been a smooth process with a combi boiler. Then I started to get much more concerned about the eco credentials of gas fired heating and decided to look at other options SUNAMP, PV, Willis, and battery but as SUNAMP was getting increasingly bad press and the Willis route would have hit our SAP score they got kicked into touch. So gas came back, but sadly our tame gas fitter was taken ill, and was unable to work, and we would have had to seek someone else so I took a look at ASHP again, plus the grant was now £7500 so we should be able to get it done for that! So in 2021 we started looking at MCS installers and that was like pulling teeth because none of them were very convincing and didn't listen to our design and insulation standards preferring to fall back on some sort of opaque arbitrary process to give us wild quotes for a straight install where a big chunk of the work was already done. The UFH is in and I had installed two 28mm pipes in the insulation from the utility room to the place we might install a heat pump just in case. So again I swithered a bit, and at that point the Umbrella schemes started to take off and it struck me that we might fit the ASHP ourselves if we could find a sound scheme to duck under. In the end after a lot of searching and a bunch of Quality Function Deployment (QFD) like exercises to compare the various offers we went with Cool Energy, although we had to wait almost a year for their smallest Heat Pump to get MCS accreditation. Its installed and commissioned now - still sorting out some teething issues, we have had our grant money and the all up cost with everything including the EMON heat meter system with all the bells and whistles has come in on the money with me doing all the plumbing, electrics and controls and them signing it all off. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

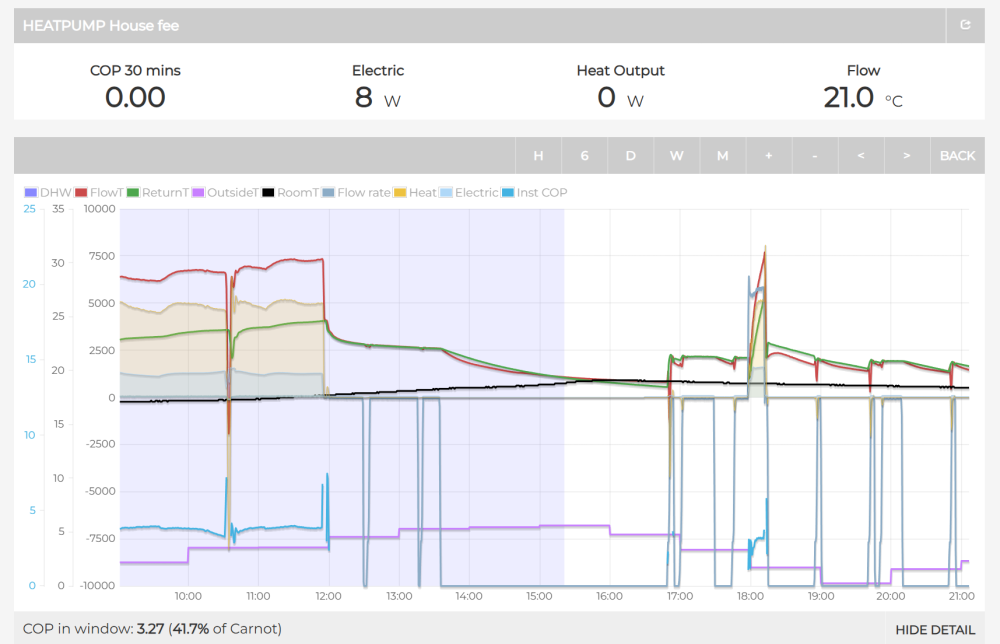

It's been a busy weekend family wise so have not had a chance to talk about any issues but you may have hit upon one I saw on Saturday. I was running with normal settings 28 degree flow and trying not to fiddle so as to limit the number of variables as @SimonD encouraged me to. (Remember I am not using WC as I cannot control the end points of the curve yet and I am awaiting a response from the manufacturer as to how to set them - hopefully tomorrow.) and for some reason at 12ish the system just stopped. Well when I say stopped I mean it stopped producing heat and just ran the pump. Those dips at about 12:30 & 13:15 are me turning off and on again - making no changes. It was a sunny day so the room temperature is rising as is the outside air temperature (OAT) but the heat pump (HP) knows nothing of the Room Temperature and it has no 'stat' anywhere. Initially I thought that the problem was the OAT sensor of the HP because it is in direct sun - something that will be sorted when the bin house is complete but for now I may have to shield it. It was up at 24 deg C. So I left it and went out for the afternoon with my Valentine! Came back at 5 and tried to start it, now the OAT sensor was normal, about what the EMON trace shows (remember that the EMON trace is derived from the local weather station). Still it would not start and I was now quite worried - I have broken it! However at 18:00 I thought OK lets see what happens if you call for a domestic hot water (DHW) cycle. That started first time so the main workings of the HP are in order something else must be preventing it from delivering heat. Anyway while watching some telly across the evening I just prodded it with reductions in the flow temperature, a few times to no avail. I slept on it and this morning I decide to go the other way - upped the flow temperature setting to 31 and off it went. Nothing broken but something odd going on - now all I need to know is why this occurred. Reflecting on it all I think there are aspects of two things hitting the issues in this chart. The first is the OAT sensor - If it gets too hot it won't allow the HP to run anything but the pump, so I am going to have to shield it for now. ( I do assume it will allow the DHW cycle to run however even though I did not try this.) This ties up with your experience above @JohnMo. Secondly if the delta (Δ) T is less than some value, I think around 5, it won't allow the unit to start although it might allow less if it was already running. So as I lowered the setpoint down in the evening it was too close to the return temperature because the slab (hovering across this whole period at around 22 deg C) was feeding back return water at too high a temperature. If I increase the setpoint enough it would start without issues. I managed to trip the same behaviour on Sunday evening and it is clear that for this heat pump it won't start if the return temperature, after perhaps couple of minutes of the pump starting up, gets too close to the set point the pump won't start but that you can get it to start by upping the setpoint, letting it run for a few minutes and then backing the set point off to where you wanted it to be in the first place. So now all I have to do is find out what setting(s) causes this behaviour, perhaps its some sort of overlap between dead bands somewhere in the system or some such. I don't think we can turn this off on ours but I have to say I have not seen much, if any, modulation in output below about 3kW, I will hunt through the trends data and see. I already have all the flow meters wide open. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

MikeSharp01 replied to fatgus's topic in Heat Insulation

True payback can be long although it seems that payback is not always a good reason not to do it because the 'value' dimension gets lost. So while you can know both most people know the cost of things but cannot articulate the value. I suspect that if you stand back far enough on the payback side only in £ terms you will be hard pressed to make self building pay back. -

You cannot realy believe that because you already have a lot of automaton in your house it's just not all joined up with a unified majordomo. So it's all about where you are in the automaton onion layers, where you automate everything on the outside and you just have digital thermometer on the inside. Between them are just layers but if you peel down the layers it still looks like any other onion. So home automation is about layers, if you have anything automatic you must have home automtion. QED

-

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

I need to look at the Agile tariffs to help once I get it settled down and have the full BMS integration details. As it is I only have the read codes for the Modbus link. So although I can turn it on and off using the call for heat contact I cannot switch modes to DHW other than at the controller itself so not much good for the agile tariffs. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

I think the 70T is the whole structure without the cladding or insulation. The slab is 100m2 at an average depth of 200mm so 20m3 of concrete. Which interestingly is what it says on the slab concrete bill IIRC. So 50T inc the steel or there abouts. Its been too hot in here for the last two days. I have added no heat in since the 10th and what with solar gain, high local temps, and me working at plaster boarding, the temperature today is 0.7 oC lower than it was on Tuesday when I turned it off. 19.9 when I turned the heat pump off and 19.2 now! Can I be impressed with that? The slab has lost 2oC over the same period and is now at 19.44oC so perhaps some charging will be needed as the whole house drops together. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Yes I get that and I was only Joking anyway. Yes I am being now as the house is too hot for heavy plaster boarding so I have left it off while I await the technical curve setting details. Even leaving it off is quite instructive though. the slab has lost 1 degree in 24 hours with an external temperature (OAT) of 10 degrees form 21.5 - 20.5 while over the same period the room temperature has dropped slightly less - could be because I was working in there today. -

Two questions relating to UFH manifolds

MikeSharp01 replied to Bancroft's topic in Underfloor Heating

Ours is 1.2kW at -3, half that is 600W is there such a Heat pump? - I think your latest goes down to 1kW, ours only goes down to 1.8kW. We are still a long way from COP of 6 although today I was playing again and I managed a short run at 5. -

Whole house Audio one presumes, is that for making sure the same music is everywhere.

-

We are always interested on here. Sometimes driven by pure schadenfreude but mostly because we know we will go, or have already been, there.

-

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Yes I recall now you mention it. To be fair the heat pump is, for the most part working well. The house is over warm now, so I have turned it off until I can get some more info from the manufacturer about controlling the curve. As it stands although I thought I had control of the two endpoints on the 'custom' curve I don't so I am awaiting an update on how to get control of it. I did think today, in the midst of my frustration with this, that now I have my MCS certificate I should just pop a Willis heater in to run it when the output required is less than the heat pump minima - how cheeky would that be? -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Yes. I have now turned it off to let it settle and then tomorrow I will set much lower points and I was wondering if I had the numbers too high perhaps even the wrong way around because there is a hint the heat goes up when the temperature goes up but that may just be surmise as finding those set point parameters was somewhat guess work. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

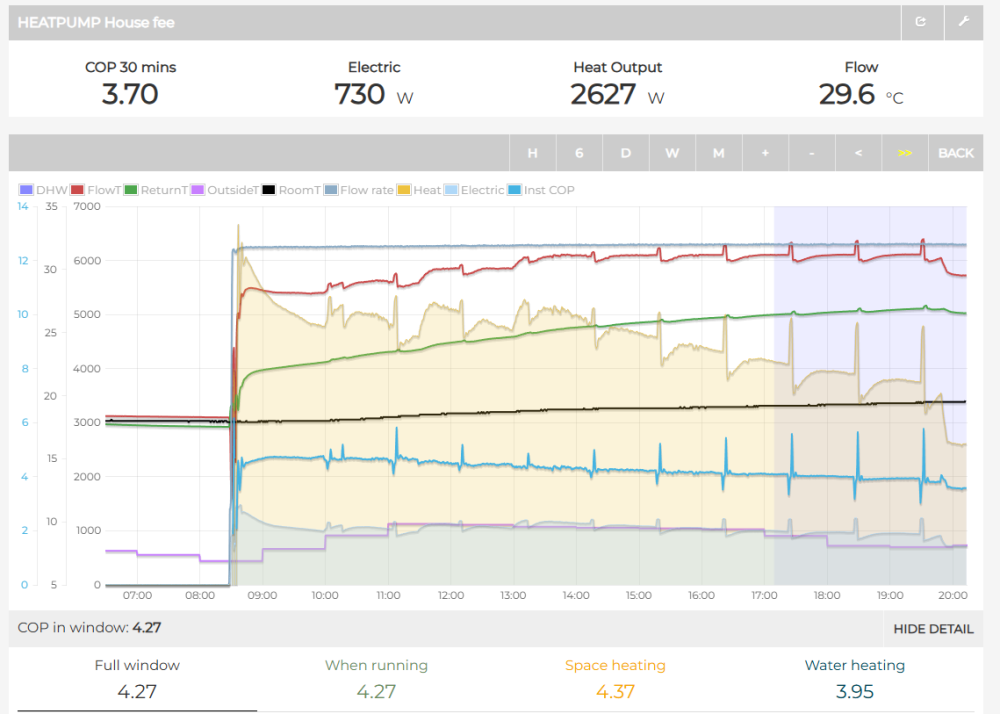

Ok I have set up Weather compensation on the CE-iH6+ heat pump with its Carel controller using the Huilian App. It's a bit of a faff because the manual does make it clear what the various settings are that control that start the end points of the curve (line). Getting ChatGPT and CoPilot (I like to use both so they check each others work!) to hunt around and a bit of experimenting it all became bit clearer. It is clear that two of the values are fixed - you can do nothing about them in this system. The minimum Outside Air Temperature (OAT) is fixed at -5 oC the Maximum OAT is fixed at +15 oC. The curve runs between these two values in X and you can set the Y values as flow temperatures for them both. So for anyone who is using this same heat pump: To set a custom curve (one you can play with flatten / lift / drop) you need to select Curve 9 in the User Para menu via the Huilian App. Then for the top of the curve, lowest Outside Air Temperature (OAT) which is fixed at -5oC, flow setpoint you use "Heat Set temp" parameter and I set mine to 32oC and for the lower setpoint (OAT fixed at +15OC) you actually use the "Auto set temp" parameter and I set mine to 28oC. The Graph is interesting on a number of fronts. The heat pump has been running all day - no cycling or defrosting, although as you can see as I took this screenshot things are happening! I will take a look when I have finished this post. Over the day it has been modulating down the output and the COP has not been bad. The Delta T is now under 5 (approaching 3 at the very end - which is thumping the COP) and the slab temperature (not on the graph has climbed from 19.62 to 23.31oC so a bit further to go and we will hit the hard limit on the slab temperature. Not that I have implemented the stat for that as not sure how best to do it I will just turn the thing off. The best thing today has been the sun shine so for most of the daylight hours we were getting all the heat for free! Perhaps the worst is that looking at how the house performs I really need a much smaller heat pump, might have to think about following in @JohnMos steps. Finally looking at the very end it looks like, for some reason (I have not changed anything), it has jumped (modulated) the output down to 2.6kW and is running it down more slowly from there. Minimum we can go is 1.8kW on this unit! It must give up eventually trying to limbo under the wire. At which point it will go into short cycling. Need to get the BMS connection up and running so I can get some more intelligence into it from there. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

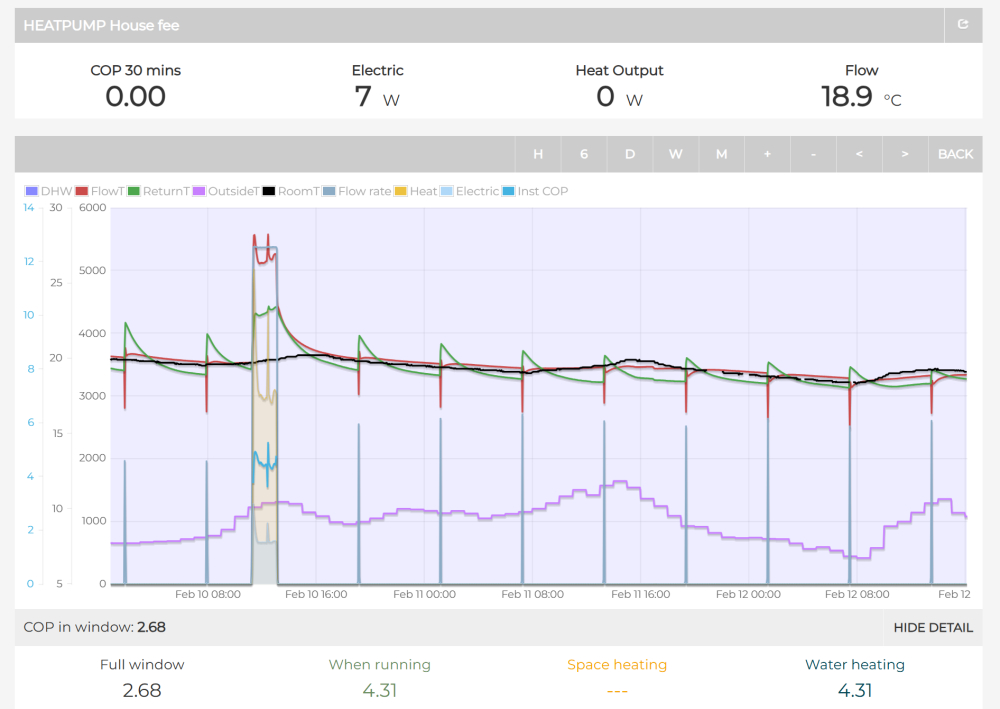

We did have some sediment when we did the original pre commissioning wash through but not a great deal. I did that earlier this week first backwards, as you suggest, and then forwards. The flow rate was prodigious both ways at 12L but of course that was at 4 bar pressure, the pump measures just over 0.6 bar. I then ran Sentinel X800 for a couple of hours and flashed that out, then put X400 in and have left that to see if it can do any more. The long and the short of all this work, and taking out any Glycol, is that I have improved the flow rate a little in the long run and so across the UFH by, well, nothing really, about 30l/hr and most of that improvement is probably due to the higher flow temperature changing the viscosity of water (you can see the effect of this in chart below). Anyway I am not too downhearted because we have managed to find a stable operating point at COP of 4.0+ and got the house up to temperature. At the end of that group of runs the slab temperature reached 23.8 deg C and so turned it off because that is about what we want in the final event. Next week I will connect a slab temperature probe directly to the EMON so I can watch it all in one place. Zooming out to now you can see that the house temperature lags the slab by 7-8 hours! Obvs the period of inactivity hist the overall COP but I am not displeased by even that. I am not sure I need to reach for an industrial pump as I think @SimonD was correct in urging patience while the system settles down and I think we have clear evidence that approach worked here. One more thing I found when making adjustments is that the Control on IN / OUT switch actually refers to using external or internal sensor but has no effect, when set toe external, unless you also turn on Weather compensation. So where to from here is my next question. I need to either switch on weather compensation and see if I can tune that or run the UFH in much lower flow temperature chunks against a stat that could be room temperature but looking at it might usefully be slab temperature given the way the system (house / slab/ heat pump) performs although I am not sure. -

Yes and perhaps the question is who supplies the gravy for this train.

-

Some might argue that although this appears to be the case in fact the real thing in the driving seat is perhaps vested interest, but once removed, so the vested interests that focus the governments interests. Long may it continue.

-

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

How did you control it. -

Interesting couple of days with the new heat pump.

MikeSharp01 replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

How do you control it