akjos

Members-

Posts

35 -

Joined

-

Last visited

Everything posted by akjos

-

Great write-up and very clear. Easy to follow for anyone designing a new system. One thing I’ll add, the heatloss calculation is such a crucial piece of information, so really make sure it’s correct. Whoever does it, needs to spend at least a few hours analysing all parts of the building.

-

Of course it would. But usually it’s hard to find smaller units. 2.5 or 3 are very common and might have a good deal, so instead of chasing every W sometimes it’s better to just install something which is practically available.

-

A 2.5kw or 3.5kw unit would be more than enough for your room and would work great.

-

I have a similar setup, two UFH manifolds, on on ground and one on first, same piping as you but without any mixing valves and pumps on the manifolds. The ASHP flow and return are directly piped into the manifold as the internal ASHP pump has enough power in my case to push flow through everything. If you remove the mixing valves and still don't have flow in the ground floor manifold, try closing of the first floor one and check again. Water will take the flow of least resistance, so it might be the case that your first floor manifold just passes the whole flow through, so you'll need to add resistance so water reaches the second one. This should have been calculated as design though, and if all flow rates for each loop are correct this shouldn't be a problem. Worth checking though.

-

Your heatpump needs around 2-2.5x the capacity in flow rate in l/min. So 9kw unit you’ll need 18-22l/min for the unit to work. Otherwise you’ll get flow rate errors. Not the individual rooms or UFH loops you can calculate by the heat output formulas gives above. But you heatpump overall needs the high flow rate to function.

-

As JohnMo said, many variables to take into account, which means nobody will be able to tell you what to set your heat curve to without knowing the details. The simple answer is: Don’t fix it if it ain’t broken. The more complex approach, if it isn’t working properly right now or you want a better performing system: 1. Figure out your heat loss. Preferably room by room at certain outside design temp. (Example: -3C). 2. Get the data sheets for your radiators and calculate what temperature needs to flow through them with a delta T of 5C to achieve the heat loss from 1. 3. Look at the Grant manual and see the heat curve lines. Find the one which gives you the needed flow temp at the design temp. 4. That’s the curve which will work best for you.

-

What you're describing is exactly what is being used in commercial settings for many years: VRF Systems, i.e variable refrigerant systems. You'd have experience them most probably in hotels and similar. Essentially there are big condenser units and then there is a main trunk with both hot and cold refrigeration lines branching to each unit. The cool thing is they can even balance themselves out, i.e if one unit needs cooling, and another heating, they can work between each other as condenser and evaporator and not use the big outside unit. Really cool stuff, but overkill for residential for sure.

-

L9 Error - Flow rate - Ecodan 8.5kW ASHP

akjos replied to athlonoc's topic in Air Source Heat Pumps (ASHP)

When you re-pressurised it, did you bleed all air out? Make sure all air valves are open as trapped air can also cause flow rate issues. -

Combining radiators with UFH - some surprising conclusions

akjos replied to sharpener's topic in Air Source Heat Pumps (ASHP)

From a theory and calculation perspective I think your conclusions make sense. But in reality this setup would be unpractical. If I understand correctly, based on your following statement: you have modelled the system to receive 45'C flow on both Rads and UFH. Your UFH return is 20'C because the flow rate needs to be very low to only output 2.5kW. UFH has a huge surface area, and feeding it 45'C it makes sense to only require a tiny portion of the overall flow rate. But in reality, you don't want to feed 45'C to UFH and have a 20'C return. There will be big fluctuations across the floor, cold spots, hot spots and flooring most probably wouldn't support it. UFH should be at 5-7'C delta T to be comfortable, that's why the 'more conventional' setup has a separate pump and mixes the flow. Ideally we'd run the whole system on a lower temp, oversize rads and have everything running on a lower flow temp with both rads and UFH giving an acceptable delta T. -

From what I’ve read online, Hitachi are one of the best. I was considering them but found a really good price on a Midea unit and got that one instead. If price is good, I’d definitely go for the Hitachi, they’ve been around forever..

-

Mitsubishi Ecodan immersion heater

akjos replied to NightMail's topic in Air Source Heat Pumps (ASHP)

@NightMail are you still seeing high usage of the immersion heater even with warmer outdoor temperatures? It's absolutely normal for your COP to fall in the colder months. -

Mitsubishi Ecodan immersion heater

akjos replied to NightMail's topic in Air Source Heat Pumps (ASHP)

There is usually a setting in the ASHP unit where you can specify under which temperature conditions the booster heater should be used for DHW. This is usually meant for very low outside temperatures, where you don’t want the ASHP stopping your central heating in order to heat DHW. So the unit can use the booster heater in those situations and not have any down-time in your central heating. My Midea unit has these setting in the controller, though I’m not sure how the Mitsubishi is configured, or if it is configurable at all. -

From what I’ve seen they’re really good units for a good price. Pretty much all in one nice compact package on the monobloc artic series. Contains also an expansion and pump inside the unit. I’ll be getting an 8kw mono for my house deep retrofit soon. Check this out as well: Also here are some technical specs: https://www.microwell.sk/assets/uploads/matrix/files/downloader/TM_Midea_A_series_Mono_M-Thermal_Heat_Pump_R32_2020513_V1_7.pdf

-

ASHP size (don’t sigh I’ve done the calcs)

akjos replied to Kelvin's topic in Air Source Heat Pumps (ASHP)

How are you going to distribute the heat? UFH, rads something else? What flow temperature was it designed at? also how big is your property? If your heat loss is 3.6kw, a 11kw unit seems unnecessarily big. Anyway it’s worth knowing your whole design. -

Samsung 8kw R32 Monobloc Air Source Heat Pump

akjos replied to Ceridunn's topic in Air Source Heat Pumps (ASHP)

Water expands as it heats up, so you definitely need an expansion vessel both on your heating circuit and your DHW. Just search for Robokit online. -

In the summer, can a heat pump do cooling *and* hot water?

akjos replied to Garald's topic in Air Source Heat Pumps (ASHP)

For the heat pump itself it’s no issue at all to switch between heating and cooling as much as you like. That’s exactly what it does during defrost in winter constantly. It switches to cooling and runs hot gas outside to melt frost on the coils, then back to heating. As @jack mentioned, you have to pay attention inside where you might have condensation. But if you use fan coil units for cooling, those usually have their own condensate drain. -

Samsung 8kw R32 Monobloc Air Source Heat Pump

akjos replied to Ceridunn's topic in Air Source Heat Pumps (ASHP)

If I remember correctly, Samsungs don't have an internal pump. So you need one pump external to the unit which will run your system. I'm not sure about the latest generations though. You can easily check it by popping the lid and seeing if there's a pump in there by the water heat exchanger. Flow rate is the most important thing of a heat pump and each needs about 2x-2.5x the capacity in l/min. So in your case (8kw), you need around 16-20l/min flow rate running always when your heat pump is on. In a simple system (no buffer, no LLH etc), you need to make sure all your UFH loops are open and the total flow rate across them matches your required 16-20l/min. If you have zones that close, you will need either a bypass valve to make sure you have the required flow when zones close, or do hydraulic separation with a LowLossHeader. But with the hydraulic separation you will need a second pump as you'll have primary and secondary circuits then. Also, check out Graham's playlists on Samsung fault codes and how to resolve them: https://www.youtube.com/@myheatpumpchannel7577/playlists There are a few on flow rate as well. -

Makes sense. Microbore has a high pressure drop due to the small pipe diameter (meaning your pump needs to work harder to get the required flow rate through) so you need the additional pump. Your installer seems to have done the correct thing to hydraulically separate your circuits with a LLH, as otherwise the two pumps would work against each other and could lead to premature failure.

-

Some monobloc heatpumps have a pump inside the unit (ex. Midea), but others don't and need an external pump (ex. older Samsung, not sure about the newest gen). Pressure drop across your whole heating system needs to be calculated, but if it falls within the capacity of the pump head, you can run the whole heating from the one pump (be it inside the unit or outside). BUT that's only the case if you don't have any 4-port buffer, LLH or CCT which create hydraulic separation. If you do have any of 4-port buffer, LLH or CCT, you essentially have a primary and secondary circuit, then your circuits are separated and each needs its own pump. Primary circuit is from heatpump to 4-port buffer, LLH and back, and secondary circuit is from the separation to your heating emitters and back.

-

It sounds like your calculation as to heat demand match those on the MCS as well as the Heat pump estimates. So there shouldn't be any issues there... As for the electrical consumption and COP, that's a whole different story and depends fully on how your system is set up. As @JohnMo already mentioned: What system components do you have, how is it plumped, do you have enough system volume, defrosts, run times, flow temps, immersion etc etc etc. You could set up OpenEnergyMonitor to track a lot of this and then calculate the COP. As far as the advertised COP from the manufacturers, I think that's a momentarily value. Meaning your heat pump has started up and is running a constant flow temp of 35'C at 7'C ambient for example. If you checked your COP at that specific time, it would probably match. But if you take it as a whole day it won't due to all the other factors mentioned above. Except maybe if you have a system which is set up to perfectly match your heat demand and run 24/7 with all being one zone, no buffers, no HW. More realistically you need to compare to the SCOP (Seasonal COP) over a longer time period.

-

Net zero retrofit requirements

akjos replied to ColdHouse's topic in Energy Efficient & Sustainable Design Concepts

As others stated, digging up the concrete and insulating beneath is costly and messy. If you have the height, you could instead insulate above (create a floating floor). Essentially just add rigid insulation board above your concrete slab, vapour barrier and then a liquid screed. You could even add UFH in the screed if you like. BUT you loose from the room height, so it all depends on your situation. -

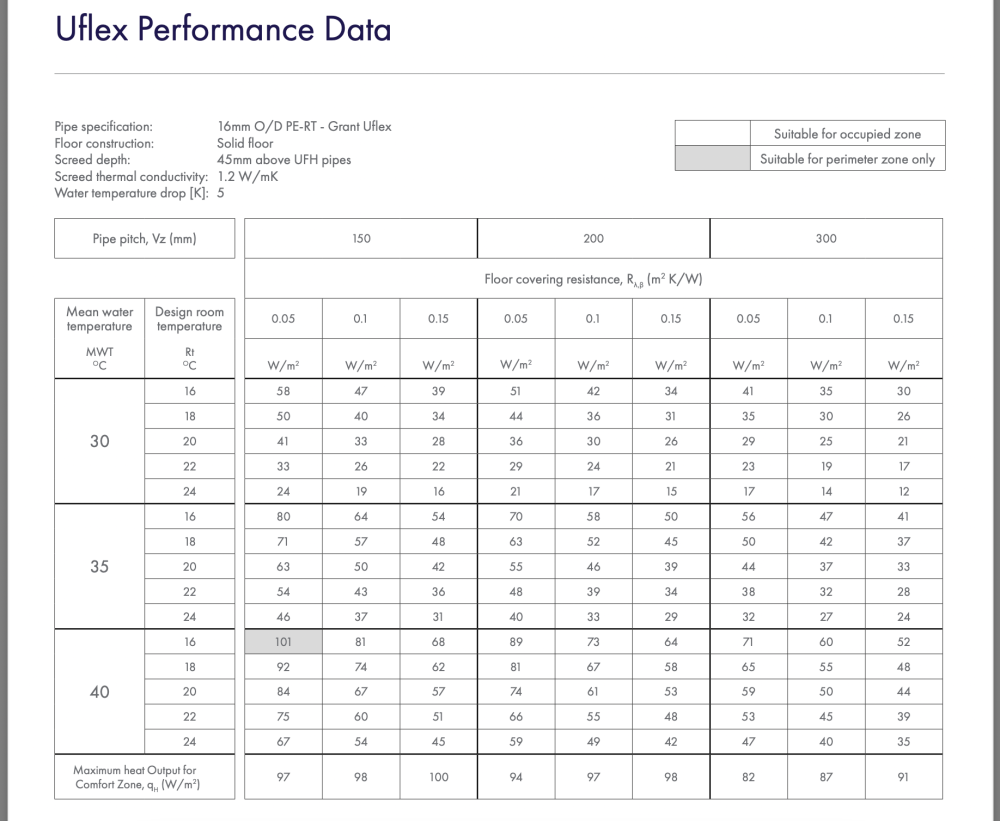

doesn’t that only work with a perfect floor as you need to know the pipe volume / spread in the floor as that has a direct influence on the transfer or are you assuming 100mm spacing ..? Good point, it works for any floor as long as the flow temp is set to match the required heat output. For ex.: - 200mm centres would require a higher flow temp to give the 50W/m2 vs. 150mm which would require a lower flow temp to give the same 50W/m2. I calculate using a delta T of 5'C as that's what most ASHP target on the heat-exchanger I think and also it gives a comfortable floor (low difference between one and the other side of the room). The key is: Design pipe spacing based on heat loss per /m2, then you can calculate the needed flow rate using the formula above. Weather compensation on the ASHP will take care of the rest (i.e when it's hotter outside you need less heat, so the flow temp will drop and thus the W/m2 output too as per above table -- delta T stays at 5 constantly as does the calculated flow rate in each circuit).

-

That leads to overheating of smaller zones - only works when you have a single large zone. Much better is to use self balancing actuators that reduce flow to balance to the d7°C or similar. 👍 yes agree the flow rate needs to be set in each zone according to the heat loss. Self balancing actuators could do that but are pricey. The same can be achieved by simply setting the correct flow rate on each zone using the manual flow rate gauges and screws. For example: Total house 100m2 with heat loss of 5KW (or 50W p/m2). A small UFH zone 5m2 (ex. bath or whatever), would have a heat loss of 250W. Flow for that zone can be calculated using: l/s = KW / (delta T * 4.2) ==> l/s = 0.25 / (5*4.2) ==> 0.012 l/s or around 0.7 l/min needed for that zone. Anything more will lead to overheating.

-

It does work but it depends on how the system is set up. Since we don't know much about this exact design, we can't say for sure. You are right about the mixing valve but this would apply in systems where you have a boiler running higher flow temps for radiators and you want to mix down the UFH circuit. If the UFH circuit it the only thing you have, no need to mix anything, just setting the flow temp lower on the ASHP would work and be more efficient for the heat pump. Short-cycling doesn't seem to be taken care of even in the current design. As @Benpointer mentioned, it runs only in 5-10min cycles. So the ASHP starts up and heats up the flow temp. Then the mixing valve closes shortly after and the ASHP only pushes flow through the bypass valve. This is a short circuit and the return temp quickly rises, leading to the ASHP shutting down. Cycle continues after a while. A longer run-time can be achieved with just one pump if the following is done: 1. Have the UFH loops always open. No zones or actuators. 2. Control the flow temp on the ASHP via weather compensation. So higher temp when it's cold outside and lower when it's warm. This has to be calculated though so that you have the required heat output on your UFH based on the heatloss of your house. 3. Have one pump push everything through the ASHP and the UFH when there is heat requirement. If you have a highly efficient house you could even run the UFH circuit 2-3 degrees above room temp continuously and it will act as a self-regulating surface (i.e heat when required and absorb heat (cool) when your room temp overshoots a little). Anyway this is a change to the whole system potentially. I'd try it just to see if flow and return pumps actually work. I suspect they might have failed though. In your current design, flow and return pumps are on the same hydraulic circuit without any hydraulic separation and they push-pull on each other, leading to preliminary failure. It's possible this has happened, but you can easily verify by doing what you suggested and see if they run. But I think it's general consensus you don't need one of those pumps. I'd remove the return one.

-

Has this ever worked or is it something which just happened now? Overall it seems to me you have too many pumps in your system. Has the installer given you any information why they put a pump on your return pipework? Your flow pump (F) should be able to handle the circuit by itself. The only issue I see with your UFH pump pulling water through your ASHP is that it might throw a fault code (flow detected when there shouldn’t be). I know Samsung does this but not sure about Mitsubishi. BUT if your UFH pump really does that, then it means your system can be powered completely by a single pump. So you’ll only have pump F and nothing else. No need for return pump and also no need for UFH pump if that’s the only thing you have (i.e no radiators). Also you wouldn’t need a mixing valve and instead control water temp via weather compensation. Much simpler system.