Tim Pearson

Members-

Posts

14 -

Joined

-

Last visited

About Tim Pearson

- Birthday March 1

Personal Information

-

About Me

AWHP, Solar, EV domestic user.

-

Location

Cheshire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Tim Pearson's Achievements

Member (3/5)

0

Reputation

-

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Ok so update below. I did locate the two valves for the DHW and CH valves, appeared fine. Having done the previous checks (filter, flow switch, bleed rads) and with the pressure at 1 bar, I decided to refill the system (partially drained). Pressure remained at 1 bar. I then turned all the rads, UFH settings to freeze mode and fired up the AWHP, asking for DHW. The CH 14 error did not reappear and the DHW heated to 45 deg. Then adjusted the UFH settings and the heating came on. That was a week ago - so far no issues. Pressure is still at 1 bar, which I know is on the low end. 3 points. 1. Is it feasible that the 1 bar pressure is “helping” to avoid pump capacity issues? (less pressure, less strain on the pump). 2. After 5 partial drains last year, the forthcoming “service” includes a glycol check. I expect more will need to be added and was told by the UK AWHP distributor that this is an expert job which requires pressure inserted G to dissolve the (very viscous liquid) and avoid blockages cause by G “blobs”. Pressure insertion process is very slow and installers are told to allow 1/2 day on a new install to fill the system with glycol. Not something I could do myself. Does this make sense? 3. My installer service visit has still not been arranged (they still think my system isn’t working). The distributor told me most of the “industry” is focussed on solar installs (higher margins). So much for service and support. Owners of AWHP are going to be stretched to maintain annual service and protect warranty if this continues. Best Tim -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

You are correct. I’ve shown the CH pump, also motorised valve actuator. Pressure is 1.5 bar (ignore red arrow). Reckon my Therma V ASHP is as yours - unaware (not connected/integrated) with the CH pump. Don’t understand this point. “In my case I'm not using the Air + Water control option with Load Compensation so there wouldn't be any point anyway”. thx for FB. T -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

There’s only one cable from the CH pump, to the Honeywell power unit. Att 1. CH and HW both have their own two way valve, means I can manually open individually or together to test. T -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

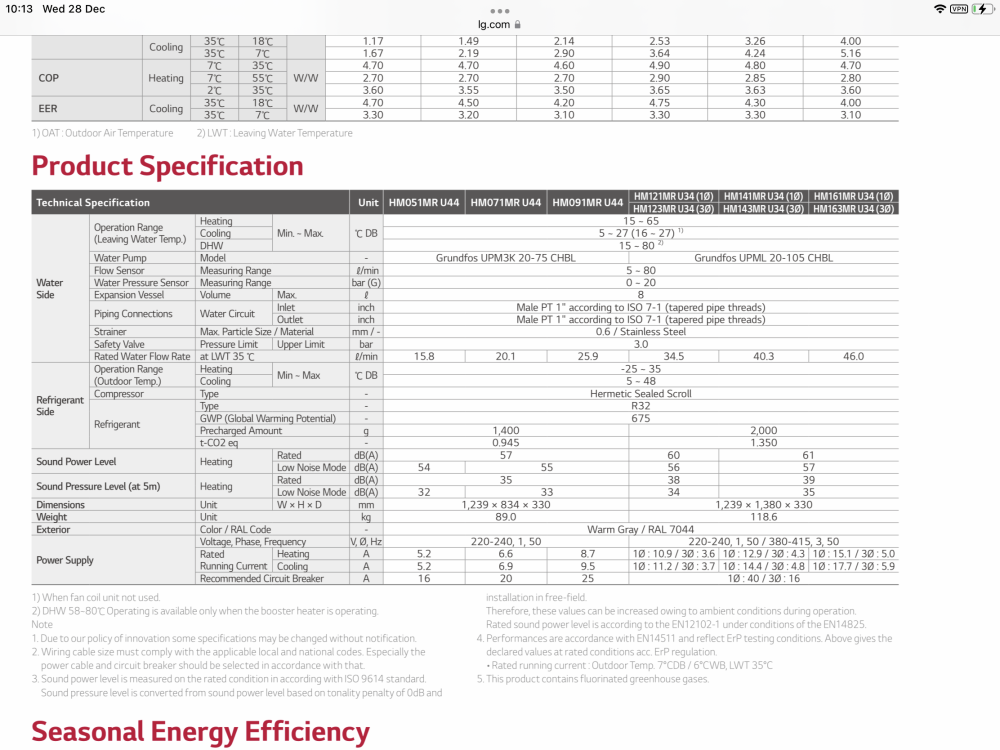

Ok so updates as follows. 1. Flow Switch Flow switch removed and paddle appears ok. No debris. Connection and wiring checked, appears ok. Option remains to replace with lower switch rate. (ProDave). 2. ASHP pump Grundfoss 20-105 installed aligns to recommended spec. (Att 1). Document confirms runs at max. (per HughF I would assume that LG, like all good heatpump manufacturers, use a PWM controlled primary pump so they have control over the delta-T. So there should be no need to check what speed it is running at.) However, comments (AKJOS) and engineering document (Att 2) suggest inadequate flow with this single 20-105 pump. Option to add additional pump, or upgrade existing (15 to 25?). 3. Two way valve Located two way valve, as per guidance. Re valve response time (Kelvin, ProDave, ReedRichards) there is a manual switch on this valve. I’m unclear on how to check if there is an automatic by-pass. “But most motorised valves take less than 10 seconds to open, and there should be some form of automatic bypass valve to give some flow even when all motorised valves are shut. If you suspect this is your issue, you can manually open most motorised valves, so do that to one of your valves and see if the CH14 error stops.” Question - if it’s two way, then is the default (off/closed position) usually set on DHW or heating? Option remains to - refill the system. - check for ASHP motor running. - manually open two way valve and see if this has any impact. (Any guidance on exactly when to do this? When ASHP is running?). Again, thx all and HNY! Tim -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Help me out here Kelvin. Where would you expect the 2 way valve to be located? In the loft next to the buffer tank and DHW cylinder? -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Thx Kelvin, will keep it on the “to be followed up” list. T -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Ok so partially drained, filter removed (little or no debris), cleaned and reinserted. Flow switch is a Sika V3. Unclear which model at this stage, but label indicates 15l/min set point. Not yet removed to check paddle operation. Also, it may have an adjusting screw, tbc. Powered by cable back to control board - blue connector. Attached info. Any more suggestions before I remove FS, check paddle, any flow adjustment option? On electrical connection, what is there to check and how? thx again T Data sheet VK3 flow switch.pdf Ea3000_FlowSwitch operating instructions .pdf -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Thx. Just checked installer settings on the LG controller - pump capacity set to 100%. Still need to check if the the Grundfoss pump in the outdoor ASHP unit is set to max. Tim -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Ok so looking at all those comments and using @ReedRichards checklist. 1. Strainers and filters blocked. Will check and clean filter (on next dry day ..). 2. Water pump, possible fault. - per @AKJOS, pump capacity should be 30 LPM (2.5 * 12j. Rated flow per attached technical document is only 34.5, so little tolerance. Recommends pump set to max (need to work out how to check this setting). - technical document I found refers to use of additional pump, also suggested by @ProDave, or replacement with larger pump (yes, there are isolating valves, enabling filter removal and cleaning). I have attached this technical document. See in particular - piping schematic (pp 15). - reference to CH14 errors arising from pump setting (pp28), including the following info. “The water pump is variable type which is capable to change flow rate, so it may be required to change default water pump capacity in case of noise by water flow. In most case, however, it is strongly recommended to set capacity as Maximum. Note • To secure enough water flow rate, do not set water pump capacity as Minimum. It can lead unexpected flow rate error CH14. • When installing the product, install additional pump in consideration of the pressure loss and pump performance.”. 3. Flow switch abnormality (leave for now). 4. PCB fault (leave for now). PS document too big to attach, see https://cms.intermetal.bg/storage/uploads/2019/12/02/5de4e66b09ef03.---LG-MONOBLOC.pdf Thx for support, Tim -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Ok thanks to all. Will follow up on suggestions. T -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Ok so thx to all so far - update and system overview. Update - switched off/on ASHP multiple times and on 26th it started heating again. That lasted a full 24 hours and then CH14 error reappeared. No heating/DHW and error message on LG controller. Actions - bled rads whilst system was working. System Configuration Heating HM121M.U33 LG R32 Therma-V 12 Kw Monobloc (installed 5/19) Buffer Tank - 50L Cordivari Volano Termico PDC Hanging Radiators - 6 across 55 sq m UFH - 4 zones across 65 sq m Heatmiser UH8 - RF Wilo Para 25/6 43/SCU pump Pressure steady at 2 bar DHW Storage 180L horizontal unvented cylinder Pump - Grundfoss UPS3 15-5065 130 Controllers Therma V controller, wired to AWHP Honeywell Home Hub wireless relay box, T3 controller Heatmiser xone controllers for UFH Comments 1. Flow Rate Error How do you identify where the CH14 flow error is occurring, in the DHW or the heating system? The buffer tank acts as a hyperbolic separator, so there are 2 flow rates : heat pump flow rate and terminal flow rate. Can the LG control monitor both flow rates? Assuming the AWHP pump must be sized correctly (for the HPFR), surely an additional pump should only be of benefit in increasing the terminal flow rate? NB The Grundfoss pump on the Therma V (water side) is the same model (UPML 20-105 CHBL) across all the 12, 14 and 16 KW versions. -

Octopus Cosy - new tariff for ASHP owners

Tim Pearson replied to George's topic in Air Source Heat Pumps (ASHP)

7 Kwh That’s impressive ! What capacity is your PV set up? -

LG Therma V Monobloc CH14 flow error

Tim Pearson replied to Tim Pearson's topic in Air Source Heat Pumps (ASHP)

Thx to ReedRichards and ProDave for those prompt replies. Will check out the details tomorrow. Appreciated. T. -

Anyone got any experience on approach to resolving constant CH14 flow error on LG AWHP? Following 4/22 service, I’ve had a further 3 instances this year (annus horribilis 😏) 6/22 cleaned out filter and resolved. 10/22 checked filter, no success, then called out installer for service but resolved itself before they arrived, (after multiple shut downs/restarts). 12/22 arrived home from Egypt after UK cold snap to discover AWHP running but not producing heat. No error messages, later reported CH14 error. My installer yet to confirm repair visit a week after reporting - reckon they’re far too busy on new installs to deal with service/support issues.. T