Search the Community

Showing results for tags 'vent axia'.

-

Hi Everyone, In my new build flat, which is 4 years old I have a Vent Axia Kinetic Sentinel Plus B model installed. In the first 2 years the machine was operating correctly, I usually replaced filters every 6 month, and I had a major service carried out by HRV Group in 2023 September, where they told me the machine is working correctly. During that service I mentioned to them that I hear an unusual sound from the machine, and it got louder. When the technician visited, he told me it's normal. A year almost passed and yesterday on the 6th of June I noticed the machine got loud like an airplane. I have created a video which you can find here: I contacted Vent Axia to ask about warranty, and if they are able to investigate and rectify the issue without any extra costs for me, but no answer yet. My questions are: Is this noise normal with a 4 year old unit? What is the warranty on these machines? What could be causing this excessive noise? Thanks for all the help!

-

Following on from the excellent post by @DOIGAN where he replaced the bearings in one of the fans from his MVHR, this is a short post to detail the steps to replace the bearings in the extract fan in my Vent Axia Sentinel Kinetic Plus B (being a slightly different model and fan to that of the link below) The process I followed is basically the same as laid out by @DOIGAN in his original post. I've added a couple more pictures and descriptions below. To get at the fans, the unit has to be stripped down. First the duct spigots and blanking plates are removed. Both the back and front covers are then removed, allowing the top and side panels to be taken off - the side panels slide/interlock with the top and bottom panels. You should then have access to the fans on either side which are bolted to the poly core: I then disconnected the power connector to avoid having to try and unplug from the motherboard / cause any other issues. From this point I followed the process as per @DOIGAN Removing the circlip was a bit challenging, as for some reason the hub assembly would not depress, it turns out because the spring beneath wasn't seated properly. I managed to get the circlip off, but naturally it pinged up into the air and I spent several minutes searching for it until finally finding it some distance away. The bearings themselves (one on either end of the hub) popped out easily. I used the same bearings as @DOIGAN Reassembled and back into the MVHR unit. Cost - my time and £7.99 for a pack of 10 bearings vs £298.43 + VAT + shipping charge for a replacement fan from Vent Axia. Vent Axia were unable to give me any detail of the bearings used when I emailed to ask.

-

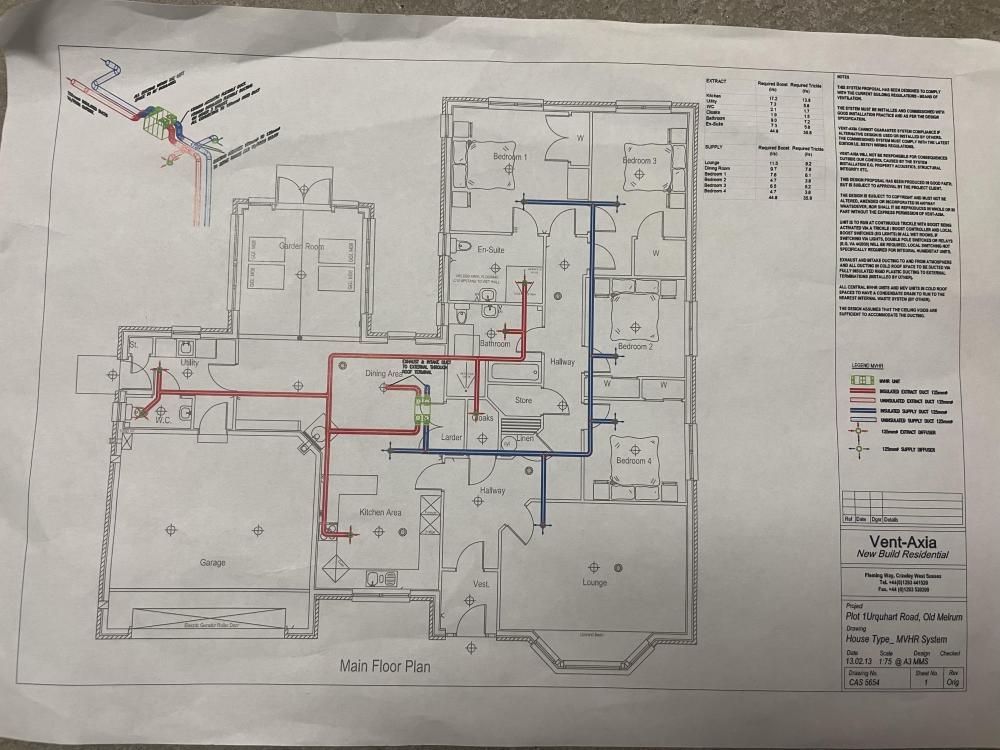

Hello, just looking for some advice on my MVHR. We moved into the house a few months ago and the previous owner had this installed when the house was first built in 2013. Didn’t no much, if anything about them but he gave an overview of how it worked. I’ve a few questions though regarding how it should be setup in terms of flow rates, it has been set at 45% normal air flow from the day we moved in. The heat recover part - it seams to be cold air coming into the supply rooms from each ceiling vent. I thought it would of be at least a little warm? there’s an extract in the kitchen, pretty much right above the cooker but don’t feel it does much at all in terms of removing any odours or steam. Same with the bathroom extracts, when the showers on, room still fills up with a lot of condensation. As shower does seem to trigger the humidity sensor and boosts it to 54% How does the summer bypass work on this system? attached some photos of what is installed and also a diagram of the layout the owner left. On the layout drawing there is sum of L/s for trickle and also for boost. Is that what I should be setting up my normal and boost air flow to be? Convert the Litres/sec to cubic meters and hour than work out the percentage of the max flow rate the unit can provide? any other tips to get the most out of the system? With moving in and getting settled, some plumbing jobs to take care first, I’ve only just started to look into the MVHR system now.

-

We have four pieces of foam with our Vent Axia sentinel and there are no instructions as to what they are for. I assume they are to be fitted on the back of the unit for sound deadening although the gap to the rear of the unit is greater than the foam? TIA

-

I’ve just spent most of last week installing the distribution boxes, ducting and plenums on my BPC/Vent Axia system. I thought it would be worthwhile sharing some pictures, It went well and was relatively easy to do. I tried to keep ducting passing over each other in the joists to a minimum but it was unavoidable in some places. Having two ducts on top of each other in a web joist was a bit tight and didn’t leave a lot of room for insulation. I had already installed the 150mm PVC pipe through the roof and drilled a 150mm hole for the second PVC pipe through the wall. I then mounted the Vent Axia unit on the wall and figured out where to mount the distribution boxes in the metal web joists between the ground and first floors. We have vaulted ceilings upstairs so it seemed easiest to mount the boxes here rather than up high in the first floor. Here’s my rough in of the MVHR unit. Ignore the angles of the pipes. These will be straightened up on the final fix. Here are the distribution boxes. Required careful planning and it didn’t seem to matter where they were because of the metal web joists there was always at least one duct which was a tight squeeze through the joists. I have a change in levels between the main part of the house and the lower level which causes a bit of head scratching as to how the get the ducts from one section to another. This was exacerbated by the fact that there was a steel running across the lower level which I had to navigate around. I built a dummy stud wall in the lower level and ran the ducts behind this. I need to get 3 extract and 2 supply ducts into the lower level. Here’s a photo after the first 4 ducts were run. A bit of boxing in required to hide them, but relatively easy solution. and here’s what it looks like in the lower level. And finally, a ceiling mounted and wall mounted plenum. I quite enjoyed doing it and it was satisfying to see it all done.

-

This weekend is MVHR install weekend (hopefully). We are looking for some pointers from anyone who has installed a Vent Axia Kinetic Sentinel unit. BCP has supplied all the kit. Very thorough. Could do with an idiots guide for the plan of attack though. First attempt at a plan. How does this sound? 1. site manifolds 2. Site plenums 3. Cut duct lengths and join between manifold and plenum (cutting holes in walls and floors as needed) 4. Site unit 5. Figure out how to connect all those silvery pipes from the unit to the manifolds 6. Put in pipes to outside Is this a reasonable approach? We have trawled this site for photos. Any out there that show all the connections to and from the unit itself and the manifolds? It looks like it should be fun (or the makings of a divorce) ?

- 18 replies

-

I am not fitting boost switches for my mvhr as the wife and kids will simply not use them and was going to depend solely on the humidity sensor within the unit. On speaking with BPC they inferred that for longer runs ie over 2m not to rely on the in-built sensor as ideally you would want boost before that. Bathroom will be fine as it is more or less below the manifolds, en-suites are further away and I was thinking of using the room sensors but not sure if this is ideal as it will boost unnecessarily, I know others have done this. The only other option I can think of is to use humidity sensors remote from the unit/manifold possibly mounted in the ceiling plenum in some way. Would the dhc-100 that @JSHarris used be suitable for this, though the sensor looks quite big? There is a round bit on the top of the plenum looks like it could be drilled out to take a small sensor fixed in place.

-

One of the final significant jobs I had to do before we moved in was connect up and commission the MVHR. All the radial ductwork and individual plenums had been fitted at first fix, however I had left installing and connecting the actual unit until the loft has been insulated, as I didn't want to risk pipe connections being damaged. The day before we were due to move in, the insulation contractor having laid all the loft insulation, I spent a couple of hours in the loft space above our vestibule connecting ducts for the air intake, air exhaust, and the supply and extract ducts to the distribution boxes. I decided to locate the MVHR in our (cold) loft space, primarily to free up space in my service cupboard which houses our DHW cylinder, UFH manifold and CU. The installation manual advises that where the MVHR unit is located in a cold rather than warm part of the envelope it should be insulated. I initially considered lining the whole of the relevant loft area with insulation, but having worked out the cost, and then being able to salvage a number of sheet insulation offcuts from the skip, I ended up forming an insulated box around the MVHR unit. As you can see in the picture, it's a very simple box, the relevant supply and extract ducts simply cored through the insulation. Our MVHR unit is a Vent-Axia Kinetic Sentinel Plus. These can be supplied in either left hand or right hand format to suit your installation. My plans had originally shown the air intake and exhaust on the Southeast roof of the house, but as the house was being built it became clear it would be more convenient for those vents to be located on the northwest side of the house. Making that change left me with a problem of having an MVHR unit with the duct spigots for the internal supply and extract on the wrong side of the unit. Fortunately the Vent Axia units can be reconfigured by taking off the front and back of the unit, disconnecting and removing the control panel, rotating the unit chassis through 180 degrees, then reassembling so that the back is now the front. Having connected all the ductwork, the final thing to do was connect the condensate pipe I had fitted during first fix (which discharges to a rainwater trap outside) to the flexible condensate pipe on the base of the MVHR unit. Having switched the MVHR on, I then went about balancing the system using an Air Flow meter borrowed from my builder. This was a relatively straightforward process and just required minor adjustments to individual diffusers in each room. Our system is currently operating at a normal supply rate of 32% which equates to 150m3/hr. Having measured efficiency during cold and windy weather, it operates at 90% efficiency in terms of temperature differential (room temperature to supply air temperature). In warmer weather, the Summer Bypass, which I have set to come on when internal air temperatures exceed 22C and ambient air is above 10C, automatically activates. If ambient air temperature exceeds internal house temperatures, as was the case last week, the summer bypass remains inactive so that outgoing stale air can cool incoming fresh air (albeit the effect is negligible). As others have found, whilst summer bypass does provide limited cooling of incoming air, it is not on its own enough to cool the house. Cross ventilation by opening windows remains the most effective way of providing such cooling (in the absence of any active or UFH cooling). The final feature worth mentioning is the humidity sensor, which variably boosts the ventilation rate to ensure RH does not exceed the level set in the controller. This also seems to be working well, auto boosting ventilation when showers are used. When cooking, if we deem it necessary, we can manually boost ventilation to assist in the extraction of cooking odours. Overall I pleased with how the system is operating. The one thing I have noticed compared to other MVHR systems we have lived with is the noise of the fans which you can hear through the ductwork. This is the first house where we have used a radial system rather than 150mm main ducts with branches off, so it may be the duct choice, as I can't recall hearing fan noise on previous installations. To combat this issue, I've ordered some self adhesive acoustic foam sheet, and plan to construct a silencer out of scrap MDF and timber, line with foam and externally insulate, to fit between the MVHR unit and distribution boxes. I'll report back in due course how effective this is. The final tweak to the system that I'm considering is fitting a CO2 sensor so that the unit can auto boost ventilation rates as required. Vent Axia want £350 for their sensor which is a non starter, but looking around, the following may be an option as it seems suited to the parameters of the Vent Axia: https://www.digikey.co.uk/products/en?keywords=235-1413-ND Again I'll report back when I've looked into this some more. Next entry - 2nd fix plumbing